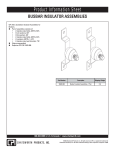

Download 20B-IN025 - Rockwell Automation

Transcript