Download User Manual - Temperature & Process Instruments, Inc.

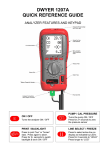

Transcript