Download C`ENTER

Transcript

Umted States Patent [191

[11]

Patent Number:

Mezei, Louis M. et a1. '

[45]

Date of Patent:

[54]

USER CONTROLLED OFF-CENTER LIGHT

4,253,846

4,255,788 3/1981 Schwartz et al.

364/413.07

. . . ..

LING AND REACI'ION

[75]

Inventors: Mezei, Louis M_, Fremont; Bradley

‘

4,268,268

5/1981

Blum

4,319,882

3/ 1982

Sharma ........... ..

. .... .. ..

4,451,433

5/1984 Yamashita et a1.

422/63

4,478,094 10/1984 Solomaa et al. ..

73/ 863.32

4,556,641 12/1985 Kano et al.

Stephen J. Moehle’ both of Berkeley;

4,580,895

4/1986

Patel . . . . . . . . . . . . . .

436/52

436/63

422/73 x

. . . .. 356/39

Brent S. Noorda,

Pleasant H111,

.

4, 665 , 553 5 /l987

4,608,246

8/1986

Bayer et a1.

Gershman et al.

.. 424/11

356/39 X

J°sePh T- W‘d‘mas’ Berkeley; James

A- Zei?in, P‘edm‘mt’ all 01' Cahf-

4 678 894

4,683,120

7/1987 Shafer ............. ..

7/1987 Meserol et a1.

364/416 x

....... .. 422/72

.

'

'

'

4,713,348

Asslgnee. Cetus Corporation, Emeryvllle, Cahf.

Appl. No.: 906,101

[22] Filed:

Smythe et a1. ...................... .. 436/53

s_ Albom, Richmond; coppock, Stan;

- ,

[73]

[21]

Oct. 10, 1989

ABSORBANCE READING ADJUSTER IN A

AND

3/1981

4,873,633 .

12/1987

Ullman ........ ..

436/501

4,719,087 V1988 Hanaway .... n

422/102

4,727,033 2/1988 Hijikata et a1. ..................... .. 356/39

Sep. 11, 1986

Primary Examiner-Clark A. Jablon

Attorney, Agent, or Firm-Ronald C. Fish; Kevin R.

Kaster; Albert P. Halluin

[57]

ABSTRACT

A host computer controls a plate reader which optically

Related US. Application Data

[63]

Continuation-impart of Ser. No. 788,998, Oct. 18, 1985,

abandoned’

[51]

Int. Cl.4 ................... .. G01N 33/48; GOlN 21/01;

reads the results between donor samples and reagents.

G01N 33/80; G01N 35/02

The system provides the user with the ability to change

[52] US. Cl. ............................... .. 364/413.08; 356/39;

356/442; 422/73

[58] Field of Search ---------------- -- 364/416, 555; 422/73;

356/39, 4421 440

[56]

References Cited

the position of off-center light absorbance readings to

maximize the power of the machine to discriminate

between positive and negative agglutination reactions.

In addition, the user can tailor thresholds for absorb

ances used to distinguish between positive, negative and

“no type determined” reactions.

U.S. PATENT DOCUMENTS

4,130,395 12/1978 Chryssanthou ..................... .. 424/11

7 Claims, 4 Drawing Sheets

W

HAVl

C

ABSORB

ANC E

POSITIVE

REACTIONS

1,511

‘POSITIVE

ACTUAL ABSORBANCE

AT POSITIVE THRESHOLD

.1 1 1,.

NEGATNE

NEGATlVE

THRESHOLD ‘maesuow REACTIONS Atrgls’gll-?

ACTUAL ABSORBANCE

AT NEGM’NETt-RESHOlD

ABSORB

ANCE

POSITIVE

REACTION

AGGLUTINA

TION

NUMER OF NTD'S

AT CURRENT

THRESHOLD

SETTING

WELL

C‘ENTER

""11 \

meant?“

WALL

‘~—'

U

DEFINA

READINBéE

POSITIONS

131141958811“

WELL WALL

US. Patent

HOST

0ct.10,1989

Sheet 1 0f 14

[/20

4,873,633

MAINFRAME

CPU

DEC

PDP

II

30

PRINTER

/

(32

(22

KEYBOARD

28

CENTRIFUGE

(

PLATE

READER

TERMINAL

24J

ORBITAL /34

SHAKER

I

LIQUID

HANDLER

26

LIQUID

HANDLER

AND PLATE

#2

HANDLING

MECHANISM

FIG. I

LIQUID

HANDLER

. . .

#N

US. Patent

Oct.10,1989

Sheet 2 of 14

4,873,633

US. Patent

Oct. 10,1989

I Sheet 3 0114

4,873,633

LOGON FOR SYSTEM

STARTUP USER

_/lO2

PRIV TABLE FIVE

MAIN MENU

#104

LOG ON FOR

SYSTEM sTARTUP

REAGENT DATA

HANDLING

"54

('40

QUALITY CONTROL

PROCEDURES

LIQUID HANDLING

PARAMETER

A00

DEFINITION

PLATE READING

EDIT RESULTS _/-|7O

(I90

REsULTs

SUMMARY

READER

CALIBRATION

/— O0

5

( 300

SYSTEM

CONFIGURATION

FILE

OPERATIONS "400

.

('38

IM MUNOASSAY

F IG . 3

US. Patent

Oct. 10, 1989

Sheet 4 0f 14

4,873,633

LIQUID HANDLING

MENU

A06

(H2

'

BROM PROCEDURE FOR

3 ABO/Rh TESTING:

'08

[H6

PROCEDURE FOR

ABO/Rh TESTING=

SAMPLE HANDLING

REAGENT HANDLING

QROCM PROCEDURE FOR

no,

ABO/Rh TESTING ,-II4

L

SELECT CRITERIA "'8

FOR REPEAT LIQ.

HANDLING

I

(120

(I30

OPTIONS F OR

SPECIFYING WBN'S

NTD S

OF SAMPLES FOR

I

REPEAT LIQ.

HANDLING

[T122

‘

DISPLAY OF NTD'S

—‘

PROCESSED BY WBN

_

I

PRINT

(I32

PROC. FOR REPEAT

LIO. HANDLING

Q__l

FOR SAMPLES

PROC. FOR REPEAT A24

LIQ. HANDLING

_

('34

FOR NTD S

I

B

BROM PROC. FOR REPEAT

YES LIO. HANDLING

(

126

PROC. FOR REPEAT

YFEOQA LIO. HANDLING OF

NTD'S= SAMPLE

(I28

_

SAMEEZAN‘éE'PINE

HANDLING

FOR SAMPLES:

SAMPLE HANDLING

('36

SAME: REAGENT

HANDLING

i

FIG. 4

US. Patent

Oct. 10, 1989

Sheet 5 of 14

4,873,633

QUALITY

CONTROL

MENU

NO BROMELIN PROCEDURE FOR202

PRETREAT

CHECKING REAGENT

CELL SUSRENSIONS

(I64

(204

ABSORB OF REAGENT

BROMFEEQ QEIXEEIEQRCCETECSISSNS

CELL SUSP

FRET

A

SAMPLE HANDLING ‘

TABLE a MENU

RESULTS NOT

ACCEPU[ ] VIEW

I N67

ACCEPTED

(#68PROC. FOR CHECKING

(206

QC

ADJUST CELL

PRINT

CHART

»

SUSPENSION

REAGENT CELL SUSF;

J

REAGENT HANDLING

L

DO QC LIQ.

|

HANDLING

BI

PLATE READING

.

QC OPERATOR OK

ID LOGON

NO

LIO. HANDLING

ID OF QC BROM

SAMPLES

I18; _I LI42

LI44

(‘I46

SIEOCEDURE FOR

—

BROM FROG FOR QC;

YES

SAMPLE HANDLING

RESULTS OF

Qc PROcEDURE /-'52

I48/

I-IEJ

PROC. FOR QCI

REAGENT HANDLING

PERFORM QC

LIQ. HANDLING

150/

"'53

L

a cOLLEcT

~

ABS. DATA

NO

BROM PROG. FOR H69

CHECKING

DONOR CELL

SUSP

1

fl?!

PROc. FOR

BRQM CHECKING

I75\

DO QC LIQ

HANDLING 'a

fl73

PROc. ‘FOR

CHECKING

DONOR GELL

DONOR CELL

E‘IISNPISLSIRIIPLE

RIEESEEN‘TSIS’IIN‘DLING

I

PLATE READING

CHECKING REAGENT

IGIJ

PROc. FOR SAMPLE

EAIIEIINGFOR

IrERGO

To

EICHEER

REAGENT TITER

_—____I

58

FIGSB

HANDLING \IGT

~—l63

FIG. 5A

US. Patent

To

FIGSAT

0ct.10,1989

Sheet 6 of 14

4,873,633

FROM

‘FIG. 5A

QUALITY CoNTRoL

CoNT' D

1

VIEW TITER

GRAPHS

'62

I

(I66

(‘I70

ABSORBANCE OF DoNoR

CELL sUsPENsIoNs

‘

‘

RESULTS

NOT

ADJUSTING

DONOR CELI

‘ ACCEPTED SUSP

ACCERTI [PRINT )—1 CHART

VIEW (QC/I75

77

I

REAGENT

DATA

HANDLING

I56w

CURRENT

REAGENT DATA

TABLE

REAGENT DATA FILE

l— PRINT J

('58

ACCESS To REAGENT DATA MODULE

LOGON

UsER RRIvILEGE TABLE FIVE

LACCESS NoT OK

ACCESS OK

(I60

CURRENT

REAGENT DATA

TABLE

REAGENT DATA

FILE

[MAIN MENU‘

F166

EB LPRINTJ

US. Patent

0a. 10, 1989

Sheet 7 0f 14

4,873,633

PLATE READING

MAIN MENU

EDIT RESULTS

REREAD ROW

fws

AUTOMATICALLY

I

LOGON TO ENTER

OR EDIT ABO/Rh

TEST RESULTS

MANUALLY

NO ACCESS |_

ACCESS

OK

ENTER 0R

EDIT

RESULTS

MANUALLY

'

ENTER

RESULTS

MANUALLY

FOR WBN

I

EDIT RESULTS

FOR WBN

LOGON TO ENTER

OR EDIT DU TEST

RESULTS

MANUALLY

/I72

ACCESS

OK

ENTER OR

r-I74

EDIT DU

RESULTS FROM

CURRENT LIST

No ACCESS I=

LOGON TO ENTER

OR EDIT MISC.

TEST RESULTS

M A NUALLY

_

NOACCESS

L

I

SELECT

ACCESS TEST TO

OK

ENTER EDIT

RESULTS

I

I

ENTER OR

EDIT RESULTS

FOR SELECTED

TEST

l

ENTER REMARKS

MAIN MENU

FIG. 7

US. Patent

Oct. 10,1989

4,873,633

Sheet 8 of 14

RESULTS SUMMARY

(2H

WBN LIST FOR

SPECIFIED

DISPLAY OF WBN “20'

T" GROUP AND

TEST RESULTS

TYPE

I

(2I3

DISPLAY OF

T’ TEST STATUS

207

@ (215

DIRECTORY OF

,

" PLATE INFO TABLE

EEEIJ

DISPLAY OF

UNVERIFIED Rh

NEGATIVE LIST

E

FOR PLATE 4?

_

I

j

DIRECTORY OF

ANTI BODY SCREEN

PLATES

POSITIONS FOR

EZIT

l

PLATE =I=I=

E

DISPLAY OF

ABO/ Rh TOTALS

DISPLAY OF DATA J

__|93

~223

E

(225

LIST OF OMITTED

CAROUSEL

F POSITIONS

_.IPRINT LAB TEST RECORD

E

FIG. 8

US. Patent

4,873,633

‘Sheet 9 0f 14

Oct. 10, 1989

FIG. 9A

502

PLATE READER

NO

CALIBRATION LOGON‘ Acct-35

READER CALIBRATION _,_ 504

MENU

@

( 506

—-| DETERMINING THRESHOLD VALUES I

(“508

BROM PROC. FOR LIQ. HANDLING

OF THRESH. DETERM PLATES

NO

r510

BROM PROC, FOR SAMP HANDLING

YES FOR THRESH. DETERM. PLATES

PROC. FOR REAGENT HANDLIMS

. OF THRESHOLD DETERM PLATES

I

SPECIFY HISTOGRAM

TO

REVIEW

_

.

I

EVAL. TEMP THRESHOLD

VALUES MENU

MANUAL ENTRY OF SAMPLE

INFO FOR EVAL OF TEMP

THRESH. VALUES

L

DISPLAY OF NTDS DERIVED

FROM THRESH. DETERM.

PROCESS

I

NOT OK

DIS P LAY OF DISCRE PANCIES

BETWEEN ENTERED SAMPLE

VALUES AND THRESHOLD

2K

DETERM. PROCESS

520i

522A VERIFY UPDATE OF

F— THRESHOLD

NO

TO

r98.

FROM

FIG. 9B

VALUES

REPLACE

I

I

REPLACE REVIS E

H I STOGRAMS

524

532

L___________I

OK

INoT OK (528

SPECIFY HISTO

GRAMS TO REVIEW

I

( 5530

REVIEW OF EDITED

THRESHOLD

VALUES MENU

| {2 3 4 5

US. Patent

TO FIG.

9A

Oct. 10,1989

Sheet 10 0f 14

4,873,633

FROM

FIG. 9A

I

{540

BROM PROCEDURE FOR

PLATE READING

YES POSITION

DETERMINATION

f544

SAME- REAGENT HANDLING

(542

RRoc. FOR PLATE

BROM READING POSITION

NO

DETERMINATION:

LIQ. HANDLING

V

(548

STEPS OFF CENTER

DETERMINATION

L546

(554

VERIFY UPDATE OF

PLATE READING

POSITION

FIG. 9B

US. Patent

L06 0 N

0a. 10, 1989

NO

ACCESS

Sheet 11 0f 14

4,873,633

MAIN MENU

FILE OPERATIONS

MENU

TRANSFER COMPLETED

r404

RESULTS TO DISK

408

_ REVISE STORED

DATA

I

RESET DATA

FOR SPECIFIED

WBN ENTRY

‘DELETE DATA lI

RESET DATA

FOR SPECIFIED

PLATE ENTRY

4IO

IL——I

DELETE ENTRIES DELETE ENTRIES DELETE

BY DATE

BY PLATE

BY WBN

K

I

k

4II

BACKUP FILES

4I2

406

DISPLAY DATA STATISTICS

FORMAT FLOPPY DISK/—-402

MAIN MENU

FIG. IO

(

4I3

DELETE IF

TRANSFERRED

TO MAINFRAME

IL4I4

US. Patent

Oct. 10, 1989

Sheet 12 Of 14

4,873,633

NO

ILO GON F OR SYST EM c ONFIGURATIONI'——>@

ACCESS

ACCESS OK

SYSTEM CONFIG.

MENU

(304

(306

MODIFY CURRENT

TEST FORMAT

MODIFY ADO/Rh

LIQ. HANDLING

PROC.

I

I

@

(‘302

CURRENT TABLE OF

USER ID/ SYSTEM

SECURITY INFO

I

(30s

—-IMODI FY MAINFRAME HANDSHAKE]

3270

EMULATION

SNA

EMULATION

SPECIFY HANDSHAKE

FOR RS232 PROTOCOL

I

I

I

—-IsEI_EcT LAB REPORT FORM |~3IO

J

MODIFY IMMUNOASSAY FORMAT _,3|4

AN D LIO. HANDLING

I

_-IMODIFY ERROR HANDLING METHODI~3I2

I

—-IMODI FY HARDWARE OOMPLEMENT]

I

FIG. II

US. Patent

Oct. 10, 1989

Sheet 13 0f 14

4,873,633

0/0 OF

TOTAL

wELLS

HAVING

EAcH

ABSORB

ANCE

I

I III II PPM“ II

WES‘?

POSITIVE

5'9

yPOSITIVE

REACTIONS

xxxx’TfL23

I II

¥_“’—/

NEGATIVE

NEGATIVE

THRESHOLD THRESHOLD REACTIONS

YYYY/ 525

ACTUAL ABSORBANCE

AT POSITIVE THRESHOLD

ASAIVIRLE

W

POSSIBLE

22 2’/5.2 I

ACTUAL ABSORBANCE

AT NEGATIVE THRESHOLD

NUMBER OF NTD'S

AT CURRENT

THRESHOLD

SETTING

WELL

ABSORBANCE

CENTER

POSITIVE

REACTION

AGGLUTINA

TION

I

POS TION

ABSORBANCE READING

POSITIONS

FIG. ISA

WALL

READING

I

RELATIVE TO

H4

WELL WALL

USER

DEFINABLE

READING

POSITIONS

FIG. I38

US. Patent

Oct.10,1989

Sheet 14 0f 14

4,873,633

ABSORBANCE

I<——|65

I

|

l

|

I

I

:

2

:

4

:

8

|

'

: i

I6 32

DTLuTToN OR TITER

ABSORBANCE

MAX.

,

.

_

- ' ' "

MEAN

MIN

I23

WBN

I23

135

620

3o---- eo---

90

DAY

KNOWN

EXPERIMENTALLY

WBN

TYPE

DETERMINED

BLOOD TYPE 23 TEMPLATE

FAPOS

BPOS

o

BPOS++———++

APos +——+++—+'

o

FIG. l6

— —

+ —

— —

+

+

1

4,873,633

2

not subject to automated liquid handling. Test results

USER CONTROLLED OFF-CENTER LIGHT

ABSORBANCE READING ADJUSTER IN A

LIQUID HANDLING AND REACTION SYSTEM

This application is a continuation-in-part of Ser. No.

788,998, ?led Oct. 18, 1985, now abandoned.

CROSS REFERENCE TO MICROFICHE

APPENDIX

There is included herewith micro?che appendices,

consisting of 10 micro?che and 461 frames, including

the hex format object code controlling the various pro

from these antibody screen tests and other tests done by

hand must be recorded for each donor’s blood for

which these tests are done. Further, testing procedures

for blood typing can change over time in that different

dilution values are often needed for different batches of

reagents to get the proper absorbance readings. Fur~

ther, the amount of dilution of the red blood cells

should be optimized. The data for the optimal dilution

values must be recorded.

Further, other process parameters of the blood typing

sequence should be subject to customization to enable

the various users to customize their testing procedures

to conform to local practice. This data de?ning the

cessors in the system.

15 characteristics of each step, such as the amount of each

BACKGROUND OF THE INVENTION

sample to be placed in each well, which wells in which

to place samples, the amount of dilution in certain steps,

The invention pertains to the ?eld of systems for

the wells to place reagents in, the number of mixes at

automatically performing blood typing operations, and,

various points in the process and various other criteria,

more particularly, to systems for controlling automated

liquid handling apparatus to do blood typing and for

should be subject to customization, should be easily

interpreting the results from a plate reader and for man

changeable, and should be remembered by some mecha

aging the data generated by the liquid handling appara

nism so that it can be automatically invoked each time a

tus and the plate reader apparatus and for printing vari

procedure is performed without having to look it up

every time. Of particular importance is the amount of

dilution of each particular reagent which should be used

ous reports.

Modern blood banks must perform thousands of 25

blood typing and antibody screening operations and

manage the data resulting from such tests. These opera

to optimize the absorbance for that reagent and to con

serve the amount of reagent used. These reagents are

tions involve the handling of thousands of samples of

donor blood, the pipetting of reagents into samples of

often quite expensive.

the plasma and red blood cells from the donor blood

accountability system such the quality of data generated

in the testing is consistently high and the persons per

forming the testing can be determined. For example, it

and the optical reading of the wells containing the

donor samples and the reagents to determining the pat

Further, it is useful to have a quality control and

is useful to know the expiration data for all the reagents

in stock and the associated absorbance values for each

constitutes a template which characterize the blood as 35 reagent lot over the period of its usage. It is also useful

to compare the test results for known sample types to

being from a particular blood group and having a par

the results that should have been obtained as a check on

ticular Rh factor. Each test of each donor’s blood in

the accuracy of the system. It is also useful to be able to

volves pipetting of multiple samples of that donor’s

generate reports on daily or monthly activities to deter

plasmas into multiple wells and pipetting of multiple

mine the amount of certain types of blood in stock and

samples of diluted red blood cell samples into multiple

where it can be found. The number of “no type deter

wells. Multiple diluted reagents are then added to the

multiple wells containing plasma and red blood samples

mined” test outcomes (hereafter NTD).

Thus, a large amount of data in the form of process

and various reactions either occur or do not occur de

controlling parameters and test results are involved in

pending upon the blood type and the reagent in each

well. Typically, these reactions manifest themselves as 45 blood typing and antibody screening operations, and a

large amount of record keeping for this data is involved.

clumps of protein in the bottom of the well for a posi

Therefore a need has arisen for a system which can

tive reaction and no clumps for negative reactions, the

tern of positive and negative responses to various rea

gents. The pattern of positive and negative responses

pattern of positive and negative reactions determines

perform these thousands of liquid handling steps reli

the blood type.

The blood type can be determined by placing the

multiple wells under a strong light source and reading

ably and tirelessly and which can handle the thousands

the optical absorbence, i.e., the amount of light which

gets through the bottom center of the well. Typically

absorbance readings are taken on both sides of the cen

of data records which characterize the liquid handling

and which constitute the data record for each donor.

Further, such a system should be access controlled and

implement accountability. It should also ease quality

control operations and maintain data useful in quality

ter, bottom of each well, and the results are compared 55 control efforts. Such a machine should also maintain all

test results and be able to communicate them to a main

to certain threshold criteria for absorbance. The com

frame computer for permanent storage or allow them to

parison of the readings will indicate the presence of a

be archived onto permanent magnetic storage. Such a

clump at the bottom of the well (low absorbance in the

machine should also enable the automated generation of

off center readings) and therefore a positive reaction or

the absence of a clump and therefore a negative reaction 60 reports for management.

(high absorbance on both off center readings).

SUMMARY OF THE INVENTION

Clearly, the process of blood typing of thousands of

The invention is a system for performing a host of

donor samples involves many thousands of liquid .han

functions which aid in the operational work and man

dling steps and the generation of many thousands of

absorbance readings for the multiple wells devoted to 65 agement of a blood bank. The invention consists of

various off the shelf components and a custom designed

each donor. Further liquid handling steps are involved

liquid handler combined in one system, all controlled by

in automated antibody screening, and some special tests

may have to be done by hand on the blood which are

a comprehensive software resident in a host computer

3

4,873,633

4

which allows the user to control blood typing and other

host is also coupled to an orbital shaker and a centrifuge

liquid handling operations in the liquid handler and to

for re-suspension and re-separation of liquids and sam

ple cells during some system operations.

manage the data which results therefrom. The system

automates: much of the liquid handling involved in

The host software also contains routines for imple

processing donor samples for ABO/Rh blood typing

tests and antibody screening; sample and plate identi?

menting quality control operations. Such operations

include verifying test procedures by processing a small

number of known blood type samples and checking the

experimental data against the known results, and verify

ing that the dilution of cell suspension reagents and

donor cells produce absorbances in the proper range.

The system can also test the titer of antibody reagents.

The data management functions of the invention

cation using a bar code reader; plate reading for the

ABO/Rh tests; record keeping for quality control data

and test results for individual samples; access to infor

mation on test status; and printing of laboratory records

and transmission of information to a mainframe com

puter for on-line storage.

The physical system includes a Digital Equipment

Corporation PDP-ll MICRO with a 10 megabyte hard

include the management of data in the form of: test

procedure parameters for liquid handling, plate reading

disk and a VT220 terminal. The host system 20 runs a

commercially available operating system. The control

software is resident in the host. It is coupled to a custom

designed liquid handling system which has several mi

croprocessors resident therein which control various

stepper motors, bar code read heads and monitor vari 20

ous sensors. The process controlling parameters to con

and histograms; quality control data consisting of rea

gent lot numbers and expiration dates with associated

absorbances of these reagent lots over the period of

their usage; test results including blood groups and

probable type; manually added data from such tests as

DU tests, antibody screens, hepatitis, HTLV III, CMV,

RPR and other tests; and test status for the day of a

trol operations of the liquid handler come from the host

range of parameters such as the number of A+ samples

computer after being de?ned by the user at the host

that have been processed, the number of NTD’s during

terminal. Once the process parameters are loaded, the

resident software in the liquid handler controls various 25 the day and the status of testing for particular plates.

transfers of donor blood plasma and red blood cells to

BRIEF DESCRIPTION OF THE DRAWINGS

various wells in plates loaded by an automated plate

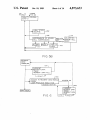

FIG.

1 is a block diagram of the interconnection of

reader. The resident software also controls dilution of

the various components of the system.

the red blood cells before depositing them in wells and

FIG. 2 is perspective view of the liquid handler of the

the transfer of speci?ed quantities of various types of

system.

reagents into the wells containing the donor’s blood

FIG. 3 is a flow diagram of the user options for vec

plasma and diluted red blood cells. Each plate can hold

toring processing to various sub-functions that the sys

samples from eight donors, and the donor samples are

tem can perform.

stored in test tubes in a circular, rotating lazy-susan-like

FIG. 4 is a flow diagram for steps performed in al

device which is controlled by the software of the liquid 35

lowing the user to customize the process parameters

handler.

The plates so ?lled are then unloaded by a plate han

controlling liquid handling operations.

dler device, and manually transferred to a plate reader

FIGS. 5A and 5B are a ?ow diagram of the process of

Model Autoreader EL309 manufactured by Biotech

allowing the user to monitor and control various quality

Instruments which is also coupled to the host. The plate 40 control functions.

reader then obtains absorbance readings on the wells in

FIG. 6 is flow diagram for the process of allowing the

the plates after reading the bar codes on each plate.

user to create and access various reagent data for use in

These absorbance readings for each well on each plate

insuring proper processing and improving reliability of

are sent to the host with the bar code of the plate for

test results.

45

interpretation.

FIG. 7 is a flow diagram of the plate reading function

The host knows which wells of each plate contain

of the system and a flow diagram of the process fol

samples from which donors having obtained this infor

lowed in allowing the user to edit or enter various re

mation by downloading the bar code data read by the

sults from testing.

liquid handler from the donor test tubes and the plates

FIG. 8 is a ?ow diagram for the process followed in

that received samples from each tube. The absorbance

allowing the user to specify results summaries the user

values are interpreted by plotting histograms for the

number of samples having each absorbance for each

would like to see.

FIGS. 9A and 9B are a ?ow diagram of the process

that the system follows in allowing the user to calibrate

different type of reagent. The user is then allowed to

de?ne the threshold values between the positive and

negative reactions for each reagent by viewing the

histogram and graphically moving an arrow to the de

sired threshold value. A “no man’s land” region where

the absorbance does not clearly indicate either a posi

tive or a negative value is also de?ned, and samples

having absorbance values falling in this region are

tagged as NTD. The user de?ned thresholds for each

type of reagent de?ne “templates” or patterns of posi

55

the plate reader and to adjust the thresholds used by the

host computer in interpreting test results.

FIG. 10 is a ?ow diagram of the process used by the

system in performing various ?le operations.

FIG. 11 is a flow diagram of the process used by the

system in allowing the user to con?gure the system for

a speci?c installation.

FIG. 12 is an illustrative histogram for a single rea

gent illustrating the meaning of adjusting the thresholds

tive and negative reactions which will de?ne each par

used in interpreting test results.

ticular blood type. The absorbance values for each

FIG. 13A shows a typical well bottom with a positive

sample are then compared to these templates and typed 65

reaction button.

as to their blood group type.

FIG. 13B shows a typical graph resulting from a

The host is also coupled to a printer, and the user can

request various pre-formatted management reports. The

positive reaction button.

_

5

4,873,633

6

much of the liquid-handling involved in processing

donor samples for ABO/Rh tests and antibody

DETAILED DESCRIPTION OF THE

PREFERRED EMBODIMENT

Referring to FIG. 1 there is shown a block diagram of

screening,

sample and plate identi?cation using a bar code reader,

the system of the invention. The system is comprised of 5 plate reading for ABO/Rh tests,

record keeping for quality control and test results for

a Digital Equipment Corporation PDP-ll MICRO host

individual samples,

computer 20 which coordinates the activities of the

system under the control of the resident software in

cluded herewith as the appendices and the user (not

shown) who enters commands through a keyboard 22 in

response to information displayed by the software on a

access to information to test status, and

printing of laboratory records and transmission of infor

mation to a mainframe computer for on-line storage.

ProGroup Automated Blood Typing System Bene?ts

terminal 24. The host computer 20 runs the commer

The ProGroup TM automated blood typing system is

a ?exible system, designed to adapt to the way work is

cially available Micro RSX operating system for the

PDP 11/23, ll/53 or ll/73 computer versions available

from Digital Equipment Corporation. The application

already organized in the user’s laboratory. The user

de?nes the way he or she wants particular procedures

carried out, and ProGroup TM automated blood typing

software which implements the functions described

herein is included herewith an appendix. The host com

system executes these tasks at command.

puter is coupled by RS232 serial ports and connecting

Automating liquid-handling makes test results more

cables to a number of liquid handling and plate handling

mechanisms of which liquid handler 26 is an example. 20 reliable, and allows employment of lab workers having

less skill. Features like computerized, data management

The preferred embodiment of the system can control up

techniques and the built-in bar code reader reduce the

to 8 liquid handlers. The details of the liquid handlers

incidence of operator error.

and plate handling mechanism are given in a copending

ProGroup TM automated blood typing system does

U.S. pat. application assigned to the assignee hereof

not require any previous experience with automated

liquid-handling equipment, or with computers.

entitled “Automated Liquid Handling Apparatus And

Process With Plate Handler”, ?led Oct. 18, 1985, Ser.

No. 789,945, now abandoned, and another U.S. pat.

ProGroup System Overview

application entitled “Liquid Manipulation Device and

Method”, ?led Jul. 5, 1985, Ser. No. 752,449, now aban 30

doned, both of which are hereby incorporated by refer

ence. The object code for the liquid handler disclosed in

the above identi?ed patent application has been

changed somewhat since the filing date thereof. The

latest object code is included herewith in the appendices

hereto. The object code appendices are labelled for the

particular microprocessor in the liquid handler for

There follows more detail on the individual compo

nents of the system.

Liquid-Handler

5

The liquid-handling portion of the ProGroup TM

automated blood typing system consists of the follow

ing items.

ProGroup TM automated blood typing system liquid

which each is intended.

The host 20 is also coupled by an RS232'link to a

handler 26, shown in more detail in FIG. 2, automates

and an orbital shaker 34 are also part of the system but

are not connected to the host 20. The centrifuge and

four permanently mounted liquid delivery heads (X, Y

orbital shaker are commercially available off the shelf

components and are used to process the plates after the

samples and reagents have been put in the wells by the

liquid handler 26 and before the plates are loaded in the

plate reader 28. Collectively, the above described sys

head 44. One or several of these can be used in the

course of a single procedure, since there is no require—

ment to remove one head to install another. The X, Y

and 63 of several sizes to minimize cross-contamination.

tem may hereafter be referred to as the ProGroup TM

The ProGroup TM automated blood typing system

automated blood typing system or the system.

The ProGroup TM automated blood typing system

automates many aspects of the blood typing and group

111 and a maximum of 200 ul.

the pipetting of donor plasma directly from a carousel

20 of tubes 22 into designated wells of a microplate. The

plate reader 28 which optically reads the absorbance

ProGroup TM automated blood typing system mixes

values for samples in various wells in plates ?lled with

donor red blood cells with diluent in designated propor

samples and reagents loaded from the liquid handler.

tions before transferring the cells to the wells of the

The plate reader is commercially available from BioTek

microtitre plates 56 and 58. ProGroup TM automated

Instruments, Inc. under the designation Autoreader

EL309.

45 blood typing system ?lls the ABO/Rh plate 56 and the

antibody screening plate 58 with the appropriate rea

The host 20 is also coupled by an RS232 link to a

gents from a reagent trough 62. The ProGroup TM

printer 30 upon which the host 20 prints the various

automated blood typing system liquid handler includes

reports of which the system is capable. A centrifuge 32

head 28, 12 channel head 42, ?ll manifold 46, and wash

head and 12 channel head use disposable pipette tips 24

accurately transfers volumes between a minimum of 10

Two identical bar code readers (not shown) are built

ing procedures performed in blood banks. This section 60 into the liquid-handler: one for reading the bar code 21

on the sample tube (actually located above the top sur

face of the carousel 20, and the other for reading the bar

code 57 and 59 on the microplates (actually located on

ProGroup TM Automated Blood Typing System

the other sides of the plates). The bar code on the sam

Functions

65 ple tube is the basis for the Whole Blood Number

(WBN) that identi?es the donor sample. The bar code

The major ProGroup TM. automated blood typing

on the microplate allows the system to pair the test

system functions are broadly de?ned below. ProGroup

results from the plate reader with the WBN of the sam

TM automated blood typing system automates:

provides a brief introduction to the functioning of the

system.

7

4,873,633

8

ple donor. The bar code readers can recognize Code

the computer, so the user can quickly generate hard

Bar or Code 39 labels.

copies of laboratory records.

Plate Stacker (not shown) holds six 96-well micro

plates for ABO/Rh testing. Each plate can accommo

date samples from eight donors. These plates are fed

into the liquid-handler 26 one by one for processing.

Once ?lled, a plate is automatically transferred off the

bed 74 of the liquid-handler, into the other rack of the

The ProGroup TM automated blood typing system is

used by laboratory personnel at three levels:

plate stacker.

The Technician, who operates the machine on a daily

basis, running test and printing results.

7 The Supervisor, who performs quality control proce

dures, adds to or revises test data as necessary, handles

the storage of information on the ProGroup TM auto

‘

mated blood typing system host computer 20, and data

Plate Reader

The Plate Reader 28 reads ABO Rh plates automati

cally and transmits data points to the ProGroup TM

transfers data to a mainframe computer.

The Director, who creates the initial framework for

the ProGroup. This includes tasks such as defining who

will be using the system, how the tests will be carried

out, and how test results should be interpreted. The

automated blood typing system host computer 20 for

interpretation. The results are reported by group and

type, or as NTD (No Type Determined) readings. An

NTD sample can be reread automatically with the plate

Director modi?es this framework as necessary, to re

?ect changes in system users, test protocol, etc..

reader, in which case the results stored on the computer

Security Precautions

are updated automatically. Alternatively, the row of

wells can be examined visually, or the liquid handling 20 The system utilizes a user privilege table and user

identi?cation at logon time to guarantee accountability

and the reading of that sample can be repeated manu

and to insure that only users with the proper authoriza

ally. In the latter case, the user inputs information

tion have access to certain portions of the program and

through the computer keyboard to modify the results of

certain data files.

the sample processing procedure.

The following publicly available documents are in

25

corporated by reference for support material.

Orbital Shaker

MICRO PDP-ll System Owner’s Manual Digital

The ProGroup TM automated blood typing system

Equipment Corporation.

includes an orbital shaker 34 as part of the system. The

Pro/Pette Liquid Handling System User’s Manual

Cetus Corporation.

shaker is used to resuspend the cells after the liquid

handling is complete, and then again after the plate has

been centrifuged. The orbital shaker can accommodate

up to eight plates.

Automated Microplate Reader Model EL309 Opera

tor’s Manual, Bio-Tek Instruments, Inc..

Installing and Using the LASO Printer, Digital Equip

ment Corporation.

Centrifuge

The centrifuge 32 can be an instrument such as the

Beckman TJ-6R Tabletop Centrifuge. It is used in a

known manner on the plates from the liquid handler 26

35

LASO Programmer’s Reference Manual, Digital

Equipment Corporation.

Orbital Shaker User Manual.

ABO/Rh Testing

before they are placed in the liquid handler.

Host Computer

ProGroup TM automated blood typing system auto

mates the typing and grouping of donor samples. This

The host of the ProGroup TM automated blood

typing system is the computer 20, called the host com

puter 20. The host computer 20 directs the operation of

the liquid handler 26 and the plate reader 28, and man

section describes the liquid-handling, resuspension, and

plate reading tasks the ProGroup TM automated blood

ages the data generated by the other equipment. The

user primarily interacts with the ProGroup TM auto

mated blood typing system through the host computer

20. The user uses the host computer 20 to select the

function the user wants the ProGroup TM automated

blood typing system to perform, and to view stored data

in tabular or graphic form. The host computer 20 allows

the user to modify data that has been created through

automatic procedures. The user can also enter addi

tional information pertaining to donor samples, such as

antibody screen results, or Hepatitis and HTLV III

results.

The host computer 20 is a DEC MICRO PDP-ll

computer with a 10 Mbyte hard disk and a VT 220

typing system performs for ABO/Rh testing.

Liquid-Handling Functions

The ProGroup TM automated blood typing system

liquid handler 26 transfers donor plasma out of the tubes

22 into designated wells of a microplate 56. It also trans

fers donor red blood cells into a special predilution

block 60, mixes the cells with a de?ned quantity of

diluent, then pipettes them into the appropriate wells of

the microplate 56. Then the ProGroup TM automated

blood typing system fills the plate with the reagents

from the reagent plate 62 for the assay.

Options

Referring to FIG. 3 there is shown the main menu

and logon process. Referring to FIG. 4 there is shown

the liquid handling process flow chart for the organiza

tion of the software if the liquid handling parameter

terminal with graphics capability. The computer 20 60 definition menu selection 100 is selected in FIG. 3. FIG.

runs the software included herewith as Appendix A on

the RSXll operating system which is commercially

available from Digital Equipment Corporation.

Printer

The ProGroup TM automated blood typing system

also includes an LASO dot matrix printer 30 from Digi

tal Equipment Corporation. The printer is connected to

4 would be reached after the user identified himself in

the logon step 102 and was accepted as a permissible

user. Processing would then vector to the main menu

screen 104 wherein all the options shown in FIG. 3

65 would be presented to the user. If he selected option

100, processing would be vectored to the liquid han

dling menu 106 after going through a logon step (not

shown). The liquid handling menu selection allows the

4,873,633

10

liquid-handler. A set of six 96-well microplates is loaded

into the plate stacker on the other side of the liquid-ham

dler. Each plate can hold sample from eight donors.

user to specify the process parameters of the liquid

handling assay for blood typing, NTD determination

and repeat liquid handling with or without bromelin

pre-treatment. Since these process parameters are criti

cal to accuracy of results, only supervisors or higher are

Reagents for the test, including properly diluted cell

suspension and antisera are placed in a row of wells in

allowed to log into this function of the system. The user

the reagent MicroTrof 62, along with a set of 12 tips.

speci?es the following aspects of liquid-handling for the

This MicroTrof also contains a row of reagents and a

ABO/Rh test:

whether or not a Bromelin pre-treatment is being

row of tips for the antibody screening test to be de

scribed later herein. The reagent MicroTrof is placed at

10 the back of the liquid-handler bed 74.

used, choice 108 or 110,

The predilution block 60 is placed just in front of the

which blood typing test should be executed (the op

reagent Microtrof. The block contains a trough of dilu

tions are A, B, (A,B), Rh, Cell Suspension, A1, A2, B,

ent, and several wells where the donor cells are mixed

and Serm Blank), step 112 and, what test format is being

with diluent.

used (i.e., which tests are being carried out in which

columns of the microplate to de?ne the format and

ABO/Rh Testing Procedure

arrangement of the template, i.e., the pattern of positive

and negative reactions which de?ne the blood type),

When the liquid-handler is set up and ready for oper

ation the ?rst step is to carry out the automatic homing

step 112.

and priming procedure. Then the user pushes the

The liquid handling may be done on the plates in any

START key on the hand-held controller 94. The plate

order and the plates may be read in any order. The

stacker places a 96-well plate on the liquid-handler

liquid handlers such as device 26 read the bar codes of

table, and the bar code 59 on that plate is read. The bar

all the tubes containing donor samples that are pipetted

codes 21 on the ?rst group of eight tubes are also read.

into a particular plate. These bar codes are sent to the

Then the liquid-handler picks up the ?rst ProGroup

host computer 20 along with the bar code of the plate

into which samples from the identified tubes were 25 TM automated blood typing system tip from the carou~

sel and withdraws the appropriate amount of donor

placed. The host computer knows which rows of each

plasma from the top of the tube. Aliquots of plasma are

plate contain aliquots of blood from each donor because

placed, one by one into the wells of the plate 56 that are

the control software of the liquid handler always places

designated for reverse typing tests. Next the liquid-han

samples in the plates in the same order relative to the

dler withdraws the required quantity of donor red

order of the tubes from which the samples were re

blood cells for the forward typing tests. Aliquots of

moved. The identi?cation data of the plates and the

cells are placed into the wells of the predilution block

WBNs that are in each plate are stored by the host

60, which already contain the required amount of dilu

computer in a lookup table along with any tag data that

ent. This diluent had been placed in the wells by the

the liquid handler appends to the identi?cation data for

the plate bar code. Such tag data can include data that 35 microprocessor of the liquid handler previously in ac

the plate is a steps off center plate (this will be explained

cordance with data received from the host regarding

more fully below) or is a donor cell suspension or rea

how much dilution the supervisor wants in the test

procedure for red blood cells. The diluent and cells are

mixed according to data regarding how many mixes

that are desired which was speci?ed by the user and

sent from the host to the liquid handler, and then the

gent cell suspension plate etc. Because this data is per

manently stored in a look up table, the order in which

the plates are read by the plate reader is unimportant.

The plates can be loaded in the plate reader in any

order. The plate reader then reads the bar code for each

plate and sends it to the host computer 20. The host

computer then looks up the bar code in the look up

table, and determines if any special instructions need to 45

tainer (not shown).

When the microplate 56 is ?lled with donor samples,

be sent back to the plate reader, e.g. as to wavelength to

be used for the light or whether or not to do a steps off

the l2-channel head picks up reagents from the reagent

Micro-trof 62 and ?lls the row of the plate 56 containing

the ?rst donor’s samples with the pattern of reagents

center series of light absorbance readings.

Parameters

mixture is pipetted into the forward testing wells of the

microplate. The used ProGroup TM automated blood

typing system tip is then ejected into a used tip con

50

speci?ed by the user in the liquid handling procedure

set-up step previously described (the user must ?ll the

The user de?nes the test protocol by specifying in

reagent trof 62 wells with the proper reagents in accor

steps 114 and 116 for no bromelin and bromelin pre

dance with the desired pattern). The row of Pro/Pette

treatment respectively the:

tips used for this operation is then ejected back into the

volume of donor plasma to be pipetted into the wells

55 Microtrof.

of the microplate,

At this point, the liquid-handling on the plate is ?n

volume of donor cells, the volume of diluent to be

ished. The plate is loaded back into the plate stacker to

mixed with the cells (thus the concentration of the

await completion of the remaining ?ve plates in that

donor cell suspension) and the number of mixes,

group.

concentration of the reagent cell suspension, and

When all six are done, they are moved to the orbital

titer of the reagent antisera.

shaker for resuspension. Next they are centrifuged at

Liquid Handler Set-Up

Bar coded tubes containing properly prepared donor

low speed to cause the cells to settle. Then, they are

resuspended. This sequence of steps disperses the cells

when the test results are negative, but causes the cells in

mated blood typing system carousel. The carousel holds 65 a positive test to clump together in a tight button at the

bottom of the well.

48 tubes and 48 ProGroup TM automated blood typing

blood samples are loaded into the ProGroup TM auto

system disposable tips. The carousel mounts at the side

of the ProGroup TM automated blood typing system

The ?nal step is to load each plate into the automatic

plate reader. Plate reading can occur no less than three