Download DeviceNet is a registered trademark ODVA. - BRP -

Transcript

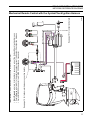

SAFETY INFORMATION This booklet is written for qualified, factory-trained technicians who are already familiar with the use of Evinrude ®/Johnson ® Special Tools. This booklet is not a substitute for work experience. It is an organized guide for installation of the ICON gauge system. This booklet uses the following signal words identifying important safety messages. A DANGER Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury. A WARNING Indicates a potentially hazardous situation which, if not avoided, CAN result in severe injury or death. A CAUTION Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate personal injury or property damage. It also may be used to alert against unsafe practices. IMPORTANT: Identifies information that will help prevent damage to machinery and appears next to information that controls correct assembly and operation of the product. These safety alert signal words mean: ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED! Always follow common shop safety practices. If you have not had training related to common shop safety practices, you should do so to protect yourself, as well as the people around you. It is understood that this booklet may be translated into other languages. In the event of any discrepancy, the English version shall prevail. DO NOT perform any installation until you have read the instructions and checked the pictures relating to the installation procedures. Be careful, and never rush or guess a service procedure. Human error is caused by many factors: carelessness, fatigue, overload, preoccupation, unfamiliarity with the product, and drugs and alcohol use, to name a few. Damage to a boat and outboard can be fixed in a short period of time, but injury or death has a lasting effect. When replacement parts are required, use Evinrude/Johnson Genuine Parts or arts with equivalent characteristics, including type, strength and material. Using substandard parts could result in injury or product malfunction. Torque wrench tightening specifications must be strictly followed. Replace any locking fastener (locknut or patch screw) if its locking feature becomes weak. Definite resistance to turning must be felt when reusing a locking fastener. If replacement is specified or required because the locking fastener has become weak, use only authorized Evinrude/Johnson Genuine Parts. If you use procedures or service tools that are not recommended in this instruction booklet, YOU ALONE must decide if your actions might injure people or damage the outboard. The following trademarks are the property of Bombardier Recreational Products Inc. or its affiliates. Evinrude ® I-Command ™ Evinrude ® E-TEC ® Johnson ® † NMEA 2000 is a registered trademark of the National Marine Electronics Association or its subsidiaries. † DeviceNet is a registered trademark ODVA. † Deutsch is a registered trademark of The Deutsch Company. © 2011 BRP US Inc. All rights reserved. TM, ®, and the BRP logo are registered trademarks of Bombardier Recreational Products Inc. or its affiliates. Before working on any part of the outboard, read the following SAFETY information. A DANGER Contact with a rotating propeller is likely to result in serious injury or death. Assure the engine and prop area is clear of people and objects before starting engine or operating boat. Do not allow anyone near a propeller, even when the engine is off. Blades can be sharp and the propeller can continue to turn even after the engine is off. Remove propeller before servicing and when running the outboard on a flushing device. DO NOT run the engine indoors or without adequate ventilation or permit exhaust fumes to accumulate in confined areas. Engine exhaust contains carbon monoxide which, if inhaled, can cause serious brain damage or death. A WARNING Wear safety glasses to avoid personal injury, and set compressed air to less than 25 psi (172 kPa). The motor cover and flywheel cover are machinery guards. Use caution when conducting tests on running outboards. DO NOT wear jewelry or loose clothing. Keep hair, hands, and clothing away from rotating parts. During service, the outboard may drop unexpectedly. Avoid personal injury; always support the outboard’s weight with a suitable hoist or the tilt support bracket during service. To prevent accidental starting while servicing, disconnect the battery cables at the battery. Twist and remove all spark plug leads. The electrical system presents a serious shock hazard. DO NOT handle primary or secondary ignition components while outboard is running or flywheel is turning. Gasoline is extremely flammable and highly explosive under certain conditions. Use caution when working on any part of the fuel system. Protect against hazardous fuel spray. Before starting any fuel system service, carefully relieve fuel system pressure. Do not smoke, or allow open flames or sparks, or use electrical devices such as cellular phones in the vicinity of a fuel leak or while fueling. Keep all electrical connections clean, tight, and insulated to prevent shorting or arcing and causing an explosion. Always work in a well ventilated area. Replace any locking fastener (locknut or patch screw) if its locking feature becomes weak. Definite resistance to tightening must be felt when reusing a locking fastener. If replacement is indicated, use only authorized replacement or equivalent. 2 ICON GAUGE INSTALLATION GUIDE SAFETY INFORMATION ICON Gauge Installation Guide 3 ICON GAUGE INSTALLATION GUIDE TABLE OF CONTENTS TABLE OF CONTENTS ICON Gauge Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 5 in. (127 mm) Pro Series Tachometer and Speedometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 in. (89 mm) Pro Series Tachometer and Speedometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 in. (127 mm) 3-n-1 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 in. (89 mm) Basic Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 in. (51 mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 5 6 6 7 Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Multiple Gauges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Warning Horns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Pressure Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Network Power and Grounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Network Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 8 8 8 8 Network Reference Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Electronic Remote Control Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Mechanical Remote Control Network with the I-Command Ignition and Trim/Tilt Harness . . . . . . . . . . . 10 Mechanical Remote Control Network with the SystemCheck Harness . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Gauge Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Drilled Hole Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Instrument Panel Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Gauge Spacing (center to center) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Instrument Panel Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Hole Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Fastening the Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Gauge Back Clamp Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Weather Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Tachometer Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Tachometer Harness 12 Socket Plug Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Tachometer Harness NMEA 2000 Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Tachometer Harness Gauge Buss Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Tachometer to speedometer harness connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Tachometer harness connection to 2 in. gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Tachometer Harness Power Connection and Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Speedometer Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Speedometer Harness 12 Socket Plug Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Speedometer Harness Gauge Buss Plug Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Speedometer Harness Gauge Buss Receptacle Connector Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 2 in. Gauge Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 2 in. Gauge Harness Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Analog Input Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Analog Input Harness Installation to Auxiliary Fuel Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 ICON Gauge Backlight Adjustment Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 Backlight Adjustment Kit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 NMEA 2000 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 4 ICON GAUGE INSTALLATION GUIDE ICON GAUGE KITS ICON Gauge Kits 5 in. (127 mm) Pro Series Tachometer and Speedometer 1 2 008602 Ref 1 1 2 NS 2 NS P/N 766162 766185 766170 766169 766193 766192 Name of Part TACHOMETER , ICON Pro with LCD, 5 in. - Black TACHOMETER , ICON Pro with LCD, 5 in. - White SPEEDOMETER 80 MPH, ICON Pro with LCD, 5 in. - Black SPEEDOMETER 50 MPH, ICON Pro with LCD, 5 in. - Black SPEEDOMETER 80 MPH, ICON Pro with LCD, 5 in. - White SPEEDOMETER 50 MPH, ICON Pro with LCD, 5 in. - White Qty 1 1 1 1 1 1 3.5 in. (89 mm) Pro Series Tachometer and Speedometer 1 2 008599 Ref 1 1 2 NS 2 NS P/N 766161 766184 766168 766167 766191 766190 Name of Part TACHOMETER , ICON Pro with LCD, 3.5 in. - Black TACHOMETER , ICON Pro with LCD, 3.5 in. - White SPEEDOMETER 80 MPH, ICON Pro with LCD, 3.5 in. - Black SPEEDOMETER 50 MPH, ICON Pro with LCD, 3.5 in. - Black SPEEDOMETER 80 MPH, ICON Pro with LCD, 3.5 in. - White SPEEDOMETER 50 MPH, ICON Pro with LCD, 3.5 in. - White Qty 1 1 1 1 1 1 5 ICON GAUGE INSTALLATION GUIDE ICON GAUGE KITS 5 in. (127 mm) 3-n-1 Series 1 2 008604 Ref 1 1 2 2 P/N 766160 766183 766166 766189 Name of Part TACHOMETER , ICON Basic Multi Function with Temp and Trim, 5 in. - Black TACHOMETER , ICON Basic Multi Function with Temp and Trim, 5 in. - White SPEEDOMETER 80 MPH, ICON Basic Multi Function with Fuel and Volt, 5 in. - Black SPEEDOMETER 80 MPH, ICON Basic Multi Function with Fuel and Volt, 5 in. - White Qty 1 1 1 1 3.5 in. (89 mm) Basic Series 1 2 008606 Ref 1 1 2 NS NS 2 NS NS 6 P/N 766159 766182 766165 766164 766163 766188 766187 766186 Name of Part TACHOMETER, ICON Basic Single Function, 3.5 in. - Black TACHOMETER, ICON Basic Single Function, 3.5 in. - White SPEEDOMETER 80 MPH, ICON Basic Single Function, 3.5 in. - Black SPEEDOMETER 50 MPH, ICON Basic Single Function, 3.5 in. - Black SPEEDOMETER 30 MPH, ICON Basic Single Function, 3.5 in. - Black SPEEDOMETER 80 MPH, ICON Basic Single Function, 3.5 in. - White SPEEDOMETER 50 MPH, ICON Basic Single Function, 3.5 in. - White SPEEDOMETER 30 MPH, ICON Basic Single Function, 3.5 in. - White Qty 1 1 1 1 1 1 1 1 ICON GAUGE INSTALLATION GUIDE ICON GAUGE KITS 2 in. (51 mm) 1 2 3 4 5 6 008608 Ref 1 1 NS NS 2 2 3 3 NS 4 4 5 5 NS 6 6 NS NS NS NS P/N 766171 766194 766172 766195 5008300 5008640 766173 766196 766174 766197 764271 766175 766198 766176 766177 766199 766200 766201 765510 766179 766180 766181 766202 766203 766204 765976 765977 765512 766074 Name of Part WATER PRESSURE, 30 PSI, 2in. - Black WATER PRESSURE, 30 PSI, 2in. - White WATER PRESSURE, 60 PSI, 2in. - Black WATER PRESSURE, 60 PSI, 2in. - White WATER PRESSURE SENSOR KIT, 30 PSI WATER PRESSURE SENSOR KIT, 60 PSI TRIM, 2 in. - Black TRIM, 2 in. - White OIL LEVEL, 2 in. - Black OIL LEVEL, 2 in. - White *SINGLE ENGINE OIL LEVEL SENDING UNIT KIT, 1.8 Gal tank WATER TEMPERATURE, Engine, 2 in. - Black WATER TEMPERATURE, Engine, 2 in. - White FUEL LEVEL, Tank 1, 2 in. - Black FUEL LEVEL, Tank 2, 2 in. - Black FUEL LEVEL, Tank 1, 2 in. - White FUEL LEVEL, Tank 2, 2 in. - White FUEL LEVEL, Auxiliary Tank ( Tank 3), 2 in. - White *HARNESS, Analog Input VOLT, Battery 1, 2 in. - Black VOLT, Battery 2, 2 in. - Black VOLT, Battery 3, 2 in. - Black VOLT, Battery 1, 2 in. - White VOLT, Battery 2, 2 in. - White VOLT, Battery 3, 2 in. - White PLUG, Weather PLUG, Weather HARNESS, 2 in. Gauge to Gauge, 12 in. (30 cm) INSTRUCTION SHEET, ICON Gauge A B C D E F Requires water pressure sensor kit, 30 psi, P/N 5008300 Requires water pressure sensor kit, 60 psi P/N 5008640 Includes single engine oil level sending unit kit (1.8G tank), P/N 764271 Includes analog input harness, P/N 765510 Included with 2 in. gauges Included with tachometers and speedometers A A B B C C D E F E E, F Qty 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 7 ICON GAUGE INSTALLATION GUIDE NETWORK CONNECTIONS Network Connections Read the ICON Gauge User’s Guide, P/N 766075, prior to network assembly. ICON gauges can be installed with electronic or mechanical remote control networks and are compatible with “DeviceNet” and “NMEA 2000” networks. Connect ICON gauge components to a new or existing: • Electronic Remote Control Network • Mechanical Remote Control Network with the I-Command Ignition and Trim/Tilt harness • Mechanical Remote Control Network with the SystemCheck harness See Network Reference Diagrams on pages 9, 10, and 11. Multiple Gauges Any ICON tachometer can be assembled with it’s equal ICON speedometer or any number of ICON 2 inch accessory gauges. Warning Horns All ICON tachometers and speedometers have internal warning horns. The warning horns have a resonant frequency of 4200 +/- 500 Hz. The sound level is 95 db at 30 cm. The warning horn will sound: • For one second each time power is turned ON for the system • For customized warnings such as fluid level or trim level. See the ICON gauge user’s manual, P/N 766075, for a complete list of customized warnings • When an error message is initiated by the EMM of the engine • For engine gear position changes • For each button press on the PRO tachometer or PRO speedometer The warning horn feature can be enabled or disabled within the audio menu of the PRO tachometer or PRO speedometer gauge. IMPORTANT: The horn included with the SystemCheck harness is not used with ICON gauge networks. Pressure Ports ICON Basic and ICON 3-n-1 tachometers have pressure ports which are used to support pitot speed input. ICON PRO tachometers do NOT have pressure ports. Network Power and Grounds Identify which battery supplies power to the system. Connect all power supply batteries in parallel. For electronic remote control networks, connect the tachometer purple power wire (pin 5) to the accessory power terminal block. See Electronic Remote Control Network on p. 9. Ground the ICON gauge system directly to the negative terminal of the PRIMARY or power supply battery. See BATTERY INSTALLATION in the current Evinrude E-TEC Predelivery and Installation Guide. Network Connectors Apply Dielectric Grease only to the seals of network connectors. 8 (–) (+) _ VOLT 13.6 V TRIM 3 TACH H (–) NMEA BUSS NMEA DEVICE BUSS (+) 6 + SPEEDO/GAUGE SPEEDO/GAUGE A B C D DN UP A B C D MID DN MID UP 16 10 1 14 12 16 10 1 14 12 0 VOLT 13.6 V TRIM H TACH NMEA BUSS VOLT 13.6 V TRIM VOLT 13.6 V TRIM 6 SPEEDO/GAUGE SPEEDO/GAUGE TACH TACH CLOCK 12:24 PM FUEL LEVEL CLOCK 12:24 PM FUEL LEVEL GAUGES SPEEDO SPEEDO See page 15 for tachometer harness connection details. GAUGES A B C D DN MID DN A B C D UP ESUF BUSS NMEA DEVICE BUSS FUSE MID • Black Ground wire (pin 4) to negative terminal of the PRIMARY or power supply battery • Purple Power wire (pin 5) to the accessory power terminal block • 5-pin NMEA 2000 connector to a NMEA 2000 backbone t-connector IMPORTANT: Required power connections for each tachometer at each station: UP 16 10 1 14 12 16 10 1 14 12 RUN 008671 008672 OFF ICON GAUGE INSTALLATION GUIDE NETWORK REFERENCE DIAGRAMS Network Reference Diagrams Electronic Remote Control Network A B C D A B C D DEVICE DEVICE DEVICE FUSE 9 (–) (+) _ NMEA 3A + CO VOLT 13.6 V TRIM BUSS BUSS SPEEDO/GAUGE TACH CLOCK 12:24 PM FUEL LEVEL SPEEDO See page 15 for tachometer harness connection details. DEVICE BUSS DEVICE DEVICE 10 ® RIA FA GAUGES IA® T RI M MID UP SVILLE, CT M ADE UNCA IN U . S.A .D DN RP. CO A B C D R FA LP 80 R FA IA® 1 16 VO LT 14 10 SVILLE, CT MA DE UNCA IN U . S.A .D 12 RP. CO LP 80 Required Connections IMPORTANT: Required power connections for each tachometer: • Tachometer harness black wire to ground • Black Tachometer Ground harness wire (pin purple 4) towire the to black ignition accessory (switched ground B+) wire of the I-Command Ignition Trim/Tilt Harness • Purple Fuel tank Power sender wire black (pin to 5) ground to purple accessory power wire of the I-Command Ignition and Trim/Tilt Harness • 5-pin NMEA 2000 connector to a NMEA 2000 backbone t-connector 008672 ICON GAUGE INSTALLATION GUIDE NETWORK REFERENCE DIAGRAMS Mechanical Remote Control Network with the I-Command Ignition and Trim/Tilt Harness 6A 8A A B C D (–) (+) _ DEVICE NMEA 3A BUSS BUSS BUSS DEVICE DEVICE + VOLT 13.6 V TRIM SPEEDO/GAUGE TACH CLOCK 12:24 PM FUEL LEVEL GAUGES IA® T RI M MID .S.A .D UP SVILLE, CT MA DE UNCA IN U DN RP. CO A B C D R FA LP 80 R FA IA® 16 1 14 10 VO LT SVILLE, CT MA DE UNCA IN U 12 RP. CO .S.A .D LP 80 6A 8A 008673 See page 18 for connection details SPEEDO See page 15 for tachometer harness connection details. • Black Ground wire (pin 4) to the black accessory wire of the SystemCheck Ignition Harness • Purple Power wire (pin 5) to the purple accessory wire of the SystemCheck Ignition Harness • 5-pin NMEA 2000 connector to a NMEA 2000 backbone t-connector IMPORTANT: Required power connections for each tachometer: ICON GAUGE INSTALLATION GUIDE NETWORK REFERENCE DIAGRAMS Mechanical Remote Control with the SystemCheck Ignition Harness A B C D 11 ICON GAUGE INSTALLATION GUIDE GAUGE DIMENSIONS Gauge Dimensions 3.5 in. (89 mm) Gauges 2.76 in. (70 mm) 3.79 in. (86 mm) Stud 8-32 UNC 3.37 in. (96 mm) 1 2 3 4 5 6 12 11 10 9 8 7 Pressure Port 4.28 in. (109 mm) Horn 008600 5 in. (127 mm) Gauges 2.69 in. (68 mm) 4.68 in. (111 mm) Stud 8-32 UNC 4.37 in. (119 mm) 1 2 3 4 5 6 12 11 10 9 8 7 Pressure Port Horn 4.65 in. (118 mm) 008605 2 in. (51 mm) Gauges 2.23 in. (57 mm) 2.22 in. (56 mm) Stud 8-32 UNC D C A B B C A D A B 2.06 in. (52 mm) 3.82 in. (97 mm) 008610 12 ICON GAUGE INSTALLATION GUIDE INSTRUMENT PANEL CLEARANCES Instrument Panel Clearances Gauge Spacing (center to center) • • • • • 5 3/8 in. (144 mm) between 5 in. instruments 4 1/8 in. (105 mm) between 5 in. instruments and 2 in. instruments 3 15/16 in. (100 mm) between 3.5 in. instruments 3 1/4 in. (83 mm) between 3.5 in. instruments and 2 in. instruments 2 3/4 in. (70 mm) between 2 in. instruments Instrument Panel Thickness One inch (26 mm) maximum. Hole Sizes IMPORTANT: Check space behind panel for adequate instrument clearance. • 4 3/8 in. (111 mm) for 5 in. instruments • 3 3/8 in. (86 mm) for 3.5 in. instruments • 2 1/16 in. (53 mm) for 2 in. instruments Fastening the Gauge Insert instrument into panel hole. Install back clamp, washers and wing nuts. Tighten wing nuts finger tight. Gauge Back Clamp Kits 2.65 in. (67 mm) 2.72 in. (69 mm) 2.23 in. (57 mm) 4.73 in. (120 mm) 3.39 in. (86 mm) 2.22 in. (56 mm) 1 2 3 008632 Ref P/N 1 766105 KIT, Backclamp, 2 in. gauge 2 766106 KIT, Backclamp, 3.5 in. gauge 3 766107 KIT, Backclamp, 5 in. gauge Name of Part A B C Qty 1 1 1 A Included with 2 in. gauge B Included with 3.5 in. gauge C Included with 5 in. gauge 13 ICON GAUGE INSTALLATION GUIDE FASTENING THE GAUGE Weather Plugs Install weather plugs to seal open receptacles. 2 1 D C A B B C A 1 2 3 4 5 6 12 11 10 9 8 7 D A B 008630 Ref P/N 1 765977 WEATHER PLUG, 6-pin 2 765976 WEATHER PLUG, 4-pin Name of Part A Included with Tachometers and Speedometers B Included with 2 in. gauges 14 A B Qty 1 1 ICON GAUGE INSTALLATION GUIDE TACHOMETER HARNESS Tachometer Harness IMPORTANT: Required power connections for all tachometers: 2, 3, 4, 5, TACH • Black Gauge Ground wire (pin 4) to ground • Purple Gauge Power wire (pin 5) to accessory switched B+ • 5-pin NMEA 2000 connector to a NMEA 2000 backbone t-connector 1 To NMEA Public Network To Speedometer Harness or 2 in. Gauge A B C D NMEA SPEEDO/GAUGE 18 in. (457 mm) 36 in. (914 mm) White Analog Input Wires (pins 4, 7, 8) Black Gauge Ground Wire (pin 4) Purple Gauge Power Wire (pin 5) 008613 Ref 1 2 3 4 5 P/N 765499 3011715 3011714 514858 3011716 Name of Part HARNESS, Tachometer *CONNECTOR, 12 Socket plug *TERMINAL, Socket *SEAL, Plug *LOCKWEDGE, 12 Socket plug A Qty 1 1 12 1 1 A Included with tachometer gauge 15 ICON GAUGE INSTALLATION GUIDE TACHOMETER HARNESS 12 11 2 10 3 9 4 8 5 6 TACH 1 Data Low - Blue - 12 Data High - White - 11 NMEA Ground - Black - 10 NMEA Power - Red - 9 Analog IN 3 - White - 8 Analog IN 2 - White - 7 7 Tachometer Harness 12 Socket Plug Connector Detail 1 - Red - Gauge Buss Power 2 - White - Gauge Buss Data 3 - Green - Gauge Buss Data 4 - Black - Gauge Buss Ground 5 - Purple - Gauge Power 6 - White - Analog IN 1 008614 Tachometer Harness NMEA 2000 Connector Detail NMEA 2000 Ground - Black - 3 NMEA NMEA 2000 Buss Data High - White - 4 NMEA 2000 Buss Data Low - Blue - 5 NMEA 2000 Power - Red - 2 Shield - Bare - 1 008615 Tachometer Harness Gauge Buss Connector Detail A B C D A - Gauge Buss Power - Red B - Gauge Buss Data - White C - Gauge Buss Data - Green D - Gauge Buss Ground - Black/Shield 008616 Tachometer to speedometer harness connection: This connection is REQUIRED when a speedometer is installed on the gauge buss. Connect the 12-pin connector to the tachometer. Connect the 4-socket plug to the 4-pin receptacle of the speedometer harness. 16 ICON GAUGE INSTALLATION GUIDE TACHOMETER HARNESS 1 6 SPEEDO TACH Connect the 5-pin NMEA 2000 connector to the device port of a t-connector on the NMEA 2000 network. 2 1 2 3 4 5 6 1 1 2 2 3 3 4 4 5 5 6 6 12 11 10 9 8 7 12 12 11 11 10 10 9 9 8 8 7 7 7 DEVICE 5 1. 2. 3. 4. 5. 6. 7. TACH 3 A B C D SPEEDO/GAUGE A B C D BUSS NMEA GAUGES 4 008617 12-pin connector Tachometer 4-socket plug 4-pin receptacle 5-pin NMEA 2000 connector T-connector Speedometer Tachometer harness connection to 2 in. gauge: This connection is required when a speedometer is NOT installed on the gauge buss. Connect the 12-pin connector to the tachometer. Connect the 4-socket plug to position B on the 2 in. gauge. Connect the 5-pin NMEA 2000 connector to the device port of a t-connector on the NMEA 2000 network. 2 TACH 1 6 4 A B C D DEVICE BUSS NMEA SPEEDO/GAUGE D 1. 2. 3. 4. 5. 6. 12-pin connector Tachometer 4-socket plug 2 in. gauge 5-pin NMEA 2000 connector T-connector C C D B 5 A B B A A 3 008618 17 ICON GAUGE INSTALLATION GUIDE TACHOMETER HARNESS Tachometer Harness Power Connection and Analog Inputs Power connections are required for each tachometer, analog input connections are optional. Pro Series Gauge Required power connections: • Black Ground wire (pin 4) to ground • Purple Power wire (pin 5) to accessory switched B+ • 5-pin NMEA 2000 connector to a NMEA 2000 backbone t-connector Optional analog inputs: Fuel, Ballast, Baitwell, Fresh Water, Gray Water, and Black Water Levels; Rudder and Trim Position. Optional analog input connections: • White Analog IN 1 wire (pin 6) to analog device signal wire • White Analog IN 2 wire (pin 7) to analog device signal wire • White Analog IN 3 wire (pin 8) to trim signal wire Basic or 3-n-1 Series Gauges Required power connections: • Black Ground wire (pin 4) to ground. • Purple Power wire (pin 5) to switched B+ • 5-pin NMEA 2000 connector to the NMEA 2000 backbone t-connector Optional analog inputs: Fuel Tank 1, Trim, and Fuel Tank 2. Optional analog input connections: • White Analog IN 1 wire (pin 6) to fuel tank 1 signal wire • White Analog IN 2 wire (pin 7) to trim signal wire • White Analog IN 3 wire (pin 8) to fuel tank 2 signal wire TACH Installation for Analog Inputs SPEEDO/GAUGE A B C D NMEA 1 Black - Ground (pin 4) Purple - Power (pin 5) White - Analog IN 1 (pin 6) White - Analog IN 2 (pin 7) White - Analog IN 3 (pin 8) 1. Tachometer Harness 18 008619 ICON GAUGE INSTALLATION GUIDE SPEEDOMETER HARNESS Speedometer Harness 2, 3, 4, 5, 6 SPEEDO Power connections are not required for the speedometer. Power is supplied to the speedometer directly from it’s connection to the tachometer harness. 1 A B C D TACH GAUGES 36 in. (914 mm) 18 in. (457 mm) 008620 Ref 1 2 3 4 5 6 P/N 765509 3011715 3011714 514858 3011716 514690 Name of Part HARNESS, Speedometer *CONNECTOR, 12 Socket plug *TERMINAL, Socket *SEAL, Plug *LOCKWEDGE, 12 Socket plug *PLUG, Sealing Qty 1 1 8 1 1 1 A A Included with speedometer gauge 12 11 2 10 3 9 4 8 5 7 6 Gauge Buss Ground - Black - 12 Gauge Buss Data - Green - 11 Gauge Buss Data - White - 10 Gauge Buss Power - Red - 9 No Connection (N/C) - White - 8 No Connection (N/C) - White - 7 1 SPEEDO Speedometer Harness 12 Socket Plug Connector Detail 1 - Gauge Buss Power - Red 2 - White - Gauge Buss Data 3 - Green - Gauge Buss Data 4 - Black - Ground 5 - No Connection (N/C) 6 - White - No Connection (N/C) 008621 19 ICON GAUGE INSTALLATION GUIDE SPEEDOMETER HARNESS Speedometer Harness Gauge Buss Plug Connector Detail A B C D A - Gauge Buss Power - Red B - Gauge Buss Data - White C - Gauge Buss Data - Green D - Gauge Buss Ground - Black/Shield 008622 Speedometer Harness Gauge Buss Receptacle Connector Detail A - Gauge Buss Power - Red B - Gauge Buss Data - White C - Gauge Buss Data - Green D - Gauge Buss Ground - Black/Shield 008623 Speedometer Harness Installation Connect the 12-pin connector to the speedometer. Connect the 4-socket plug to position B on the 2 in. gauge. Connect the 4-pin receptacle to the 4-socket plug on the tachometer harness. 2 SPEEDO 1 TACH 4 1 2 3 4 5 6 12 11 10 9 8 7 3 TACH GAUGES A B C D SPEEDO/GAUGE A B C D NMEA D 20 12-pin connector Speedometer 2 in. gauge Tachometer harness C C D B 1. 2. 3. 4. A B B A A 008624 ICON GAUGE INSTALLATION GUIDE 2 IN. GAUGE HARNESS 2 in. Gauge Harness Use the 2 in. gauge to gauge harness to connect 2 in. gauges together. 1 A - Gauge Buss Power - Red B - Gauge Buss Data - White C - Gauge Buss Data - Green D - Gauge Buss Ground - Black/Shield A B C D A B C D 008611 Ref P/N Name of Part 1 765512 HARNESS, 2 in. Gauge, 12 in. (30 cm) - 765514 HARNESS, 2 in. Gauge, 24 in. (61 cm) - 764515 HARNESS, 2 in. Gauge, 30 in. (76 cm) A Qty 1 1 1 A Included with 2 in. gauge 2 in. Gauge Harness Installation Connect one 4-socket plug to position A connector on the first 2 in. gauge. Connect the opposite plug to position B connector on the second two 2 in. gauge. Continue connecting additional harnesses from position A to position B as required for each 2 in. gauge on the network. 1 3 4 2 D C B A B C B C D B 1. 2. 3. 4. D A 4-socket plug First 2 in. gauge Opposite plug Second 2 in. gauge A A A B C D B A 008612 21 ICON GAUGE INSTALLATION GUIDE ANALOG INPUT HARNESS Analog Input Harness Install this harness with ICON PRO tachometers to connect auxiliary fuel tank analog inputs. Install with ICON Basic and ICON 3-n-1 tachometers to connect the Backlight Adjustment Kit, P/N 766108. See ICON Gauge Backlight Adjustment Kit on p. 23. Install this harness with ICON Basic and ICON 3-n-1 tachometers in dual engine applications to assign a gauge to the starboard engine: • Connect the harness to the required tachometer gauge • Connect Analog IN 5 (pin-3) to ground This allows the selected tachometer to display information for the starboard engine. 3, 4, 5, 6, 7 2 1 N/C - 6 N/C - 5 Analog IN 4 - White - 4 6 1 5 4 2 3 1 - N/C 2 - N/C 3 - White - Analog IN - 5 008626 Ref 1 2 3 4 5 6 7 P/N 765510 502526 3011704 3011705 3011706 514858 514690 Name of Part Qty AR 2 1 1 2 1 4 HARNESS, Analog Input *BUTT CONNECTOR, Heat Shrink *CONNECTOR, 6 Socket plug *LOCKWEDGE, 6 Socket plug *TERMINAL, Socket *SEAL, Plug *PLUG, Sealing Analog Input Harness Installation to Auxiliary Fuel Tanks Connect Analog IN 4 (pin-4) from harness to fuel tank #3 pink signal wire. Connect Analog IN 5 (pin-3) from harness to fuel tank #4 pink signal wire. Connect 6-socket plug of the analog input harness to the ICON PRO tachometer. 1 3 4 Fuel Tank #3 1 2 3 4 5 6 12 11 10 9 8 7 Fuel Tank #4 2 1. 2. 3. 4. 22 Analog IN 4 (pin-3) Analog IN 5 (pin-4) Six socket plug ICON PRO tachometer 008627 ICON GAUGE INSTALLATION GUIDE ICON GAUGE BACKLIGHT ADJUSTMENT KIT ICON Gauge Backlight Adjustment Kit The ICON Basic and ICON 3-n-1 tachometers do not have an internal backlight adjustment feature. Install this kit with ICON Basic and ICON 3-n-1 tachometers to control backlight adjustment. IMPORTANT: The backlight adjustment feature for ICON PRO tachometers is an internal function of the gauge. This kit is not used with ICON PRO tachometers. Dimmer Switch Side View White Red Black 1 29 in. (737 mm) 2 29 in. (457 18 (737 mm) 008628 Ref 1 2 NS P/N 766114 766108 765510 766235 Name of Part KIT, ICON Digital Gauge Backlight Adjustment DIMMER SWITCH, Ay. HARNESS, Analog Input *INSTRUCTION SHEET, Backlight Adjustment Kit Qty AR 1 1 1 Backlight Adjustment Kit Installation Select a mounting location which is not exposed to elements of the weather. Drill one 7/16 in. (11 mm) hole in dash. Install lighting dimmer switch through back of dash. Install washer and base nut, tighten 10 to12 inch pounds (1 to 1.5 N·m). Install knob-spacer nut and adjustment knob, tighten 10 to 12 inch pounds (1 to 1.5 N·m). Connect red and white wires to Analog Input 5 (pin-4) of the analog input harness. Connect black wire to ground (negative terminal of the ICON gauge system power supply battery). Connect the 6-socket plug of the analog input harness to the ICON Basic or ICON 3-n-1 tachometer. 1 2 3 4 5 6 12 11 10 9 8 7 008629 23 ICON GAUGE INSTALLATION GUIDE NMEA 2000 ACCESSORIES NMEA 2000 ACCESSORIES NMEA 2000 accessories available for interface to the ICON gauges. Connect NMEA 2000 accessories to the device port of a t-connector on the NMEA 2000 network. Description of Kit 24 P/N Triducer, transom mount, Speed/Depth/Temp 764671 Triducer, thru-hull, Plastic, Speed/Depth/Temp 764673 Transducer, transom mount, Depth/Temp (no speed) 764672 GPS Receiver/antenna 765349 SOW Paddle Wheel Kit 764193 Oil Tank Level Kit, 1.8 Gallon – one engine one oil tank (instance 0) 764271 Oil Tank Level Kit, 1.8 Gallon – two engines two oil tanks (instance 0 and 1) 764273 Oil Tank Level Kit, 3.0 Gallon – one engine one oil tank (instance 0) 764272 Oil Tank Level Kit, 3.0 Gallon – two engines two oil tanks (instance 0 and 1) 764274 Oil Tank Level Kit, 3.0 Gallon – three engines three oil tanks (instance 0, 1 and 2) 764275 Oil Tank Level Converter Kit, 10 Gallon – one oil tank (instance 0) 763737 Block-Mounted Engine Water Pressure Sensor Kit 30 psi 5008300 Block-Mounted Engine Water Pressure Sensor Kit 60 psi 5008640 NMEA 2000 Single Engine Water Pressure Kit 765038 NMEA 2000 Dual Engine Water Pressure Kit 765045 NMEA 2000 Triple Engine Water Pressure Kit 765046