Download BevLes Roast & Hold B 8832400.cdr

Transcript

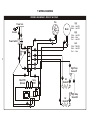

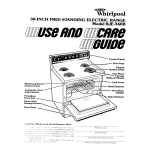

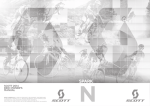

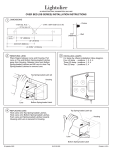

Innovative Foodservice Equipment Custom Designed for Performance, Service and Value. INSTALLATION AND OPERATING INSTRUCTIONS TEMPER SELECT HOT HOLDING CABINET ROAST & HOLD Model: HRH Series INTENDED FOR OTHER THAN HOUSEHOLD USE RETAIN THIS MANUAL FOR FUTURE REFERENCE UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES ! WARNING: For your safety do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance. Keep the area free and clear of combustibles. (See ANZI Z83.14B, latest version) ! ! WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the Installation, Operating and Maintenance Instructions thoroughly before installing or servicing this equipment. ! ! WARNING: Initial heating of unit may generate smoke or fumes and must be done in a well-ventilated area. Overexposure to smoke or fumes may cause nausea or dizziness. ! This equipment has been engineered to provide you with year round dependable service when used according to the instructions in this manual and standard commercial kitchen practices. ANSI/NSF 4 Phone: Fax: Toll Free: Website: E-mail: P/N 8832400 2/08 +1 (214) 421-7366 +1 (214) 565-0976 +1 (800) 441-1601 www.BevLes.com [email protected] BevLes 729 Third Avenue Dallas, TX 75226 1 IMMEDIATELY INSPECT FOR SHIPPING DAMAGE All containers should be examined for damage before and during unloading. The freight carrier has assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent or concealed, a claim must be made with the delivering carrier. A) Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can supply the necessary forms. B) Concealed damage or loss if not apparent until after equipment is uncrated, a request for inspection must be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all contents and packaging material. Installation and start-up should be performed by a qualified installer who thoroughly reads, understands and follows these instructions. The BevLes Company takes pride in the design and quality of our products. When used as intended and with proper care and maintenance, you will experience years of reliable operation from this equipment. To ensure best results, it is important that you carefully read and follow the instructions in this manual. Installation and start-up should be performed by a qualified installer who thoroughly reads, understands and follows these instruction. If you have questions concerning the installation, operation, maintenance or service of this product, write Technical Service Department BevLes Company, Inc., 729 Third Avenue, Dallas, TX 75226. 1. SAFETY PRECAUTIONS Before installing and operating this equipment be sure everyone involved in its operation is fully trained and aware of all precautions. Accidents and problems can result by a failure to follow fundamental rules and precautions. The following words and symbols, found in this manual, alert you to hazards to the operator, service personnel or the equipment. The words are defined as follows: ! DANGER: This symbol warns of imminent hazard which will result in serious injury or death. ! ! WARNING: This symbol refers to a potential hazard or unsafe practice, which could result in serious injury or death. ! ! CAUTION: This symbol refers to a potential hazard or unsafe practice, which may result in minor or moderate injury or product or property damage. ! ! NOTICE: This symbol refers to information that needs special attention or must be fully understood even though not dangerous. ! 2. GENERAL INFORMATION THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE WARNING: Check the data plate on this unit before installation. Connect the unit only to the voltage and frequency listed on the data plate. Connect only to 1 or 3 phase as listed on the data plate. ! ! WARNING: Electrical and grounding connections must comply with the applicable portions of the national electrical code and/or other local electrical codes. ! ! WARNING: Do not use oven cleaners, caustic solutions or mechanical means to clean the appliance as they will damage the interior stainless surface. ! ! 2 ! NOTICE: The unit when installed, must be electrically grounded and comply with local codes, or in the absence of local codes, with the national electrical code ANSI/NFPA70- latest edition. Canadian installation must comply with CSA-STANDARD C.22.2 Number 0 M1982 General Requirements-Canadian Electrical Code Part II, 109-M1981- Commercial Cooking Appliances. ! ! WARNING: This appliance must be serviced by an Authorized Service Technician only. Disconnect the power supply before cleaning or servicing the cabinet. Regular and thorough cleaning will help to keep the cabinet operating properly. If service is required, contact an Authorized Service Agency, your dealer or the factory to obtain a qualified technician for the required maintenance/service. ! ! WARNING: Disconnect device from electrical power supply and place a Tag Out-Lockout on the power plug, indicating that you are working on the circuit. ! ! ! WARNING: Neglecting to keep fan opening clean could result in cabinet failure. TABLE OF CONTENTS SECTION 1 2 3 4 5 6 7 8 ITEM PAGE Safety Precautions General Information Installation Instructions Operating Instructions Cleaning Instructions Specifications Wiring Diagram Parts Lists & Exploded Views A. Half & Full Size (Full Width Models) B. Half & Full Size (Narrow Width Models) Warranty 9 2 2 3 4 9 10 11 12 12 14 16 IMPORTANT FOR FUTURE REFERENCE Please complete this information and retain this manual for the life of the equipment. For Warranty Service and/or Parts, this information is required. Model Number Serial Number Date Purchased The data plate for the unit is located on the left side panel on the upper rear of that panel. Check the voltage requirements on the data plate. Connect the unit only to the voltage configuration specified on the data plate. 3. INSTALLATION INSTRUCTIONS BEFORE USING THE CABINET: 1. 2. 3. 4. ! Place cabinet on level floor in a well ventilated area. Plug unit into proper wall outlet. Push the power switch to ON and press the start button. Let run for one hour. Let the cabinet cool and clean the inside with a mild detergent and hot water. CAUTION: During operation the air is VERY HOT when the door is opened. 3 ! 4. OPERATING INSTRUCTIONS PROGRAMMING INSTRUCTIONS (TIMER VERSION) To Set Cook Temperature: 1. 2. 3. Press “COOK” button. Use “ARROW” keys to set desired cook temperature. Press “SET” button to set cook. To Set Hold Temperature: 1. 2. 3. Press “HOLD” button. Use “ARROW” keys to set desired hold temperature. Press “SET” button to set hold temperature. To Set Cook Time: 1. 2. 3. Press “TIME” button. Use “ARROW” keys to set desired cook time. Press “SET” button to confirm selected cook time. Note: Safe food holding temperature is 140°F/60°C for beef and is higher for poultry and some other products. PROGRAMMING INSTRUCTIONS (PROBE VERSION) To Set Cook Time or Probe Temperature: 1. Press the Probe/Time Button until the LED indicates the mode you intent to use. 2. Press the Time/Probe button 3. Use Arrow keys to set desired cook time or probe temperature. 4. Press Set button to confirm selected cook time or probe temperature. To Set Cook & Hold Temperatures: 1. Set the cook & hold temperatures the same as in the timer version listed above. Note: Safe food holding temperature is 140°F/60°C for beef and is higher for poultry and some other products. OPERATION Press “START” to begin cooking. The unit will heat to the cook temperature and stay there for the time programmed or until the product probe reaches the programmed temperature. The unit will then lower the temperature to the programmed hold temperature and remain there until the stop button is pushed. At any time during the operation you can push the OVEN TEMP button and the temperature inside the cabinet will be displayed. NOTE: If the display is flashing power has been lost to the unit for longer than 3 seconds. Check the product to make sure it has been properly cooked. ! CAUTION: All foodservice equipment should be operated by trained personnel only. Do not allow your customers to come in contact with any surface labeled “CAUTION HOT”. Never pour cold water into heated unit. Never hold food below 140°F/60°C or above 40°F/4.45°C. 4 ! Time/Temp Display Cook SP Button Up Button Hold LED Cook LED *Heat On LED *Timed Mode LED Indicator *Probe Mode LED Indicator ON (I) OFF (O) POWER Press “PROBE/TIMED” button to determine control mode. PROGRAMMING INSTRUCTIONS TO SET COOK TEMP: 1. PRESS "COOK" BUTTON 2. USE ARROW KEYS TO SET DESIRED COOK TEMPERATURE 3. PRESS "SET" BUTTON TO SET COOK TEMPERATURE TO SET HOLD TEMP: 1. PRESS "HOLD" BUTTON 2. USE ARROW KEYS TO SET DESIRED HOLD TEMPERATURE 3. PRESS "SET" BUTTON TO SET HOLD TEMPERATURE TO SET PROBE TEMPERATURE OR COOK TIME: 1. PRESS "PROBE/TIME" BUTTON 2. USE ARROW KEYS TO SET DESIRED PROBE TEMPERATURE OR COOK TIME 3. PRESS "SET" BUTTON TO CONFIRM SELECTED PROBE TEMPERATURE OR COOK TIME PRESS "START" TO BEGIN COOKING Set Button COOK SET TIME Roast & Hold HOLD OVEN TEMP START STOP CONVECTION COOKING & HOLDING SYSTEM *Probe/Time Mode Selector Button Down Button Oven Temp Button Hold SP Button Start Button Stop Button *NOTE: NOT AVAILABLE ON ALL UNITS Probe/Time SP Button Button Descriptions ! ! ! ! ! ! ! ! ! Cook SP - Displays current Cook SP temperature and allows changes. Probe Time SP - Displays current probe temp or cook time SP (depending on cook mode selected) and allows changes. Hold SP - Displays current Hold SP temperature and allows changes. Up - Increments displayed parameter value during programming. Down - Decrements displayed parameter value during programming. Set - Accesses the Setup mode and saves new parameter values. Oven Temp - Momentarily displays current Oven temperature. Start - Starts Cook cycle. Stop - Aborts Cook cycle. LED Descriptions ! ! ! ! ! Probe Mode LED - Illuminates when the controller is in Probe cook mode. Timed Mode LED - Illuminates when the controller is in Timed cook mode. Heat On LED - Illuminates when Heat output is energized. Cook LED - Illuminates while controller is in the Cook mode. Hold LED - Illuminates when the controller is in the Hold mode. 5 OPERATOR MANUAL Cook & Hold Controller OPERATION: When power is first applied to the controller the currently installed software version number will be displayed for a few seconds and a self diagnostic routine will be initiated. If no errors are detected the Fan and Heat output relays will energize and the oven will begin heating to the Hold setpoint temperature. The display will flash until the Hold set point is achieved. When the oven has reached the Hold temperature the Hold lamp will illuminate. The Fan and Heat outputs continue to cycle On & Off as required to maintain the oven at the Hold set point until a Cook cycle is initiated. Should a problem be detected during the self diagnostic routine at startup, the controller will suspend operation until the error is corrected. An error code will be displayed to aid in troubleshooting (see self diagnostic and troubleshooting section). SETTING THE HOLD TEMPERATURE: To change the Hold set point momentarily press the HOLD key (the Hold lamp will flash to show you are in the Hold set point programming mode). Use the UP and DOWN ARROW keys to change the displayed value as desired. Press the SET key to accept and store this new set point value. Note: If no key is pressed for 10 seconds while in the programming mode the controller will automatically return to the run mode and retain the original set point value. SELECTING THE COOK MODE: The SELECT key is used to select either a temperature terminated (Probe) or time terminated (Timed) cook cycle. The appropriate Mode lamp will illuminate to show the current Mode setting. Upon power up the controller will always default to the mode that was last used. When the Probe mode is selected the probe temperature is continuously displayed. However, if the probe sensor is not connected or is faulty the controller will lock-out (output relays will open) and a dashed line followed by the numeral 2 will be displayed. The position of the line indicates the failure mode detected (see the self-diagnostic & troubleshooting section). SETTING THE COOK TEMPERATURE: To change the Cook set point momentarily press the COOK key (the Cook lamp will flash to show you are in the Cook set point programming mode). Use the UP and DOWN ARROW keys to change the displayed set point value. Press the SET key to accept and store this new set point value. SETTING PROBE TEMP OR COOK TIME: To change the Probe Temperature Set point (Probe Mode) or Cook Time (Timed Mode) momentarily press the PROBE TIME key (the appropriate Probe or Timed lamp will flash). Use the UP and DOWN ARROW keys to change the displayed set point value. Press the SET key to accept and store this new set point. INITIATING A COOK CYCLE: A cook cycle is initiated by pressing the START key. After about 2 seconds the Fan and Heat relays will energize and the oven will begin to heat to the Cook set point. During the Cook cycle the Fan relay remains energized continuously while the Heat relay will cycle as required to maintain the oven at the cook set point. During a timed cook cycle (Timed mode) the display will show the time remaining in the Cook cycle and during a temperature terminated cook cycle (Probe mode) the probe temperature will be continuously displayed. The actual oven temperature can be viewed at any time by momentarily pressing the OVEN key. Approximately 10 seconds after the OVEN key is released the previous display will be restored. Any set point values can be changed on the fly during a Cook cycle by pressing the appropriate programming key and following the steps shown above. When the cook cycle is complete (countdown timer reaches zero or the probe set point temperature is reached) the controller automatically reverts to the Hold set point and an audible alarm sounds five (5) one second bursts indicating the Cook cycle is complete. 6 The Cook cycle can be stopped at any time by pressing the STOP key. Once stopped, however, the cycle must be restarted from the beginning. POWER LOSS ALARM: The display will flash when power is restored after a power loss. If power is lost during a Cook cycle, the Cook cycle will continue where it left off upon restoration of power. Pressing any key will stop the flashing display. ! CAUTION: All foodservice equipment should be operated by trained personnel only. Do not allow your customers to come in contact with any surface labeled “CAUTION HOT”. Never pour cold water into heated unit. Never hold food below 150°F or above 40°F. ! OVEN TEMPERATURE ALARM: The Oven Temperature Alarm function can be turned On or Off at will (see Setup Programming below). When activated the oven temperature alarm provides separate High and Low alarm set points. An audible alarm sounds one second bursts and the display flashes whenever the oven temperature drops below the low set point or exceeds the high set point. Pressing any key will silence the audible alarm but the display will continue flashing until the temperature returns to an acceptable value. Setup Programming The Setup Mode is accessed by pressing and holding the SET key for several seconds until the"diFF" prompt is displayed (while in Setup mode all outputs are de-energized). Momentarily press an UP or DOWN ARROW key will display the current parameter value. Continuing to hold the ARROW key will increment or decrement the value. Pressing the SET key will accept the new value and advance to the next parameter. Repeatedly pressing the SET key will step through each parameter without making any changes. Refer to the table below for a list of the programmable parameters, the range of acceptable values and the factory defaults. When locked ("Loc" parameter turned "On") the Setup Mode cannot be accessed as described above. The Setup Mode can only be unlocked by removing power from the controller then reapplying power while holding the SET key. Display diFF PSLL _tr _AL _ALL _ALH _F/C _oF1 _oF2 _LoC Parameter Description Range of Values Default 1 to 25°F or °C 0°F to 245°F H=hrs/mins L=mins/secs 4°F 100°F H Alarm Low set point (Note 1) Alarm High set point (Note 1) Fahrenheit or Celsius display units (Note 2) on or oFF 0 to Max SP 0 to Max SP F or C oFF HSLL CSLH F Oven sensor offset Probe sensor offset Parameter lock _ +99°F or °C _ +99°F or °C on or oFF 0°F 0°F oFF On-Off differential for Cook & Hold set points Probe Set point Limit Low Time range for timed cook mode Temperature Alarm Notes: 1. 2. These parameters only display if Alarm function is activated (on). When switching from °C to of display some values may convert to illegal magnitudes (e.g. 50°C will convert to 122°Fwhich is greater than max. allowed of 99°F). Therefore, all parameters should be checked for correct values when display units are changed. SELF DIAGNOSTICS & TROUBLESHOOTING: Error checking is done continuously while the controller is in operation. Should an error occur an error code will be displayed. The error codes and the corrective action required are described below. 7 Display Description Corrective Action “ 1“ At top of display Oven sensor open Check for broken or disconnected lead wires or damaged oven sensor. Repair wiring or replace sensor. “ 1“ At bottom of display Oven sensor shorted Check for shorted lead wire or damaged oven sensor. Repair wiring or replace sensor. “ 2“ At top of display Oven sensor open Check for broken or disconnected lead wire or damaged meat probe sensor. Repair wiring or replace sensor. “ 2“ At bottom of display Probe sensor Shorted Check for shorted lead wire or damaged meat probe sensor. Repair wiring or replace sensor. “ “ At center of display Chksum error Re-initialize the controller by removing power from the controller then reapplying power while simultaneously pressing the HOLD & DOWN ARROW keys. CAUTION: Initializing removes all user programmed values from memory and restores the default values. CALIBRATION CABINET TEMPERATURE: ! ! ! ! ! ! ! ! ! ! ! ! ! Make sure the cabinet temperature is stable it should have been run at the same temperature for at least 45 minutes with your measuring probe in place in the center of the cabinet. Record the display temperature and your measured cabinets center temperature. If the two temperatures are within 5°F do not attempt adjustment. There is typically that much error in most measuring devices. If the temperature difference is more than 5°F you may choose to adjust calibration Unlock the programming function by pushing and holding the set button while turning off the power to the unit and then turning it back on. Push and hold the SET key for several seconds until “diFF” is displayed in the window Release the SET key and then push it several times until “_oF1” is displayed in the window Subtract the temperature measured in the center of the cabinet from the display temperature Push the UP or DOWN arrow button until you reach the total from above. Allow the cabinet temperature to stabilize for about ten minutes and recheck the temperature. The display versus measured cabinet temperature should be within 5°F in not repeat the procedure. Relock the programming function by pushing and holding the SET key for several seconds until “diFF” is displayed in the window Release the SET key and then push it several times until “_LoC” is displayed in the window Push an arrow key until the display indicates “on” Don’t push any buttons for ten (10) seconds and the control will drop out of the program mode. CALIBRATION PROBE TEMPERATURE: ! ! ! ! ! Make sure the temperature probe is stable it should have been in the product for a few seconds and if should be reading the same temperature for several seconds before comparing to the display read out. Make sure the two temperature probes are in close proximity. Record the display temperature and the product temperature. If the two temperatures are within 3°F do not attempt adjustment. There is typically that much error in most measuring devices. If the temperature difference is more than 3°F you may choose to adjust calibration Unlock the programming function by pushing and holding the set button while tuner off the power to the unit and then turning it back on. Push and hold the SET key for several seconds until “diFF” is displayed in the window 8 ! ! ! ! ! ! ! ! Release the SET key and then push it several times until “_oF2” is displayed in the window Subtract the product temperature measured from the display temperature Push the UP or DOWN arrow button until you reach the total from above. Allow the product temperature to stabilize for about five minutes and recheck the temperature. The display versus measured product temperature should be within 3°F in not repeat the procedure. Relock the programming function by pushing and holding the SET key for several seconds until “diFF” is displayed in the window Release the SET key and then push it several times until “_LoC” is displayed in the window Push an arrow key until the display indicates “on” Don’t push any buttons for ten (10) seconds and the control will drop out of the program mode. 5. CLEANING INSTRUCTIONS Daily Cleaning: 1. Turn off power switch and unplug the unit from the wall outlet. 2. Allow the unit to cool before cleaning. ! WARNING: To avoid burns allow the unit to cool before cleaning. ! 3. Open the doors and remove all pans and hangers from the unit. Take them to the sink and thoroughly clean. 4. Clean the interior and exterior of the cabinet with warm soapy water. ! WARNING: Do not use steel wool or other abrasive cleaners. Do not use cleaners or sanitizers containing chlorine, Iodine, ammonia or bromine as these will damage the finish on the stainless steel. ! ! WARNING: Do not use a water jet (pressure sprayer) to clean the unit. This could damage some of the components. ! 5. Wash the control panel with a damp cloth, do not use excess water on the control panel. 6. Reinstall the hangers and pans. Leave the door partially open to allow these parts and the interior of the cabinet to thoroughly dry. Weekly Cleaning: 1. In addition to the daily cleaning remove the top air ducts from each side of the internal cabinet. To remove these lift up and then pull away from the internal wall. 2. Remove the bottom air duct from each side of the internal cabinet. After the top air ducts have been removed you can lift and pull away from the internal wall. 3. Take these parts to the sink and thoroughly clean. ! WARNING: Do not use steel wool or other abrasive cleaners. Do not use cleaners or sanitizers containing chlorine, Iodine, ammonia or bromine as these will damage the finish on the stainless steel. ! 4. Reinstall these parts by installing the bottom air ducts first. Place the openings in the back of the air duct over the spacers on the side wall and slide down into position. After the bottom air ducts are installed repeat the process with the top air ducts. Monthly Cleaning: 1. Vacuum the openings in the center of the rear panel. ! Caution: Failure to clean these openings on a regular basis can cause the control components to overheat and shorten their life. 9 ! 6. SPECIFICATIONS FULL WIDTH MODELS FULL SIZE (HRHR74W12) HALF SIZE (HRHR44W6) ON (I) TOSET 1. P 2. RES COOK P RO USEAS 3. "COOK" PR RROWTEMPGRAMMING TOSET ES : S "S BUTT 1. P ET"KEY IN 2. RES HOLDTE STRUCTI B S TOON USEAS 3. "HOL UT PR RROW M TON SET ONS TOSET ES D" P: TOSDESIR S "S BUTTON 1. ET E PR CO ET"KEY D COOK 2.USE ES OK B S CO S "TMET UT TO OK 3. P ARROW I IME: TON SET TEMPERA PR RES "B TOS DESIR ESS S "S K UT ET E "S ET" EYS TO TU HOLD HO TART B TO N RE UT LD D TEM " T TONSET TE O PE MPE BEGIN TOCDESI RA R RE ONFI TUR ATURE D COOK E R CO INGM SE OK TIME LECT ED CO OK TIM E OFF PO (O) WER COOK OVEN TEMP TIME START STOP SET HOL D Ro CONV as t ECTI ON & COO KI NG Ho & ld HO LDING SYST EM ON ()I OFF POW (O) ER TO 1. SET PRESS COOK P 2. ROGRA USE TEMP: COOK" " 3. ARR PRESS M TO OW BUTTONMIN G " 1. SET SET" KEYS N I S PRESS HOLD TRU 2. BUTTON TO USE CTON HOLD" " TEMP: SET 3. I ARR PRESS TO DESIRED TO S OW BUTTON SET " 1. SET SET" KEYS COOK COOK PRESS COOK 2.USE BUTTON TO TIME: TIME" " SET 3. TEMPERA ARROW PRESS DESIRED PRESS BUTTONTO SET SET" " KE TURE HOLD HOLD "START" YS BUTTON TO TE TEMPERA SET TO MPE TO DESIRED BEGINCO RA CONFIRM TURE TURE OKING COOK SELECTE TIME D COOK TIME OV EN TEMP TIM E STA RT STOP CO OK HO LD SET Ro CONV as ECTI ON t& COOK Ho ING & ld HOLD ING SYST EM 54.250 (1378mm) ON (I) OFF (O) POWER PROGRAMMING INSTRUCTIONS TO SET COOK TEMP: 1. PRESS "COOK" BUTTON 2. USE ARROW KEYS TO SET DESIRED COOK TEMPERATURE 3. PRESS "SET" BUTTON TO SET COOK TO SET HOLD TEMP: 1. PRESS "HOLD" BUTTON 2. USE ARROW KEYS TO SET DESIRED HOLD TEMPERATURE 3. PRESS "SET" BUTTON TO SET HOLD TEMPERATURE TO SET COOK TIME: 1. PRESS "TIME" BUTTON 2.USE ARROW KEYS TO SET DESIRED COOK TIME 3. PRESS "SET" BUTTON TO CONFIRM SELECTED COOK TIME PRESS "START" TO BEGIN COOKING 54.250 (1378mm) COOK SET TIME Roast & Hold HOLD OVEN TEMP START STOP CONVECTION COOKING & HOLDING SYSTEM ON (I) OFF (O) POWER PROGRAMMING INSTRUCTIONS TO SET COOK TEMP: 1. PRESS "COOK" BUTTON 2. USE ARROW KEYS TO SET DESIRED COOK TEMPERATURE 3. PRESS "SET" BUTTON TO SET COOK TO SET HOLD TEMP: 1. PRESS "HOLD" BUTTON 2. USE ARROW KEYS TO SET DESIRED HOLD TEMPERATURE 3. PRESS "SET" BUTTON TO SET HOLD TEMPERATURE TO SET COOK TIME: 1. PRESS "TIME" BUTTON 2.USE ARROW KEYS TO SET DESIRED COOK TIME 3. PRESS "SET" BUTTON TO CONFIRM SELECTED COOK TIME PRESS "START" TO BEGIN COOKING COOK SET TIME Roast & Hold HOLD OVEN TEMP START STOP CONVECTION COOKING & HOLDING SYSTEM 73.625 (1870mm) 43.625 (1108mm) 28.125 (714mm) 28.125 (714mm) 34.000 (864mm) 34.000 (864mm) NARROW WIDTH MODELS FULL SIZE (HRHR74W12) HALF SIZE (HRHR44P16) ON (I) OFF PO (O) WER TOS ET 1.PRESS C 2.USE OO PROGRAM K TE " 3.PRESS AR COO MP ROWKEY TOS K"BU: MING ET "SET"BUTT T 1.PRESS INS TO H S TR 2.USE OL N DTEMP: TOSET UCTIONS " 3.PRESS AR HOLD" O N ROWKEY TOS TO DESI BU SET RE ET "SET"BUTT 1.PRESS TTON CO COOD COOKTE S TOSET 2US OK . K E ARROW "TIM TIM O 3.PRESS E: N T DE MPERA E"BUT PRE O SETSIRE SS "SET"BUTT KE T TU "S YSTOON HOLD HOLD RE TA D TEMP RT SE "T TEM O ON TD PE BEGNTO ESI ERATURE RAT I CO RED URE NFR C COOKI I M OO NG SE K T LECTE IME DC OO K TIM E OV TE EN MP COO ST TIME K ART ST OP HO LD SE T Ro CO ast NV EC TION & COO Ho KING & ld HOLD ING SY STE M ON (I) OF F( POWE O) R TO 1. SETCOO PRESS"CO 2. PR USE K TEMP: OGRA 3. ARROW PRESS"SE OK" MMING TO B 1. SETHOL PRESS"HOT" KEYSUTT INSTRU ON 2. USE D B U TO TEMP: TT SETDESIR 3. CTONS ARROW PRESS"SE ON I LD" TO TO B SET ED 1. SETCOO KEYS UT PRESS"T T" TON COOKCO 2.USE K B U TO OK 3. AR IM TIME:TTON SETDESIR PRESS"SE TEM ROWE" PR PER BUTTONTO SET ESS KEYS ATUR ED "START"T T" HOLDHO B E UT TO SET LD TEMPE TEM O TON BEGIN TO DESIRE RA PER CONFIR TUR ATURE D COOK COO E KINGM SELE TIME CT ED CO OK TIME OV TE EN MP CO TIM E ST ART STOP HO OK LD SET Roa CO NV EC TIO st N & COOK Ho ING & ld HO LDING SYS TE M 47.875 (1216mm) ON (I) OFF (O) POWER PROGRAMMING INSTRUCTIONS TO SET COOK TEMP: 1. PRESS "COOK" BUTTON 2. USE ARROW KEYS TO SET DESIRED COOK TEMPERATURE 3. PRESS "SET" BUTTON TO SET COOK TO SET HOLD TEMP: 1. PRESS "HOLD" BUTTON 2. USE ARROW KEYS TO SET DESIRED HOLD TEMPERATURE 3. PRESS "SET" BUTTON TO SET HOLD TEMPERATURE TO SET COOK TIME: 1. PRESS "TIME" BUTTON 2.USE ARROW KEYS TO SET DESIRED COOK TIME 3. PRESS "SET" BUTTON TO CONFIRM SELECTED COOK TIME PRESS "START" TO BEGIN COOKING 47.875 (1216mm) 47.750 COOK SET TIME HOLD OVEN TEMP START STOP Roast & Hold CONVECTION COOKING & HOLDING SYSTEM ON (I) 73.625 (1870mm) OFF (O) POWER PROGRAMMING INSTRUCTIONS TO SET COOK TEMP: 1. PRESS "COOK" BUTTON 2. USE ARROW KEYS TO SET DESIRED COOK TEMPERATURE 3. PRESS "SET" BUTTON TO SET COOK TO SET HOLD TEMP: 1. PRESS "HOLD" BUTTON 2. USE ARROW KEYS TO SET DESIRED HOLD TEMPERATURE 3. PRESS "SET" BUTTON TO SET HOLD TEMPERATURE TO SET COOK TIME: 1. PRESS "TIME" BUTTON 2.USE ARROW KEYS TO SET DESIRED COOK TIME 3. PRESS "SET" BUTTON TO CONFIRM SELECTED COOK TIME PRESS "START" TO BEGIN COOKING COOK SET TIME HOLD OVEN TEMP START STOP Roast & Hold CONVECTION COOKING & HOLDING SYSTEM 43.625 (1108mm) 25.000 (635mm) 25.000 (635mm) 34.000 (864mm) 10 34.000 (864mm) 34.000 7. WIRING DIAGRAM WIRING DIAGRAM - ROAST & HOLD Fan Power Line Ground L1 120V White - Lead #13 Black - Lead #12 Motor 208V White - Lead #13 Black - None Red - Lead #12 N 15 15 Power Switch 13 14 Pilot Light 2 240V White - Lead #13 Black - Lead #12 Red - None 12 13 4 7 11 1 9 14 1 12 3 5 Meat RTD Optional Temp RTD RTD 2 RTD 1 6 High Temp Sensor #1 7 6 9 4 8 55 220V 120V AC-N 3 Air 10 Heater #1 Air Heater #2 11 High Temp Sensor #2 8. PARTS LISTS & EXPLODED VIEWS PARTS LIST - HALF SIZE & FULL SIZE (FULL WIDTH MODELS) ITEM 120V P/N 208/240V P/N DESCRIPTION 1 781185 781185 Magnetic Latch 2 784692 784692 Lift-Off Hinge 3 781155 781155 Magnetic Gasket 4 781283 781283 Wire Hanger 5 x 25 Chrome 781284 781284 Wire Hanger 5 x 25 Stainless Steel (Optional) 5 741134 741134 Bottom Air Duct (Full Size Units Only) 6 741135 741135 Top Air Duct (Full Size Units Only) 7 780040 780040 5" Caster 8 780036 780036 5" Caster With Brake 9 781147 781147 Pull Handle (Full Size Units Only) 10 720319 720319 Door 11* 720321 720321 Door With Window 12* 783004 783004 Spacer - Air Duct 13 782068 701015 Power Cord 14 1101500 1101500 Stain Relief 15 1302200 1302200 Power Switch 16 741094 741094 Channel Support 17 781304 781304 Temperature Controller 18 784872 784872 Probe - Air 19 741485 741485 Air Duct - Half Size Units 20 781276 781276 Hi Limit Switch 21 784680 784682 Cooling Fan 22 781160 781163 Air Heater Air Heater (Alternate High Watt Version) 781248 23 781279 781280 Blower Motor 24 1210810 1210810 Blower Wheel 25* 1101600 1101600 Terminal Block 26 2411450 2411450 Water Pan *NOT SHOWN 12 EXPLODED VIEW - HALF SIZE (FULL WIDTH MODELS) EXPLODED VIEW - FULL SIZE (FULL WIDTH MODELS) 13 13 14 14 23 23 20 20 23 23 13 22 18 14 18 20 18 20 21 21 24 24 15 22 22 24 13 24 21 21 ON (I) OF F (O) POW ER 17 TO 1. SET P 2. RES COO P ROG US 3. E S "C K TE P AR OOK MP RAM TO RES RO MIN " : 1. SET S "S W KE BU G P ET" Y TT INS 2. RES HOL S ON TRU US D BUTTTO 3. E S "H TE CT P AR OLD"M ON SET IONS P: TO RES RO T DE 1. SET S "S W KEBUTTO O SETSIRED P ET" Y COO COO 2.USRES COO S S " K BUTTTO N K 3. E AR K TIMETIME ON SET P TE PRERES ROW " : MPE TO DE SS S "S KEBUT SETSIRED RAT "ST ET" Y TON UR HOLD HOLD ST ART BUTT E O " TO ONSET TEMP T EMP BE TO DE ERAT ER GIN C SIR ONF ED UREATURE COO COO KI IRM NG SE K TIM LECT E ED COOK TIME COOK OVEN TEMP TIME ST ART STOP 10 10 HO LD SE T Ro NV EC as TION t CO 26 & CO Ho OK ING & 26 ld HO LD ING SY ST EM 4 4 14 14 15 ON (I) OFF PO (O) WER 17 TO 1. SET PRE COO 2. USESS K PRO 3. PRE AR"COOTEM GRA TO SS ROW K" P: MMIN BUT 1. SET "SET KEY G PRE HOL IN TO 2. STR USESS D " BUTS TO N 3. UCTI T PRE AR"HOL EM TON SET P TO ON TO DES SS ROW D" : S BUTTO 1. SET "SET KEY SE IRED PRE COO T COO 2.US SS " S COO K BUT TO N 3. E A "TIM K TIM TON SET K PRE R TEM ROWE" E: PRE SS TO DES PER SS "SET K BUT SE IRED EYS TO ATU "STA T HOL " N HOL RE RT"BUT TO D TEMD TEM TO TONSET BEG TO DES PER PE ATU RATU IN CONIRE COOKF D RE RE IRM COO ING S K ELECTIME TED COO K TIME 9 OVE TEMN P TIM E STA RT STO P HOL D 9 6 6 COO K SE T Ro NV EC as TIO t CO N & CO OK ING Ho & ld HO LD IN G SY 1 STE M 26 26 16 16 27 1 27 5 10 10 2 2 1 1 3 3 19 3 3 2 7 7 4 4 8 8 7 7 8 8 2 PARTS LIST - HALF SIZE & FULL SIZE (NARROW WIDTH MODELS) ITEM 120V P/N 208/240V P/N DESCRIPTION 1 781185 781185 Magnetic Latch 2 784692 784692 Lift-Off Hinge 3 781156 781156 Magnetic Gasket 4 741563 741563 Bottom Air Duct 5 741561 741561 Top Air Duct (Full Size Units Only) 6 780040 780040 5" Caster 7 780036 780036 5" Caster With Brake 8 781147 781147 Pull Handle (Full Size Units Only) 9 720322 720322 Door 10* 720323 720323 Door With Window 11* 783004 783004 Spacer - Air Duct 12 782068 701015 Power Cord 13 1101500 1101500 Stain Relief 14 1302200 1302200 Power Switch 15 720515 720515 Pan Slide Assembly 16 781304 781304 Temperature Controller 17 784872 784872 Probe - Air 18 750382 750382 Spacer - Pan Slide Assy 19 781276 781276 Hi Limit Switch 20 784680 784682 Cooling Fan 21 781160 781163 Air Heater 781248 Air Heater (High Watt Version) 22 781279 781280 Blower Motor 23 1210810 1210810 Blower Wheel 24* 1101600 1101600 Terminal Block 25 2411450 2411450 Water Pan *NOT SHOWN 14 EXPLODED VIEW - HALF SIZE (NARROW WIDTH MODELS) EXPLODED VIEW - FULL SIZE (NARROW WIDTH MODELS) 12 12 13 13 17 17 22 22 22 22 19 17 19 17 12 21 19 21 23 23 23 23 21 13 20 14 20 13 20 20 15 14 ON (I) OFF POW (O) ER 16 TO 1.PRSET COOK PROG 2.U ESS 3.PRSE AR"C TEMP:RA OO MMING TO ESS ROW K" BUTTO 1.PRSET "SET"KEYSTO INSTRU HOLD 2.U ESS N BU CT TTON SET 3.PRSE AR"H TEMP: IONS OL TO ESS ROW D" TO DESIR BU SET ED 1.PRSET "SET"KEYSTO TTO COOK COOKC N 2.U ESS OOKTEM B SEA "TIME" TIMUTTON SET 3.PR R PER PR ESS ROW B E: TO DESIR ESS "SET"KEYS UTTON SET ED ATU "ST HOLD H RE OLDTEM ART" BU TO TTONSET TEMPE TO PERA BEG TO DESIRED RATUR IN CON T CO FI CO E URE OKN RMSELOKTI I G EC ME TEDC OO K TME I OV TE EN MP COOK TIME ST AR T ST OP HOL SET D Ro V as CON EC TION t& COOK Ho & ld HOL IN G DIN G ON (I) OFF PO (O) WER 16 TO 1. SET PRES CO PR 2. U S"COKTE OGR 3. SE A PRES R OOK"M P AMMNG R : TO I S"SOW BU 1. SET K INSTR PRES HO ET" EYS TTON 2. UC U S"HLD T BUT TO SE TION T 3. SE A PRES R OLDEMP ONTO T D S : R TO ES S"SOW " BUTT SE IRED 1. SET K TC PRES CO ET" EYS ON OOKCOOK 2.U S"TOKTI BUT TO TE 3. SE ARROIME M TO SET MPE PRES E: NTO D PRE ES "B RATU SS S"S W KE UTTON SET IRED RE "S ET" YS HOLD H TA OLD RT BUT TO S TE TEM "T TO ET MP OB NTO DE ERA PER EGINC CON SR I E TU AT RE UR FIRD COO OOKN E KTI I GM SELEC M TE E DC OOK TM I E 25 25 OVEN TEMP TIME COO K STA RT STOP HOL D 5 SET Ro V as CON 25 ECT ION t& Ho COO KING 25 SYS TE M & ld HO LDI NG 8 SYST EM 8 15 27 3 2 2 9 9 4 4 4 1 1 2 26 6 18 6 9 1 3 3 9 1 7 7 6 27 15 7 7 6 2 9. BEVLES COMPANY LIMITED WARRANTY 729 Third Avenue * Dallas, TX 75226 Phone: +1 (214) 421-7366 Fax: +1 (214) 565-0976 1. Bevles warrants to the original purchaser that on the date the equipment is shipped (sold), it will be free of defects in materials or workmanship. Bevles will, at it’s discretion, repair or replace, during the warranty period printed below, any part that has a defect in material or workmanship that was present when the product shipped from Bevles, and which manifests itself during the warranty period under normal use and service. ! ! Parts: Two* years from date of original shipment from the Bevles factory. Labor: One** year from date of original shipment from the Bevles factory. * Air Circulation Blower Assemblies (motors) and Power Switches shall be one year from date of original shipment. Calrod “Air” Heating Elements shall be three years from date of original shipment. ** All electrical components 120 days from date of original shipment. 2. Bevles must be contacted, and pre-approval must be issued by the Bevles factory prior to any type of service being performed. Bevles assumes no responsibility for any charges that were not expressly authorized by the Bevles factory, or for any charges that exceed, in Bevles’ solejudgement, normal and customary amounts. 3. Bevles will pay UPS Ground charges for any part that has a defect in material or workmanship that was present when the product shipped from Bevles, and which manifests itself during the first year of the warranty period under normal use and service. All warranty replacement parts will ship F.O.B. Bevles factory, Cheyenne, WY 82007. 4. This warranty shall be void in its entirety if any abuse of, misuse of, alteration/modification of or improper maintenance of original product occurs. If, at any time a claim is reported to Bevles, and the purchaser is delinquent in payment for the product, warranty will not apply. 5. Buyer’s Remedies-If a Bevles product fails due to a defect in material or workmanship in conformity with the warranties in paragraph one, buyer shall notify Bevles of such failure within a reasonable time, but in no event beyond fifteen (15) days of such discovery of defect in material or workmanship. Bevles shall provide, in its sole discretion, either the repair or replacement of any defective or any nonconforming part. Bevles specifically disavows any other representation, warranty or liability relating to the continued use of the product. 6 Exclusion of consequential and incidental damages-In no event shall Bevles be liable for any incidental, special, indirect, or consequential damages, whether resulting from non-delivery or from the use, misuse, or inability to use the product, or from defects in the product, or from Bevles’ own negligence or other tort. This exclusion applies regardless of whether such damages are sought for breach of warranty, breach of contract, negligence, or strict liability in tort or under any other legal theory. 7. Disclaimer of warranties-The warranties contained in paragraph one above are the exclusive warranties given by Bevles and supersede any prior, contrary, or additional representations, whether oral or written. Bevles hereby disclaims and excludes all other warranties-whether expressed, implied, or statutory-including any warranty of merchantability, any warranty of fitness for a particular purpose, and any implied warranties otherwise arising from course of dealing or usage of trade. 4/02 1/05 16