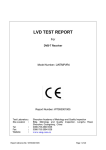

Download APPLICATION FOR LOW VOLTAGE DIRECTIVE On

Transcript