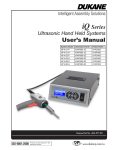

Download LS User`s Manual

Transcript