Download TRANSMISSIONS

Transcript

A

GROUP 21

TRANSMISSIONS

CONTENTS

Page

MANUAL TRANSMISSIONS—3 SPEED . . .

SPECIFICATIONS

54

89

Page

TIGHTENING REFERENCE

TORQUEFLITE TRANSMISSIONS

10

1

TORQUEFL1TE TRANSMISSION (A-727-B)

INDEX

Page

G e n e r a l Information . . . . . .

1

Hydraulic Control S y s t e m

11

Operating Instructions

12

Service Diagnosis

12

S e r v i c e in V e h i c l e . . . . . . . . .

.........

. . . 18

Air P r e s s u r e T e s t s

25

Aluminum Thread Repair

18

Band Adjustments

22

Console Gearshift

20

Extension H o u s i n g a n d Output S h a f t B e a r i n g . . 26

Extension H o u s i n g Yoke S e a l

26

Gearshift Linkage Adjustment

19

Governor

27

Hydraulic Control P r e s s u r e T e s t s

22

Hydraulic Control P r e s s u r e A d j u s t m e n t s

24

Lubrication

19

Neutral Starting S w i t c h

21

Parking L o c k C o m p o n e n t s

28

S p e e d o m e t e r Pinion

—

26

Throttle Rod Adjustment

22

Valve Body and A c c u m u l a t o r Piston

29

S e r v i c e Out of V e h i c l e

29

A s s e m b l y — S u b - A s s e m b l y Installation

48

Disassembly—Sub-Assembly Removal

I n s t a l l a t i o n — T r a n s m i s s i o n , Converter a n d

Drive Plate

Fluid L e a k a g e

Recondition S u b - A s s e m b l i e s . . . . . . . . . . . . . . . . .

A c c u m u l a t o r Piston a n d S p r i n g

Extension Housing B u s h i n g R e p l a c e m e n t

Front C l u t c h

Governor a n d Support

Kickdown Servo a n d B a n d

L o w - R e v e r s e Servo a n d B a n d

Oil P u m p and Reaction S h a f t S u p p o r t . . . . . . .

Overrunning C l u t c h

Parking L o c k S p r a g

Planetary G e a r Train

Rear Clutch

Valve Body A s s e m b l y . . . . . . . . . . . . . . . . . . . . . .

R e m o v a l — T r a n s m i s s i o n a n d Converter

P u m p Oil S e a l

Starter Ring G e a r

Torque Converter F l u s h i n g

Specifications

Tightening R e f e r e n c e

Page

32

50

52

34

38

38

41

38

47

47

39

46

38

45

43

35

29

32

30

31

69

70

GENERAL INFORMATION

identification

c l u t c h r e t a i n e r . T h e h y d r a u l i c s y s t e m consists of a n

m a r k i n g s a r e cast i n r a i s e d l e t t e r s about 3 / 8 i n c h

oil p u m p , a n d a single v a l v e body w h i c h c o n t a i n s a l l

h i g h o n t h e l o w e r left s i d e of t h e t r a n s m i s s i o n b e l l

of the v a l v e s e x c e p t the g o v e r n o r v a l v e .

T h e TorqueFlite Transmission model

housing.

T h e A-727-B

V e n t i n g of t h e t r a n s m i s s i o n i s a c c o m p l i s h e d b y a

TorqueFlite

Transmission servicing

procedures a r e i n general the same for a l l models.

C A U T I O N : T r a n s m i s s i o n operation r e q u i r e m e n t s are

different for each vehicle and engine

combination

a n d some internal parts will be different to provide

for

this. Therefore, when

r e p l a c i n g p a r t s , refer to

the seven digit part number stamped on left side of

the t r a n s m i s s i o n oil pan flange.

The

A-727-B

transmission

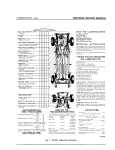

( F i g . 1) c o m b i n e s

torque c o n v e r t e r a n d a fully-automatic

a

3-speed g e a r

system. T h e converter housing and transmission case

are a n integral aluminum casting. T h e transmission

consists of t w o m u l t i p l e d i s c c l u t c h e s , a n o v e r r u n -

drilled

passage through

the upper

p a r t of t h e o i l

pump housing.

T h e torque c o n v e r t e r i s a t t a c h e d to t h e c r a n k s h a f t

through a

flexible

d r i v i n g plate. C o o l i n g of t h e con-

v e r t e r is a c c o m p l i s h e d b y c i r c u l a t i n g t h e t r a n s m i s s i o n

fluid

t h r o u g h a n oil-to-water

type cooler, located i n

t h e r a d i a t o r l o w e r tank. T h e t o r q u e c o n v e r t e r a s s e m bly i s a s e a l e d u n i t w h i c h c a n n o t b e d i s a s s e m b l e d .

T h e t r a n s m i s s i o n fluid i s

filtered

by an internal

" D a c r o n T y p e " filter a t t a c h e d to t h e l o w e r s i d e of t h e

v a l v e body a s s e m b l y .

E n g i n e torque

is transmitted

to t h e torque

con-

ning clutch, two servos and bands, and two planetary

v e r t e r t h e n , t h r o u g h t h e i n p u t shaft to t h e m u l t i p l e

g e a r sets to p r o v i d e t h r e e f o r w a r d ratios a n d a r e -

d i s c c l u t c h e s i n t h e t r a n s m i s s i o n . T h e p o w e r flow de-

v e r s e ratio. T h e c o m m o n s u n g e a r of t h e p l a n e t a r y

p e n d s o n t h e application of t h e c l u t c h e s a n d b a n d s .

g e a r sets i s c o n n e c t e d to t h e f r o n t c l u t c h b y a d r i v i n g

R e f e r to " C l u t c h E n g a g e m e n t a n d B a n d

s h e l l w h i c h i s s p l i n e d to t h e s u n g e a r a n d to t h e f r o n t

Chart."

Application

FLEXIBLE DRIVE PLATE

ENGINE C R A N K S H A F T

NN116B

Fig. I— TorqueFlite

Transmission

and Torque Converter

(A-727)

A

-TORQUEFLITE—TRANSMISSION

—

ENGINE

21

RUNNING

NN34C

Park Hydraulic

Circuits

ENGINE iUNNSNG

HH35C

Neutral Hydraulic

Circuits

21-4

TRANSMISSION—TORQUEFLITE

Drive-Breakaway

Mydmmim

Circuits

A,

TORQUEFLITE—TRANSMISSION

21-5

SERVO

ftEAft

• H I CLUTCH

CiUiCH

CONVERTER

30-75 psi

L U B R I C A T I O N . . . . . . . 5-30 psi

|"

j

~

CONTROL SYSTEM IN

TO LUB.

DRIVE (SECOND)

PUMP

H A L F THROTTLE

NR734A

Drive-Second Hydraulic

Circuits

j

21-6

TRANSMISSION—TORQUEFLITE

Drive-Direct

Hydraulic

Circuits

——TORQUEFLITE—TRANSMISSION

A

Drive-Kiekdown

Hydraulic

Circuits

21-7

21-8

A

TRANSMISSION—TORQUEFLITE

SERVO

REAR CIUICH

I T. C CONTROL VA.

-^^yj,

Pi

j

* ...,^0

OIL PRESSURES

55 psi

LINE

COOLER

PUMP SUCTION

I&GUIATOR

Jo O

GOVERNOR

6-55 psi

CONVERTER

30-75 psi

LUBRICATION

O CM

5-30 psi

J

CONTROL SYSTEM IN

TO L U B .

^9°°

^

o

c

MANUAL SECOND

HIGH PRESS.

RELIEF VALVE

CLOSED THROTTLE

PUMP

OIL

FILTER

NR7 37A

•

Selector Lever Second—Hydraulic

Circuits

A

TORQUEFLITE—TRANSMISSION

Selector Lever Low—Hydraulic

Circuits

21-9

21-10

A

TRANSMISS10N—T0RQUEFL1TE

Reverse Hydraulic

Circuits

A

TORQUEFLITE—TRANSMISSION

21-11

HYDRAULIC CONTROL S Y S T E M

the t r a n s m i s s i o n (in c o n j u n c t i o n w i t h t h r o t t l e p r e s s u r e ) to c o n t r o l upshift a n d d o w n s h i f t s p e e d s .

T h e h y d r a u l i c c o n t r o l c i r c u i t s on p a g e s 3 t h r o u g h

10 show the position of the v a r i o u s v a l v e s w i t h c o l o r

coded p a s s a g e s to indicate those u n d e r h y d r a u l i c

p r e s s u r e f o r a l l operations of the t r a n s m i s s i o n .

T h e throttle v a l v e t r a n s m i t s r e g u l a t e d p r e s s u r e to

the t r a n s m i s s i o n (in c o n j u n c t i o n w i t h g o v e r n o r p r e s s u r e ) to c o n t r o l upshift a n d d o w n s h i f t s p e e d s .

T h e h y d r a u l i c c o n t r o l s y s t e m m a k e s the t r a n s m i s sion f u l l y a u t o m a t i c , a n d h a s f o u r i m p o r t a n t f u n c t i o n s

to p e r f o r m . I n a g e n e r a l w a y , the c o m p o n e n t s of a n y

automatic c o n t r o l s y s t e m m a y be g r o u p e d into t h e

following b a s i c g r o u p s :

Flow Control

T h e p r e s s u r e s u p p l y s y s t e m , the p r e s s u r e regulati n g v a l v e s , the flow c o n t r o l v a l v e s , a n d the c l u t c h e s

and band servos.

T a k i n g e a c h of these basic groups or s y s t e m s i n

t u r n , the c o n t r o l s y s t e m m a y be d e s c r i b e d a s follows:

Pressure

Supply

System

T h e p r e s s u r e s u p p l y s y s t e m consists of a n oil p u m p

d r i v e n b y the e n g i n e t h r o u g h the torque c o n v e r t e r .

T h e single f r o n t p u m p f u r n i s h e s p r e s s u r e for a l l the

hydraulic and lubrication requirements.

Pressure

Regulating

Valves

T h e p r e s s u r e r e g u l a t i n g v a l v e s consist of a r e g u lator v a l v e w h i c h controls l i n e p r e s s u r e at a v a l u e

d e p e n d e n t on t h r o t t l e o p e n i n g .

The torque converter control valve maintains

torque c o n v e r t e r o p e r a t i n g p r e s s u r e a n d t r a n s m i s s i o n

lubricating pressure.

T h e g o v e r n o r v a l v e t r a n s m i t s r e g u l a t e d p r e s s u r e to

Valves

T h e m a n u a l v a l v e obtains the different t r a n s m i s sion d r i v e r a n g e s as s e l e c t e d b y the v e h i c l e operator.

T h e 1-2 s h i f t v a l v e a u t o m a t i c a l l y s h i f t s t h e t r a n s m i s s i o n f r o m low to s e c o n d o r f r o m s e c o n d to low

d e p e n d i n g on the v e h i c l e operation.

T h e 2-3 shift valve a u t o m a t i c a l l y s h i f t s the transm i s s i o n f r o m s e c o n d to d i r e c t o r f r o m d i r e c t to s e c o n d

d e p e n d i n g on the v e h i c l e operation.

T h e k i c k d o w n v a l v e m a k e s p o s s i b l e a f o r c e d downshift f r o m d i r e c t to s e c o n d - s e c o n d to b r e a k a w a y or

d i r e c t to b r e a k a w a y ( d e p e n d i n g on v e h i c l e speed) b y

d e p r e s s i n g the a c c e l e r a t o r p e d a l p a s t the detent

" f e e l " n e a r w i d e open throttle.

T h e s h u t t l e v a l v e h a s two s e p a r a t e f u n c t i o n s a n d

p e r f o r m s e a c h i n d e p e n d e n t l y . T h e first i s that of

p r o v i d i n g f a s t r e l e a s e of the k i c k d o w n b a n d , a n d

s m o o t h f r o n t c l u t c h e n g a g e m e n t w h e n the d r i v e r

m a k e s a "lift-foot" u p s h i f t f r o m s e c o n d to d i r e c t . T h e

s e c o n d f u n c t i o n of the s h u t t l e v a l v e i s to r e g u l a t e

the application of the k i c k d o w n s e r v o a n d b a n d w h e n

m a k i n g d i r e c t to s e c o n d k i c k d o w n s .

Clutches,

Band

Servos

and

Accumulator

T h e f r o n t a n d r e a r c l u t c h pistons, a n d b o t h s e r v o

CLUTCH ENGAGEMENT AND BAND APPLICATION CHART

Drive-Ratio

Front

Clutch

Rear

Clutch

Front

(Kickdown)

Band

Rear

(Low-Rev)

Band

N-NEUTRAL

DISENGAGED

DISENGAGED

RELEASED

RELEASED

D-DRIVE

(Breakaway)

2.45 to 1

DISENGAGED

ENGAGED

RELEASED

RELEASED

HOLDS

(Second)

1.45 to 1

DISENGAGED

ENGAGED

APPLIED

RELEASED

OVER R U N S

(Direct)

1.00 to 1

ENGAGED

ENGAGED

RELEASED

RELEASED

OVER R U N S

KICKDOWN

(To S e c o n d )

1.45 to 1

DISENGAGED

ENGAGED

APPLIED

RELEASED

OVER R U N S

(To Low)

2.45 to 1)

DISENGAGED

ENGAGED

RELEASED

RELEASED

HOLDS

2-Second

1.45 to 1

DISENGAGED

ENGAGED

APPLIED

RELEASED

OVER R U N S

1-LOW

2.45 to 1

DISENGAGED

ENGAGED

RELEASED

APPLIED

PARTIAL HOLD

R-REVERSE

2.20 to 1

ENGAGED

DISENGAGED

RELEASED

APPLIED

NO M O V E M E N T

Lever Position

Overrunning

Clutch

NO M O V E M E N T

21-12

- A

TRANSMISSION—TORQUEFLITE

SHIFT PATTERN SUMMARY

CHART

Condition

Car Speed To Axle Ratios

Chrysler

2.76:1

3.23:1

C l o s e d Throttle

1-2 Upshift .

C l o s e d Throttle

2-3 Upshift .

Wide Open Throttle 1-2 Upshift

Wide Open Throttle 2-3 Upshift

3-2 Kickdown L i m i t

3-1 K i c k d o w n L i m i t

C l o s e d Throttle Downshift

8-14

14-19

33-52

77-90

66-31

30-34

6-13

pistons a r e m o v e d h y d r a u l i c a l l y to engage t h e

c l u t c h e s a n d a p p l y the b a n d s . T h e pistons a r e r e leased by spring tension w h e n hydraulic pressure is

r e l e a s e d . O n t h e 2-3 u p s h i f t , t h e k i c k d o w n s e r v o piston i s r e l e a s e d b y s p r i n g t e n s i o n a n d h y d r a u l i c p r e s sure.

T h e a c c u m u l a t o r c o n t r o l s t h e h y d r a u l i c p r e s s u r e on

the a p p l y s i d e of t h e k i c k d o w n s e r v o d u r i n g the 1-2

shift; t h e r e b y , c u s h i o n i n g t h e k i c k d o w n b a n d a p p l i c a tion at a n y throttle position.

OPERATING

INSTRUCTIONS

7-13

13-18

31-49

72-85

62-76

28-32

6-12

Imperial

2.94:1

742

12-16

28-44

66-77

56-69

25-29

5-11

Starting

Engine

T h e engine w i l l start w i t h t h e s e l e c t o r l e v e r i n

e i t h e r the P (park) o r N (neutral) positions.

(1) A s a safety p r e c a u t i o n w h e n s t a r t i n g i n the N

(neutral) position, a p p l y t h e p a r k i n g o r foot b r a k e .

(2) D e p r e s s t h e a c c e l e r a t o r p e d a l one-third of

t r a v e l to i n s u r e p r o p e r c h o k e operation.

(3) T u r n the ignition k e y a l l t h e w a y to t h e r i g h t to

S T A R T position. W h e n the e n g i n e s t a r t s , r e l e a s e the

k e y a n d it w i l l r e t u r n to the O N position.

The TorqueFlite transmission will not permit starting the engine by pushing or towing.

T h e transmission will automatically upshift and

d o w n s h i f t at a p p r o x i m a t e l y the m i l e s p e r h o u r g i v e n

i n the S h i f t P a t t e r n S u m m a r y C h a r t . All shift speeds

given in the " C h a r t " may vary somewhat due to production tolerances and rear axle ratios. The quality

of t h e s h i f t s Is v e r y i m p o r t a n t . A l l s h i f t s s h o u l d be

smooth, responsive, and with no noticeable engine

runaway.

Mountain

Driving

W h e n d r i v i n g i n the m o u n t a i n s w i t h e i t h e r h e a v y

l o a d s or w h e n p u l l i n g t r a i l e r s , the 2 (second) o r 1

(low) position s h o u l d be s e l e c t e d on u p g r a d e s w h i c h

r e q u i r e s h e a v y throttle for 1/2 mile or m o r e . T h i s

r e d u c e s t h e possibility of o v e r h e a t i n g t h e t r a n s m i s s i o n a n d c o n v e r t e r u n d e r these conditions.

Gearshift

and Parking

Lock

Controls

T h e transmission is controlled by a "lever type"

gearshift incorporated within the steering column.

T h e c o n t r o l h a s s i x s e l e c t o r l e v e r positions: P (park),

R ( r e v e r s e ) , N (neutral), D (drive), 2 (second) a n d 1

(low). S o m e v e h i c l e s a r e e q u i p p e d w i t h a " l e v e r t y p e "

console g e a r s h i f t w h i c h h a s t h e s a m e s e l e c t o r l e v e r

positions. T h e p a r k i n g l o c k i s a p p l i e d b y m o v i n g t h e

s e l e c t o r l e v e r p a s t a gate to t h e P position.

C A U T I O N : Never apply the parking lock until the

vehicle has stopped; otherwise, a severe ratcheting

noise will occur.

Towing

Vehicle

Transmission Inoperative: T o w the v e h i c l e w i t h a

r e a r e n d p i c k u p o r r e m o v e t h e p r o p e l l e r shaft.

Transmission Operating Properly: T h e v e h i c l e m a y

be t o w e d s a f e l y i n N (neutral) w i t h r e a r w h e e l s o n t h e

g r o u n d at a s p e e d not to e x c e e d 30 m p h . If the vehicle

is to be towed for extended distances, it should be

done with a rear end pickup or the propeller shaft

removed. B e c a u s e t h e t r a n s m i s s i o n r e c e i v e s l u b r i c a tion only w h e n t h e engine is r u n n i n g , it is good practice to always tow a disabled vehicle with a rear end

pickup o r r e m o v e t h e p r o p e l l e r shaft.

SERVICE

DIAGNOSIS

T h e t r a n s m i s s i o n s h o u l d not be removed nor d i s a s s e m b l e d until a careful d i a g n o s i s is m a d e ,

the definite c a u s e d e t e r m i n e d a n d a l l p o s s i b l e external c o r r e c t i o n s performed. In diagnosing

any a b n o r m a l shift condition, a l w a y s m a k e t h e h y d r a u l i c p r e s s u r e t e s t s before d i s a s s e m b l y or

r e p l a c e m e n t of parts.

Condition

HARSH ENGAGEMENT

IN D, 1, 2 A N D R

Possible Cause

(a) E n g i n e idle s p e e d too high.

(b) Hydraulic p r e s s u r e s too high or low.

Correction

(a) Adjust engine idle s p e e d to s p e c i f i c a tions. R e - a d j u s t throttle linkage.

(b) I n s p e c t fluid level, t h e n perform hydraulic p r e s s u r e t e s t s a n d a d j u s t to

specifications.

-TORQUEFLITE—TRANSMISSION

Condition

21-13

Correction

Possible Cause

(c) A d j u s t low-reverse b a n d .

(d) Perform p r e s s u r e t e s t s to determine

c a u s e a n d c o r r e c t a s required.

for

sticking,

(e) A c c u m u l a t o r s t i c k i n g , broken rings (e) I n s p e c t a c c u m u l a t o r

broken rings or spring. R e p a i r a s

or s p r i n g .

required.

(f) Low-reverse servo, band or linkage (f) I n s p e c t servo for d a m a g e d s e a l s , binding linkage of faulty band lining. R e malfunction.

pair a s required.

(g) Worn or faulty front a n d / o r

rear (g) D i s a s s e m b l e a n d i n s p e c t c l u t c h . R e pair or r e p l a c e a s required.

clutch.

(c) Low-reverse band out of a d j u s t m e n t

(d) Valve body malfunction or leakage.

DELAYED ENGAGEMENT

IN D, 1,2, AMD R

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

linkage (b) Adjust control linkage.

(a) Low fluid level.

(b) Incorrect gearshift control

adjustment.

(c) Hydraulic p r e s s u r e s too high or low.

(d)

(e)

(d) Oil filter clogged.

(e) Valve body malfunction or leakage.

(f)

A c c u m u l a t o r sticking, broken rings or (f)

spring.

(g) C l u t c h e s or

operating.

s e r v o s s t i c k i n g or

not (g)

(h)

(h) Faulty oil pump.

(i)

(j)

Worn or faulty front a n d / o r

rear (i)

clutch.

Worn or broken input shaft a n d / o r (j)

reaction shaft support s e a l rings.

(k)

(k) Aerated fluid.

R U N A W A Y OR H A R S H

U P S H I F T A N D 3-2

KICKDOWN

(0

Perform hydraulic p r e s s u r e t e s t s and

a d j u s t to s p e c i f i c a t i o n s .

R e p l a c e oil filter.

Perform p r e s s u r e t e s t s to determine

c a u s e a n d c o r r e c t a s required.

Inspect accumulator

for

sticking,

broken rings or spring. R e p a i r a s

required.

Remove valve body a s s e m b l y a n d

perform air p r e s s u r e t e s t s . Repair a s

required.

Perform hydraulic p r e s s u r e t e s t s . Adj u s t and repair a s required.

Disassemble and inspect clutch. Repair or r e p l a c e a s required.

I n s p e c t a n d replace s e a l rings a s

required,

also

inspect

respective

bores for wear. R e p l a c e parts a s required.

I n s p e c t for air leakage into pump s u c tion p a s s a g e s .

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) Incorrect throttle linkage adjustment. (b) Adjust throttle linkage.

(a) Low fluid level.

(c) Hydraulic p r e s s u r e s too high or low.

(d) K i c k d o w n band out of a d j u s t m e n t .

(e) Valve body malfunction or leakage.

(f)

Governor malfunction.

(g) A c c u m u l a t o r s t i c k i n g , broken rings or

spring.

(h) C l u t c h e s or

operating.

s e r v o s s t i c k i n g or

(i)

K i c k d o w n servo,

malfunction.

band

or

(j)

Worn or faulty front c l u t c h .

not

linkage

(k) Worn or broken input shaft a n d / o r

reaction shaft support s e a l rings.

(c) Perform hydraulic p r e s s u r e t e s t s a n d

a d j u s t to s p e c i f i c a t i o n s .

(d) A d j u s t kickdown band.

(e) Perform p r e s s u r e t e s t s to determine

c a u s e a n d c o r r e c t a s required.

(f) I n s p e c t governor a n d repair a s required.

(g) I n s p e c t

accumulator

for sticking,

broken rings or spring. R e p a i r a s

required.

(h) Remove valve body a s s e m b l y a n d perform air p r e s s u r e t e s t s . R e p a i r a s

required.

(i) I n s p e c t servo for s t i c k i n g , broken s e a l

rings, binding linkage or faulty band

lining. R e p a i r a s required.

(j) D i s a s s e m b l e a n d i n s p e c t c l u t c h . R e pair or r e p l a c e a s required.

(k) I n s p e c t a n d r e p l a c e s e a l rings a s

required,

also

inspect

respective

bores for wear. R e p l a c e parts a s

required.

21-14

TRANSMISSION—TORQUEFLITE

Condition

NO U P S H I F T

Correction

Possible Cause

(a) Low fluid level.

(b) Incorrect throttle linkage a d j u s t m e n t ,

(c) Kickdown band out of a d j u s t m e n t .

(d) Hydraulic p r e s s u r e s too high or low.

(e) Governor s t i c k i n g or leaking.

(f)

Valve body malfunction or leakage.

(g) C l u t c h e s or

operating.

s e r v o s s t i c k i n g or

not

(h) Faulty oil pump.

(i)

Kickdown servo,

malfunction.

band

(j)

Worn or faulty front c l u t c h .

or

linkage

(k) Worn or broken input shaft a n d / o r

reaction shaft support s e a l rings.

NO K I C K D O W N O R

NORMAL DOWNSHIFT

(a) Incorrect throttle linkage a d j u s t m e n t

(b) Incorrect gearshift control

linkage

adjustment.

(c) K i c k d o w n band out of a d j u s t m e n t

(d) Hydraulic p r e s s u r e s too high or low.

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) A d j u s t throttle linkage.

(c) Adjust kickdown band.

(d) Perform hydraulic p r e s s u r e t e s t s a n d

a d j u s t to s p e c i f i c a t i o n s .

(e) Remove a n d c l e a n governor. R e p l a c e

parts if n e c e s s a r y .

(f) Perform p r e s s u r e t e s t s to determine

c a u s e and correct a s required.

(g) Remove valve body a s s e m b l y and perform air p r e s s u r e tests. R e p a i r a s required.

(h) Perform hydraulic p r e s s u r e t e s t s , a d j u s t or repair a s required.

(i) I n s p e c t servo for sticking, broken s e a l

rings, binding linkage or faulty band

lining. R e p a i r a s required.

(j) D i s a s s e m b l e and inspect c l u t c h . R e pair or replace a s required.

(k) I n s p e c t and replace s e a l rings a s required, a l s o i n s p e c t respective bores

for wear. R e p l a c e parts a s required.

(a) Adjust throttle linkage.

(b) A d j u s t control linkage.

(c) A d j u s t kickdown band.

(d) Perform hydraulic p r e s s u r e t e s t s a n d

a d j u s t to s p e c i f i c a t i o n s .

(e) R e m o v e a n d c l e a n governor. R e p l a c e

(e) Governor s t i c k i n g or leaking.

parts if n e c e s s a r y .

(f) Perform p r e s s u r e t e s t s to determine

(f) Valve body malfunction or leakage.

c a u s e and c o r r e c t a s required.

(g) C l u t c h e s or s e r v o s s t i c k i n g or not (g) R e m o v e valve body a s s e m b l y a n d

perform air p r e s s u r e t e s t s . R e p a i r a s

operating.

required.

(h) K i c k d o w n servo, band or linkage m a l - (h) I n s p e c t servo for sticking, broken s e a l

rings, binding linkage or faulty band

function.

lining. R e p a i r a s required.

(i) D i s a s s e m b l e t r a n s m i s s i o n a n d repair

(i) Overrunning c l u t c h not holding.

overrunning c l u t c h a s required.

SHIFTS ERRATIC

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) I n s p e c t for air leakage into pump

Aerated fluid.

suction passages.

(c) A d j u s t throttle linkage.

Incorrect throttle linkage a d j u s t m e n t

Incorrect gearshift control

linkage (d) A d j u s t control linkage.

adjustment

(e) Perform hydraulic p r e s s u r e t e s t s a n d

H y d r a u l i c p r e s s u r e s too high or low.

a d j u s t to s p e c i f i c a t i o n s .

(f) R e m o v e a n d c l e a n governor. R e p l a c e

Governor s t i c k i n g or leaking.

parts if n e c e s s a r y .

(g) R e p l a c e oil filter.

Oil filter clogged.

(h) Perform p r e s s u r e t e s t s to determine

Valve body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

C l u t c h e s or s e r v o s s t i c k i n g or not (i) R e m o v e valve body a s s e m b l y a n d perform air p r e s s u r e t e s t s . R e p a i r a s reoperating.

quired.

(j) Perform hydraulic p r e s s u r e tests, a d Faulty oil pump.

j u s t or repair a s required.

(a) Low fluid level.

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

-TORQUEFLITE—TRANSMISSION

Condition

21-15

Correction

Possible Cause

(k) Worn or broken input s h a f t a n d / o r (k) I n s p e c t a n d replace s e a l rings a s required, a l s o i n s p e c t respective bores

reaction s h a f t support s e a l rings.

for wear. R e p l a c e parts a s required.

S L I P S IN FORWARD

DRIVE POSITIONS

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

(k)

S L I P S IN R E V E R S E O N L Y

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) I n s p e c t for air leakage into pump

Aerated fluid.

suction p a s s a g e s .

Incorrect throttle linkage a d j u s t m e n t . (c) A d j u s t throttle linkage.

Incorrect gearshift control

linkage (d) A d j u s t control linkage.

adjustment.

(e) Perform hydraulic p r e s s u r e t e s t s a n d

H y d r a u l i c p r e s s u r e s too low.

ad j u s t to s p e c i f i c a t i o n s .

(f) Perform p r e s s u r e t e s t s to determine

Valve body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

for sticking,

A c c u m u l a t o r sticking, broken rings or (g) I n s p e c t a c c u m u l a t o r

broken rings or spring. R e p a i r a s respring.

quired.

C l u t c h e s or servos s t i c k i n g or not (h) Remove valve body a s s e m b l y a n d perform a i r p r e s s u r e tests. R e p a i r a s reoperating.

quired.

Worn or faulty front a n d / o r

rear (i) D i s a s s e m b l e a n d i n s p e c t c l u t c h . R e pair or r e p l a c e a s required.

clutch.

(j) D i s a s s e m b l e t r a n s m i s s i o n a n d repair

Overrunning c l u t c h not holding.

overrunning c l u t c h a s required.

Worn or broken input shaft a n d / o r (k) I n s p e c t a n d replace s e a l rings a s required, a l s o i n s p e c t respective bores

reaction shaft support s e a l rings.

for wear. R e p l a c e parts a s required.

(a) L o w fluid level.

(a) Low fluid level.

(b) Aerated fluid.

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) I n s p e c t for air leakage into pump

suction passages.

linkage (c) A d j u s t control linkage.

(c) Incorrect gearshift control

adjustment.

(d) Hydraulic p r e s s u r e s too high or low.

(d) Perform hydraulic p r e s s u r e t e s t s a n d

a d j u s t to s p e c i f i c a t i o n s .

(e)

Adjust

low-reverse band.

(e) Low-reverse band out of adjustment.

(f) Perform p r e s s u r e tests to determine

(f) Valve body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

(g) Front c l u t c h or rear servo, sticking or (g) Remove valve body a s s e m b l y a n d

perform a i r p r e s s u r e tests. Repair a s

not operating.

required.

seals,

(h) Low-reverse servo, band or linkage (h) I n s p e c t s e r v o for d a m a g e d

binding linkage or faulty band lining.

malfunction.

Repair a s required.

(i) Perform hydraulic p r e s s u r e tests, a d (i) Faulty oil pump.

j u s t or repair a s required.

S L I P S IN A L L P O S I T I O N S

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) Perform hydraulic p r e s s u r e tests a n d

Hydraulic p r e s s u r e s too low.

a d j u s t to s p e c i f i c a t i o n s .

(c) Perform p r e s s u r e t e s t s to determine

Valve body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

(d) Perform h y d r a u l i c p r e s s u r e tests, a d Faulty oil pump.

j u s t or r e p l a c e a s required.

C l u t c h e s or s e r v o s s t i c k i n g or not (e) R e m o v e valve body a s s e m b l y a n d

perform a i r p r e s s u r e t e s t s . Repair a s

operating.

required.

Worn or broken input s h a f t a n d / o r (f) I n s p e c t a n d r e p l a c e s e a l rings a s required, a l s o i n s p e c t respective bores

reaction s h a f t support s e a l rings.

for wear. R e p l a c e parts a s required.

(a) L o w fluid level.

(b)

(c)

(d)

(e)

(f)

21-16

TRANSMISSION—TORQUEFLITECondition

NO DRIVE IN ANY

POSITION

Possible Cause

(c)

(d)

(e)

(f)

(a) Perform hydraulic p r e s s u r e t e s t s a n d

a d j u s t to s p e c i f i c a t i o n s .

(b) Perform p r e s s u r e t e s t s to determine

Valve body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

C l u t c h e s or servos, s t i c k i n g or not (c) R e m o v e valve body a s s e m b l y a n d

perform air p r e s s u r e tests. R e p a i r a s

operating.

required.

(d) D i s a s s e m b l e a n d i n s p e c t c l u t c h . R e Worn or faulty rear c l u t c h .

pair or r e p l a c e a s required.

(e) D i s a s s e m b l e t r a n s m i s s i o n a n d repair

Overrunning c l u t c h not holding.

overrunning c l u t c h a s required.

Worn or broken input shaft a n d / o r (f) I n s p e c t and r e p l a c e s e a l rings a s required, a l s o i n s p e c t respective bores

reaction shaft support s e a l rings.

for wear. R e p l a c e parts a s required.

(a) H y d r a u l i c p r e s s u r e s too low.

(b)

(c)

(d)

(e)

(f)

NO DRIVE IN

REVERSE

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) Perform hydraulic p r e s s u r e t e s t s a n d

H y d r a u l i c p r e s s u r e s too low.

a d j u s t to s p e c i f i c a t i o n s .

(c) R e p l a c e oil filter.

Oil filter clogged.

(d) Perform p r e s s u r e t e s t s to determine

V a l v e body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

(e) Perform hydraulic p r e s s u r e t e s t s , a d Faulty oil pump.

j u s t or repair a s required.

C l u t c h e s or s e r v o s s t i c k i n g or not (f) R e m o v e valve body a s s e m b l y a n d

perform air p r e s s u r e t e s t s . R e p a i r a s

operating.

required.

(a) L o w fluid level.

(b)

NO DRIVE IN

FORWARD DRIVE

POSITIONS

Correction

(a) Incorrect gearshift control

adjustment.

(b) H y d r a u l i c p r e s s u r e s too low.

(c)

(d)

(e)

(f)

(g)

linkage (a) A d j u s t control linkage.

(b) Perform hydraulic p r e s s u r e t e s t s a n d

a d j u s t to s p e c i f i c a t i o n s .

(c) A d j u s t low-reverse band.

Low-reverse band out of a d j u s t m e n t .

(d) Perform p r e s s u r e t e s t s to d e t e r m i n e

Valve body malfunction or leakage.

c a u s e and c o r r e c t a s required.

Front c l u t c h or rear servo, s t i c k i n g (e) R e m o v e valve body a s s e m b l y a n d

perform air p r e s s u r e t e s t s . R e p a i r a s

or not operating.

required.

seals,

L o w - r e v e r s e servo, band or linkage (f) I n s p e c t servo for d a m a g e d

binding linkage or faulty band lining.

malfunction.

R e p a i r a s required.

(g) D i s a s s e m b l e a n d i n s p e c t c l u t c h . R e Worn or faulty front c l u t c h .

pair or r e p l a c e a s required.

DRIVES IN NEUTRAL

(a) Incorrect gearshift control

linkage (a) A d j u s t control linkage.

adjustment.

(b) Perform p r e s s u r e t e s t s to determine

(b) Valve body malfunction or leakage.

c a u s e a n d c o r r e c t a s required.

(c) I n s p e c t c l u t c h and repair a s required.

(c) R e a r c l u t c h dragging.

DRAGS OR LOCKS

(a) Adjust kickdown band.

(a) K i c k d o w n band out of a d j u s t m e n t

(b) A d j u s t low-reverse band.

(b) L o w - r e v e r s e band out of a d j u s t m e n t

(c) K i c k d o w n a n d / o r low-reverse servo, (c) I n s p e c t servo for sticking, broken s e a l

rings, binding linkage or faulty band

band, linkage m a l f u n c t i o n .

lining. R e p a i r a s required.

(d) D i s a s s e m b l e a n d i n s p e c t c l u t c h . R e (d) Front a n d / o r rear c l u t c h faulty.

pair or r e p l a c e a s required.

(e) I n s p e c t condition of planetary gear

(e) Planetary gear s e t s broken or s e i z e d .

s e t s a n d r e p l a c e a s required.

(f) Overrunning c l u t c h worn, broken or (f) I n s p e c t

condition

of

overrunning

seized.

c l u t c h a n d r e p l a c e parts a s required.

GRATING, SCRAPING

GROWLING NOISE

(a) K i c k d o w n band out of a d j u s t m e n t

(a) A d j u s t kickdown band.

(b) L o w - r e v e r s e band out of a d j u s t m e n t

(b) A d j u s t low-reverse band.

(c) Output s h a f t bearing a n d / o r b u s h i n g (c) R e m o v e extension h o u s i n g a n d

damaged.

p l a c e bearing a n d / o r b u s h i n g .

re*

•TORQUEFLITE—TRANSMISSION

Correction

Possible Couse

Condition

21-17

broken (d) I n s p e c t condition of governor s u p port and repair a s required.

(e) I n s p e c t condition of pump a n d repair a s required.

(f) Front a n d / o r rear c l u t c h faulty.

(f) D i s a s s e m b l e and i n s p e c t c l u t c h . R e pair or r e p l a c e a s required.

(g) Planetary gear s e t s broken or s e i z e d .

(g) I n s p e c t condition of planetary gear

s e t s a n d replace a s required.

(h) Overrunning c l u t c h worn, broken or •(h) I n s p e c t

condition

of

overrunning

c l u t c h a n d replace parts a s required.

seized.

(d) Governor support binding or

s e a l rings.

(e) Oil pump s c o r e d or binding.

(a) Refill to correct level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) I n s p e c t pump for n i c k s or burrs on

(b) P u m p s u c k i n g air.

mating

surfaces,

porous c a s t i n g ,

a n d / o r e x c e s s i v e rotor c l e a r a n c e . R e p l a c e parts a s required.

(c) R e m o v e and recondition valve body

(c) Valve body malfunction.

assembly.

(d) Overrunning c l u t c h inner race d a m - (d) I n s p e c t and repair c l u t c h a s required.

aged.

BUZZING N O I S E

(a) Low fluid level.

HARD TO F I L L , OIL

FLOWS OUT FILLER

TUBE

(a) High fluid level.

(b) Breather clogged.

(c) Oil filter clogged.

(d) Aerated fluid.

OIL LEAKAGE

(a) R e p l a c e rubber " 0 " ring s e a l . I n s p e c t

for bore porosity

(b) R e p l a c e rubber s e a l

S p e e d o m e t e r Drive Pinion S e a l

(c) C a n often be stopped by tightening

Oil P a n G a s k e t

the attaching bolts to proper torque

(150 in-lbs.). If n e c e s s a r y , replace gasket. I n s p e c t oil pan gasket mounting

f a c e for f l a t n e s s . C a u t i o n : Do not overtorque pan bolts.

(d) R e p l a c e "0" ring s e a l . I n s p e c t for tube

F l u i d Filler T u b e

d a m a g e , and bore porosity.

(e) If leakage c a n n o t be stopped by tightFluid L i n e s and Fittings

e n i n g a fitting, replace the defective

part.

Manual Control L e v e r

(f) R e p l a c e either or both the m a n u a l

lever or throttle lever shaft s e a l ,

(g) T o r q u e to specified torque. If leak perPipe Plugs

s i s t s , replace plug.

R e a r Extension S e a l

.(h) C h e c k for O.D. Bore d a m a g e and replace seal.

R e a r B e a r i n g A c c e s s Plate

(i) R e p l a c e g a s k e t

Extension Bolts

(j) R e p l a c e bolt

(k) R e p l a c e gasket and c h e c k for s e a l i n g

Extension Gasket

s u r f a c e d a m a g e on c a s e and extension

Kickdown B a n d Adjusting S c r e w

(I) Apply s e a l e r

(m) R e p l a c e s w i t c h a n d / o r gasket

Neutral S w i t c h

F l u i d L e a k a g e in Converter H o u s i n g (n) S e e s e c t i o n on Fluid L e a k a g e

Area

(a) S p e e d o m e t e r Adaptor

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

(k)

(I)

(m)

(n)

TRANSMISSION

OVERHEATS

(a) Drain fluid to c o r r e c t level.

and c l e a n breather

vent

opening in oil pump housing.

(c) R e p l a c e oil filter.

(d) I n s p e c t for air leakage into pump

suction passage.

(b) I n s p e c t

(a) Refill to c o r r e c t level with Automatic

T r a n s m i s s i o n F l u i d , A Q - A T F , Suffix A.

or (Dexron).

(b) Kickdown band a d j u s t m e n t too t i g h t (b) A d j u s t kickdown band.

(c) Low-reverse band a d j u s t m e n t

too (c) A d j u s t low-reverse band

tight

(d) I n s p e c t t r a n s m i s s i o n cooling s y s t e m ,

(d) Faulty cooling s y s t e m .

c l e a n a n d repair a s required.

(a) Low fluid level.

21-18

TRANSMISSION—TORQUEFLITE

Condition

Correction

Possible Cause

(e) C r a c k e d or restricted oil cooler line (e) Inspect, repair or r e p l a c e a s required.

or fitting.

(f) I n s p e c t pump for incorrect c l e a r a n c e ,

(f) Faulty oil p u m p .

repair a s required.

(g) Insufficient c l u t c h plate c l e a r a n c e in (g) M e a s u r e c l u t c h plate c l e a r a n c e a n d

correct with proper s i z e s n a p ring.

front a n d / o r rear c l u t c h e s .

S T A R T E R WILL NOT

E N E R G I Z E IN N E U T R A L

OR P A R K

(a) Incorrect gearshift control linkage (a) Adjust control linkage.

adjustment.

(b) Faulty or incorrectly a d j u s t e d neutral (b) T e s t operation of s w i t c h with a test

lamp. A d j u s t or r e p l a c e a s required.

starting s w i t c h .

(c) I n s p e c t lead a n d t e s t with a t e s t

(c) Broken lead to neutral s w i t c h .

lamp. Repair broken lead.

cate torque c o n v e r t e r stator c l u t c h p r o b l e m s . A r o a d

STALL TEST

W A R N I N G : D U R I N G T E S T L E T N O O N E S T A N D IN

F R O N T OF V E H I C L E .

T h e s t a l l test consists of d e t e r m i n i n g t h e e n g i n e

s p e e d obtained at f u l l throttle i n D position. T h i s test

c h e c k s t h e torque c o n v e r t e r stator c l u t c h o p e r a t i o n ,

a n d t h e h o l d i n g ability of t h e t r a n s m i s s i o n c l u t c h e s .

T h e t r a n s m i s s i o n o i l l e v e l s h o u l d b e c h e c k e d a n d the

e n g i n e b r o u g h t to n o r m a l o p e r a t i n g t e m p e r a t u r e bef o r e s t a l l operation. Both the parking and service

brakes must be fully applied and front wheels blocked

while making this test.

D o n o t h o l d t h e throttle open a n y l o n g e r t h a n i s

n e c e s s a r y to obtain a m a x i m u m e n g i n e s p e e d r e a d i n g ,

test w i l l b e n e c e s s a r y to identify t h e exact p r o b l e m .

If s t a l l speeds a r e 250-350 r p m below specification,

a n d t h e v e h i c l e operates p r o p e r l y at h i g h w a y speeds,

but h a s poor through-gear

a c c e l e r a t i o n , t h e stator

o v e r r u n n i n g c l u t c h is s l i p p i n g .

I f s t a l l s p e e d a n d a c c e l e r a t i o n a r e n o r m a l , b u t abn o r m a l l y h i g h throttle o p e n i n g i s r e q u i r e d to m a i n t a i n h i g h w a y speeds, t h e stator c l u t c h h a s seized.

B o t h of these stator defects r e q u i r e r e p l a c e m e n t of

the torque c o n v e r t e r .

NOISE

and never longer than five seconds at a time. I f m o r e

A w h i n i n g o r s i r e n - l i k e noise d u e to fluid flow i s

t h a n one s t a l l c h e c k i s r e q u i r e d , o p e r a t e the e n g i n e

at a p p r o x i m a t e l y 1,000 r p m i n n e u t r a l f o r 20 s e c o n d s

to cool t h e t r a n s m i s s i o n fluid b e t w e e n r u n s . I f e n g i n e

speed exceeds the m a x i m u m limits shown, release the

accelerator immediately since transmission clutch

s l i p p a g e is i n d i c a t e d .

n o r m a l d u r i n g s t a l l operation w i t h s o m e c o n v e r t e r s ;

STALL SPEED ABOWE SPECIFICATION

If s t a l l s p e e d e x c e e d s t h e m a x i m u m specified i n

c h a r t b y m o r e t h a n 200 r p m , t r a n s m i s s i o n c l u t c h

slippage is indicated. Follow the transmission oil

p r e s s u r e a n d a i r p r e s s u r e c h e c k s outlined i n t h e S e r v i c e o n V e h i c l e s e c t i o n to d e t e r m i n e t h e c a u s e of

slippage.

STALL SPEED BELOW

SPECIFICATION

L o w s t a l l s p e e d s with a properly tuned engine i n d i -

h o w e v e r , l o u d m e t a l l i c noises f r o m loose p a r t s o r i n t e r f e r e n c e w i t h i n t h e a s s e m b l y i n d i c a t e a defective

torque c o n v e r t e r . T o c o n f i r m that t h e noise originates

w i t h i n t h e c o n v e r t e r , operate

t h e v e h i c l e at light

t h r o t t l e i n D a n d N o n a hoist a n d l i s t e n u n d e r t h e

transmission bell housing.

STALL SPEED

SPECIFICATION CHART

Engine

Model

(C.I.D.).

Transmission

Type

383-2 B B L .

383-4 B B L

440-4 B B L .

A727

A727

A727

Engine

Speed

(RPM)

1850-2100

2350-2650

2000-2300

SERVICE PROCEDURES

SERVICE IN VEHICLE

Various transmission components c a n be removed

for repairs without removing the transmission f r o m

vehicle. T h e removal, reconditioning and installation

procedures f o r these components are covered here,

e x c e p t v a l v e body r e c o n d i t i o n i n g , w h i c h i s d e s c r i b e d

o n P a g e 34.

ALUMINUM THREAD

REPAIR

Damaged or worn threads i n the aluminum transm i s s i o n case a n d v a l v e body c a n b e r e p a i r e d b y t h e

u s e of H e l i - C o i l s . E s s e n t i a l l y , this r e p a i r consists of

d r i l l i n g out the w o r n o r d a m a g e d t h r e a d s , t a p p i n g the

hole w i t h a s p e c i a l H e l i - C o i l T a p , a n d i n s t a l l i n g a

H e l i - C o i l I n s e r t into the t a p p e d hole. T h i s b r i n g s t h e

TORQUEFLITE—TRANSMISSION

Heli-Coil Insert

Thread

Size

Part

No.

Insert

Length

10-24

1/4-20

5/16-18

3/8-16

7/16-14

1185-3

1185-4

1185-5

1185-6

1185-7

.285"

3/8"

15/32"

9/16"

21/32"

21-19

Drill

Tap

Inserting

Tool

Extracting

Tool

Size

Part

No.

Part

No.

Part

No.

528-3N

528-4N

528-5N

528-6N

528-7N

1227-6

1227-6

1227-6

1227-6

1227-16

13/64"

17/64"

Q

X

29/32"

hole b a c k to its o r i g i n a l t h r e a d size.

T h e c h a r t lists t h e t h r e a d e d hole sizes w h i c h a r e

u s e d i n the a l u m i n u m case a n d v a l v e body, a n d t h e

n e c e s s a r y tools a n d i n s e r t s f o r the r e p a i r of d a m a g e d

or w o r n t h r e a d s . H e l i - C o i l tools a n d i n s e r t s a r e r e a d i l y available f r o m m o s t automotive parts j o b b e r s .

Some thread drag may occur in screwing a bolt into

the installed Heli-Coil insert. Therefore, a torque

reading should be taken of the thread drag with an

inch-pound torque wrench and added to the specified

bolt torque, so that all bolts securing a particular part

will be tightened to the same torque.

LUBRICATION

T h e t r a n s m i s s i o n fluid a n d filter s h o u l d p r o v i d e

satisfactory l u b r i c a t i o n a n d protection to t h e automatic transmission a n d no change is recommended i n

vehicles used i n normal service. Regularly scheduled

fluid a n d filter c h a n g e s , t h e r e f o r e w i l l not b e r e q u i r e d , except w h e n t h e operation of the v e h i c l e i s

classified as s e v e r e .

If, f o r a n y r e a s o n , t h e f a c t o r y fill fluid i s r e p l a c e d

w i t h another fluid, t h e fluid m u s t b e c h a n g e d e v e r y

t h r e e y e a r s o r 36,000 m i l e s i n n o r m a l service.

F l u i d Level

I n s p e c t fluid l e v e l e v e r y s i x m o n t h s w i t h e n g i n e

a n d t r a n s m i s s i o n at n o r m a l o p e r a t i n g t e m p e r a t u r e .

R e f e r to " L u b r i c a t i o n a n d M a i n t e n a n c e " , G r o u p 0.

T h e t r a n s m i s s i o n s h o u l d not b e i d l e d i n gear f o r l o n g

periods.

Trailer

Towing

Service

and Hard

Usage

If v e h i c l e i s u s e d f o r t r a i l e r t o w i n g o r i s u s e d i n

hard or severe service, more frequent servicing is req u i r e d as outlined.

D r a i n a n d r e f i l l t r a n s m i s s i o n a n d r e p l a c e filter

i n i t i a l l y at 36,000 m i l e s o r 3 y e a r s a n d e v e r y 12,000

m i l e s o r 12 m o n t h s thereafter.

Drain and

Refill

(1) R a i s e v e h i c l e o n a hoist. P l a c e a d r a i n c o n t a i n e r

with a large opening, under the transmission oil p a n .

(2) L o o s e n p a n bolts, tap p a n to b r e a k it loose a l l o w i n g fluid to d r a i n , t h e n r e m o v e t h e o i l p a n .

(3) R e m o v e a c c e s s plate f r o m i n f r o n t of c o n v e r t e r ,

r e m o v e d r a i n p l u g a l l o w i n g t h e fluid to d r a i n ( F i g . 2).

(.203")

(.265")

(.332")

(.397")

(.453")

3

4

5

6

7

CPB

CPB

CPB

CPB

CPB

I n s t a l l a n d tighten c o n v e r t e r d r a i n p l u g to 110 i n c h p o u n d s , a n d i n s t a l l t h e access plate.

(4) I f n e c e s s a r y , a d j u s t t h e r e v e r s e b a n d .

(5) I n s t a l l a n e w filter o n bottom of t h e v a l v e body,

a n d tighten r e t a i n i n g s c r e w s to 3 5 i n c h - p o u n d s .

(6) C l e a n t h e o i l p a n , a n d r e i n s t a l l u s i n g a n e w

g a s k e t . T i g h t e n p a n bolts to 150 i n c h - p o u n d s .

(7) P o u r s i x q u a r t s of A u t o m a t i c T r a n s m i s s i o n

F l u i d , A Q - A T F Suffix " A " (Dexron) into t h e t r a n s m i s sion.

(8) S t a r t e n g i n e a n d allow to idle f o r at l e a s t two

minutes. W i t h parking brake on, move selector lever

m o m e n t a r i l y to e a c h position e n d i n g i n the n e u t r a l

position.

(9) A d d sufficient fluid to b r i n g fluid l e v e l to the

" A D D O N E P I N T " mark.

(10) R e c h e c k fluid l e v e l a f t e r t r a n s m i s s i o n i s at

n o r m a l o p e r a t i n g t e m p e r a t u r e . T h e l e v e l s h o u l d be

between the " F U L L " m a r k and " A D D O N E P I N T "

m a r k ( F i g . 3).

C A U T I O N : To prevent dirt from entering transmission, make certain that dip stick cap is fully seated

onto the filler tube.

G E A R S H I F T LINKAGE ADJUSTMENT

(Column Shift) (Fig. 4)

(1) A s s e m b l e a l l l i n k a g e p a r t s l e a v i n g a d j u s t a b l e

r o d e n d free.

(2) P l a c e g e a r s h i f t selector l e v e r i n P A R K position

a n d l o c k s t e e r i n g c o l u m n w i t h ignition k e y .

(3) Move shift c o n t r o l l e v e r o n t r a n s m i s s i o n a l l the

w a y to r e a r (in P A R K detent) ( F i g . 5).

(4) S e t a d j u s t a b l e r o d to p r o p e r l e n g t h a n d i n s t a l l

w i t h n o l o a d i n e i t h e r direction on linkage.

Fig. 2—Converter Drain Mug

21-20

A

TRANSMISSION—TORQUEFLITE

ND167A

Fig. 3—Dip Stick

Markings

Fig. 5—External Controls and

Mdimtments

(5) C h e c k a d j u s t m e n t as follows:

(5) C h e c k A d j u s t m e n t a s follows:

(a) S h i f t effort m u s t be f r e e a n d detents f e e l

c r i s p . A l l gate stops m u s t be positive.

(b) D e t e n t position m u s t be close e n o u g h to gate

stops i n n e u t r a l a n d d r i v e to a s s u r e that h a n d l e v e r

w i l l not r e m a i n out of detent position w h e n p l a c e d

against gate a n d t h e n r e l e a s e d .

(c) K e y s t a r t m u s t o c c u r w i t h shift l e v e r h e l d

d o w n against the p a r k gate.

(a) S h i f t effort s h o u l d be f r e e e n o u g h so detents

feel crisp.

(b) D e t e n t position m u s t be close e n o u g h to gate

stops i n n e u t r a l a n d d r i v e to a s s u r e that h a n d l e v e r

w i l l not r e m a i n out of detent position w h e n p l a c e d

against gate a n d t h e n r e l e a s e d .

(c) K e y start a n d l o c k i n g m u s t o c c u r w i t h shift

l e v e r h e l d b a c k against the p a r k gate.

(6) If console r e m o v a l i s r e q u i r e d , d i s c o n n e c t batt e r y g r o u n d c a b l e . R e m o v e set s c r e w a n d shift k n o b

L I N K A G E A D J U S T M E N T (Console Shift)

(Fig. 8)

o r h a n d l e . P r o c e e d as outlined i n B o d y S e c t i o n 23.

(7) A f t e r console i s i n p l a c e , i n s t a l l shift k n o b as

(1) A s s e m b l e a l l l i n k a g e p a r t s l e a v i n g a d j u s t a b l e

rod ends free.

follows: w i t h g e a r s h i p l e v e r h i N E U T R A L , t h r e a d button, s p r i n g a n d k n o b a s s e m b l y on the cable e n d u n t i l

(2) A t s t e e r i n g c o l u m n u p p e r e n d , l i n e u p l o c a t i n g

slots i n bottom of shift h o u s i n g a n d b e a r i n g h o u s i n g .

I n s t a l l suitable tool to h o l d this a l i g n m e n t a n d l o c k

d i m e n s i o n f r o m top of button to top of k n o b i s 1 3 / 3 2 "

( F i g . 6). S e c u r e k n o b w i t h set s c r e w .

(8) C o n n e c t battery g r o u n d cable.

c o l u m n w i t h ignition k e y .

(3) P l a c e c o n s o l e l e v e r i n P A R K a n d m o v e shift cont r o l l e v e r on t r a n s m i s s i o n a l l the w a y to the r e a r (in

P A R K detent).

(4) S e t a d j u s t a b l e r o d s to p r o p e r l e n g t h w i t h no

l o a d a p p l i e d i n e i t h e r d i r e c t i o n on l i n k a g e .

PY228

Fig. 4—Gearshift

Linkage

Fig. 6—Console Gearshift

Unit

21-21

TORQUEFLITE—TRANSMISSION

A,

SCREWS (2)

CONTACT

SEAL

SCREWS (4)

WIRING

CONNECTOR

SWITCH

NU450

Fig. 9—Nevtral-Park Starting Switch and

Back-Up Light Switch

c a m i n only Park a n d Neutral positions.

(1) T o test s w i t c h , r e m o v e w i r i n g c o n n e c t o r f r o m

s w i t c h a n d test f o r continuity b e t w e e n c e n t e r p i n of

s w i t c h a n d t r a n s m i s s i o n case. C o n t i n u i t y s h o u l d exist

only w h e n t r a n s m i s s i o n i s i n Park o r Neutral.

NN564C

Fig. 7—Removing or Installing

Console

BACK-UP LIGHT AND NEUTRAL

STARTING SWITCH (Fig. 9 and 10)

Replacement a n d Test

T h e Neutral Starting Switch is the center terminal

of t h e 3 t e r m i n a l s w i t c h . I t p r o v i d e s g r o u n d f o r t h e

starter solenoid circuit through the selector lever

(2) C h e c k g e a r s h i f t l i n k a g e a d j u s t m e n t b e f o r e r e p l a c i n g a s w i t c h w h i c h tests b a d .

(3) U n s c r e w s w i t c h f r o m t r a n s m i s s i o n c a s e a l l o w i n g

fluid to d r a i n into a c o n t a i n e r . Move s e l e c t o r l e v e r to

Park a n d t h e n to Neutral positions, a n d i n s p e c t to s e e

that t h e s w i t c h operating l e v e r fingers a r e c e n t e r e d

in switch opening i n the case.

(4) S c r e w s w i t c h a n d n e w s e a l into t r a n s m i s s i o n

case a n d tighten to 24 foot-pounds. R e t e s t s w i t c h w i t h

the test l a m p .

STEERING COLUMN

LOWER ROD

Fig* i—Console Gearshift

PY231

Linkage

TRANSMISSION—TORQUEFLITE

21-22

•A

If a d a p t e r C-3705 i s n o t u s e d , tighten a d j u s t i n g s c r e w

to 72 i n c h - p o u n d s .

(4) B a c k off a d j u s t i n g s c r e w 2 t u r n s . H o l d a d j u s t i n g s c r e w i n t h i s position a n d tighten l o c k n u t to 3 5

foot-pounds.

(5) R e i n s t a l l o i l p a n u s i n g a n e w gasket. T i g h t e n o i l

p a n bolts to 150 i n c h - p o u n d s .

(6) F i l l t r a n s m i s s i o n w i t h " A u t o m a t i c T r a n s m i s s i o n

F l u i d A Q - A T F Suffix A , ( D e x r o n ) .

THOTTLE ROD ADJUSTMENT (Fig. 11)

W i t h e n g i n e at operating t e m p e r a t u r e a n d c a r b u r e t o r off fast idle c a m , a d j u s t idle s p e e d of e n g i n e

u s i n g a t a c h o m e t e r . R e f e r to " F u e l S y s t e m " G r o u p

14, f o r idle s p e e d Specifications a n d c a r b u r e t o r linkage a d j u s t m e n t .

Fig. I©—Bottom View of Transmission

(Pan Removed)

(5) A d d fluid to t r a n s m i s s i o n to b r i n g u p to p r o p e r

level.

(6) T h e B a c k - U p L i g h t S w i t c h C i r c u i t i s t h r o u g h t h e

two outside t e r m i n a l s of t h e 3 t e r m i n a l s w i t c h .

(7) T o test s w i t c h , r e m o v e w i r i n g c o n n e c t o r f r o m

s w i t c h a n d test f o r continuity b e t w e e n t h e t w o outside

pins.

(8) C o n t i n u i t y s h o u l d e x i s t only w i t h t r a n s m i s s i o n

i n R e v e r s e position.

(9) N o continuity s h o u l d e x i s t f r o m e i t h e r p i n to

the case.

BAND ADJUSTMENTS

Kickdown

Band

T h e kickdown band adjusting screw i s located on

left side of t r a n s m i s s i o n c a s e n e a r t h e t h r o t t l e l e v e r

shaft ( F i g . 5).

(1) L o o s e n l o c k n u t a n d b a c k off a p p r o x i m a t e l y five

turns. Inspect adjusting screw for free turning i n the

t r a n s m i s s i o n case.

(2) U s i n g w r e n c h , T o o l C-3380 w i t h a d a p t e r C - 3 7 0 5 ,

tighten b a n d a d j u s t i n g s c r e w 4 7 to 50 i n c h - p o u n d s . I f

a d a p t e r C-3705 i s n o t u s e d , t i g h t e n a d j u s t i n g s c r e w to

72 i n c h - p o u n d s w h i c h i s t h e t r u e t o r q u e .

(3) B a c k off a d j u s t i n g s c r e w 2 t u r n s . H o l d a d j u s t i n g s c r e w i n t h i s position a n d t i g h t e n l o c k n u t to 2 9

foot-pounds.

Low and Reverse

Band

(1) R a i s e v e h i c l e , d r a i n t r a n s m i s s i o n fluid a n d r e move oil pan.

(2) L o o s e n a d j u s t i n g s c r e w l o c k n u t a n d b a c k off

n u t a p p r o x i m a t e l y five t u r n s ( F i g . 10). I n s p e c t a d j u s t ing screw for free turning i n the lever.

(3) U s i n g w r e n c h , T o o l C-3380 w i t h a d a p t e r C - 3 7 0 5 ,

tighten b a n d a d j u s t i n g s c r e w to 4 7 to 50 i n c h - p o u n d s .

(1) F o l l o w detailed i n s t r u c t i o n s i n L u b r i c a t i o n S e c tion f o r l i n k a g e l u b r i c a t i o n of a l l m o d e l s .

(2) D i s c o n n e c t c h o k e at c a r b u r e t o r o r block c h o k e

v a l v e i n f u l l open position. O p e n throttle slightly to

r e l e a s e fast i d l e c a m , t h e n r e t u r n c a r b u r e t o r to c u r b

idle.

(3) L o o s e n t h e t r a n s m i s s i o n throttle r o d a d j u s t m e n t

lock s c r e w .

(4) H o l d t h e t r a n s m i s s i o n l e v e r f o r w a r d against i t s

stop w h i l e a d j u s t i n g the t r a n s m i s s i o n l i n k a g e . (On

e n g i n e s w i t h solenoid idle stops, the solenoid p l u n g e r

m u s t also b e i n its f u l l y e x t e n d e d position).

(5) A d j u s t t h e t r a n s m i s s i o n r o d b y p u l l i n g f o r w a r d

on the slotted l i n k w i t h a slight effort so that t h e r e a r

edge of the slot i s against t h e c a r b u r e t o r l e v e r p i n .

Tighten transmission rod adjustment locking screw.

Note: T h e slotted l i n k a n d t r a n s m i s s i o n l e v e r m u s t

be h e l d f o r w a r d w h i l e t h e l o c k i n g s c r e w i s b e i n g tightened.

(6) T o c h e c k t r a n s m i s s i o n l i n k a g e f r e e d o m of operation, m o v e slotted l i n k to the f u l l r e a r w a r d position,

t h e n allow it to r e t u r n slowly, m a k i n g s u r e it r e t u r n s

to t h e f u l l f o r w a r d position.

(7) L o o s e n c a r b u r e t o r cable c l a m p n u t . A d j u s t position of cable h o u s i n g f e r r u l e i n the c l a m p so that a l l

s l a c k i s r e m o v e d f r o m cable w i t h c a r b u r e t o r at c u r b

idle. T o r e m o v e s l a c k f r o m cable, move f e r r u l e i n t h e

clamp i n direction away from carburetor lever.

(8) B a c k off f e r r u l e 1 / 4 " . T h i s p r o v i d e s 1 / 4 " f r e e

play. T i g h t e n cable c l a m p n u t to 4 5 inch-pounds.

(9) C o n n e c t c h o k e r o d o r r e m o v e b l o c k i n g

fixture.

HYDRAULIC CONTROL P R E S S U R E T E S T S

Line Pressure

and Front

Release

Pressure

Servo

L i n e p r e s s u r e a n d f r o n t s e r v o r e l e a s e p r e s s u r e tests

m u s t b e m a d e i n D (drive) position w i t h r e a r w h e e l s

f r e e to t u r n . T h e t r a n s m i s s i o n fluid m u s t b e at operati n g t e m p e r a t u r e ( 1 5 0 ° F to 2 0 0 ° F ) .

TORQUEFLITE—TRANSMISSION

A.

Fig. I I - T h r o t t l e Rod

(1) I n s t a l l a n e n g i n e t a c h o m e t e r , r a i s e v e h i c l e on a

hoist a n d position t a c h o m e t e r so it c a n be r e a d u n d e r

the v e h i c l e .

(2) C o n n e c t two 0-100 p s i p r e s s u r e g a u g e s , T o o l C 3292 to p r e s s u r e take-off points at s i d e of a c c u m u lator a n d at front s e r v o r e l e a s e ( F i g . 12).

(3) W i t h c o n t r o l i n D (drive) position, s p e e d u p

e n g i n e s l i g h t l y u n t i l t r a n s m i s s i o n s h i f t s into

direct.

( F r o n t s e r v o r e l e a s e w i l l be p r e s s u r i z e d i n direct.) R e d u c e engine s p e e d s l o w l y to 1,000 r p m . L i n e p r e s s u r e

21-23

Adjustment

sion throttle lever for looseness on the valve body

shaft when making pressure tests.

Lubrication

Pressures

T h e l u b r i c a t i o n p r e s s u r e test s h o u l d be m a d e at

s a m e t i m e that l i n e p r e s s u r e a n d f r o n t s e r v o r e l e a s e

p r e s s u r e s a r e tested.

(1) I n s t a l l a " t e e " fitting b e t w e e n c o o l e r r e t u r n l i n e

fitting a n d fitting h o l e i n t r a n s m i s s i o n c a s e at r e a r

left side of the t r a n s m i s s i o n case ( F i g . 13). C o n n e c t a

at this time (1,000 r p m ) m u s t be 54-60 p s i , a n d f r o n t

s e r v o r e l e a s e p r e s s u r e m u s t not be m o r e t h a n 3 p s i

below l i n e p r e s s u r e .

(4) D i s c o n n e c t throttle l i n k a g e f r o m t r a n s m i s s i o n

throttle l e v e r a n d m o v e throttle l e v e r g r a d u a l l y to

full

throttle position. L i n e p r e s s u r e m u s t

rise

to

a m a x i m u m of 90-96 p s i j u s t b e f o r e o r at k i c k d o w n

into low gear. F r o n t s e r v o r e l e a s e p r e s s u r e m u s t follow l i n e p r e s s u r e u p to the k i c k d o w n point a n d s h o u l d

not be m o r e t h a n 3 p s i below l i n e p r e s s u r e .

I f l i n e p r e s s u r e i s not 54-60 p s i at 1,000 r p m , s e e

"Hydraulic Control Pressure Adjustments".

If f r o n t s e r v o r e l e a s e p r e s s u r e s a r e l e s s t h a n p r e s s u r e specified a n d l i n e p r e s s u r e s a r e w i t h i n

limits,

there is excessive leakage i n front clutch a n d / o r front

s e r v o c i r c u i t s . Always inspect the external transmis-

Fig. 12—Pressure Test Locations (Right Side of Case)

21-24

TRANSMISSION—TORQUEFLITE-

0-100 p s i p r e s s u r e gauge, T o o l C-3292 to t h e " t e e "

fitting.

(2) A t 1,000 e n g i n e r p m , w i t h throttle c l o s e d a n d

transmission i n direct, the lubrication pressure should

be 5-15 p s i . L u b r i c a t i o n p r e s s u r e w i l l b e a p p r o x i m a t e l y d o u b l e d a s throttle i s o p e n e d to the m a x i m u m l i n e

pressure.

R e a r S e r v o Apply

Pressure

(1) C o n n e c t a 0-300 p s i p r e s s u r e gauge, T o o l C-3293

to a p p l y p r e s s u r e take-off point at r e a r s e r v o ( F i g . 13).

(2) W i t h t r a n s m i s s i o n c o n t r o l i n R ( r e v e r s e ) position a n d e n g i n e s p e e d s e t at 1600 r p m , t h e r e v e r s e

s e r v o a p p l y p r e s s u r e s h o u l d be 230 to 300 p s i .

Throttle

Pressure

N o p r o v i s i o n s a r e m a d e to test t h e t h r o t t l e p r e s s u r e .

I n c o r r e c t throttle p r e s s u r e s h o u l d only b e s u s p e c t e d

if p a r t throttle shift s p e e d s a r e e i t h e r v e r y d e l a y e d

or o c c u r too e a r l y i n r e l a t i o n to v e h i c l e speeds. I n

w h i c h c a s e , t h e throttle l i n k a g e s h o u l d b e a d j u s t e d

before throttle p r e s s u r e setting i s a d j u s t e d .

HYDRAULIC CONTROL P R E S S U R E

ADJUSTMENTS

Pressure

Line

A n i n c o r r e c t throttle p r e s s u r e setting w i l l c a u s e i n c o r r e c t line p r e s s u r e r e a d i n g s e v e n t h o u g h l i n e p r e s s u r e a d j u s t m e n t i s c o r r e c t . A l w a y s i n s p e c t a n d cor-

Governor

Pressure

(1) C o n n e c t a 0-100 p s i p r e s s u r e gauge, T o o l C-3292

to g o v e r n o r p r e s s u r e take-off point, l o c a t e d at l o w e r

left s i d e of e x t e n s i o n n e a r t h e m o u n t i n g flange ( F i g .

13).

(2) G o v e r n o r p r e s s u r e s s h o u l d f a l l w i t h i n t h e l i m i t s

given i n the "Governor Pressure Chart."

I f g o v e r n o r p r e s s u r e s a r e i n c o r r e c t at t h e g i v e n

v e h i c l e speeds, t h e g o v e r n o r v a l v e a n d / o r w e i g h t s a r e

probably sticking.

distance between the manual valve (valve in 1-low

position) and line pressure adjusting screw (Fig. 14).

This measurement must be 1-7/8 inches; correct by

loosening spring retainer screws a n d repositioning the

spring retainer. The regulator valve may cock and

hang up in its bore if spring retainer is out of position.

If l i n e p r e s s u r e i s not c o r r e c t , it w i l l b e n e c e s s a r y

to r e m o v e v a l v e body a s s e m b l y to p e r f o r m t h e a d -

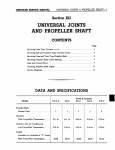

GOVERNOR PRESSURE CHART

Vehicle Speed To Axle Ratios

Chrysler

Imperial

2.76:1

3.23:1

2.94:1

r e c t throttle p r e s s u r e a d j u s t m e n t before a d j u s t i n g t h e

l i n e p r e s s u r e . Before adjusting line pressure, measure

justment.

Pressure

Limits*

psi

The

approximate

adjustment

is

1-5/16

inches,

m e a s u r e d f r o m v a l v e body to i n n e r edge of t h e adjusti n g n u t ( F i g . 15). H o w e v e r , d u e to m a n u f a c t u r i n g tole r a n c e s , the a d j u s t m e n t c a n b e v a r i e d to obtain speci-

20-22

48-57

77-85

17-19

41-49

66-73

19-22

48-57

77-85

15

50

75

* T h e governor p r e s s u r e should respond smoothly to

c h a n g e s in m.p.h. a n d s h o u l d return to 0 to 1-1/2 psi

w h e n the v e h i c l e is stopped. High p r e s s u r e a t s t a n d still (above 2 psi) will prevent the t r a n s m i s s i o n from

downshifting.

LUBRICATION

PRESSURE

(COOLER RETURN

FITTING)

fied l i n e p r e s s u r e .

T h e adjusting screw may be turned with an A l l e n

wrench.

One complete

turn

of

adjusting

screw

c h a n g e s c l o s e d throttle l i n e p r e s s u r e a p p r o x i m a t e l y

1-2/3 p s i . T u r n i n g a d j u s t i n g s c r e w c o u n t e r c l o c k w i s e

increases pressure, and clockwise decreases pressure.

Throttle

Throttle

Pressure

pressure cannot

be tested

accurately:

GOVERNOR

PRESSURE

REAR SERVO

APPLY

PRESSURE

NN71A

Fig. 13—Pressure Test Locations (Rear End of Case)

Fig. 14—Measuring Spring Retainer

Location

-TORQUEFLITE—TRANSMISSION

21-25

c o r r e c t fluid p r e s s u r e , b e c a u s e of i n o p e r a t i v e c l u t c h e s

or b a n d s . T h e i n o p e r a t i v e u n i t s , c l u t c h e s , b a n d s a n d

servos c a n be located through

a s e r i e s of tests b y

s u b s t i t u t i n g a i r p r e s s u r e f o r fluid p r e s s u r e ( F i g . 17).

The front a n d rear

clutches, kickdown

servo, a n d

l o w - r e v e r s e s e r v o m a y b e tested b y a p p l y i n g a i r p r e s s u r e to t h e i r r e s p e c t i v e p a s s a g e a f t e r v a l v e b o d y a s s e m b l y h a s b e e n r e m o v e d . T o m a k e a i r p r e s s u r e tests,

p r o c e e d a s follows:

C A U T I O N : Compressed air supply must be free of all

dirt or moisture. Use a pressure of 30 to 100 psi.

SB

Front

NN72A

Fig. 15—Lira© iprcssswr® Adjustment

therefore,

the adjustment

Clutch

A p p l y a i r p r e s s u r e to f r o n t c l u t c h " a p p l y " p a s s a g e

a n d l i s t e n f o r a d u l l " t h u d " w h i c h i n d i c a t e s that r e a r

should be measured if a

clutch i s operating. Hold a i r pressure on for a f e w

seconds a n d inspect system for excessive oil leaks.

m a l f u n c t i o n i s evident.

(1) Remove v a l v e body a s s e m b l y f r o m t r a n s m i s s i o n

Rear

to p e r f o r m a d j u s t m e n t .

(2) Loosen throttle l e v e r stop s c r e w l o c k n u t a n d

b a c k off a p p r o x i m a t e l y five t u r n s ( F i g . 16).

Clutch

A p p l y a i r p r e s s u r e to r e a r c l u t c h " a p p l y " p a s s a g e

a n d l i s t e n f o r a d u l l " t h u d " w h i c h i n d i c a t e s that r e a r

(3) I n s e r t gauge p i n of T o o l C-3763 b e t w e e n t h e

throttle l e v e r c a m a n d k i c k d o w n v a l v e .

clutch is operating. Also check f o r excessive oil leaks.

If a dull " t h u d " cannot be heard in clutches, place

(4) B y p u s h i n g i n o n t h e tool, c o m p r e s s k i c k d o w n

finger tips on clutch housing and again apply air

v a l v e against i t s s p r i n g so throttle v a l v e i s c o m p l e t e l y

pressure. Movement of piston can be felt as clutch is

bottomed i n s i d e t h e v a l v e body.

applied.

(5) A s f o r c e i s b e i n g e x e r t e d to c o m p r e s s s p r i n g ,

tighten throttle l e v e r stop s c r e w finger tight against

throttle l e v e r t a n g w i t h t h r o t t l e l e v e r c a m t o u c h i n g

Kickdown

Servo

D i r e c t a i r p r e s s u r e into f r o n t s e r v o " a p p l y "

pas-

the tool a n d t h e throttle v a l v e bottomed. Be sure ad-

sage. O p e r a t i o n of s e r v o i s i n d i c a t e d b y a t i g h t e n i n g

justment is made with spring fully compressed and

of t h e f r o n t b a n d . S p r i n g t e n s i o n o n s e r v o

valve bottomed in the valve body.

should release the band.

(6) R e m o v e tool a n d t i g h t e n stop s c r e w l o c k n u t

L IN E PRESSURE T O A C C U M U L A T O R ^ ^ ^ ,

F

R

?

N

T

S

E

R

piston

^ °

securely.

FRONT SERVO

AIR P R E S S U R E T E S T S

A

" N O D R I V E " condition

RELEASE

•

might exist even with

| PUMP

< AUCTION

:f-1-

/ ^ T O O L

.

PUMP

KICKDOWN

\

PRESSURE

I'

- VALVE

FRONT

CLUTCH

' APPLY

*

PEAR

J

APPLY

LOCK

NUT

' J TO

CLUTCH

TORQUE

•••••

CONVERTER

THROTTLE

LEVER

FROM

STOP

SCREW

NN73A

£'%

0

ITftreffffi/© \Pv®mure Adjustment

TORQUE

CONVERTER

ND8A

W

T O COOLER -><

Fig. 17—Air Pressure

Tests

21-26

.A

TRANSMISSION—TORQUEFLITE

Low and Reverse

Servo

D i r e c t a i r p r e s s u r e into s e r v o " a p p l y " passage.

O p e r a t i o n of s e r v o i s i n d i c a t e d b y a t i g h t e n i n g of t h e

r e a r b a n d . S p r i n g t e n s i o n o n s e r v o piston s h o u l d r e lease the band.

I f c l u t c h e s a n d s e r v o s operate p r o p e r l y ; no u p s h i f t

or e r r a t i c shift c o n d i t i o n s i n d i c a t e that m a l f u n c t i o n

e x i s t s i n the v a l v e body.

SPEEDOMETER

• RETAINER

RING

PINION

BOLT A N D

WASHER

NN362

PINION

Removal

and

Installation

R e a r a x l e g e a r ratio a n d t i r e size d e t e r m i n e s p i n i o n

g e a r size r e q u i r e m e n t s . R e f e r to ' S p e e d o m e t e r P i n i o n

C h a r t ' i n Specifications f o r p i n i o n u s a g e .

(1) R e m o v e bolt a n d r e t a i n e r s e c u r i n g s p e e d o m e t e r

p i n i o n a d a p t e r i n t h e e x t e n s i o n h o u s i n g ( F i g . 18).

(2) W i t h c a b l e h o u s i n g c o n n e c t e d , c a r e f u l l y w o r k

a d a p t e r a n d p i n i o n out of t h e e x t e n s i o n h o u s i n g .

(3) I f t r a n s m i s s i o n fluid i s f o u n d i n c a b l e h o u s i n g ,

r e p l a c e s e a l i n t h e a d a p t e r ( F i g . 19). S t a r t s e a l a n d

r e t a i n e r r i n g i n t h e a d a p t e r , t h e n p u s h t h e m into

a d a p t e r w i t h T o o l C-4004 u n t i l tool bottoms ( F i g .

20).

C A U T I O N : Before installing pinion and adapter assembly make sure adapter flange and its mating area

on extension housing are perfectly clean. Dirt or sand

will cause mis-alignment resulting in speedometer

pinion gear noise.

(4) N o t e n u m b e r of g e a r teeth a n d i n s t a l l s p e e d o m e t e r p i n i o n g e a r into a d a p t e r ( F i g . 19).

(5) R o t a t e t h e s p e e d o m e t e r p i n i o n gear a n d a d a p t e r

a s s e m b l y so t h a t the n u m b e r on t h e adapter, c o r r e s p o n d i n g to t h e n u m b e r of t e e t h on the gear, i s i n t h e

6 o'clock position as t h e a s s e m b l y i s i n s t a l l e d ( F i g . 18).

(6) I n s t a l l r e t a i n e r a n d bolt, w i t h r e t a i n e r tangs i n

a d a p t e r positioning slots. T a p adapter firmly into t h e

e x t e n s i o n h o u s i n g a n d tighten r e t a i n e r bolt to 100

inch-pounds.

ADAPTER

OIL SEAL

RETAINER

RING

Fig. 19—Speedometer

y o k e out of

CAUTION:

surface on

installation

Drive

transmission extension housing.

Be careful not to scratch or nick ground

sliding spline yoke during removal and

of the shaft assembly.

(2) R e m o v e t h e e x t e n s i o n h o u s i n g y o k e s e a l ( F i g .

21) w i t h T o o l C-3985.

(3) T o i n s t a l l a n e w s e a l , position s e a l i n o p e n i n g of

e x t e n s i o n h o u s i n g a n d d r i v e it into h o u s i n g w i t h T o o l

C-3972 ( F i g . 22).

(4) C a r e f u l l y guide f r o n t u n i v e r s a l j o i n t y o k e into