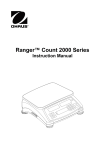

Download Trooper® Scale & Trooper® Count Scale

Transcript