Download Electric Fryers

Transcript

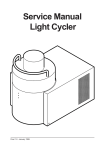

f/ 3 Service Manual Installation Instructions Operating Instructions Warranty Policy & Procedures for Electric Fryers Model EF-30 American Wyott Foodservice Equipment Co. P.O. Box 1829 Cheyenne, WY 82003 (307) 634-5001 FAX: (307) 637-8071 \ T 'd 1 ) TZbLSEL0TZT:Ol T L 0 3 L E 9 L0E llOAM MdU:WO?IJ T b : L 0 EQBZ-SO-Bnkj Description ...............................................................................2 Installation Thermostat Callbratlon ............................................................ :................. 2 .............................................................................. 3 .............................................................................. 4 Maintenance ......................................................................... Cleaning ................................ . . . ...................................... 7 P Supply Connection 5-7 .......................................................................... 8-9 Troubleshooting Gulde ............................................................................10 Suggested Temperatures & Tlmes...........................................................1 1 Servlce ....................................................... ............... 12 Replacement Parts * . . ... General Information I1 General Installation 1. Atways clean equipment thoroughly before first use. (See general cleaning instructions.) 2. Check rating label for your model designation 8 electrical rating. 3. For best results, use stainless steel countertops. 4. Attach legs to units. General Operation Instructions 1. All foodservice equipment should be operated by trained personnel. 2. Do not allow your customers to come in contact with any surface labeled 'CAUTION HOT'. 3. Where applicable, never pbur cold water into dly heated units. 4. Where applicable, do not cook, warm o i hold food directly in liner pans (well) pans. Always use steamtable pandinsets. etc. 5. NEVER hold food below 140°F. General Cleaning Instructions 1. NEVER clean any electrical unit by immersing it in water. Tum unit off and allow it to cool down before surface cleaning. 2. Always clean equipment thoroughly before first use. Clean unit daily. Except where noted on charts: Use warm, soapy water. Mild cleansers 8 PLASTIC scouring pads may be used lo remove baked-on food and water scale on metal units. 3. Unplug electrical units before cleaning or sewicing. All service should be performed by an American Wyott authorized service agency. General Troubleshooting Always ask 8 check: 1. Is the unit connected to a live power source. 2. Check circuit breaker. 3. Is power switch on & pilot light glowing? 4. Check rating label. Are you operating unit on proper voltage? If the above checks out and you still have problems, call an American Wyoti authorized service agency (page 14-27). E'd T2PLSEL0T2T :01 TL03 LE9 LOE llOAM NdU:WOW TP:LB E002-SO-9llU DESCRIPTION 1 INSTALLATION & SUPPLY CONNECTION installation 1. Follow General lnslallation lnslructions on Page 1. ELECTRIC FRYERS These elecliic units are designed for countertop operation. They are used for producing eventy cooked, perfectty fried products. Screw legs into the errnanentb fastened nuts on'the four comers f the unit and tighten by hand. Level the fryer by turning the adjustment screw at the bottom of each leg. Do not slide unit with legs mounted, lift if necessary to move unit. 1 I Supply Connection I. All units are provided with two terminal bbcks for field wire connections on the rear of the unit. The hrge lecminal block (marked X-Y-2) is for power suppty connections. The smaller auxiliary terminal bbck (marked 1.2-3)b for connection to a fire protection circuit, or a danger swi(ch. All units are ptwded with two knockouts: a 3 4 . conduit size for power supply and a tn' conduit size for auxiliary terrninal block wires. Both knockouts are located on the rear leg ch,annel and are accessible by removing the rear panel. 1 2. 1 I Remve rear panel. Mount suitable 3 4 ' wnduit fiiing.in power suppty knockout. The kncclout hole for I& conduit f i i n g is covered with a cbsure plug. Remove this dug and mount a in' wnduit fining for connections to auxiliary terminal block. Caution: Do not remove closure plug m e r i n g in' size bockout opening if connedions to a fire protectioncirwit are not required. Rerrmal of the cbsure plug under this condition may result in a shock hazard. 3. Connect field wire to the power terminal block as indicatedan wiring diagram. Wire must be of the type suitable for 90°C sewice and of thickness as indicated on marking on rear panel. T2PLSELB12T:Ol TL03 LE9 LBE ELECTRIC FRYERS SUPPLY CONNECTION Field wire connections to auxiliary t e t m i ~bkck l must be of sue indicated on marking on rear panel and sulable for 90°C service. Lead wires to the auxiliary terminal block must be connected per instmclions on the wiring diagram located on rear panel; depending on whether the fire protection circuit has a Normally Open (N.O.) or a Normalb Closed (N.C.) switch. * The auxiliary terminal block wiring must not be changed if connections to a fire protection system are not made. The fryer is factory assembled for operating without connedions to a fire protection system. For testing, the rated amperages are listed below: 3 phase 240V 208V X I Y 29 50 I I z 29 x I Y z 25 44 25 I I NOTE: These values are nominal ratings. Field wire connections must be capable of withstanding anticipated surges. Replace rear panel. Ensure that equipment is grounded by installing a grounding lead to ground lug b l e d near the terminal bkck. CAUTION: Installing personnel should be guided by National ElectricalCode NFPA No. 70.1978, and applicable local codes. THERMOSTAT CALIBRATION Checking Thermostat Calibration The fryer themostat is carefully calibrated at the factory so that dial settings match actual frying compound temperatures. Feld recalibration is seldom necessary unless the unit has been mishandled in lransl or abused. Recalibration should not be resorted to unless wnsidergble experience with amking resuns definitety proves that the control is not maintaining the temperature to which the dial is set. 1. To check frying compound temperatures when recalibrating, use a precision test instrument, or a good grade mercury thenometer. Fill fry tank wilh frying compound to 'FULL' mark. 2. Flying compound temperature should b e checked at the center of the tank, approximatety 1' to 1112' below surface of frying compound. 3. Turn the dial of the themstat being checked to the 350'F mark. 4. Allow temperature to stabilize, or until the thermostat cycles to 'OFF' three times after starting with cokl frying oonpound. With power 'ON'. read highest and lowest frying compound temperatures, as themstat cycles through at least two cycles. Average the reading. 5. Thermostat s k u l d be recalibrated if temperature reading is not wlhin 10 degrees of the control knob selling (350'F 4- 1O0F).If recalibration is required, continue wfih steps 6.7.8 and 9. 6. Remove control knob by grasping outer edgeand pulling straight oul, wilhoul twisting or turning. 7.Hokl thermostat dial shaft 'B' (figura I ) stationary with pliers, and with a screwdriver, turn screw 'A' clockwise to obtain a bwer temperature: or counterclockwise for higher temperature. Each 114 turn (90° rotation) of screw 'A' represents 18'F. 8. Replace thermostat control knob 9. Recheck thermostat as in steps 4 and 5 above. If the fat temperature is not within 20 degrees of dial setting (350°F +20°F), I- it means that the sensing element is inoperative and the themstatic control should be replaced. 12bLSZLBTZI:Ol TLB3 LE9 LBE ELECTRIC FRYERS MAINTENANCE ,- -&- I I'" I L--- I flgure I 1 Removing Fly Tanks a. Remove fry baskets. b. Carefully grasp the black handle. CAUTION: may be hot, on the end post on top rear corner of the fryer with the !,:ft hand, a i d the element 11fl handle resting on fry tank front. with right hand. c. Lift the element handle while at the same time, pulling the pbstw: handle. This will permit lifting the elements to just above frying compound level in tank. The element can be left in ths position for draining frying compund. d. Again. lift the element handle wt~ilepulling the plastic handle, until the elements lock themsetves at a higher position. e. Firmty grasp both handles of fry tank and lifl it oul. f. After replacing the fry tank, simpty pull the plastic handle; and at the samelime, pull down the element handle until the elements rest on fry tank bottom. g. Both the lifting our and bwering of elements can be done in one swing, without Sopping at the intermediate position. L* Filling Fry Tank . . 1. Ensure circuit breaker is at the 'ON' position. This is done by pressing the 'RESET or 'ON'part of the red rocker handle on the front panel. 2. Set the thermostat to 'OFF' and push in the red swilch marked 'ON-OFF' to turn unit on. Red indicating light on the switch will come on. Turn the thermostat knob to the 300" mark and a yellow cycling light marked 'HEAT ON' will come on. Push the red swlch to turn it 'OFF'. The fryer control circuit has now been check and the fryer is ready for use. Caution: Do no1 leave elements on without frying compound in the tank. I a. Fill the fry lank to the 'FULL' rrork with approximately 30 lbs. of liquid or melted frying compound. Do not overfill. MAINTENANCE NOTE: Do not use solid frying compound unless the fryer is equipped with a mett cycle option. Air holes caused when packing solid frying compound into the fryer can cause hot spots on the heating element sheath, resuling in momentary ovemeatingof some of the frying campound and premature frying compound breakdown. It can also damage the heating elements. If it is necessary to use solid frying compound, it must be melled before &ding to fry tank. Turn the thermostat to the desired frying temperature and push in the red 'ONOFF' switch to 'ON'. The yellow 'HUT ON' l~ghtwill stay on until the temperature set on the thermostat is rea:hed, then the light cycles off. The fryer is now ready to begin frying. Afler a load has been fried, do not lower the next load into the frying compound until the 'HEAT ON' light cycles off. b. Do not allow frying compound level to drop more than 112' below the 'FULL' mark. For proper operation of ltik fryer and go+ frying results, the frying compound level should be maintained. c. Use a quality frying compound. d. Filter the frying compound frequently, at least once a day. e. Skim out food particles frequently with the strainerlskimmer. I - 1. Add at least 15% (of fry tank capacity) of fresh frying compound daily more if possible without overloadina the tank. If 15% ot the frvina - compound is not - ? bsed during hying, remove &me of the frying campound for other use (gravy. griddle frying, etc.) to permit adding fresh frying compound. g. Do not werkad the fry baskets. Approximately half-full or even less is correct. If foods are taking longer 10 fry than lhe chart shows. or are n d browning. over- kxding is a probable cause. h. Prepare the food property: i. Keep sah out of the frying wmpaund. Do not salt foods with the basket above the kettle. j. Assure a good thermostat operation. k. Keep the fry tank and elements clean. ELECTRIC FRYERS - MAINTENANCE & C L E A ~ ~ , @ G 2. If the fryer is equipped with the 'Automatic Melt Cycle' -lion, the fry tank can be filled with solid frying compound. The men cycle can also be used to melt frying compound which has solidified since its last usage. To operate the melt cycle, push the whiie switch marked 'MELT ON' to 'ON'. The fryer may be lefl unattendedlduringthe melt*cle operation. It takes approximately 18 minutes to melt 30 lbs. of solid frying compound. After the solid frying compound has metted, push the mett cycle switch to 'OFF'. The fryer will then heat the frying compound to the temperature set on the thermostat. Cleaning I . Follow General Cleaning lnstructlons on Page 1. a. Before the first time use, clean the protective oil from the bright pans and interior of tank with a solmion of washing soda or other grease dissolving rnateriial. 2. The frequency of cleaning shoukl depend on the load conditions. Set a definite cleaning schedule corresponding to how hard the kettle is used. Cleaning should be done at least once a week. a. Turn the thermostat to '0kl and allow unit to cool down. b. L i the elements to drain position. Wire brush or scrape elements to remove any solids adhering to the elements. c. Raise the elements. Lift out fry tank. Strain the frying compound into a clean container. d. Replace empty fry tank. .lower elements to rest inside the tank. e. Add water to the 'FULL' rnbrk on tank. Add any good gradeof cleaner, following cleaner instructions. f. Turn the thermostat to 250°F and let the heating unil bring the solution to a g. bil. h. billong enough to bosen or dissolve all varnish or carbon deposits. approximatety 30 minutes. i. Turn the un2 off and lift out the elements to drain position. If necessary, clean the thermostat bulbs using a long-handledfiber or j. plastic brush and mild soap solution. k. Rinse with clean water to remove all cleaning mixture. I. Lifi owthe fry tank and drain. Repeat steps j and k with fry tank. m. Rinse the inside of the tank wilh 2 cups of vinegar. n. Rinse with clean water until the vinegar odor is gone. The fry tank must be thoroughty rinsed, since even a trace of cleaner left inside the tank will ruin frying compound. o. Dly thoroughby. Replace the tank and lower the elements. p. Shut the unit off and cover tank until ready for further use. q. Thin tilms of oil subjected to frying temperatures quickly form into a gummy consistency. In order to avoid these gum formations. keep all other surfaces of the unit clean by polishing stainless steel surfaces wilh a damp cloth. To remove discolorations or oil film, a non-abmsive cleaner may be used. 7 3 T ~ 'd 6 TZbLSTLBT2T:Ol TL03 L69 LBE I I n l v t c n l b m l v vv I uI I SERVICE Service I . Cautlon: a. Before servicing the unit, d k e certain the fry tank frying compound and elements are cool enougkto avoid bums. A b. Before opening corrgonent aacess panels, ensure the eledrical power supply cord to main terminal bbck and power supply to the auxiliary terminal block BOTH have been disconnected. 2. To replace red 'ON-OFF switch, yellow cycling light or circuit breaker, while 'MELT ON' switch and melt cycle control assembly for melt cycle option: a. Remove the thermostat control knob by grasping outer edge and pulling straight out. without twisting a turning. b. Remove two screws at top of front panel. Pull top edge to open. c. Disconnect leads to switch, light or circuit breaker and remove the damaged mrmnent. Mark dixonneded leads to .dentiry them. t new circuit breader (or r e H cycle oohtrol) with fasteners prod. ~ o u hthe vided. The new switch or ligv is snapded into place from the front of the panel. e. Connect leads to corresponding terminals on new component. Check completed circuit against circllit digram on rear panel. Reverse steps a and b to close front panel. f. 3. To replace magnetic contactor, terminal bbck, ground lug or auxiliary terminal a. b. c. d. e. block: Remove four screws securing the rear panel to the unit. Let the rear panel fall down straight before pulling it out. Disconnect leads l o the damaged component. Connect the leads lo cofreqmding terminel on the new component. Remove screws securing thedamaged component to the mounting panel. Remove the damaged compnent and install a new compnent, in the same position. Check completed circuil against circuit diagram on rear panel. Mount the rear panel and put unit in operation. 1. g. 4. To replace blown fuses or fuse block: a. Open rear panel as i n step h above. b. Remove damaged fuses and replace with 40 ampere one-time fuse. c. To replace fuse block, remove fuse and disconnect wire leads to the damaged fuse block. Mark disconnected leads to identfy them. d. Replace new fuse block in the same position. e. Conned leads to correspondmg terminal on new fuse block. Check completed circuit against circuit diagram on rear panel. 31,137 'd i2bLSTL0i2l:Dl l L 0 3 LC9 LQE ELECTRIC FRYERS SERVICE hi 5. To replace element: a. b c. d. e. 1. g. Remove screws securing pwotal head cover to pivotal head. Remove pivotal head cover and gasket. Lifi up the elements to drain position. Remove thermostat bulb and capillary tube elamps. Remove element supporl assembty. Disconnect leads to element and mark them for identifiication. Remove the element retaining nuts inside the pivotal head. Remove element. Mount the new element and reverse steps a through f to reassemble. 6. To replace hi-limit thermostat: I a. Remove pivotal head cover and gasket as in step 5a. b. Remove hi-limit themrostaiibulb and capillary tube clamps from element. c. Dislodge capillary bushing fmm hole in pivotal head. d. Remove bushing and thread the thermostat cepillary and bulb through hole in pivotal head. e. Disconnect leads to the da%magedhi-ljmrt thermostat and transfer them to comespondmg leads on the new thermostat. 1. Remove screws securing the thermostat. Secure new hi-limit thermostat with screws and reverse steps a through d to g. reassemble. 7. To replace cycling thermostat: a. Remove front panel (steps2a and 2b), rear panel (step 3a), pivotal head cover, and gasket (step 5a). b. Remove cover on back of i n d post, located on right rearcomer of the unit. Remove thermostat capillary and bulb from the pivotal head as in steps 6b c. through 6d. d. Disconnect nuts securing the thermostat coil to end post and to pivotal head. Both are accessible from rear of end post. e. Oixonnect leads to the damaged thermostat and mark them for identification. f. Remove screws securing the thermostat to front panel. g. Manewer the thermostat to rear of the unit (through right side passage) and then into the right side end post (through opening on top panel). h. Remove t h e m s t a t abng with bulb and capillary from the opening on back of right side end post. W~ndthe t h e m s t a t coil (Supplied with new thermosat) around the capillary I. of new thermostat. at approximately the same position from bulb as on the damaged thermostat. Note: The t h e m s t a t coil should cover approximtely 'I1' to 12' of capillary length. Wrap the portion of thermostat capillary which is covered by the therrnostat j. mil, into approximately two turns of 1re' to 2' diameter. k. Reassemble the themasat by reversing steps 7a through 7h. RUG-05-2003 07:44 FR0m:RPW WYOTT High rmislure m e n l ir, f a d belly friod lnadequale frying corrpound 1lClDVer Conlamirutim d frjirg ~ ~ m p o u (duo r d b sin a dher la%* nra1ori;lI) Frying in foem Faoj bed o*cr being fried may qualiv mm exbust slack Pox q w l i y d lryinp, cPrrpolud-eirherinto1 a ahar wrm6sive uae Cxking lime too h n lrakquate filleting d IyinQrsmvwndioxccsrjve cmmhr in Iq lank Kmping lood in fyitq mmpouod ahar cmkng l ~ d o q m r cle~ning s dfy lank AMERICAN W O l T SUGGESTED TEMPERATURES & TIMES 1 I IFahrenheit) Tlme In Minutes 350 2.3 Control Setting Frenchtoast 1 . .... Gi; ited, 5...s;o'.?., . :.,,,I . bench.fried,san&qj&es. :.;. ;,., $ ': - : . . . 0 ... :... : ~ ~ , l :.',~ , 2 ' . . I NO. 1 Z 3 6 5 G 7 8 10 11 12 13 I1 15 16 17 19 20 22 23 24 25 26 27 28 29 31 32 33 36 35 36 37 38 39 10 41 42. 43 46 46 47 48 49 50 51 52 54 55 58 59 60 61 DESCRIPTION A TANK WELDHENT PIVOT HEAD UELD. FRONT PANEL ASSY TOP SUPPORT ASSY. SIDE P m E L WELD. LEG PAD UELDNENT POST THEM END POST LOCKING END TOP CROSS ANGLE FRONT 6 REAR CHAN. PANEL, REAR PANEL, TOP LINER WELD'T KNOB GUARD n/s 8-32 x 318 TRHD BOTTOH COVER PIVOTAL HEAD COVER END POST BACK COVER FLEHENT SUPPORT ELEMENT CLAMP BAR CONTCTR MTG PANEL ELEMENT LIPT HANDLE PLUNGER BODY PLUNGER PLUG WIRE PROTECTION STRP SPRING, PLUNGER GASKET, PIVOTAL HD GASUT. END POST BASKET. L.A. PRY BASKET R.H. PRY KNOB, CONTROL KNOB. PULL GBOWT PLUG. 718" VENT C U n P . THERnO, BULB HOLEPLUG, KNOB INDEX C U P , TUBE M/S PN HD 6-32 X 116" S. S H/S 6-23 X 3/8" nls IR HD 1 0 4 x 318" S.S. I1.H.C.S. 10-24 X 112" S.S. HEX NUT 6-32 srs LEGS NUT, 5/8"-18 ELASTIC STOP PLAT WASHER, 1 / 4 " POP RIVET 1/8" X 118" S.S. MARKER. SUPPLY MILKER, DlSCONNECI LABEL, GROUND WRNG LABEL, RESET W I R I N G DIAGRAM LABEL 1NO. 62 66 67 1 QTY 1 2 1 68 1 63 70 71 72 7 2n 7 1 1 2 2 73 1 74 75 76 77 78 79 80 83 1 2 84 86 87 88 89 90 2 4 1 1 2 6 23 2 15 1 1 91 I 2 92 95 2 1 96 1 2 97 ( DESCRIPTION LABEL, FUSE WARNING CONTACTOR, MAGNETIC BLOCK, TERHINAL BLOCK, WIRE CONNECTOR SUIZCH, LIGHTED PIB SUITCH. HIGH LIHIT ELEEENT, 6OOOU 208V ELEHENT, 2 4 0 V THERHOSTAT SPRING, THERMOSTAT WIRE T I E S FUSE BLOCK FUSE CIRCUIT BREAK!iK INDICATOR LIGHT, AMBER NUT "u" # I 0 ZN $10 X 3/8" SHT HET SCREW 110-24 HEX .lCP S.S. TINNERHAN NUT H/S PN HD 8-32 X 112 S I S LABEL, CONNECTION SOIJDERLESS LUG CAP BULB CLAMP MIS 8-32 x 1 S / S RD NUT 8-32 HEX MET LOCK GRAPHICS APCIIWOTT INSULATION RIVET POP 1/8" X 15/64'' S / S IERHINAL L RUG-05-2003 07:47 FR0M:RPW WYUTT GAS PARTS LIST PART # DESCRIPTION 3525-03-56 PILOT TUBE COMPLETE WITH TIP 4 N D SCREW 3527-02 BURNER TUBE WITH ELBOW 3503 BRASS PILOT TIP 3532 BURNER COMPI FTE WITH CAP -NATURAL GAS, 1000 BTU 3533 BURNER COMPLETE WITH C.4P - PROPANE GAS, 2500 BTU 3530 RI JRNER CONTROL VALVE 3505 PILOT CONTROL VALVE 3511 BURNER CONTROL KNOB 3501 GAS PRESSURE REGULATOR FOR NATIJR4L GAS 3553 GAS PRESSURE KEGULATOR FOR PROPANE GAS 3507 MINI PILOT (THERMOCOUPLE) 3508 SAFETY PILOT VALVE 3507-08 SAFETY PILOT FOR INDIVIDUAL SECTION 2701-9214 RADIATION OR HEAT DISTRIBUTION PLATE 3570 BRASS ORIFICE 1/2" AUXILIARY TE-1 BLOW FG+I FIREPROTEC~CN SYSTEM CONTACTO(I CIRCUIT BRK. REGULATING l . I. -L . ,m. I a D c b Comrtlsn .. ~han bloc. c-Usumfi. m v s a weaam@kdesd L UrC.,dW(ulY).C.cQ3v..ila r w h ~ 1 . w Pat-w.. Car* c.ol I*.