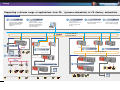

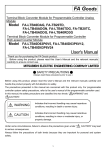

Download MELSEC Process Control/Redundant System

Transcript