Download SL430 Series

Transcript

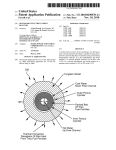

SL430 Series LED Minor Surgery Lights User Manual & Installation Guide QAM.SL430.1015.5 Page 1 of 42 Table of Contents 1. Introduction ........................................................................................... 3 1.1 Supported Lights ................................................................................ 3 1.2 Lighting Specification .......................................................................... 4 1.3 Pre-Installation Responsibilities and component packing list ............................ 4 2. Operation.............................................................................................. 5 2.1 Range of Motion ................................................................................. 5 2.2 Pre-Start Checks ................................................................................ 6 2.3 Powering On & Variable Intensity ............................................................ 6 2.4 Using the Removable Handle .................................................................. 7 3. Assembly Guide Section ............................................................................. 8 3.1 Ceiling Mounted SL430 ......................................................................... 9 3.1.1 Attachment methods and void suspension .......................................... 10 3.1.2 Installing the Ceiling plate............................................................. 11 3.1.3 Wiring and transformer layout ........................................................ 13 3.1.4 Primary rotation arm installation ..................................................... 14 3.1.5 Suspension arm Installation ........................................................... 15 3.1.6 Lighthead Installation .................................................................. 16 3.1.7 Attaching the Ceiling Cover ........................................................... 18 3.2 Mobile Mounted SL430 ........................................................................ 19 3.3 Wall Mounted SL430 .......................................................................... 27 3.3.1 Installing the wall plate ................................................................ 28 3.3.2 Wiring and transformer layout ........................................................ 29 3.3.3 Primary rotation arm installation ..................................................... 30 3.3.4 Suspension arm Installation ........................................................... 31 3.3.5 Lighthead Installation .................................................................. 32 3.3.6 Attaching the Wall Mount Cover ...................................................... 33 4. Maintenance ........................................................................................ 34 4.1 Maintenance schedule ........................................................................ 34 4.2 Safety Precautions ............................................................................ 34 4.3 Cleaning ........................................................................................ 35 4.4 Fuses and their replacement ................................................................ 35 4.5 Adjustments.................................................................................... 36 4.5.1 Wall / Ceiling Mounted Adjustments .................................................... 36 4.5.1.1 Rotation Arm .......................................................................... 36 4.5.1.2 Suspension Arm ....................................................................... 36 4.5.1.3 Lighthead .............................................................................. 37 4.5.2 Mobile Mounted Adjustments ............................................................. 38 4.5.2.1 Suspension arm........................................................................ 38 4.5.2.2 Lighthead Arm ......................................................................... 38 4.5.2.3 Lighthead .............................................................................. 39 4.5.3 Detaching Parts ............................................................................. 39 5. Troubleshooting Guide ............................................................................ 40 6. Warranty Information ............................................................................. 41 6.1 Returns Policy ................................................................................. 41 6.2 Warranty Details .............................................................................. 42 Page 2 of 42 1. Introduction Thank you for choosing a Daray SL430 Series minor surgery light. The SL430 Series of lights are specifically designed to meet the demanding needs of today’s medical department whilst providing the finest quality design with superior performance, reliability and value. This manual has been provided to give detailed descriptions covering the performance, operation and safety information of the device. It’s recommended that users read through this manual before using the device so they are aware of how to operate the device and all of its features appropriately. This user & installation guide contains all the information you need for installation, operation and maintenance of the light. Restrictions and Liabilities Information in this document is subject to change and does not represent a commitment by DARAY. Changes made to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by DARAY for the use or reliability of software or equipment that is not supplied by DARAY For further information on our product range and find out more about our company please visit www.daray.co.uk or call 0333 321 0971 This product was designed & manufactured in Great Britain by: Daray Ltd. Marquis Drive, Moira Swadlincote Derbyshire DE12 6EJ 1.1 Supported Lights The Following Models are supported in this Manual SL430LM Mobile Mounted SL430 Minor surgery Light SL430LC Ceiling Mounted SL430LW Wall Mounted Page 3 of 42 1.2 Lighting Specification Light Specifications Light intensity @ 0.75m 88,000 lux ± 5% Light intensity @ 1m 72,000 lux ± 5% Colour Temperature 4,000K Colour Rendering Index (CRI) Up to 95 Colour Rendering (R9) 90 Electrical Draw 13.5W 0.115 Amps Light Field Diameter (d50) 200mm Depth of Illumination 800mm Light Intensity Adjustment Range 9 Stages (10% - 100%) Temperature Rise on Surgeon ≤2°C Average working life Input Rating >50,000 Hours 230V 50Hz This equipment cannot be used where there is an air mixture of flammable anaesthetic gas and air or oxygen and nitrous oxide Transportation condition: environment temperature -40~+55°C, relative humidity: ≤93% atmosphere: 500~1060hpa 1.3 Pre-Installation Responsibilities and component packing list This document is a guide to the steps that need to be performed to correctly install the SL430 Minor surgery light. However, the work required to be performed is the responsibility of the owner or designated contractor/s. All fixings between Daray lights and the building super-structure must be approved by either the chief project engineer or an appropriate and competent structural assessor. The components supplied by Daray for fitting / installation should be the following items in the specified quantities. SL430 Mobile Mounted Pack List Lighthead Qty Mobile base with 5 wheels (2 lockable) vertical tubing Weighted securing joint (3 parts) Upper suspension Arm Power Supply Box Manual 1 1 1 1 1 1 1 SL430 Ceiling Mounted Pack List Lighthead & suspension arm Ceiling plate (+downtube) Rotation arm Ceiling Mount Cover Qty Qty 1 SL430 Wall Mounted Pack list Lighthead & suspension arm Wall plate 1 1 Rotation arm Wall Mount Cover 1 1 Manual 1 Manual 1 1 1 1 Page 4 of 42 2. Operation 2.1 Range of Motion The range of motion between the SL430 series varies. This is an image depicting the range of motion on a standard mobile mount version. Suspension Arm Lighthead Control Panel Weighted securing joint Vertical Tubing Mobile Base Page 5 of 42 2.2 Pre-Start Checks Please check (when using the mobile version) that the power cable is without visible damage, harsh folds, knots or cuts in the rubberised coating. Users should not look directly into the light as it is bright and will illuminate when powering on. If you are using a mobile version; check that the cable is fully connected to the device and that the plug is fully inserted into the power socket, when switching the power on. Please check (when applicable) that the head and arms are without visible damage, and all LED’s are present in the head. 2.3 Powering On & Variable Intensity The SL430 Series uses a single button (on the side of the head) to power the light on and off. Next to this switch are 2 controls for the lights variable intensity; The Intensity has 9 levels that you can switch between. The stage you are currently on is displayed on the small screen as pictured below. Press the up button to change the light intensity up and the down button to reduce it. Page 6 of 42 2.4 Using the Removable Handle The SL430 also has a removable handle for easy cleaning. Simply push the metal button at the top of the handle to remove the handle. To place the handle you should push the handle back on to the metal spigot and ensure the button clicks in place to lock it Push Button to remove the handle Page 7 of 42 3. Assembly Guide Section Page 8 of 42 3.1 Ceiling Mounted SL430 The ceiling structure must be capable of handling up to a 500kg load. The procedures below are detailed to a high level however If in doubt please consult a qualified electrician. Minimum Room Requirements Maximum Room Requirements Live Electric Circuitry The SL430 Series ceiling mounted light has a standard fixing height of 2.35m. The design works off a fixed plate system and has a large vertical motion. Please note, if the fixing point for your light is above 2.5m then a bespoke solution may be required. If you have a suspended ceiling then you will need to construct a mounting platform to bring the light down to the required height. For open ceiling / bespoke solutions please contact daray for more information. All personnel working around live circuitry should be qualified and following proper procedures Heavy or Difficult fittings Fitting the ceiling plate can be difficult and aspects of the fitting may require more than one person; this work should only be attempted by appropriate and competent personnel. Existing Environmental Factors When fitting, considerations have to be taken for existing services such as; fire alarms, vents, lights, etc. along with interior ceiling construction and any surrounding hazard. Page 9 of 42 These instructions are based on the assumption of a fresh fit into a room with no previous lighting structures. With installations onto sites with equipment already in place, we recommend that the previous lights’ mounting plates be removed and the new ones fitted as if into a fresh fitting. After concluding the structural stability of the ceiling structure it will be necessary to assess the construct and decide on the best course of action for installing the ceiling plate. There are various different methods for loading the plate onto the ceiling, below are various example methods that can be used. 3.1.1 Attachment methods and void suspension The ceiling mount is split into 2 parts, the fixing plate and the ceiling plate. Please note, the recommended room height allowed for fixing requires the bottom of the ceiling plate to be no lower than 2.4m. Bolted Directly into a structural slab and secured with chemical bonding This is our primary choice for mounting our lights to the ceiling structure, appropriate rawl bolts and chemical bonding should be used to secure the fitting. Bolted to a Uni-strut Construct When using a uni-strut construct for mounting the ceiling plate, you should ensure that the unistrut is cross braced to ensure it is secure and does not move. Welded to structure The fixing plate is the component that would be welded to the structure; any welding must be assessed to be capable of handling a 500Kg load. System anchored to composite deck A customised composite deck could be used either in conjunction with or as a replacement to the fixing plate. Any substitute parts must meet safety standards and be assessed by a competent structural assessor. The composite deck is designed to spread the weight of the light over an enlarged area. System bolted to structure This system requires prior planning during the base construction phase of the ceiling above, bolts should be fed through the metal ceiling prior to the concrete base being poured. These bolts should be based on the fixing plate layout in section 3.5.1 Dependant on the choice of attachment method, and whether the light is being attached in a void or directly onto an open surface ceiling; custom mounting aspects may be required. Daray’s standard mounting recommendation is to have the fixing plate directly bolted into the structure of an open surface ceiling when possible. Ultimately the mounting method used is the responsibility of the project engineer or fitter. This includes the specification of attachment hardware, lateral bracing and the suitability of the surface to be fixed to. Page 10 of 42 3.1.2 Installing the Ceiling plate The location of the light should be decided by the end user / project manager or through schematical drawings. Once the location has been decided it will be necessary to first mark the location of the ceiling plate. Ceiling Superstructure Locking Nut Ceiling Plate Adjusting Nut Fixing Bolt Ceiling Plate Downtube As shown, fitting your ceiling plate requires bolts be inserted directly into the ceiling super structure. The ceiling plate can however be fitted to an optional fixing plate instead. The fixing plate would then attach to the ceiling super structure instead of the ceiling plate. Whichever fixing method used; it is highly advisable that the plate being fixed to the ceiling, is secured with a minimum of 4 bolting points to ensure a complete and sturdy fit. Once the bolts are fitted and secured, you will need to attach a locking nut to each bolt before attaching the ceiling plate. Now fit the ceiling plate by sliding the fixing points onto the bolts and attach a 2nd (adjusting) nut to the bolts. Ceiling plate Dimensions 170mm 13mm Page 11 of 42 Once the ceiling plate has been fitted, it will be necessary to ensure that it is balanced on the vertical plane. This can be achieved by adjusting the 2nd level of nuts (the adjusting nut). Once this adjustment has been done tighten the 1st level of nuts down to the ceiling plate to lock the plate into position. After any adjustment it will be necessary to check that all fixings are still sound and that locking nuts are tight. Once secure you will need to attach the downtube to the ceiling plate using the bolts provided. It is recommended that you fit the downtube with the cable hole facing the same direction as the transformer. Page 12 of 42 3.1.3 Wiring and transformer layout Before working on electrical connections please make sure that the power to the light is switched off at the source and secured so that it will not be turned on during your work. The mains power supply should meet IEC60245-1 requirements and should be fitted with a fixed master switch. (The switch should meet IEC328 requirements and the directional movement parts of the switch should meet IEC447 requirements and the symbols should meet IEC60601-1 requirements.) Ideally the cable used to power the light should be of a 1.5mm twin and earth type. Daray recommends that the power supplied uses an earthed switched fused spur, protected with a 3 amp fuse. The wiring should be as follows: Live terminal brown wire. Neutral terminal blue wire. Earth terminal green/yellow wire. The above wiring is for modern wiring applications (post 2000). On completion of the wiring, the next stage will be attaching the suspension arms to the ceiling mount. Before any cabling can be done you will need to feed the mains connection down through the 5th hole on the ceiling plate between two of the fixing points, You will also need to feed the low voltage cables from the arm system through the hole in the downtube once it is fitted. Cables need to be fed through this hole The mains connection should be wired and fused via a switched fused spur located within the room whenever possible. All other connections in the light are low voltage DC connections that will be connected using the connectors that are already fitted within the light. Page 13 of 42 3.1.4 Primary rotation arm installation The Ceiling plate will need to have its downtube system bolted to it. The downtube component is a fixed length piece which cannot be modified. If you require a customised length of downtube please contact daray. The primary rotation arm is fitted to a 360 Degree arm boss system; the arm boss is the section that is inserted into the downtube and secured in place with 2 locking screws. Before attaching the arm into the downtube; you will need to remove the 2 locking screws from their housing on the side, you should also ensure the ceiling mount is absolutely true on the vertical plane and that the bolts that attach the downtube to the ceiling plate are tight. Before inserting the primary arm to the downtube you will need to place the Ceiling Mount Cover (CMC) onto the arm boss. You will then need to attach the cables from the arm system to the cables that have been fed through the downtube. Warning, please observe the Cable Polarities and ensure that they match, incorrectly wiring the device will cause damage to the system With the cables connected you will need to pull them back up through the hole whilst inserting the arm boss. This is to prevent any accidental damage to the cables during install. Page 14 of 42 Reinsert the two locking screws to secure the primary arm to the downtube. Before progressing onto fixing any other arms, ensure that the rotation arm is attached securely. 3.1.5 Suspension arm Installation The Suspension arm uses an internal plug system which allows it to have 360 degree rotation. To install the arm you will need to first remove the screws from each side of the arm joint. Push the suspension arm’s spigot into the rotation arm and re-insert the screws that secure it. Page 15 of 42 Warning, Please observe the Cable Polarities and ensure that they match, incorrectly wiring the device will cause damage to the system 3.1.6 Lighthead Installation The lighthead has a small arm section and is the final component that needs to be attached to the arm system. For this section the connection is a mini Molex to ensure the correct polarity connection. Remove the screw from the end of the suspension arm and then, whilst ensuring the cables do not get caught, slide the head onto the suspension arm. Making sure the screw point locates in line with the drilled hole on the arm. Page 16 of 42 Once aligned, tighten the screws to lock the head onto the rest of the light. Supply power to the light and check that all the light modules are illuminated. The light can now be tested by applying power and pressing the power button on the head. Check the arm and head for smooth and correct movement. Your new Daray light is now ready for use. Page 17 of 42 3.1.7 Attaching the Ceiling Cover Once you have checked that the light works and all modules and connections are secure you will need to secure the Ceiling mount cover. With the CMC previously attached to the light during the construction and attachment of the primary rotation arm, all you now need to do is push the cover up to the ceiling plate to cover all electronics. When in place tighten the screw points located on the outside (visible side) of the cover. These are tension screw joints that will tighten the CMC onto the downtube securing it against movement. Check arm and head for smooth and correct movement. If the head is drifting, or if the movement of the arm is stiff, use a hex tool to adjust the tensions detailed in the maintenance section of this manual. To gain full support of our warranty please fill in the warranty details online at http://www.daray.co.uk/docs/warranty.php NOTE: The mains power supply should meet IEC60245-1 requirements. Page 18 of 42 3.2 Mobile Mounted SL430 The procedures below are detailed to a high level however If in doubt please consult a qualified electrician. Live Electric Circuitry All personnel working around live circuitry should be qualified and following proper procedures Environmental Responsibility Once our products are installed all packaging should be disposed of appropriately and recycled where appropriate and in accordance with local governing regulations. For the mobile assembly, the base will need to have all the wheel casters inserted in place. These are locked in by simply pushing them into the base, at the correct point they will click and lock in. Page 19 of 42 Making sure all the wheels are in place, set the base down facing up and lock the brakes of the casters: This will avoid movement during assembly. The next step is to attach the weighted securing joint to the base. Place the top half of the weighted securing joint on the top of the castor base, then whilst holding this part in place, carefully turn the entire base over onto its side. Once turned over place the second white section of the weighted securing joint into the slot at the centre of the castor base. Page 20 of 42 Turn the weight so the Large arrow points between two of the legs Once installed, the power lead for this light will trail from this lower section perpendicularly to the 2 screws on the joint shown above. To ensure the cable is in the correct location you will need to turn the lower section of the weighted securing joint so that the halfway point between the 2 screws is located between 2 of the legs of the castor base. Once aligned, insert the bolting pin through the weighted joint. You will now need to insert the vertical tubing before you can lock the weighted joint and base together. With the pin inserted in the base, carefully lift the top of the base up and insert the threaded side of the vertical tubing into the top of the weighted securing joint. Page 21 of 42 Align the vertical tubing so that the curve in the tube is above your chosen cable location. Once in place tighten the securing pin into the joint and tubing using the Hex key provided. Now that the vertical tubing and weighted securing joint are locked to the base you will need to feed the power cables from the power supply box through the base and the tubing. We recommend the use of a guide wire to feed the cables through. Page 22 of 42 With the wires successfully fed through the stand, you will need to connect the power supply box to the bottom of the base. With the base of the securing joint already aligned for the correct position of the power lead, you will need to remove the 2 screws from the bottom of the joint. Line up the holes and re-insert the screws, locking the power box in place on the bottom of the light. Warning, You must ensure that the grounding cable is threaded onto the screw when you attach the supply box, failure to ground the light could cause severe damage to users and the light. Page 23 of 42 The next stages of the light assembly are the suspension arms and lighthead. Stand up the base of the light and its vertical tubing, being careful not to lose the ends of the power cables back down the vertical tubing. Remove any guide wires that are still attached and fold the wires down over the side to stop them sliding back down the tubing. Remove the screw located at the top of the vertical tubing. Remove the suspension arm (below) from the packaging. Connect the cables from the suspension arm to the cables protruding out the top of the vertical tubing. Feed the wires inside the vertical tubing and insert this section into the suspension arms joint. Warning, Please observe the Cable Polarities and ensure that they match, incorrectly wiring the device will cause damage to the system Page 24 of 42 Re-insert the screw removed from the vertical tubing to lock the suspension arm onto the stand. Page 25 of 42 Remove the locking screw at the end of the suspension arm, then to connect the lighthead to the suspension arm you will need to connect the plastic locking connectors together. Feed the cable into the end of the suspension arm as much as possible and fit the lighthead’s arm onto the suspension arm. Re-insert the screw to lock arm in place. Plug the power cable into the mains supply point and power on the light. Check that all the lights are illuminated and that the arm and head have smooth and correct movement. If the head is drifting, or if the movement of the arm is stiff, use a hex tool to adjust the tensions detailed in maintenance section. Your new Daray light is now ready for use. To gain full support of our warranty please fill in the warranty details online at http://www.daray.co.uk/docs/warranty.php NOTE: The mains power supply should meet IEC60245-1 requirements. Page 26 of 42 3.3 Wall Mounted SL430 The wall structure must be capable of handling a pivoting load. The procedures below are detailed to a high level however If in doubt please consult a qualified electrician. Minimum Room Requirements Live Electric Circuitry The SL430 Series wall mounted light has a standard fixing height where the bottom of the rotation arm should be no lower than 1900mm. The design works off a fixed plate system and has a large vertical motion. All personnel working around live circuitry should be qualified and following proper procedures Heavy or Difficult fittings Fitting the wall plate can be difficult and aspects of the fitting may require more than one person; this work should only be attempted by appropriate and competent personnel. Existing Environmental Factors When fitting, considerations have to be taken for existing services such as; fire alarms, vents, lights, etc. along with interior wall services/construction and any surrounding hazard. These instructions are based on the assumption of a fresh fit into a room with no previous lighting structures. With installations onto sites with equipment already in place, we recommend that the previous lights’ mounting plates be removed and the new ones fitted as if into a fresh fitting. Page 27 of 42 After concluding the structural stability of the area it will be necessary to decide on the best course of action for installing the wall plate. There are various different methods for loading the plate onto the wall; any methods used should be appropriate to the fixing point and safe. Ultimately the mounting method used is the responsibility of the project engineer or fitter. This includes the specification of attachment hardware, lateral bracing and the suitability of the surface to be fixed to. 3.3.1 Installing the wall plate The location of the light should be decided by the end user / project manager or through schematical drawings. Once the location has been decided it will be necessary to first mark the location of the fixings points. Ensure that these locations are level and install the fixing bolts. Once the bolts are fitted and secured, you will need to fit the plate by sliding the plate onto the fixing bolt points and attach a locking nut to the bolts. Once the wall plate has been fitted, it will be necessary to ensure that it is balanced on the both the vertical and horizontal planes. Once this adjustment has been done tighten the nuts down to the plate to lock it into position. After any adjustment it will be necessary to check that all fixings are still sound and that all nuts are tight. Page 28 of 42 3.3.2 Wiring and transformer layout Before working on electrical connections please make sure that the power to the light is switched off at the source and secured so that it will not be turned on during your work. The mains power supply should meet IEC60245-1 requirements and should be fitted with a fixed master switch. (The switch should meet IEC328 requirements and the directional movement parts of the switch should meet IEC447 requirements and the symbols should meet IEC60601-1 requirements.) Ideally the cable used to power the light should be of a 1.5mm twin and earth type. Daray recommends that the power supplied uses an earthed switched fused spur, protected with a 3 amp fuse. The wiring should be as follows: Live terminal brown wire. Neutral terminal blue wire. Earth terminal green/yellow wire. The above wiring is for modern wiring applications (post 2000). On completion of the wiring, the next stage will be attaching the rotation arm to the mount. The mains connection should be attached to the terminal block on the transformer. All other connections in the light are low voltage DC connections that will be connected using the connectors that are already fitted within the light. Page 29 of 42 3.3.3 Primary rotation arm installation The primary rotation arm is fitted to a 180 Degree arm boss system; the arm boss is the section that is inserted into the wall mount and secured in place with a locking screw inserted on the front of the wall mount plate. Before installing the arm ensure the wall mount is absolutely true on the vertical plane. Remove the screw from the bottom of the arm boss and Insert the rotation arm system into the wall mount bracket. Feed the DC connection down through the bottom of the wall mount housing and secure in place with the previously removed screw. Connect the DC connection from the arm to the matching connection coming off the transformer. Before progressing onto fixing any other arms, ensure that the rotation arm is attached securely. Page 30 of 42 3.3.4 Suspension arm Installation The Suspension arm uses an internal plug system which allows it to have 360 degree rotation. To install the arm you will need to first remove the screws from each side of the arm joint. Push the suspension arm’s spigot into the rotation arm and re-insert the screws that secure it. Remove Screws from each side Carefully insert spigot Line up holes Reinsert Screws Page 31 of 42 Warning, please observe the Cable Polarities and ensure that they match, incorrectly wiring the device will cause damage to the system 3.3.5 Lighthead Installation The lighthead has a small arm section and is the final component that needs to be attached to the arm system. For this section the connection is a mini Molex to ensure the correct polarity connection. Remove the screw from the end of the suspension arm and then, whilst ensuring the cables do not get caught, slide the head onto the suspension arm. Making sure the screw point locates in line with the drilled hole on the arm. Once aligned, tighten the screws to lock the head onto the rest of the light. Supply power to the light and check that all the light modules are illuminated. The light can now be tested by applying power and pressing the power button on the head. Check the arm and head for smooth and correct movement. Your new Daray light is now ready for use. Page 32 of 42 3.3.6 Attaching the Wall Mount Cover Once you have checked that the light works and all modules and connections are secure you will need to attach the wall mount cover. Move the lighthead and arms to the side. Remove the screws from the top of the wall mount and slide the Cover onto the unit. Ensure all cables are clear. The cables leading off the unit to the power should be fed along the upper left side of the unit. Screw Points Wall Mount Cover Slot Feed the edge of the cover into the gap indicated and re-insert the screws into the points located on the top of the cover. Tighten and lock the WMC onto the wall plate, securing it against movement. Check arm and head for smooth and correct movement. If the head is drifting, or if the movement of the arm is stiff, use a hex tool to adjust the tensions detailed in the maintenance section of this manual. To gain full support of our warranty please fill in the warranty details online at http://www.daray.co.uk/docs/warranty.php NOTE: The mains power supply should meet IEC60245-1 requirements. Page 33 of 42 4. Maintenance The proposed maintenance is only a suggestion. Depending on the use of the product and the operating environment, this may need to be revised more often. Daray would strongly recommend against “quick fixes” with tape, etc. If you cannot resolve a problem then please contact our helpline on 0800 878 9864 or email [email protected] 4.1 Maintenance schedule Weekly checks should include:- Range of movement testing, it should be light and easy to move throughout the range No visible signs of excessive wear. Monthly checks to include:Six monthly checks to include:- Check the vertical tubing and suspension arm for wear and report as necessary Check all electrical connections are sound and that there is no visible cable wear. All fixings to be checked and be of sound construction. 4.2 Safety Precautions For all cleaning work, power off the equipment and where possible unplug the mains socket, only minimal cleaning fluids should be used. Please do not look directly into the light source when illuminated. If the equipment is dented or scratched this should not impact the usability of our lights however we advise that you do not attempt to ‘paint’ over any damage as this will impact upon the effectiveness of any cleaning, simply use an alcohol based cleaning spray when cleaning and pay special attention to the cut. If there is damage to the power cable or if exposed wire is visible DO NOT USE Page 34 of 42 4.3 Cleaning Do not use strong chemical cleaning agents or any abrasive materials to clean the light. The light is not waterproof so the use of excessive amounts of cleaning fluids could cause serious harm or injury. The SL430 Series lights have enclosed heads with moderate Ingress Protection; we advise that the light should only be dusted with a soft flannel cloth, and the front cover gently cleaned with an alcohol-based liquid (aerosol) spray, and wiped dry. 4.4 Fuses and their replacement All versions of the SL430 series use internal transformers to control the power to the lighthead. These can be located on the mounting plates or mobile base as indicated in the assembly instructions. These transformers should never be circumvented as these lights work of a low voltage system. The mobile edition of the SL430 is a hardwired mobile unit that contains a user replaceable fuse located in the moulded plug. The wall and ceiling editions are recommended to be wired into a switched fused spur for user based fuse replacements. For any internal fuse and transformer burnout’s please contact Daray. Page 35 of 42 4.5 Adjustments The SL430 series light can have its arm movements adjusted by use of internal tension grub screws located in various sections of the arm and head. 4.5.1 Wall / Ceiling Mounted Adjustments 4.5.1.1 Rotation Arm The first tension point that can be adjusted on the SL430 is controlled through 2 grub screws located on the arm boss section of the primary rotation arm. Sideways tension 4.5.1.2 Suspension Arm The Suspension arm has two grub screw based adjustable tension points. These are for its upward movement and its sideways movement. The sideways movement is located just under the spigot that is inserted into the primary arm, the upward movement tension is controlled through an internal grub screw at the bottom of the same spigot joint. Sideways tension Vertical tension Page 36 of 42 4.5.1.3 Lighthead The Lighthead has 2 adjustment points, the connection between the heads arm and the suspension arm, and the joint at the base of the lighthead, where it connects to the arm system. Rotating tension Rotating tension Page 37 of 42 4.5.2 Mobile Mounted Adjustments 4.5.2.1 Suspension arm Unlike other mobile mounted lights, the suspension arm on the SL430 mobile has side to side movement. The tension in this is controlled through 2 grub screws located on opposite sides of the joint where the suspension arm and vertical tubing connect. The upward and downward movement of the arm is controlled by an internal grub screw, accessible through a small hole located at the top of the suspension arm joint, where it connects to the vertical tubing. Sideways tension Vertical tension 4.5.2.2 Lighthead Arm The side turning movement of the lighthead arm is also controlled by 2 tension screws located on opposite sides to the arm joint as shown below. Rotating tension Page 38 of 42 4.5.2.3 Lighthead The tilting / forward and backward movement of the lighthead itself can be adjusted by using the tension screw located at the base of the lighthead, where it connects to its arm. Rotating tension Once all your required adjustments are complete, please check for correct movement. You should be able to place the light at its highest and lowest points with little to no drift/movement in the head once positioned. We would recommend the lighthead arm and head movements should not be overly tightened so they are stiff, and should not be overly loose which would cause drift. 4.5.3 Detaching Parts De-construction of the lights should be done following a reverse order of the instructions in section 3. The SL430 is a completely enclosed lighthead as such, the head should not be opened and is only serviceable by a Daray Authorised service centre. For any issues requiring service work on the SL430 please contact daray, as unauthorised work will invalidate the warranty. Page 39 of 42 5. Troubleshooting Guide Problem Possible Cause Power Supply No light output On/Off Button Fuses Cables Low levels Poor Light output Voltage in Voltage out Light patch not focused Lighthead Loosened screw Arm drift sideways Head movement or drift Light head Corrective Actions Mobile Version - Check the plug top adapter is plugged in and switched on at the mains power socket. Wall / Ceiling Version – Check the power is being supplied to the room, that the switched fused spur is switched on and that there is power getting to the head. If not please contact Daray. Press the button on the side of the light to check if the light will power on (if not refer to power supply actions). Mobile Version - Visually check the fuse in the plug then check the continuity with a meter. Wall / Ceiling Version – Check the fuse located in the switched fused spur. Check the visible wiring and make sure the DC connections between the light and the downtube / PSU are fully connected Please check the variable intensity is not just set to its minimum. Verify that the correct mains voltage and correct transformer is being used Verify correct secondary voltage at the end of the suspension arm In the unlikely event that this happens, please contact Daray If a screw has worked loose please check all grub screws and follow the tension adjustment procedure detailed in section 4. Please check the tightness of the grub screw connections as detailed. Page 40 of 42 6. Warranty Information 6.1 Returns Policy IMPORTANT! Please fill out your warranty registration online at www.daray.co.uk/warranty or contact Daray by phone (0800 878 9864) or email [email protected] DARAY's standard warranty is 12 months. However, this period may be extended for most lighting products* free of charge by completing and submitting the warranty registration. Year 1: Year 2+: Warranty includes parts and labour (Return to Base) Parts only *UK only We want you to be completely satisfied with your purchase. If you need to return goods purchased from DARAY Ltd, please read the following information carefully. The DARAY Ltd returns policy provides guidance on when you can return goods we have supplied, and what you can expect from us once you do. To see our detailed returns policy and procedure visit www.daray.co.uk/returns TYPE OF RETURN REMEDY DAMAGED GOODS We must be notified within 24 hours of receipt. Goods which are physically damaged on delivery Dead On Arrival (DOA) Goods which do not work Goods which do not work on arrival or develop a fault within 28 days, we will advance replace the item. GOODS DEVELOPING A FAULT Goods which have developed a fault within the warranty period. If the fault develops after 28 days, but within the warranty period, we will initiate the returns procedure. NON WARRANTY If a fault develops outside the warranty period, we will Goods which have developed a fault outside the initiate the returns procedure charges may be applicable. warranty period. OTHER We will always try to help, but we cannot normally offer a Any situation which is not covered by any of the refund. above. For additional clarification, please refer to our terms and conditions at www.daray.co.uk/terms. In a small number of cases, we may determine that a replacement would not work any better than the original product we supplied. In such cases we will only offer a refund rather than a replacement for qualifying returns. Replacement bulbs and spare parts ordered on our website or from supplied part codes are not eligible for credit. We will accept returns and exchange for the correct item. If your purchase an item incorrectly you can return it within 14 days and it can be exchanged for another product of equal or higher value, excluding transportation charges incurred. Goods and packaging must be returned in their original condition. Under no circumstances will goods be accepted for return if they are damaged, have been subjected to improper handling or abuse or have been used. If you send us goods that do not qualify for return, you will invalidate your claim to any refund, and you will be obliged to compensate DARAY Ltd for the cost of return postage and any other reasonable costs incurred processing the goods. Your statutory rights are not affected. Page 41 of 42 6.2 Warranty Details TERMS AND CONDITIONS OF WARRANTY 1. To qualify for this warranty you must register on www.daray.co.uk or return to Daray Ltd (Daray) the duly completed warranty-registration form accompanying the product. 2. Daray warrants this product (excluding lamp) against faulty material and workmanship during the period of the warranty. The period of warranty is the period stated on your warranty card and commences on the date of purchase of the product. In the event that the product is not in good working order Daray will provide, during the warranty period, a free repair service within the United Kingdom. The warranty is subject to proof of purchase being provided; therefore, you should retain your original receipt. 2.1 The repair service consists of the provision of spare parts and/or replacement products (at Daray’s discretion) which will be provided on an exchange basis and will either be new, equivalent to new or reconditioned. All replaced spare parts and products shall become the property of Daray. 2.2 Daray’s only obligation under this warranty is the provision of the service as set out above. 2.3 All products are returned to Daray at the customer’s cost and risk. Products to be returned should be adequately packed. For the address to send returns to please visit www.daray.co.uk 3. Daray’s arrangements for providing service provided under this warranty may include the use of subcontractors. 4. This warranty does not cover damage or defects in the Product caused by or resulting from: Wilful neglect or negligence by anyone other than Daray; Improper use, storage or handling of the product; Use of non-Daray approved parts (such as replacement lamps) not compatible with the Product; Fire, accident or disaster; Use of non-Daray modifications other than in accordance with Daray’s instructions; Attachment of fittings and accessories not approved by Daray; Repairs, modifications carried out by service personnel not approved by Daray; Damage caused by chemical corrosion from cleaning agents not approved by Daray. Failure to use or install the product in accordance with the manufacturer’s instructions. 5. Nothing in this warranty shall have the effect of restricting or excluding the liability of Daray in respect of: a) Death and personal injury caused by the negligence of Daray, or for fraud; b) Under the Consumer Protection Act 1987 to a person who has suffered damage caused by a defective product or to a dependant or relative of such a person; c) Direct damage to your property caused by the proven negligence of Daray. 6. This agreement does not give any rights other than those expressly set out above and in particular, Daray will not be responsible for any loss of income, profits or contracts or any direct or indirect consequential loss, damage caused to or suffered by the purchaser as a direct result of this agreement. 7. This warranty is offered (subject to these terms and conditions) in addition to, and does not affect your statutory rights. 8. Daray may disclose your details and other personal information to companies within the Daray group including any subsidiary company or sub-contractor of Daray for the purposes of performing our obligations hereunder. 9. You must not resell outside the UK any products supplied by Daray and covered by the Export of Goods (Control) Order 1992 (or any law that replaces it) without obtaining all necessary licences. You also agree not to sell the product in the UK if you know or think that the person buying the product intends to export it without getting the necessary licences. You agree to impose similar conditions to these on anyone you sell the product to. 10. These conditions shall in all respect be governed and construed in accordance with English law and the exclusive jurisdiction of the English courts. Product: Serial No: Page 42 of 42