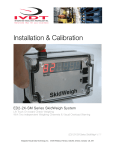

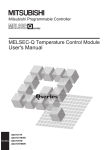

Download User`s Manual - Ocean Controls

Transcript