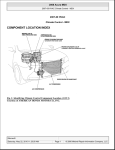

Download 21-60 Heating/Air Conditioning

Transcript