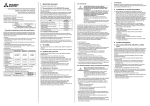

Download Safety Controller User`s Manual

Transcript