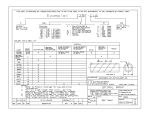

Download NX Remote I/O

Transcript