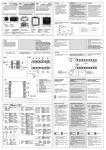

Download Eurotherm 2704 User Manual

Transcript