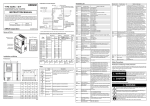

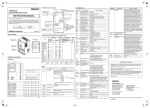

Download MX2/RX-series DeviceNet Communications Unit User`s Manual

Transcript