Download warning - Quality Machine Tools

Transcript

3UHFLVLRQ0DWWKHZV

PM-1127VF-LB

23(5$725

60$18$/

.HHS 5HDG DQG 8QGHUVWDQG WKH 2SHUDWLRQ 0DQXDO DQG 6DIHW\ ,QIRUPDWLRQ

%HIRUH 2SHUDWHG

G

TABLE OF CONTENTS

General Safety Instructions................................................................................................. 3

Specific Safety Instructions ................................................................................................. 4

Features .............................................................................................................................. 5

Physical Features................................................................................................................ 6

Set-Up ................................................................................................................................. 7

Un-Packing & Inventory ...................................................................................................... 7

Proper Grounding................................................................................................................ 8

Chuck .................................................................................................................................. 9

Steady Rest......................................................................................................................... 9

Follow Rest ......................................................................................................................... 10

Lathe Bed............................................................................................................................ 10

Headstock ........................................................................................................................... 10

Gearbox .............................................................................................................................. 11

Headstock Controls............................................................................................................. 11

Apron................................................................................................................................... 12

Saddle ................................................................................................................................. 12

Carriage Controls ................................................................................................................ 12

Lead Screw & Feed Screw.................................................................................................. 13

Tailstock .............................................................................................................................. 14

Tailstock Controls................................................................................................................ 14

Test Run.............................................................................................................................. 15

Speed Change .................................................................................................................... 16

Longitudinal Turning with Auto-Feed .................................................................................. 17

Manual Longitudinal Turning............................................................................................... 17

Facing and Recesses.......................................................................................................... 17

Turning Between Centers ................................................................................................... 18

Thread Cutting .................................................................................................................... 18

Change Gears Replacement............................................................................................... 19

Cross Slide Gib Screws Adjustment ................................................................................... 19

Top Slide Gib Screws Adjustment....................................................................................... 20

Chuck Run-out .................................................................................................................... 20

Headstock & Tailstock Alignment........................................................................................ 21

Main Spindle Bearings ........................................................................................................ 22

Lubrication........................................................................................................................... 22

Gearbox .............................................................................................................................. 22

Change Gears..................................................................................................................... 23

Saddle ................................................................................................................................. 23

Cross Slide.......................................................................................................................... 23

Cross Slide Hand Wheel ..................................................................................................... 23

Lead Screw ......................................................................................................................... 24

Tailstock .............................................................................................................................. 24

Maintenance........................................................................................................................ 24

Optional Chip Tray & Stand ................................................................................................ 25

Electrical Connections & Wiring Diagram ........................................................................... 26

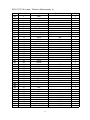

Threading & Feed Table for CX701 .................................................................................... 27

Troubleshooting .................................................................................................................. 28

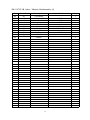

Parts Breakdown & Parts List ............................................................................................. 29

Warranty.............................................................................................................................. 46

2

GENERAL SAFETY INSTRUCTIONS

FOR MACHINES

Extreme caution should be used when operating all power tools. Know your power

tool, be familiar with its operation, read through the user manual and practice safe

usage procedures at all times.

ALWAYS read and understand the

user manual before operating the

machine.

CONNECT your machine ONLY to the

matched and specific power source.

ALWAYS

wear

safety

glasses

respirators, hearing protection and

safety shoes, when operating your

machine.

DO NOT wear loose clothing or

jewelry when operating your machine.

A

SAFE

ENVIRONMENT

is

important. Keep the area free of dust,

dirt and other debris in the immediate

vicinity of your machine.

BE ALERT! DO NOT use prescription

or other drugs that may affect your

ability or judgment to safely operate

your machine.

DISCONNECT the power source when

changing drill bits, hollow chisels,

router bits, shaper heads, blades,

knives, or making other adjustments or

repairs.

NEVER leave a tool unattended while it

is in operation.

NEVER reach over the machine when

the tool is in operation.

ALWAYS keep blades, knives and bits

sharpened and properly aligned.

ALL

OPERATIONS

MUST

BE

performed with the guards in place to

ensure safety.

ALWAYS use push sticks and feather

boards to safely feed your work through

the machine and clamp the work-piece

(when necessary) to prevent the workpiece from any unexpected movement.

ALWAYS make sure that any tools used

for adjustments are removed before

operating the machine.

ALWAYS keep the bystanders safely

away while the machine is in operation.

NEVER attempt to remove jammed

cutoff pieces until the saw blade has

come to a full stop.

3

309)/%0(7$//$7+(

63(&,),&6$)(7<,16758&7,216

EURNHQSDUWVDQGDQ\RWKHUFRQGLWLRQV

WKDWPD\HIIHFWWKHWRROVRSHUDWLRQ

7KLV PDFKLQH LV GHVLJQHG DQG

LQWHQGHGIRUXVHE\SURSHUO\WUDLQHG

DQG H[SHULHQFHG SHUVRQQHO RQO\ ,I

\RX DUH QRW IDPLOLDU ZLWK WKH SURSHU

XVHRIODWKHVGRQRWXVHWKLVPDFKLQH

XQWLO SURSHU WUDLQLQJ DQG NQRZOHGJH

KDVEHHQREWDLQHG

5HPRYH

DGMXVWLQJ

NH\V

DQG

ZUHQFKHV 5HPRYH DOO WKH WRROV XVHG

IRU DGMXVWPHQW EHIRUH WXUQLQJ WKH

PDFKLQHRQ

.HHSJXDUGVLQSODFH6DIHW\JXDUGV

PXVW EH NHSW LQ SODFH DQG LQ ZRUNLQJ

RUGHUDOOWKHWLPHVWRHQVXUHVDIHW\

%HFDUHIXO'RQRWSXW\RXUKDQGFORVH

WR WKH FXWWHU ZKLOH WKH PDFKLQH LV

UXQQLQJ

.HHSFKLOGUHQDQGYLVLWRUVDZD\$OO

FKLOGUHQDQGYLVLWRUVVKRXOGEHNHSWDW

DVDIHGLVWDQFHIURPWKHZRUNDUHD

1HYHUOHDYHWKHODWKHXQDWWHQGHGZKLOH

LWLVUXQQLQJ

'RQRWRYHUUHDFK.HHSSURSHUIRRWLQJ

DQGEDODQFHDWDOOWLPHV

:HDUSURSHUDSSDUHO/RRVHFORWKLQJ

JORYHV QHFNWLHV ULQJV EUDFHOHWV RU

RWKHU MHZHOU\ PD\ JHW FDXJKW LQ

PRYLQJ SDUWV 1RQVOLS IRRWZHDU LV

UHFRPPHQGHG :HDU SURWHFWLYH KDLU

FRYHULQJ WR FRQWDLQ ORQJ KDLU 'R QRW

ZHDUDQ\W\SHRIJORYHV

0DLQWDLQ WRROV ZLWK FDUH .HHS WRROV

VKDUS DQG FOHDQ IRU EHVW DQG VDIHVW

SHUIRUPDQFH )ROORZ LQVWUXFWLRQV JLYHQ

LQ WKH PDQXDO IRU OXEULFDWLRQ DQG

UHSODFLQJDFFHVVRULHV

$OZD\V XVH VDIHW\ JODVVHV )RU WKH

VDIHW\ RI \RXU H\HV VDIHW\ JODVVHV

VKRXOG EH XVHG ZKLOH RSHUDWLQJ WKH

ODWKH

7XUQ WKH SRZHU 2)) %HIRUH PDNLQJ

DQ\ DGMXVWPHQWV PDNH VXUH WKH VZLWFK

LV LQ WKH ³2))´ SRVLWLRQ DQG WKH FRUG LV

XQSOXJJHGIURPWKHSRZHURXWOHW

'R QRW XVH WKH ODWKH LQ GDQJHURXV

HQYLURQPHQWV 'R QR H[SRVH WKH

PDFKLQH WR UDLQ 'R QRW XVH WKH

PDFKLQHLQZHWORFDWLRQV

0DNH VXUH \RX KDYH UHDG DQG

XQGHUVWRRG DOO WKH VDIHW\ LQVWUXFWLRQV LQ

WKH PDQXDO DQG \RX DUH IDPLOLDU ZLWK

\RXU PHWDO ODWKH EHIRUH RSHUDWLQJ LW ,I

\RX IDLO WR GR VR VHULRXV LQMXU\ FRXOG

RFFXU

&KHFNIRUGDPDJHGSDUWV&KHFNIRU

SURSHU DOLJQPHQW RI PRYLQJ SDUWV

:$51,1*

7KHVDIHW\LQVWUXFWLRQVJLYHQDERYHFDQQRWEHFRPSOHWHEHFDXVHWKHHQYLURQPHQWLQ

HYHU\ VKRS LV GLIIHUHQW $OZD\V FRQVLGHU VDIHW\ ILUVW DV LW DSSOLHV WR \RXU LQGLYLGXDO

ZRUNLQJFRQGLWLRQV

3UHFLVLRQ 0DWWKHZV

309)/%±0(7$//$7+(

)($785(6

02'(/ 309)/% ± ´ [ ´ 0(7$/ /$7+( :,7+ 9$5,$%/( 63(('

$V SDUW RI WKH JURZLQJ OLQH RI:(,66PHWDOZRUNLQJ HTXLSPHQW ZH DUH SURXG WR RIIHU WKH 309)/% D

´ [ ´ 0HWDO /DWKH ZLWK 'LJLWDO 5HDGRXW %\ IROORZLQJ WKH LQVWUXFWLRQV DQG SURFHGXUHV ODLG RXW LQ WKLV

XVHU PDQXDO \RX ZLOO UHFHLYH \HDUV RI H[FHOOHQW VHUYLFH DQG VDWLVIDFWLRQ 7KH 309)/% LV D

SURIHVVLRQDO WRRO DQG OLNH DOO SRZHU WRROV SURSHU FDUH DQG VDIHW\ SURFHGXUHV VKRXOGEH DGKHUHGWR

0RWRU+3.:'& 9 $PSUPLQ

6ZLQJ2YHU %HG ´PP

6ZLQJ2YHU&URVV6OLGH ´PP

'LVWDQFH %HWZHHQ&HQWHUV ´ PP

:LGWKRI %HG ´PP

+ROH7KURXJK6SLQGOH ´ PP

7DSHULQ6SLQGOH1RVH 07

1XPEHU RI 6SLQGOH6SHHGV 9DULDEOH

5DQJHRI6SLQGOH6SHHGV ± 530DQG±530 9DULDEOH6SHHG

1XPEHU RI 0HWULF7KUHDGV 5DQJHRI0HWULF7KUHDGV PP ± PP

1XPEHURI ,PSHULDO7KUHDGV 5DQJHRI,PSHULDO7KUHDGV ± 73,

5DQJHRI&URVV)HHG ±PP 5HYROXWLRQ

5DQJHRI/RQJLWXGLQDO )HHG ± PP 5HYROXWLRQ

7RRO3RVW 7\SH :D\

0D[ &RPSRXQG 6OLGH 7UDYHO´ PP

0D[ &URVV6OLGH7UDYHO ´PP

0D[LPXP &DUULDJH 7UDYHO´ PP

7DLOVWRFN 6SLQGOH7UDYHO ´PP

7DSHULQ7DLOVWRFN6SLQGOH07

2YHUDOO'LPHQVLRQRI WKHODWKH /HQJWK ´[:LGWK´[+HLJKW´

:HLJKW.JVOEV

:DUUDQW\ <HDUV

309)/%0(7$//$7+(

3+<6,&$/)($785(6

$

9DULDEOH6SHHG6ZLWFK

1

+DOI1XW/HYHU

%

+HDGVWRFN

2

$XWR)HHG/HYHU

&

212))6ZLWFK

3

&URVV6OLGH+DQG:KHHO

'

)RUZDUG5HYHUVH6ZLWFK

4

&DUULDJH+DQG:KHHO

(

-DZ&KXFN

5

/HDG6FUHZ

)

)RXU:D\7RRO3RVW

6

)HHG7KUHDG6HOHFWRU.QRE

*

7DLO6WRFN4XLOO/RFN/HYHU

7

2LO6LJKW*ODVV

+

7DLO6WRFN

8

)HHG5DWH6HOHFWRU.QRE

,

7DLO6WRFN+DQG:KHHO

9

)HHG'LUHFWLRQ6HOHFWRU.QRE

-

7DLO6WRFN/RFN1XW

:

&KLS7UD\

.

&RPSRXQG6OLGH7UDYHUVH/HYHU

;

&KDQJH*HDU3URWHFWLYH&RYHU

/

/DWKH%HG

<

7KUHDGLQJ)HHGLQJ7DEOH

0

7KUHDG'LDO,QGLFDWRU

6(783

%HIRUH VHWWLQJ XS \RXU PDFKLQH \RX PXVW

UHDG DQG XQGHUVWDQG WKH LQVWUXFWLRQV JLYHQ

LQWKLVPDQXDO

7KH XQSDLQWHG VXUIDFHV RI WKLV ODWKH DUH

FRDWHG ZLWK D UXVW SUHYHQWLYH ZD[\ RLO DQG

\RXZLOOZDQWWRUHPRYHWKLVEHIRUHVWDUWLQJ

DVVHPEO\ 8VH D VROYHQW FOHDQHU WKDW ZLOO

QRWGDPDJHSDLQWHGVXUIDFHV

:$51,1*

309)/%LVDYHU\KHDY\PDFKLQHGRQRW

RYHUH[HUW \RXUVHOI 8VH IRUN WUXFN RU

RWKHU PHFKDQLFDO GHYLFHV IRU VDIH

PRYLQJPHWKRG

/,672)&217(17647<

$

%

&

'

(

)

*

+

,

-

.

/

0

1

2

3

4

)DFH3ODWH

&KDQJH*HDUV -DZ&KXFN -DZ&KXFN 6WHDG\5HVW )ROORZ5HVW ([WHUQDO-DZVIRU-DZ&KXFN

'HDG&HQWHU07 5HGXFH6OHHYH1R

2LO*XQ

7RROER[ :D\7RRO3RVW :UHQFKHV +H[:UHQFKHV &KXFN.H\V

6FUHZ'ULYHUV)ODW&URVV+HDG /DWKHZLWK&KLS7UD\1RW6KRZQ :KHQ VHWWLQJ XS \RXU PDFKLQH \RX ZLOO

ZDQWWRILQGDQLGHDOVSRWZKHUH\RXUPHWDO

ODWKH ZLOO PRVW OLNHO\ EH SRVLWLRQHG PRVW RI

WKHWLPH

)LJXUH309)/%)RRWSULQW

813$&.,1*

7R HQVXUH VDIH WUDQVSRUWDWLRQ WKLV PDFKLQH

LV SURSHUO\ SDFNDJHG DQG VKLSSHG

FRPSOHWHO\ LQ FUDWHV :KHQ XQSDFNLQJ

FDUHIXOO\LQVSHFWWKHFUDWHVDQGHQVXUHWKDW

QRWKLQJ KDV EHHQ GDPDJHG GXULQJ WUDQVLW

2SHQ WKH FUDWHV DQG FKHFN WKDW WKH

PDFKLQH DQG WKH SDUWV DUH LQ JRRG

FRQGLWLRQ

)LJXUH,QYHQWRU\

:KLOH GRLQJ LQYHQWRU\ LI \RX FDQ QRW ILQG

DQ\ SDUW FKHFN LI WKH SDUW LV DOUHDG\

LQVWDOOHGRQWKHPDFKLQH6RPHRIWKHSDUWV

FRPHDVVHPEOHGZLWKWKHPDFKLQHEHFDXVH

RIVKLSSLQJSXUSRVHV

3523(5*5281',1*

*URXQGLQJ SURYLGHV D SDWK RI OHDVW

UHVLVWDQFHIRUHOHFWULFFXUUHQWWRUHGXFHWKH

ULVNRIHOHFWULFVKRFN

309)/% LV HTXLSSHG ZLWK D 9

VLQJOHSKDVHPRWRU

7R SUHYHQW HOHFWULFDO KD]DUGV KDYH D

TXDOLILHG HOHFWULFLDQ HQVXUH WKDW WKH OLQH LV

SURSHUO\ZLUHG

7KLV ODWKH LV IRU XVH RQ D QRUPDO YROW

FLUFXLW 0DNH VXUH WKDW WKH DSSOLDQFH LV

FRQQHFWHG WR DQ RXWOHW KDYLQJ WKH VDPH

FRQILJXUDWLRQ DV WKH SOXJ ,I DQ DGDSWRU

SOXJ LV XVHG LW PXVW EH DWWDFKHG WR WKH

PHWDOVFUHZRIWKHUHFHSWDFOH

:$51,1*

,PSURSHU FRQQHFWLRQ RI WKH HTXLSPHQW

JURXQGLQJFRQGXFWRUFDQUHVXOWLQDULVN

RIHOHFWULFVKRFN&KHFNZLWKDTXDOLILHG

HOHFWULFLDQ LI \RX DUH LQ GRXEW DV WR

ZKHWKHUWKHRXWOHWLVSURSHUO\JURXQGHG

,W LV VWURQJO\ UHFRPPHQGHG QRW WR XVH

H[WHQVLRQ FRUGV ZLWK \RXU 309)/%

$OZD\VWU\ WR SRVLWLRQ \RXU PDFKLQH FORVH WR WKHSRZHU VRXUFH VR WKDW \RX GR QRW

QHHG WRXVHH[WHQVLRQFRUGV

:KHQ LW LV QHFHVVDU\ WR XVH DQ H[WHQVLRQ

FRUG PDNH VXUH WKH H[WHQVLRQ FRUG GRHV

QRWH[FHHGIHHWLQOHQJWKDQGWKHFRUGLV

JDXJHWRSUHYHQWPRWRUGDPDJH

<RXU 309)/% VKRXOG EH ZLUHG ZLWK D SOXJKDYLQJ SURQJV WR ILW D SURQJ JURXQGHGUHFHSWDFOHDVVKRZQLQILJXUH

'RQRWUHPRYHWKHJURXQGLQJSURQJWRILWLW

LQWR D SURQJHG RXWOHW $OZD\V FKHFN ZLWK

DTXDOLILHGHOHFWULFLDQLI\RXDUHLQGRXEW

)LJXUH9ROWV2XWOHWIRU309)/%

&+8&.

309)/% FRPHV HTXLSHG ZLWK D PP

MDZ FKXFN D PP MDZ FKXFN DQG

DPPIDFHSODWH

6HFXUHWKHVWHDG\UHVWWRWKHODWKHEHGIURP

EHORZZLWKDORFNLQJSODWH

$ VLQJOH FDS VFUHZ DORQJ ZLWK D QXW DQG

ZDVKHU KROG WKH VWHDG\ UHVW LQ SODFH DV

VKRZQLQILJXUH

7KH MDZ FKXFN LV D VFUROO W\SH FKXFN

PHDQLQJ WKDW DOO WKUHH MDZV PRYH LQ XQLRQ

ZKHQ DGMXVWHG ZKLOH WKH MDZ FKXFN

IHDWXUHV IRXU LQGHSHQGHQW MDZV 7KH MDZ

FKXFNLVXVHGWRFODPSVTXDUHRUXQHYHQO\

VKDSHGZRUNSLHFHV

7KHFKXFNVIHDWXUHWKUHHKH[QXWDQGWKUHH

VHWVFUHZVIRUPRXQWLQJDVVKRZQLQILJXUH

)LJXUH6WHDG\UHVW

726(7837+(67($'<5(67

)LJXUH&KXFNPRXQWLQJVFUHZVDQGQXWV

:KHQ UHPRYLQJ WKH FKXFN ORRVHQ WKH KH[

QXWV WXUQ WKH ZDVKHU FRXQWHUFORFNZLVH

DQGSXOORXWWKHFKXFN6HHILJXUH

67($'<5(67

7KH VWHDG\ UHVW VXSSRUWV ORQJ VPDOO

GLDPHWHU VWRFN WKDW RWKHUZLVH FRXOG QRW EH

WXUQHG 7KH VWHDG\ UHVW FDQ DOVR UHSODFH

WKH WDLOVWRFN WR DOORZ IRU FXWWLQJ WRRO DFFHV

DWWKHRXWERDUGHQGRI\RXUZRUNSLHFH

7RPRXQWWKHVWHDG\UHVW

0DNHVXUHWKHVZLWFKLVLQWKH2))SRVLWLRQ

DQGWKHFRUGLVGLVFRQQHFWHGIURPWKH

SRZHUVRXUFH

/RRVHQWKHKH[QXWVVKRZQLQILJXUH

/RRVHQNQXUOHGVFUHZDQGRSHQWKHVOLGLQJ

ILQJHUV XQWLO WKH VWHDG\ UHVW FDQ EH PRYHG

ZLWK LWV ILQJHU DURXQG WKH ZRUNSLHFH

6HFXUH WKH VWHDG\ UHVW LQ SRVLWLRQ 6HH

ILJXUH

7LJKWHQ WKH NQXUOHG VFUHZ VR WKDW WKH

ILQJHUV DUH VQXJ EXW QRW WLJKW DJDLQVW WKH

ZRUNSLHFH 7LJKWHQ WKUHH KH[ QXWV VKRZQ

LQ ILJXUH DQG OXEULFDWH WKH VOLGLQJ SRLQWV

ZLWKPDFKLQHRLO

7KHVOLGLQJILQJHUVRIWKHVWHDG\UHVWVKRZQ

LQ ILJXUH VKRXOG UHFHLYH SHULRGLF

OXEULFDWLRQ ZKHQ XVHG WR SUHYHQW

SUHPDWXUHZHDU

WZR SUHFLVLRQ JURXQG 9VLGHZD\V DUH UH

HQIRUFHGE\KHDWKDUGHQLQJDQGJULQGLQJWR

JXLGH WKH FDUULDJH DQG WKH WDLOVWRFN

DFFXUDWHO\ 7KH PDLQ PRWRU LV PRXQWHG WR

WKHUHDURIWKHOHIWVLGHRIWKHEHG

)2//2:5(67

7KH IROORZ UHVW LV PRXQWHG RQ WKH VDGGOH

ZLWK WZR FDS VFUHZV VKRZQ LQ ILJXUH DQG

LW IROORZV WKH PRYHPHQW RI WKH WXUQLQJ WRRO

2QO\ WZR VOLGLQJ ILQJHUV DUH UHTXLUHG 7KH

SODFH RI WKH WKLUG ILQJHU LV WDNHQ E\ WXUQLQJ

WRRO 7KH IROORZ UHVW LV XVHG IRU WXUQLQJ

RSHUDWLRQV RQ ORQJ VOHQGHU ZRUNSLHFHV ,W

SUHYHQWV IOH[LQJ RI WKH ZRUNSLHFH XQGHU

SUHVVXUHIURPWKHWXUQLQJWRRO

6HW WKH ILQJHUV VQXJ WR WKH ZRUNSLHFH DQG

PDNHVXUHQRWWRRYHUWLJKWHQ/XEULFDWHWKH

ILQJHUV GXULQJ RSHUDWLRQ WR SUHYHQW

SUHPDWXUHZHDU

)LJXUH/DWKHEHG

+($'672&.

0DGH IURP KLJK TXDOLW\ FDVW LURQ IRU ORZ

YLEUDWLRQWKHKHDGVWRFNLVEROWHGWRWKHEHG

ZLWKIRXUVFUHZV7KHKHDGVWRFNKRXVHVWKH

PDLQ VSLQGOH ZLWK WZR SUHFLVLRQ WDSHU UROOHU

EHDULQJVDQGWKHGULYHXQLW

7KH PDLQ VSLQGOH WUDQVPLWV WKH WRUTXH

GXULQJWKHWXUQLQJSURFHVVDQGLWDOVRKROGV

WKHZRUNSLHFHDQGFODPSLQJGHYLFHV

)LJXUH)ROORZUHVWLQVWDOOHG

/$7+(%('

7KH ODWKH EHG LV PDGH RI KLJK TXDOLW\ LURQ

DQGIHDWXUHVKLJKFKHHNVZLWKVWURQJFURVV

ULEV HQVXULQJ ORZ YLEUDWLRQ DQG ULJLGLW\ ,W

LQWHJUDWHV WKH KHDGVWRFN DQG GULYH XQLW IRU

DWWDFKLQJWKHFDUULDJHDQGOHDGVFUHZV7KH

)LJXUH+HDGVWRFN

GEARBOX

The gearbox is located on the left side of

the lathe and is mounted on the bed. It is

used to select the feeds for straight turning

as well as for thread cutting. In order to

achieve certain thread pitches, it is

necessary to replace the change gears.

The torque of the work spindle is

transmitted to the feed gears and thus to

the lead screw.

FORWARD / REVERSE SWITCH: After the

machine is switched ON, turn the switch to

“F” position for counter-clockwise spindle

rotation (forward).

Turn the switch to “R” position for clockwise

spindle rotation (Reverse).

Turning the switch to “0” position the

spindle remains idle.

Figure-9 Gearbox

Figure-11 Forward / Reverse switch

HEAD STOCK CONTROLS

EMERGENCY ON/OFF BUTTON: The

On/Off button allows to start and stop the

machine.

FEED RATE SELECTOR KNOB: Use the

feed rate selector knob to set the desired

feed or thread rates. See figure-12.

FEED THREAD SELECTOR KNOB: For

thread selecting, shift the knob to the left

and for feed selecting, shift the knob to the

right. See figure-12.

FEED DIRECTION SELECTOR KNOB:

Select the carriage travel direction when the

chuck is rotating in the forward direction or

counter-clockwise as viewed from the front

of the chuck.

Figure-10 Emergency ON/OFF button

11

SADDLE

The saddle is made from high quality cast

iron and all sliding parts are smoothly

ground to fit the V on the bed without play.

Figure-12 Gearbox controls

VARIABLE SPEED CONTROL KNOB:

Turn the knob clockwise to increase the

spindle speed and counter-clockwise to

decrease the spindle speed. The possible

speed range is dependent on the position of

the drive belt. See figure-13.

Figure-14 Saddle and apron

CARRIAGE CONTROLS

The carriage allows the cutting tool to move

along the length of the lathe bed .The cross

slide allows the cutting tool to travel

perpendicular to the bed. The carriage

features a top slide which allows linear

movement of the cutting tool at any preset

angle .This section will review the individual

controls on the carriage and provide

descriptions of their uses.

Figure-13 Variable speed control knob

APRON

The apron is mounted to the saddle and to

the front side of the bed and it houses the

half nut with an engaging lever for

activating the automatic feed. The half nut

gibs can be adjusted from the outside.

LONGITUDINAL TRAVEL HAND WHEEL:

Turning the longitudinal hand wheel, moves

the carriage left or right along the bed .The

control is helpful when setting up the

machine for turning, when manual

movement is desired during turning

operations. See figure-15.

CROSS SLIDE HAND WHEEL: Turning

the cross slide hand wheel, moves the

cross slide towards or away from the workpiece. The graduated scale can be adjusted

12

XVLQJ WKH VDPH PHWKRG DV WKH ORQJLWXGLQDO

VFDOH6HHILJXUH

723 6/,'( +$1' :+((/ 7KH WRS VOLGH

KDQG ZKHHO FRQWUROV WKH SRVLWLRQ RI WKH

FXWWLQJ WRRO UHODWLYH WR WKH ZRUNSLHFH 7KH

WRS VOLGH LV DGMXVWDEOH IRU DQJOH DV ZHOO DV

ORQJLWXGLQDO WUDYHO ,W FDQ EH DGMXVWHG D IXOO

LIQHHGHG6HHILJXUH

+$/) 187 /(9(5 7KLV OHYHU HQJDJHV

DQG GLVHQJDJHV WKH KDOI QXW RQ WKH OHDG

VFUHZ 7KH OHYHU LV RQO\ HQJDJHG ZKLOH

WXUQLQJ WKUHDGV LQ VWRFN $ ORFNRXW GHYLFH

IHDWXUH LQ WKH OHYHU PHFKDQLVP HQJDJHV

ZKHQWKHIHHGVHOHFWRULVXVHG

7+5($',1* ',$/ ,1',&$725 7KLV

LQGLFDWRU WHOOV \RX ZKHQ WR HQJDJH WKH KDOI

QXWIRUWKUHDGLQJSURFHVV6HHILJXUH

722/ 3267$ IRXUZD\ WRRO SRVW LVVXSSOLHG

ZLWK 309)/% &XWWLQJ WRROV FDQ EH

DWWDFKHG DQG UHPRYHG E\ WLJKWHQLQJ RU

ORRVHQLQJWKHFODPSLQJEROW6HHILJXUH

)LJXUH&DUULDJHFRQWUROV

)LJXUH&DUULDJHFRQWUROV

$872 )((' 6(/(&725 /(9(5 0RYLQJ

WKLV OHYHU XSZDUG HQJDJHV WKH DXWRPDWLF

ORQJLWXGLQDO IHHG 0RYLQJ WKLV OHYHU GRZQ

HQJDJHV WKH DXWRPDWLF WUDYHUVH IHHG 6HH

ILJXUH

/($'6&5(:$1')(('

6&5(:

7KH OHDG VFUHZ DQG IHHG VFUHZ DUH

PRXQWHGRQWKHIURQWRIWKHPDFKLQHEHG,W

LV FRQQHFWHG WR WKH JHDU ER[ DW WKH OHIW IRU

DXWRPDWLFIHHGDQGLVVXSSRUWHGE\EHDULQJ

RQERWKHQGV

:$51,1*

'R QRW VLPXOWDQHRXVO\ HQJDJH WKH IHHG

OHYHU DQG WKH WKUHDGLQJ OHYHU 'RLQJ VR

ZLOOGDPDJHWKHODWKH

)LJXUH/HDGVFUHZDQGIHHGVFUHZ

7$,/672&.

7$,/672&.&21752/6

7KHWDLOVWRFNVOLGHVRQD9ZD\DQGFDQEH

FODPSHGDWDQ\ORFDWLRQ7KHWDLOVWRFNKDVD

KHDY\ GXW\ VSLQGOH DQG WKH VSLQGOH FDQ EH

FODPSHG DW DQ\ ORFDWLRQ ZLWK D FODPSLQJ

OHYHU 7KH VSLQGOH LV PRYHG ZLWK D KDQG

ZKHHODWWKHHQGRIWKHWDLOVWRFN

7$,/672&. +$1' :+((/ 7XUQLQJ WKH

KDQGZKHHODGYDQFHVRUUHWUDFWVWKHTXLOOLQ

WKH WDLOVWRFN 7KH JUDGXDWHG VFDOH RQ WKH

KDQGZKHHOLVDGMXVWDEOH6HHILJXUH

48,///2&./(9(57KLVORFNOHYHUORFNV

WKH TXLOO LQ SRVLWLRQ ZKHQ WLJKWHQHG 6HH

ILJXUH

7$,/672&. /2&. /(9(57XUQ WKLV ORFN

OHYHU XS WR ORFN DQG GRZQ WR XQORFN WKH

WDLOVWRFN LQ SRVLWLRQ RQ WKH ODWKH EHG 6HH

ILJXUH

$'-8670(17 6&5(: 7KLV VHW VFUHZ LV

XVHG WR DOLJQ WKH WDLOVWRFN ZLWK WKH

KHDGVWRFN 6HH SDJH IRU GHWDLOV RQ

&HQWHU$OLJQPHQW

)LJXUH7DLOVWRFN

0DNH VXUH WR LQVWDOO WKH VHFXULQJ VFUHZ DW

WKHHQGRIWKHODWKHDVVKRZQLQILJXUHLQ

RUGHUWRSUHYHQWWKHWDLOVWRFNIURPIDOOLQJRII

WKHODWKHEHG

)LJXUH7DLOVWRFNFRQWUROV

)LJXUH ,QVWDOOLQJ WKH VHFXULQJ VFUHZ RQ

WKHODWKHEHG

TEST RUN

Once you have assembled your lathe

completely, it is then time for a test run to

make sure that the lathe works properly and

is ready for operation.

Remove all the tools used for assembling

the machine and make sure all the guards

are in place.

WARNING

Before starting the lathe, make sure that

you have read and understood the

manual and you are familiar with the

functions and safety features on this

machine. Failure to do so may cause

serious personal injury.

To ensure the carriage controls do not

move unexpectedly when the lathe is

started, rotate the feed direction selector

knob so that the arrow is pointing to the

middle (neutral) position as shown in figure21.

While test running the machine, check the

following:

The Emergency Stop & ON/OFF buttons

are working properly.

The chuck and jaws are properly secured

and working properly.

While the machine is running, turn the

variable speed control knob clockwise to

make sure it is working properly.

Let the machine run for 10 minutes at the

Low Speed.

During the test run if there is any unusual

noise coming from the lathe or it vibrates

excessively, turn OFF the power switch

immediately and disconnect from the power

source Investigate if you can find out the

problem with your machine. See page-28

for troubleshooting.

If the machine is running smoothly, proceed

to the next step.

Change the belt for High Speed and let the

machine run for another 10 minutes. See

page-16 for details on speed change.

Turn the machine OFF and turn the

Forward/Reverse switch to “R” position.

Turn the machine back ON and make sure

the spindle is rotating clockwise (reverse).

Figure-21 Feed direction selector knob

Connect the cord to the power outlet and

turn the machine ON.

WARNING

Do not make any adjustments while the

machine is running. Failure to follow this

warning can cause serious personal

injuries to the operator and damage to the

machine.

15

63(('&+$1*(

7KH URWDWLQJ VSHHG RI WKH KHDGVWRFN LV

FRQWUROOHGE\WKHSRVLWLRQLQJRIWKHEHOWVRQ

WKH SXOOH\V 7KHVH DUH DFFHVVHG E\

UHPRYLQJWKHSURWHFWLYHFRYHURQWKHHQGRI

WKHKHDGVWRFN

5HIHUWRWKH7KUHDGLQJ)HHGLQJ7DEOHIRU

/DWKH RQ SDJH RU WKH SODWH RQ WKH

KHDGVWRFN WR GHWHUPLQH ZKLFK EHOW

FRPELQDWLRQV SURGXFH ZKDW VSHHGV 7KH

VSHHG VHWWLQJV DYDLODEOH RQ WKH 309)/%

DUH±530DQG530

72&+$1*(7+(63,1'/(63(('

8QVFUHZ WKH WZR IDVWHQLQJ NQREV VKRZQ LQ

ILJXUHDQGUHPRYHWKHSURWHFWLYHFRYHU

)LJXUH6FUHZVDQGQXWVVHFXULQJWKH

PRWRUPRXQWLQJSODWH

3RVLWLRQWKHEHOWRQWKHSXOOH\VIRUKLJKDQG

ORZVSHHGDFFRUGLQJWRILJXUH

7KH ORZ VSLQGOH VSHHG LV ± 530

ZKLOH WKH KLJK VSLQGOH VSHHG LV 530

)LJXUH%HOWSRVLWLRQRQWKHSXOOH\V

)LJXUH5HPRYLQJWKHFRYHU

/RRVHQ WKH IRXU QXWV DQG VFUHZV VKRZQ LQ

ILJXUH DQG PRYH WKH PRWRU PRXQWLQJ

SXOOH\WRUHOHDVHWKHWHQVLRQRQWKHEHOW

2QFHWKHEHOWWHQVLRQLVUHOHDVHGUHSRVLWLRQ

WKH EHOW RQ WKH SXOOH\V JURRYHV IRU KLJK RU

ORZVSLQGOHVSHHG

2QFHWKHEHOWLVRQWKHULJKWJURRYHVPRYH

WKH PRWRU SXOOH\ EDFN WR LWV SRVLWLRQ WR

WHQVLRQWKHEHOW5HWLJKWHQWKHVFUHZVDQG

QXWVUHPRYHG

,03257$17

:H VXJJHVW VHOHFWLQJ WKH ORZ VSHHG ,W

SURYLGHVVWURQJHUWRUTXHZKLOHRSHUDWLRQ

/21*,78',1$/7851,1*

:,7+$872)(('

0$18$//21*,78',1$/

7851,1*

6HW WKH IHHG GLUHFWLRQ VHOHFWRU NQRE DQG

IHHG UDWH VHOHFWRU NQRE VKRZQ LQ ILJXUH

WRVHOHFWWKHIHHGGLUHFWLRQDQGIHHGVSHHG

,Q WKLV WXUQLQJ RSHUDWLRQ WKH WRRO IHHGV

SDUDOOHO WR WKH D[LV RI URWDWLRQ ORQJLWXGLQDO

RI WKH ZRUNSLHFH 0DQXDO IHHG LV

DFFRPSOLVKHG E\ WXUQLQJ WKH FDUULDJH KDQG

ZKHHO RQ WKH ODWKH DSURQ RU WKH WRS VOLGH

7KH FURVV IHHG IRU WKH GHSWK RI FXW LV

DFKLHYHG XVLQJ WKH FURVV VOLGH 6HH ILJXUH

)LJXUH )HHG UDWH VHOHFWRU NQRE IHHG

GLUHFWLRQVHOHFWRUNQREDQGFKDUW

)LJXUH6WUDLJKWWXUQLQJ

8VH WKH FKDUW RQ WKH ODWK IRU VHOHFWLQJ WKH

IHHG VSHHG RU WKH WKUHDG SLWFK 6HOHFW WKH

SURSHU JHDU VHW LI WKH UHTXLUHG IHHG RU

WKUHDG SLWFK FDQ QRW EH REWDLQHG ZLWK WKH

LQVWDOOHG JHDU VHW $XWRPDWLF IHHG LV

DFFRPSOLVKHG E\ PRYLQJ WKH DXWR IHHG

OHYHUXS6HHILJXUH

)LJXUH$XWRIHHGVHOHFWRUOHYHU

)$&,1*$1'5(&(66(6

,Q WKH IDFLQJ RSHUDWLRQ WKH WRRO IHHGV

SHUSHQGLFXODU WR WKH D[LV RI URWDWLRQ RI WKH

ZRUNSLHFH7KHIHHGLVPDGHPDQXDOO\ZLWK

WKH FURVV VOLGH KDQG ZKHHO 7KH GHSWK RI

FXW LV PDGH ZLWK WKH WRS VOLGH 6HH ILJXUH

)LJXUH)DFLQJGUHVVLQJ

TURNING BETWEEN

CENTERS

For turning between centers, it is necessary

to remove the chuck from the spindle. Fit

the MT3 center into the 5/3 reducing sleeve

(provided) and fit the reducing sleeve into

the spindle taper.

Mount the work-piece fitted with the driver

dog between the centers. The driver is

driven by a catch or face plate. See figure29.

IMPERIAL THREAD: When cutting inch

threads, the half nut and threading dial are

used to thread in a conventional manner.

The threading and feeding table on page-27

or on the headstock, specifies at which

point a thread can be entered using the

threading dial.

METRIC THREAD: The only difference in

metric thread cutting is that the half nut

must remain engaged during the entire

threading process. The thread dial can not

be utilized.

Figure-30 Half nut and threading dial

Figure-29 Turning between centers

Set the machine up for the desired thread

pitch.

IMPORTANT

Always use a small amount of grease on

the tailstock center to prevent center tip

from over heating.

Start the machine and engage the half nut.

When the tool reaches the end of the cut,

stop the machine by turning the motor off

and at the same time back the tool out off

the work-piece so that it clears the thread.

Do not disengage the half nut lever.

THREAD CUTTING

Several different threads can be cut using

the proper combination of gears and

settings.

Reverse the motor direction allowing the

cutting tool to traverse back to the starting

point.

Repeat these steps until you have obtained

results.

18

/()7 $1' 5,*+7 7+5($' &877,1*

7KH OHIW DQG ULJKW WKUHDG FXWWLQJ LV GRQH

XVLQJ WKH IHHG GLUHFWLRQ VHOHFWRU NQRE

7XUQLQJ WKH IHHG GLUHFWLRQ VHOHFWRU NQRE

FRXQWHUFORFNZLVH FXWV OHIW WKUHDG ZKLOH

WXUQLQJLWFORFNZLVHFXWVULJKWWKUHDG

6HOHFWWKHSURSHUJHDUVHWDFFRUGLQJWR\RXU

UHTXLUHPHQWV IURP WKH IHHG WDEOH JLYHQ RQ

WKH ODWKH 6HH SDJH 7KUHDGLQJ )HHGLQJ7DEOHIRUGHWDLOVDQGLQVWDOOLWRQWR

WKHTXDGUDQWXVLQJQXWVUHPRYHG

5HLQVWDOOWKHSURWHFWLYHFRYHU

,03257$17

:H VXJJHVW VHOHFWLQJ WKH ORZ VSHHG ,W

SURYLGHVVWURQJHUWRUTXHZKLOHRSHUDWLRQ

&+$1*(*($56

5(3/$&(0(17

7RUHSODFHWKHFKDQJHJHDUV

0DNHVXUHWKHVZLWFKLVLQWKH2))SRVLWLRQ

DQG WKH FRUG LV XQSOXJJHG IURP WKH SRZHU

RXWOHW

8QVFUHZ WKH WZR IDVWHQLQJ NQREV DQG

UHPRYH WKH SURWHFWLYH FRYHU WR DFFHVV WKH

FKDQJHJHDUV

8QVFUHZ WKH EROW IURP WKH OHDG VFUHZ DQG

WKHVTXDUHQXWVVKRZQLQILJXUHIURPWKH

TXDGUDQW EROWV LQ RUGHU WR UHPRYH WKH

FKDQJHJHDUV

)LJXUH&KDQJHJHDUVUHSODFHPHQW

*,%6$'-8670(17

7KHUH DUH WZR PDLQ JLE VFUHZV DGMXVWPHQW

IRUWKHPDFKLQHWKHFURVVVOLGHJLEVFUHZV

DQGWKHWRSVOLGHJLEVFUHZV

:$51,1*

0DNH VXUH WKH VZLWFK LV LQ WKH 2))

SRVLWLRQ DQG WKH FRUG LV GLVFRQQHFWHG

IURP WKH SRZHU VRXUFH EHIRUH PDNLQJ

DQ\ DGMXVWPHQWV )DLOXUH WR GR VR FDQ

UHVXOWVHULRXVSHUVRQDOLQMXU\

&52666/,'(*,%6&5(:6

$'-8670(17

7KHDGMXVWPHQWJLEVDUHORFDWHGRQWKHOHIW

VLGHRIWKHFURVVVOLGH7RDGMXVWJLEORRVHQ

WKH QXWV KROGLQJ WKH JLEV 7LJKWHQ WKH JLEV

XQWLO H[FHVV PRYHPHQW LV HOLPLQDWHG DQG

UHWLJKWHQWKHQXWV6HHILJXUH

)LJXUH &URVV VOLGH DGMXVWPHQW JLE

VFUHZV

7236/,'(*,%6$'-8670(17

/RFDWH WKH DGMXVWPHQW JLEV RQ WKH VLGH RI

WKHWRSVOLGHDVVKRZQLQILJXUH/RRVHQ

WKH QXWV KROGLQJ WKH JLEV DQG WKHQ WLJKWHQ

WKH JLEV XQWLO H[FHVV PRYHPHQW LV

HOLPLQDWHG 2QFH DOO WKH JLEV DUH WLJKWHQHG

SURSHUO\UHWLJKWHQWKHQXWV

)LJXUH7RSVOLGHDGMXVWPHQWJLEVVFUHZV

&+8&.581287

,I \RXU ODWKH UHTXLUHV D KLJKHU OHYHO RI

DFFXUDF\\RXPD\ILQGLWQHFHVVDU\WRWUXH

XSWKHFKXFNWRHQVXUHPLQLPDOUXQRXW

7RFKHFNDQGFRUUHFWWKHFKXFNUXQRXW

0RXQW D SLHFH RI EDU VWRFN LQ WKH FKXFN

7KH VWRFN VKRXOG SURWUXGH DSSUR[LPDWHO\

PP

5HPRYH WKH EROWV VHFXULQJ WKH EDFN SODWH

WR WKH FKXFN 7DS DORQJ WKH HGJH RI WKH

PRXQWLQJVKRXOGHUXQWLOWKHFKXFNDQGEDFN

SODWHDUHIUHHRIHDFKRWKHUDQGWKUHDGEDFN

SODWHRQWRWKHVSLQGOH

5HPRYHDERXWPPRIPDWHULDOIURPWKH

VXUIDFH WKDW WKH FKXFN PRXQWV WR %H

FDUHIXOQRWWRUHPRYHDQ\PDWHULDOIURPWKH

GLDPHWHURIWKHVKRXOGHU6HHILJXUH

)LJXUH7XUQLQJWKHEDFNSODWH

,QVWDOO WKH FKXFN RQWR WKH EDFN SODWH DQG

FKHFNWKHUXQRXW,IWKHUXQRXWLVQRWZLWKLQ

DQ DFFHSWDEOH UDQJH LW PD\ EH QHFHVVDU\

WRWXUQDQHZVKRXOGHURQWKHEDFNSODWH

%HIRUHWXUQLQJDQHZVKRXOGHUPHDVXUHWKH

GLDPHWHU RI WKH UHFHVV LQ WKH EDFN RI WKH

FKXFNDFFXUDWHO\

5HPRYH DSSUR[LPDWHO\ RQH KDOI RI WKH

WKLFNQHVV RI WKH VKRXOGHU DSSUR[LPDWHO\

PP 5HPRYH WKH VDPH WKLFNQHVV RII

WKHIDFHRIWKHPRXQWLQJVXUIDFH

8VH D GLDO LQGLFDWRU DQG PHDVXUH WKH UXQ

RXWDWWKHHQGRIWKHEDU,QPRVWFDVHVWKH

DPRXQW RI UXQRXW ZLOO QRW H[FHHG PP

RYHU PP ZKLFK VKRXOG EH DFFXUDWH

HQRXJKIRUPRVWDSSOLFDWLRQV,IWKHUXQRXW

RQWKHFKXFNLVH[FHVVLYHHJJUHDWHUWKDQ

PP WKH H[FHVV UXQRXW VKRXOG EH

HOLPLQDWHG

6WDUWE\UHPRYLQJWKHFKXFN

)LJXUH7XUQLQJQHZVKRXOGHURQEDFN

The finished diameter of the shoulder

should be 0.025mm larger than the

diameter of the recess in the chuck. This is

a critical step in minimizing chuck run-out.

Re-install the chuck and check for run-out.

HEADSTOCK &

TAILSTOCK ALIGNMENT

The headstock and tailstock alignment has

been adjusted properly in the factory before

the machine is shipped to you. However,

after lengthy operation, the headstock and

tailstock may be out of alignment.

To check the centers alignment:

Figure-37 Stock thicker at the tailstock end

If the stock is thinner at the tailstock end,

the tailstock needs to be moved away from

you to the amount of taper. See figure-38.

Center drill a 150mm piece of bar stock on

one end and position it between the

headstock and tailstock as shown in figure36.

Figure-38 Stock thinner at the tailstock end

Figure-36 checking headstock and tailstock

alignment

TO MOVE THE TAILSTOCK:

Turn approximately 0.025mm off diameter.

Make sure the switch is in the OFF position

and the cord is disconnected from the

power outlet.

Measure the stock with a micrometer. If the

stock is thicker at the tailstock end, the

tailstock needs to be moved towards you to

the amount of taper. See figure-37.

Adjust the tailstock offset to the amount by

turning the adjustment screw shown in

figure-39.

21

Re-tighten the two hex socket cap screws.

CAUTION

Make sure not to tighten the hex socket

cap screws excessively or it will damage

the bearing.

Figure-39 Tailstock offset adjustment screw

Turn another 0.5mm off the stock and

check for taper. Repeat this procedure until

the tailstock is aligned with the headstock.

MAIN SPINDLE BEARINGS

The main spindle bearings are adjusted at

the factory. If end play becomes evident

after considerable use, the bearings may be

adjusted.

Loosen two hex socket cap screws in the

slotted nut shown in figure-40. Tighten

slotted nut until all end play is taken up. The

spindle should still revolve freely.

Figure-40 Main spindle bearing adjustment

LUBRICATION

Lubricate all slide-ways lightly before every

use with 20W oil.

WARNING

Lathe must be serviced at all lubrication

points and all reservoirs filled to

operating level, before the lathe is

placed into service. Failure to comply

may cause serious damage.

GEARBOX

Oil must be up to the indicator mark in the

oil sight glass as shown in figure-41. Top off

with Mobilgear 627 or equivalent. Fill by

pulling the plug shown in figure-41.

Figure-41 Gear box oil sight glass & fill plug

22

7R GUDLQ WKH RLO UHPRYH WKH GUDLQ SOXJ RQ

WKH OHIW VLGH RI KHDGVWRFN 6HH ILJXUH

'UDLQ FRPSOHWHO\ DQG UHILOO DIWHU ILUVW WKUHH

PRQWKV RI RSHUDWLRQ 7KHQ FKDQJH RLO LQ

WKHKHDGVWRFNDQQXDOO\

6$''/(

/XEULFDWH WKH IRXU RLO SRUWV $ VKRZQ LQ

ILJXUHZLWK:PDFKLQHRLORQFHGDLO\

&52666/,'(

/XEULFDWH WZR RLO SRUWV % VKRZQ LQ ILJXUH

ZLWK:PDFKLQHRLO

)LJXUH*HDUER[RLOGUDLQSOXJ

&+$1*(*($56

$SSO\DIHZGURSVRIRLORQWKHJHDUVWHHWK

DQGDYRLGJHWWLQJRLORQWKHSXOOH\VDQGEHOW

)LJXUH &DUULDJH DQG FURVV VOLGH RLO ILOO

SRUWV

&52666/,'(+$1'

:+((/

/XEULFDWHWKHRLOSRUW&RQWKHFURVVVOLGH

KDQG ZKHHO VKRZQ LQ ILJXUH ZLWK :

PDFKLQH

)LJXUH&KDQJHJHDUV

)LJXUH&URVVVOLGHKDQGZKHHORLOSRUW

/($'6&5(:

/XEULFDWH WKH RLO SRUWV ' ( VKRZQ LQ

ILJXUHZLWK:PDFKLQHRLORQFHGDLO\

0$,17(1$1&(

'XULQJ WKH OLIH RI \RXU PDFKLQH \RX ZLOO

QHHGWRSUDFWLFHVRPHUHJXODUPDLQWHQDQFH

WR NHHS \RXU ODWKH LQ SHDN SHUIRUPDQFH

FRQGLWLRQ

7UHDW WKH PDFKLQH ZLWK FDUH NHHS LW

FOHDQ DQG JUHDVH DQG OXEULFDWH LW UHJXODUO\

2QO\ WKURXJK JRRG FDUH \RX FDQ EH VXUH

WKDW WKH ZRUNLQJ TXDOLW\ RI WKH PDFKLQH ZLOO

UHPDLQFRQVWDQW

)LJXUH /HDG VFUHZ DQG IHHG VFUHZ RLO

SRUWV

7$,/672&.

/XEULFDWH WKH WZR RLO SRUWV VKRZQ LQ ILJXUH

RQFHGDLO\

2LO JUHDVH DQG FOHDQLQJ DJHQWV DUH

SROOXWDQWV DQG PXVW QRW EH GLVSRVHG RII

WKURXJK WKH GUDLQV RU LQ QRUPDO JDUEDJH

'LVSRVHRIWKRVHDJHQWVLQDFFRUGDQFHZLWK

FXUUHQW ORFDO HQYLURQPHQWDO UHJXODWLRQV

&OHDQLQJ UDJV LPSUHJQDWHG ZLWK RLO JUHDVH

DQG FOHDQLQJ ZRRO LQ D VXLWDEOH FORVHG

YHVVHO DQG GLVSRVHG RI LQ DQ

HQYLURQPHQWDOO\ VRXQG ZD\ 'R QRW SXW

WKHPZLWKQRUPDOJDUEDJH

/XEULFDWH DOO VOLGH ZD\V OLJKWO\ EHIRUH

HYHU\ XVH 7KH FKDQJH JHDUV DQG WKH OHDG

VFUHZ PXVW DOVR EH OLJKWO\ OXEULFDWHG ZLWK

OLWKLXPEDVHGJUHDVH

'XULQJ RSHUDWLRQ WKH FKLSV ZKLFK IDOO

RQWR WKH VOLGLQJ VXUIDFH VKRXOG EH FOHDQHG

LQ D WLPHO\ IDVKLRQ )UHTXHQW LQVSHFWLRQV

VKRXOG EH PDGH WR SUHYHQW FKLSV IURP

IDOOLQJ LQWR WKH SRVLWLRQ EHWZHHQ WKH

FDUULDJHDQGEHGZD\

)LJXUH7DLOVWRFNRLOSRUWV

:$51,1*

0DNHVXUHWKHPDFKLQHLVWXUQHGRIIDQG

WKHFRUGLVGLVFRQQHFWHGIURPWKHSRZHU

VRXUFH EHIRUH VHUYLFLQJ DQG UHSODFLQJ

DQ\FRPSRQHQWVRQWKHPDFKLQH

$IWHU WKH RSHUDWLRQ HYHU\ GD\ HOLPLQDWH

DOOWKHFKLSVDQGFOHDQGLIIHUHQWSDUWVRIWKH

PDFKLQH WRRO DQG DSSO\ PDFKLQH WRRO RLO WR

SUHYHQWIURPUXVWLQJ

*RRG KRXVHNHHSLQJ SUDFWLFH VKRXOG EH

IROORZHGRQDGDLO\EDVLVNHHSLQJ\RXUODWKH

FOHDQDQGZHOOOXEULFDWHG

237,21$/67$1'

7KH /DWKH IHDWXUHV DQ RSWLRQDO VWDQG

ZKLFK FDQ EH ERXJKW VHSDUDWHO\

)LJXUH0RXQWLQJWKHODWKHRQWKHVWDQG

)LJXUH

6WDQGLQYHQWRU\

/,672)&217(17647<

$/HIW&DELQHW % 5LJKW&DELQHW &&RQQHFWLQJ%UDFNHWV ' 0RXQWLQJ+DUGZDUH%DJ

2QFH ERWK WKH EUDFNHWV DUH SURSHUO\

VHFXUHG WR WKH FDELQHWV SRVLWLRQ WKH FKLS

WUD\ RQ WKH FDELQHWV DOLJQLQJ WKH KROHV RQ

WKH FKLS WUD\ ZLWK WKH KROHV RQ WKH FDELQHW

1RZSRVLWLRQWKHODWKHRQWKHVWDQGXVLQJD

IRUN WUXFN $OLJQ WKH KROHV RQ WKH PDFKLQH

ZLWK WKH KROHV RQ WKH FKLS WUD\ DQG WKH

FDELQHWV

2SHQ WKH FDELQHWV DQG LQVHUW WKH EROWV DQG

ZDVKHUV SURYLGHG ZLWK WKH VWDQG IURP WKH

WRS DQG WLJKWHQ WKH QXWV IURP LQVLGH

FDELQHWV

67$1'$66(0%/<

%HIRUHDWWDFKLQJWKHEUDFNHWVWRWKHVWDQGV

WKUHDG WKH EROWV LQWR WKH KROHV WR EUHDN WKH

SDLQWHQVXULQJVPRRWKWKUHDGLQJDIWHU

&RQQHFW WKH OHIW DQG ULJKW FDELQHW E\

DWWDFKLQJ WKH EUDFNHWV WR WKH FDELQHWV DQG

VHFXULQJ WKRVH XVLQJ VFUHZV DQG ZDVKHUV

SURYLGHG

)LJXUH/DWKHPRXQWHGRQWKHVWDQG

ELECTRICAL

CONNECTIONS

The Variable Speed Lathe is rated

at 1.5-Horse Power, Single Phase, 110-Volt

and 12.3 Amps. Use the wiring diagram for

connecting the lathe to the main supply.

Make sure the lathe is properly grounded.

See page-8 for details.

WARNING

Connection of the lathe and all other

electrical work may only be carried out

by an authorized electrician. Failure to

comply may cause serious injury and

damage

to

the

machinery

and

surroundings.

WIRING DIAGRAM FOR PM-1127VF-LB

26

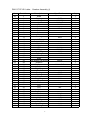

7+5($',1*)((',1*7$%/()25/$7+(

0(75,&

,1&+

PM-1127VF-LB /DWKH

PM-1127VF-LB /DWKH

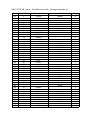

1R

3DUWV1R

'HVFULSWLRQ

/DEHO

6FUHZ

%ROW

1XW

1XW

6SLQGOH

.H\

*DVNHW

%HDULQJ

+HDGVWRFN

6FUHZ

%HDULQJ

*DVNHW

%XVK

*HDU

%HOW

6SLQGOH3XOOH\

6HW6FUHZ

:DVKHU

1XW

6FUHZ

%UDFNHW

6FUHZ

:DVKHU

'&0RWRU

0RWRU3XOOH\

6HW6FUHZ

+HDG6WRFN

%HOW&RYHU

%UDFNHW3ODWH

6SHFLILFDWLRQ

Ɏ[

0

0

[

0[

(

*DWHV

0[

.:

4W\

PM-1127VF-LB Lathe -

PM-1127VF-LB

Lathe - *HDUER[$VVHPEO\ ,

1R

3DUWV1R

'HVFULSWLRQ

6KDIW

%HDULQJ

25LQJ

1XW

3LQ

&ROODU

6FUHZ

&RYHU

&ROODU

*HDU

%HDULQJ

/HIW3OXJ

+H[6RFNHW&DS6FUHZ

:DVKHU

.H\

3LQ

25LQJ

6QDS5LQJ

%HDULQJ

*HDU

6KDIW

+H[6RFNHW&DS6FUHZ

*HDUER[

6HW6FUHZ

&ROODU

5LJKW3OXJ

6KDIW

%HDULQJ

%HDULQJ

*HDU

6QDS5LQJ

*HDU

6KDIW

.H\

.H\

*HDU

6HW6FUHZ

6KDIW

.H\

.H\

%HDULQJ

*HDU

6QDS5LQJ

%HDULQJ

6SHFLILFDWLRQ

0[

ĭ[

0[

ĭ

ĭ[

ĭ

0[

0[[

ĭ

[

[

ĭ[

[

[

ĭ

4W\

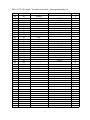

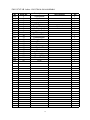

PM-1127VF-LB Lathe - *HDUER[ $VVHPEO\ ,,

1R

3DUWV1R

'HVFULSWLRQ

/HIW3OXJ

)RUN

%UDFNHW

3LQ

6KDIW

25LQJ

)RUN

*HDU

6QDS5LQJ

%HDULQJ

*HDU

5LJKW3OXJ

'LDOV%ORFN

*HDUER[&RYHU

3LQ

.QRE%DVH

.QRE

/DEHO

%DOO

6SULQJ

6FUHZ

/DEHO

2LO6LJKW

6FUHZ

6FUHZ

6KDIW

6SHFLILFDWLRQ

ĭ;

ĭ

ĭ[

ĭ

[[

0[

0[

0[

4W\

PM-1127VF-LB Lathe - 7RSVOLGH&URVVVOLGH&DUULDJH$VVHPEO\

PM-1127VF-LB Lathe - 7RSVOLGH&URVVVOLGH&DUULDJH$VVHPEO\ ,

1R

3DUWV1R

'HVFULSWLRQ

6FUHZ

+DQGOH%DVH

+DQGOH6KDIW

.QRE

:DVKHU

3RVW%DVH

6WRS

6SULQJ

7RS6OLGH

*LE

:DVKHU

+XE

,QGH[5LQJ

+H[6RFNHW&DS6FUHZ

%DOO

6SULQJ

,QGH[%DVH

3LQ

/HYHU

/HYHU

/HYHU6KDIW

%ORFN

6FUHZ

SOXJ

6HW6FUHZ

2LO%DOO

+H[6RFNHW&DS6FUHZ

&URVV6OLGH

SOXJ

+H[1XW

+H[6RFNHW&DS6FUHZ

%ORFN

6HW6FUHZ

+H[6RFNHW&DS6FUHZ

6DGGOH

:LSHU

3ODWH

6FUHZ

:LSHU

3ODWH

6WULS

+H[6RFNHW&DS6FUHZ

6WULS

6WULS

6SHFLILFDWLRQ

0[

[[

0[

ĭ

[[

ĭ[

0[

0[

0

0[

0[

0[

0[

0[

4W\

PM-1127VF-LB Lathe - 7RSVOLGH&URVVVOLGH&DUULDJH$VVHPEO\ ,,

1R

3DUWV1R

'HVFULSWLRQ

%UDFNHW

+H[6RFNHW&DS6FUHZ

%HDULQJ

&ROODU

,QGH[5LQJ

+DQGOHZKHUH

:DVKHU

+H[6RFNHW&DS6FUHZ

6SULQJ

+H[6RFNHW&DS6FUHZ

.H\

,HDGVFUHZ

*LE

+H[6RFNHW&DS6FUHZ

+H[6RFNHW&DS6FUHZ

3LQ

*UDGXDWHG&ROODU

7%ROW

&ODPSLQJ5LQJ

1XW

%ROW

+H[6RFNHW&DS6FUHZ

SOXJ

6ZLYHO%DVH

.H\

*HDU

6HW6FUHZ

6SHFLILFDWLRQ

0[

0[

0[

0[

0[

ĭ[

0[

0

0[

[

0[

4W\

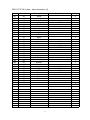

PM-1127VF-LB Lathe - $SURQ$VVHPEO\

PM-1127VF-LB Lathe - $SURQ$VVHPEO\,

1R

3DUWV1R

'HVFULSWLRQ

*HDU

3LQ

*HDU

:DVKHU

6HW6FUHZ

*HDU6KDIW

.H\

6KDIW

6QDS5LQJ

*HDU

6KDIW

*HDU

*HDU

3LQ

*HDU

:DVKHU

*HDU

*HDU

6QDS5LQJ

6KDIW

:RUP

.H\

*HDU

:DVKHU

:RUP

%HDULQJ

:RUP%DVH

3LQ

+H[6RFNHW&DS6FUHZ

:RUP

.H\

:DVKHU

6HW6FUHZ

3ODWH

3ODWH

+H[6RFNHW&DS6FUHZ

+DOI1XW

3LQ

&DP6KDIW

+H[6RFNHW&DS6FUHZ

+H[6RFNHW&DS6FUHZ

%DOO

6SULQJ

6HW6FUHZ

6SHFLILFDWLRQ

ĭ[

0[

ĭ

ĭ[

ĭ

[

ĭ[

0[

0[

ĭ[

0[

0[

ĭ

[[

0[

4W\

PM-1127VF-LB Lathe - $SURQ$VVHPEO\ ,,

1R

3DUWV1R

'HVFULSWLRQ

.QRE

+DQGOH

+DQGOH%DVH

3LQ

6KDIW

%DVH

+H[6RFNHW&DS6FUHZ

6KDIW+DQGOH

6KDIW)RU[

3LQ

%DVH

6HW6FUHZ

1XW

6KLIW/HYHU

1XW

+H[6RFNHW&DS6FUHZ

6KDIW+DQGOH

.QRE

ZDVKHU

+DQGZKHHO

6KDIW

*UDGXDWHG&ROODU

%UDFNHW

6KDIW

.H\

.H\

2LO%DOO

5LYHW

3ODWH

3ODWH

3ODWH

&ROODU

$SURQ

6SHFLILFDWLRQ

ĭ[

0[

ĭ[

0

0

0[

ĭ

[

[

ĭ

ĭ[

4W\

PM-1127VF-LB Lathe -

PM-1127VF-LB Lathe - 7DLOVWRFN%HG$VVHPEO\ ,

1R

3DUWV1R

'HVFULSWLRQ

4XLOO

.H\

1XW

6HW6FUHZ

6FUHZ

.H\

3LYRW%ORFN

6FUHZ

+DQGOH%DVH

+DQGOH6KDIW

.QRE

3LQ

2LO%DOO

7DLOVWRFNERG\

)ODQJH&RYHU

,QGH[5LQJ

+H[6RFNHW&DS6FUHZ

%DOO

6SULQJ

6OHHYH

+DQGZKHHO

.QRE

6FUHZ

1XW

:DVKHU

%UDNH%ORFN

+H[6RFNHW&DS6FUHZ

+H[6RFNHW&DS6FUHZ

6HW6FUHZ

+H[6RFNHW&DS6FUHZ

3ODWH

3ODWH

5LYHW

%DVH

%ROW

&ODPSLQJ3ODWH

%HG

1XW

3ODWH

1XW

:DVKHU

%HDULQJ

%UDFNHW

+H[6RFNHW&DS6FUHZ

6SHFLILFDWLRQ

0[

[

0

ĭ[

ĭ

0[

ĭ

ĭ[[

0

ĭ

0[

0[

0[

ĭ[

0

0[

ĭ

0[

4W\

PM-1127VF-LB Lathe - 7DLOVWRFN%HG$VVHPEO\ ,,

1R

3DUWV1R

'HVFULSWLRQ

)HHG6KDIW

+H[6RFNHW&DS6FUHZ

3LQ

3LQ

6KDIW

1XW

6SULQJ

%UDNH%ORFN

6HW6FUHZ

6KDIW

+DQGOH

6SHFLILFDWLRQ

0[

ĭ[

ĭ[

0

ĭ[[

0[

4W\

PM-1127VF-LB Lathe - (/(&75,&$/%2;$66(0%/<

PM-1127VF-LB Lathe - (/(&75,&$/%2;$66(0%/<

1R

3DUWV1R

'HVFULSWLRQ

7LPLQJ.QRE

6FUHZ

1XW

/DEOH

5)6ZLFK

6SHHG'LVSOD\

6FUHZ

0DJQHWLF6ZLFK

6FUHZ

(OHFWULFDO3ODWH

3RWHQWLRPHWHU

(OHFWULFDO%R[

)LOWHU

6FUHZ

1XW

6SHHG&RQWURO%RDUG

&RYHU

6FUHZ

)XVH+ROGHU

)XVH$

6WUDQG5HOLHI

3OXJ

6SHFLILFDWLRQ

2SWLRQDO

4W\

3. Running test

2. Function of apron

1. Function of gearbox

III. Active Inspection

7. Spindle adjustment

6. Parallelism of pulleys

5. Lubrication for sliding parts

4. Function of tailstock

3. Function of carriage

2. Function of cross slide

1. Function of top slide

II. Mechanical Inspection

4. Screw tightened

3. Corrosion damage

2. Painting damage

1. Correct label

I. Visual Inspection

ƶ

ƶ

ƶ

ƶ

OK

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

OK

4. Credibility antirust

3. Machine cleanness

2. Correct documents

1. Correct accessories

V. Final Inspection

12. Function of motor

11. Spindle safety cover

10. Function of speed readout

9. Electrical control board

8. Speed control knob

7. Emergency stop switch

6. Function of F/R switch

OK 5. Tolerance voltage test

ƶ

5.Correct mark

4. Insulation resistance

3. Earth resistance

2. Correct electrical elements

1. Connection tightened

ƶ

ƶ

ƶ

ƶ

ƶ

OK

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

ƶ

PM-1127VF-LB

4. Noise test

ƶ

OK

5. Leaky test

ƶ

IV. Electrical Inspection

6. Cutting test

Remark:

3UHFLVLRQ0DWWKHZV

Test Record

PM-1127VF-LB

Serial No.

Date

Inspector

'LIIHUHQFHEHWZHHQ

WZRFHQWHUVKLJKHU

DWWDLOVWRFN

D D

E E

3DUDOOHOLVPRIFHQWHU

OLQHRIVSLQGOHWR

FDUULDJHPRYHPHQW

DLQKRUL]RQWDOSODQH

ELQYHUWLFDOSODQH

E

D

E

5XQRXWRIVSLQGOH

WDSHUKROH

DVSLQGOHQRVH

EGLVWDQFH

D

D

E

5XQRXWRIFHQWHU

E

3(50,66,%/(

$&78$/

72/(5$1&(PP

D

',$*5$0

,163(&7,21

,7(0

5XQRXWRIVSLQGOH

QRVH

DUDGLDOSODQH

EIDFHSODQH

12

PM-1127VF-LB

12

5DGLDOUXQRXWRI¡

WHVWEDU

5DGLDOUXQRXWRI

FKXFN

3DUDOOHOLVPRIFHQWHU

OLQHRIVSLQGOHWRWRS

VOLGHPRYHPHQW

3DUDOOHOLVPRI

WDLOVWRFNTXLOOWDSHU

KROHWRFDUULDJH

PRYHPHQW

DLQKRUL]RQWDOSODQH

ELQYHUWLFDOSODQH

3DUDOOHOLVPRI

WDLOVWRFNTXLOOWR

FDUULDJHPRYHPHQW

DLQKRUL]RQWDOSODQH

ELQYHUWLFDOSODQH

,163(&7,21

,7(0

PM-1127VF-LB

D

D

E

E

',$*5$0

D D

E E

D D

E E

3(50,66,%/(

$&78$/

72/(5$1&(PP

3UHFLVLRQ0DWWKHZV

02'(/ 12

0)*

6(5,$/ 12

1:

.*6

,7(0 12

*:

.*6

',0(16,21

00

0$18)$&785(' ,1 &+,1$

72:(,66 63(&,),&$7,216

3UHFLVLRQ0DWWKHZV

02'(/ 12

0)*

6(5,$/ 12

1:

.*6

,7(0 12

*:

.*6

',0(16,21

0$18)$&785(' ,1 &+,1$

72:(,66 63(&,),&$7,216

00