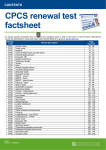

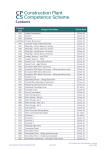

Download standard theory test questions for catergories a02

Transcript