Download User Manual Rev. 01a

Transcript

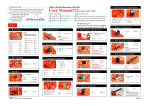

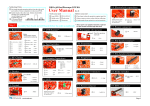

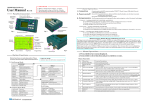

Soldering Hints DSO 138 Oscilloscope DIY Kit 1 Put leads through mounting holes from the side with part outline. Ensue component evenly touch PCB. 2 Solder leads at the other side. Solder should fully fill and cover soldering pads. Avoid bridges between neighbering pads. 3 Cut unused leads flush with cutter. User Manual 4 Screw driver 5 Flush cutter 6 Tweezers Step 1 Assembly Main Board and LCD board (follow the order as numbered) 1. Resistors Rev. 01a Before you start Tools you need 1 Iron (20W) 2 Solder wire 3 Multimeter 14. Electrolytic capacitors 5. USB Socket * 1 Check part values & quantities against part list 2 Always meter resistor values before soldering 3 Understand all part polarities and orientations * These parts are optional and not required for the normal oscilloscope function. Solder positive pole (the longer lead) to the square pad C19, C21, : 100μF / 1 6 V C22, C24, C25, C26 15. Power connector 9. Pin header (for power) : DC005 J10 Face the opening outward Note: Always meter resistor values before soldering J4 : USB mini -B J9 : 2 Pin 16. Pin-header (male) * : 180Ω R7, R36 R1, R14, R16 : 100KΩ R8, R12, R13 : 120Ω R2 : 1.8MΩ R9, R15, R26 : 1KΩ R3 : 200KΩ R10 : 3KΩ R4 : 2MΩ R11, R38 : 1.5KΩ R5 : 20KΩ R28, R40 : 470Ω R6 : 300Ω R37, R39 : 10KΩ 10. Transistors 6. Tact Switches SW4, SW5, : 6 X 6 X 5mm SW6, SW7, SW8 Q1 : 8550 Q2 : 9014 J5 : 1 X 3 pin J6 : 1 X 4 pin 17. Pin-header (female) 2. HF-Chokes 11. Regulators 7. Ceramic Capacitors : 100μH L1,L3,L4 3. Diodes Cathode D1 : 1N5819 D2 : 1N4004 (or 1N4007) C1, C9, C10, C11, C14, C15, C16, C17, C18, C20, C23 : 0.1μF C2 : 330pF C7, C8 : 120pF C3 : 3pF C12, C13 : 22pF C5 : 1pF U4 : 79L05 U5 : 78L05 12. Capacitor trimmers C4, C6 8. LED 4. Crystal : 5 - 30pF : 8MHz Solder positive pole (the longer lead) to the square pad D3 :φ3mm, green L2 : 1 X 2 pin : 2 X 20 pin 18. Slide switches SW1, SW2, SW3 : 2P3T 19. BNC connector 13. Power inductor Y1 J7, J8 J3 : 1mH/0.5A J1 : BNC Page 1 20. Test signal ring 21. JP3 22. LCD Board 1 ) Make a small ring with a lead cut-off. Note: Install to the side opposite to LCD panel. Short JP3 with solder 2 ) Solder the ring to the two holes of J2 (as shown in the photo). Step 2 Test and Use A. Check voltages B. Attach LCD board Plug LCD board into the female headers J3, J7, and J8 on the main board. : 2 X 20 pin J2, J3 : 1 X 2 pin The assembly should look like this after you have finished all parts NOTE: You need a 9V DC power supply (at least 200mA capacity) to run the scope. This power supply is not included in the kit. 1 Apply 9V power to J10 (or J9). 2 Check voltage at TP22. It should be around +3.3V. 3 If voltage at TP22 is good disconnect power. Short JP4 with solder permanently . 1 J1 C. Verify A. Use 1 Connect power supply again. You should see LCD lights up and oscilloscope panel displayed. 2 Press various buttons and move switches to verify their functions. 1 Attach probe clips to J1. 2 Touch the red clip with your finger. Do you see signal from your finger? 1 2 2 “Trigger” LED blinking twice indicates booting-up is good. 3 Troubleshooting LCD Dark No Display (No backlight) Is voltage at V+ good? No Check power Yes Is R36 value correct and soldered good? supply Fix R36 Yes Check LCD board Short JP4 if it has not been done. See Step 2 above. Press SW8. Does LED blink? Yes Check J3 soldering for possible opens or shorts Check J1 soldering on LCD board for possible opens or shorts -5.0V 4.99V Voltage References 5.02V * * -8.08V* Check +3.3V voltage Check Y1, C12, C13 Check LED installation 3.3V 0.19V * 9.39V *(Input Voltage) 6.43V 8.60V -8.11V No No Do you get about 3V No Check R36 and between J1 pin 16 & power again 18 on LCD board? Yes NOTE: The voltages in the photo are for reference only. The voltages on your board could be different. But they should be close to the values shown. * 3.3V 8.34V * -1.39V No Trace 2.16V No Are the values of AV+ and AV- correct? 0.81V Fix them Yes Set CPL switch to GND No Check U2B, U2C and and measure V1 and V2. related parts around Are they correct? these two amplifiers 0V ** 1.66V Yes Check R12 and C8 Place the negative pen of volt-meter here to do voltage measurements. ** NOTES: *: These voltages are input voltage dependent. The values shown were measured when input voltage was 9.39V. **: These voltages are measured when CPL switch (SW1) is set to GND position. Page 2 How to Use Probe Calibration Because there is always some capacitance between scope input and ground probe needs to be calibrated to achieve better measurement results for high frequency signals. This can be done with the help of the built-in test signal. To do this please follow the steps below. Display and Controls Oscilloscope Mode Horizontal Position Connectors Trigger Level Readout for Power Supply Connector for Probe [OK]: HOLD / RUN Selection [CPL]: Couple Selection [+] or [-]: Parameter Adjustment [SEN1]: Sensitivity Selection 1 Leave black clip un-connected Connect red clip to test signal output 1. Connect the red clip to the test signal terminal and leave the black clip un-connected (see photo at right). 2. Set [SEN1] switch to 0.1V and [SEN2] switch to X5. Set [CPL] switch to AC or DC. 3. Adjust timebase to 0.2ms. You should see waveform similar C6 to that shown in photos below. If traces are not stable adjust trigger level (the pink triangle on right screen border) so as C4 you get a stable display. 4. Turn C4 (capacitor trimmer) with a small screw driver so that the waveform displays sharp rightangle (photo C). 5. Set [SEN1] switch to 1V and [SEN2] switch to X1while keep all other settings unchanged. Adjust C6 so that sharp rightangle waveform is displayed. [SEL]: Parameter Selection [SEN2]: Sensitivity Selection 2 Trigger Level Indicator A – Not enough Vertical Position Indicator Sensitivity Couple Timebase Trigger (s/div) Mode (V/div) Trigger Slope “Trigged” Indicator Hints Connections Power Supply: Connect DC power supply to J9 or J10. The power supply voltage must be in the range of 8 - 12V. Probe: Connect probe to J1. Atte ntion 1. Power supply voltage must not exceed 12V. Otherwise U5 will get hot. 2. Allowed maximum signal input voltage is 50Vpk (100Vpp) with the clip probe. Operations Press on [SEL] button: Select parameter to be adjusted. The selected parameter will be highlighted. Press on [+] or [-] button: Adjust the parameter selected by [SEL] button. Press on [OK] button: Freeze waveform refresh (entering HOLD state). Press on it again will de-freeze. Change [CPL] switch: Set couple to DC, AC, or GND. When GND is selected the scope input is isolated from input signal and connected to ground (0V input). Change [SEN1] or [SEN2] switch: Press on [Reset] button: C – Good B – Too much Reset Button Adjust sensitivity. The product of [SEN1] and [SEN2] settings makes the actual sensitivity which is displayed at the lower-left corner of the panel. Perform a system reset and re-boots the oscillscope. 0V Line Alignment Sometimes you may find the 0V line (the trace corresponding to 0V input voltage) does not match with the VPOS indicator at the screen left border. This can easily be fixed by performing the “0V line alignment” function. First, set the couple switch [CPL] to GND position. Then press on [SEL] button to make VPOS indicator highlighed and hold down [OK] button for about 2 seconds. You will set the trace aligned to VPOS indicator when you release [OK] button. You may see some residue mismatch remains at the highest sensitivity settings. This is normal. The LED at bottom-right corner (labelled “TRIGGED”) is the trigger indicator. It blinks when triggers are detected. Triggers and Their Modes Triggers are events that indicate signal voltage acrossing a set level (i.e. trigger level) along a specified direction (i.e. trigger slope, rising or falling). Oscilloscope uses triggers as reference points in time for stable waveform display and measurements. Au to Mode In auto mode oscilloscope will perform display refresh no matter triggers happen or not. When triggers are detected waveform display will be displayed with reference to trigger points. Otherwise, display waveform at ramdom reference points. Normal M ode In normal mode oscilloscope will only perform display refresh when there are triggers. If no triggers happen waveform display will stay unchanged. Specifications Max realtime sample rate Analog bandwidth Sensitivity range Max input voltage Input impedance Resolution Record length Timebase range Trigger modes Trigger position range Power supply Current consumption Dimension Weight 1MSa/s 0 -- 200KHz 10mV/div - 5V/div 50Vpk (1X probe) 1M ohm/20pF 12 bits 1024 points 500s/Div -- 10us/Div Auto, Normal, and Single 50% 9V DC (8 – 12V) ~120mA 117 x 76 x 15mm 70 gram (without probe) Single M ode Single mode is the same as normal mode except that oscilloscope will enter HOLD state after a trigger has been detected and waveform display has been updated. Normal and single modes are useful for capturing sparse or single waveform. Page 3 5 4 3 ** TP1 DC 1 J1 BNC SW1A These voltages wer e measured when SW1 is at GND position. C2 2 GND 4 0.1u 220pF SEN1 SEN2 R1 100K 10mV 1 C3 3pF 0.1V 3 1V 4 R2 1.8M 1% D AV+ 2 + C5 1pF 2 10 + 9 - 4 10 VSENSEL2 11 VSENSEL1 12 CPLSEL 13 TP11 14 TP12 15 TP13 V-MON 16 TESTSIG 17 TRIG 29 TX1 30 RX1 31 USBDM 32 USBDP 33 SWDIO 34 SWCLK 37 LED 38 TP3 8 R12 120 C8 120pF R7 AVR9 1K R10 3K AV- R11 1.5K AV+ R20 10K 7 V3 100K TP4 AV+ R23 5 10K 5 TP6 SW3B 6 7 R19 1.5K 8 R14 AV+ C7 120pF CPLSEL 18 19 20 39 40 41 42 43 TL_PWM 45 VGEN 46 LCD_nRD 21 LCD_nRESET 22 BTN4 25 BTN3 26 BTN2 27 BTN1 28 TP7 R22 1.5K 20K 1% SW1B 6 VSENSEL1 6 R24 TP8 R13 120 R25 1.5K 8 3.3K VSENSEL2 12 + 13 - 14 U2D TL084/SO AV+ C10 0.1u LCD_nCS LCD_RS LCD_nWR AV- TP5 TLVL JP3 C11 C9 0.1u TP33 J4 USB_mini_B VBUS DD+ ID GND USB Buttons R31 1.5K 1 2 3 4 5 R29 R30 22 22 USBDM USBDP BTN2 + 7 PB0 PB1 PB2 PB3 PB4 PB5 PB6 PB7 PB8 PB9 PB10 PB11 PB12 PB13 PB14 PB15 VBAT 1 VDDA 9 +3.3V BOOT0 J2 C14 VSSA 8 VDD_1 VDD_2 VDD_3 24 36 48 PC13/TEMPER/RTC VSS_1 PC14/OSC32_IN VSS_2 PC15/OSC32_OUT VSS_3 23 35 47 R28 1 2 LED-K1 LED-K3 IM3 DB0 DB2 DB4 DB6 LCD_nRESET JP6 10K TESTSIG R26 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 JP5 SWDIO SWCLK R35 1K GND +3.3V V+ + 1 C22 100uF 3.3V 9.3V 1 3 2 V+ C19 + 100uF TP20 3 VIN 2 GND L3 100uH +5V U5 VOUT LM78L05/T92 1 5V 1N5819 C24 C21 100uF L1 100uH IN OUT 3 * AV- C15 0.1u L4 100uH +3.3V + C26 100uF +3.3V C C16 C17 C18 0.1u 0.1u 0.1u +3.3V Q2 9014 + TP27 TP28 TP29 TP30 0.1u VGEN 2 C23 R39 0.1u 10K R40 470 +3.3V R41 10K R42 1K 0.8V * 4 J7 J8 1 2 1 2 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 LCD_RS LCD_nRD +3.3V B LED-A LED-K2 LED-K4 V+ R36 180 DB1 DB3 DB5 DB7 +3.3V LCD HEADER Notes: 1. Part values used could be different to the values shown. Please refer to part list. 2. Parts in dash-line boxes are SMD devices. -1.4V DC 9V 5 -5V U4 79L05/TO92 C25 100uF 100uF * 6.4V AV+ C20 2 R38 1.5K * TP24 TP26 TP25 V- 1 L2 1mH/1A 8.6V + - * 8.3V R37 -8.1V D1 2 10K A D2 1N4004 0.2V 3 LM1117 -3.3/TO263 * J10 1 * * Q1 8550 8.6V TP23 2 4 + JP4 J9 1 2 * TP22 U3 + - SW8 0.1u +3.3V 470 LCD_nCS LCD_nWR IM0 +3.3V 10K + TP21 VOUT VOUT D 1K TP10 +3.3V VIN R27 J3 1 2 3 4 Test Signal Terminal TP16 TP17 3 44 LCD Module Connector J6 J5 Caution: Power supply voltage can not be higher than 12V. 22pF JP1 D3 R34 SW7 Power Supply C13 STM32F103Cx +3.3V BTN4 SEL RX1 TX1 nRST LED BTN3 - 1K 1K 22pF Y1 8MHZ PD0/OSC_IN 5 USE SWD DE BUG MODE ON LY SW5 R32 R33 PD1/OSC_OUT SW4 TP14 TP15 B 1 2 3 C12 6 PA0 PA1 PA2 PA3 PA4 PA5 PA6 PA7 PA8 PA9 PA10 PA11 PA12 PA13 PA14 PA15 0.1u SW6 Uart 2 3 4 R16 100K SWD Port BTN1 OK Trigg er Level AV- Analog Channel DB0 DB1 DB2 DB3 DB4 DB5 DB6 DB7 JP2 1K 8 3.3K R15 SW2B 5 R5 30pF 3.3K X5 ADCIN 120 - 7 X2 3 300 ** 1.6V 7 1 AV+ R6 AV- R21 R18 - TP9 U1 V2 R8 C6 C 6 30pF AV- 10K + AV+ U2C TL084/SO SW3A 1 180 R4 2M 1% R17 5 R3 200K 1% C4 U2A TL084/SO SW2A 2 X1 AV+ U2B TL084/SO 1 MCU ** 0V V1 TP2 AC 3 C1 3 2 CPL AIN V-MON A TP31 TP32 These voltages are power volt age dependent. The values shown were measured at 9.3V power voltage. 3 2 1 Page 4 5 4 D 3 2 DB0 DB2 GND1 nCS nWR IM0 YU YD LED-K1 LED-K3 IM3 DB10 DB12 DB14 DB16 nRESET VCC3 DB5 DB7 LCD1 C B 39 38 DB0 DB1 DB2 DB3 GND VCC CS RS WR RD IM0 XL YU XR YD LED-A LED-K1 LED-K2 LED-K3 LED-K4 IM3 DB4 DB10 DB11 DB12 DB13 DB14 DB15 DB16 DB17 RESET VCC VCC GND DB5 GND DB6 GND DB7 DB0 1 DB1 2 DB2 3 DB3 4 GND1 5 6 VCC1 nCS 7 RS 8 nWR 9 10 nRD 11 IM0 12 XL 13 YU 14 XR 15 YD 16 LED-A 17 LED-K1 18 LED-K2 19 LED-K3 20 LED-K4 21 IM3 22 DB4 23 DB10 24 DB11 25 DB12 26 DB13 27 DB14 28 DB15 29 DB16 30 DB17 31 nRESET 32 VCC2 33 VCC3 34 GND2 35 DB5 36 DB6 37 DB7 J1 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 1 DB1 DB3 VCC1 RS nRD XL XR LED-A LED-K2 LED-K4 DB4 DB11 DB13 DB15 DB17 VCC2 GND2 DB6 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 D C HEADER 20X2 DB0 DB2 GND1 nCS nWR IM0 YU YD LED-K1 LED-K3 IM3 DB10 DB12 DB14 DB16 nRESET VCC3 DB5 DB7 2.4" TFT J4 1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 DB1 DB3 VCC1 RS nRD XL XR LED-A LED-K2 LED-K4 DB4 DB11 DB13 DB15 DB17 VCC2 GND2 DB6 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36 38 40 B HEADER 20X2 JP1 A J2 J3 1 2 1 2 GND1 TP1 TP2 TP3 JP2 TP4 A Title GND2 2.4" TFT BASE Size A Date: 5 4 3 Document Number Rev 00A 105-13700-00A Saturday, August 23, 2014 2 Sheet 1 of 1 1 Page 5 白 J m I [SW5) I キI � Ef ω M @ 白h Jm いお 白 SWJ 間百円 酔… 引引 一 一 一 3C 1 1J E二 i1a - 市ート 『1 1 , 吋② 。 n z- d一 一 一 一 一 一 一 一 。 即時 一 J・日間 2 ; 一 一一 E 三一 一 一 」空 事@ 白申 ・ 一 三 白 U園 串 4静 圃圃 目 一 … 口内 町 町一剖 民話 … F一 。 』民 間 FJ 晶 画一 一 m 副 {γ /\ 一町一面 @一 知 山 Jf H E 町. V 甲山 ⑭間 コ 草 m C J: ・ り 日中 ー 山訳詞 t田町ザ ヱ 川引 四 回日目白日目 I (swe) I 戸山 3000Mils (7 .6cm) TP32 TP31 ・一七. -一三. ・一一・ -一一・ 一一層側面 争 |・ 4600Mils (11.7cm) Page 6 DSO138 SMD Part List ( Pre-soldered ) Type Resistor Resistor Resistor Resistor Resistor IC IC IC Descriptions 10K, 0805 3.3K, 0805 1.5K, 0805 1K, 0805 22, 0805 STM32F103C8, QFP-48 TL084, SO14 LM1117-3.3, TO263 Qty 6 3 4 4 2 1 1 1 Part Number R17, R20, R23, R34, R35, R41 R18, R21, R24 R19, R22, R25, R31 R27, R32, R33, R42 R30, R29 U1 U2 U3 Remarks Pre-soldered Pre-soldered Pre-soldered Pre-soldered Pre-soldered Pre-soldered Pre-soldered Pre-soldered Page 7