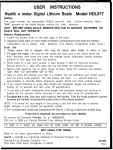

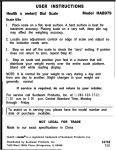

Download FP-1000/1001 User Manual

Transcript