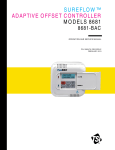

Download Model 8670 SureFlow

Transcript