Download ricoh ft5580/ft5590 field service manual

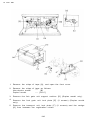

Transcript