Download Pioneer-PL-L1000-Service

Transcript

FS

Eefticec%anual

LINEAR MOTOR ARM STEREOTURNTABLE

PL-L1cI0(f

()rrrorueEr{

MODEL PL-LIOOO

COMESIN THREE VERSIONSDISTINGUISHED

AS FOLLOWS:

Type

t

Remarks

Voltage

HET

22OV and 240V (Switchablel

Europe model (without cartridge)

HBT

22OY and 24OV (Switchablel

United Kingdom model (without cartridgel

s/G

1lOV. 12OV,22OV,24OVand (Switchablel

U.S. Military model (with cartridge)

CONTENTS

1. SPECIFICATIONS

2. PANEL FACILITIES

3. DISASSEMBLY

3.1 Panel.

3.2 D.D. Motor

3.3 Tonearm

3.4 CdS Detectorand Lamp

4. PARTS LOCATIONS

5. BLOCK DIAGRAM

5.1 TonearmControl Stage .

5.2 End Detector Stage.

5.3 Arm ElevationControl Stage

5.4 SizeSelectorStage .

5.5 RepeatControl Stage

5.6 LoweringPositionDetector,Plunger

Control Stageand DescentSignal

Generator

5.7 DisplayStageand PlungerDriver .

5.8 ManualDriveStage

5.9 TrackingSensorStageand

Tonearm Driver Stage

5.10 D.D. Motor Control Stageand

D.D. Motor Stop Control

6 . C I R C U I TD E S C R I P T I O N S

6.1 FullAuto Logic .

6.2 TonearmDrive .

3

4

6

7

7

I

I

11

13

13

13

13

13

13

13

14

14

14

15

21

7. ADJUSTMENTS

7.1 D.D. Motor OperatingPoint

Adjustment

7.2 Auto Lead-inTiming Adjustment

7.3 End SensorSensitivityAdjustment

7.4 End Timer Adjustment

7.5 TrackingSensorZero Point

Adjustment

7.6 TrackingSensorGainAdjustment . . . . .

7.7 Lead-inand ReturnSpeedAdjustment . . .

8. TIMING CHART

9. TROUBLESHOOTING

9 . 1 C i r c u i tB l o c k .

9.2 MechanismBlock .

1 0 . E X P L O D E DV I E W S

10.1 Exterior

10.2 Tonearm

10.3 EV Mechanism

10.4 Bottom Plate .

11.PACK|NG....

12. SCHEMATTC

D T A G R A M( H E T , H B T m o d e t ) ..

1 3 . P . C .B O A R D C O N N E C T I O ND I A G R A M

( H E T ,H B T m o d e l )

1 4 . P A R T S L I S T O F P . C .B O A R D A S S E M B L Y

(HET,HBT model)

1 5 . S C H E M A T I CD I A G R A M ( S / c m o d e l )

1 6 . P . C . B O A R D C O N N E C T I O ND I A G R A M

(S/G model)

1 7 . P A R T S L I S T O F P . C .B O A R D A S S E M B L Y

(S/G model)

25

25

25

25

t

26

26

26

27

3: l

45

48

50

51

54

55

58

61

63

a

e

\

PL-L1 clclcl

Fr

)

ftr,

t

1. SPECIFICATIONS

Motor and Turntable

Semiconductors

DriveSystem

.. Direct-drive

Motor.

....OuartzPLLHalm

l otor

TurntablePlatter . . 31Ommdiam. aluminumalloy die-cast

InertialMass . . . . 330kg-cm2(includingplattermat mass)

Speeds

. 33-1/3 and 45rpm

*0.013%(WRMS)

Wow and Flutter

Lessthan

o.o25Yo(WRMS)

0 . 0 3 5 %( D t N )

Valuesmarked with an "*" designatethe wow and flutter j

for motor, and do not include the cartridgeor tonearmI

load.

S i g n a l - t o - N o iR

s ea t i o

M o r et h a n 7 8 d B ( D l N - B )

(with Pioneercartridgemodel PC-600)

fCs...

Transistors

Diodes

H a l El l e m e n t .s. .

LED..

PhotoTransistors.

cds..

22

17

16

....3

14

.....

5

1

Miscellaneous

PowerRequirements

HET,HBT models

. . . AC22O/24OV- (switchable)

50,60H2

- (switchable)

S/G model

. . ACl 10/12O/22O/24OY

50,60H2

P

o

w

e

r

C

o

n

s

u

m

p

t

i

o

n

..35W

RotationalCharacteristics

Dimensions

4 9 4 ( W )x 1 5 4 ( H )x 4 5 6 ( D ) m m

Build-upTime .

. Within 90o rotationat 33-1/3rpm

19-7116(W

x 6) - 1 1 1 6 ( H l 1

x7-15/16(D

i n) .

SpeedDeviation . . .

Lessthan O.OO2TI

Weight

12kg/261bfbz

Speedvs. Load Characteristics. . . . Stableup to 220 grams

Accessories

drag load

EP Adapter

1

. . Lessthan 0.00008o/o/h

SpeedDrift

at 33-1/3rpm

Screwdriver

1

Lessthan 0.00003%/degree

temp. changeat 33-1/3rpm

Overhanggauge.

......1

Tonearm

Level .

1

Type .

.......

.. LinearMotorDirect-drive C l e a n i n g c l o t h .

1

Cartridgemountingparts(HET, HBT modelsonly)

Static-balance

type, Linear-tracking

arm

Cartridgemountingscrews

EffectiveArmLength

...6

....190mm

Cartridgemountingnuts

Overhang

...2

....0mm

Cartridgemountingwashers

.......

UsableCartridgeWeight

. . .49 (min.) to 249 (max,)

2

CartridgePC-600(S/G model onty) .

Arm HeightAdjust Range

. . t3mm

1

Operatinginstructions(Frenchand German

Headshell

weight

10.5g

furnishedon modelsfor HET)

1

Subfunctions

Auto lead-in

Auto-return

Auto cut

Ouick repeat

Ouick play

Ouick stop

Stylus pressure d i rect-readoutcounterweight

Arm heightadjustingdevice

Cueingdevice

Freestop hinges

NOTE:

Specif ications and design subject to

without natice, due to improvements.

possibte modif ication

T

2 . P A N E L F A C I L I TE

IS

I

@ Dust cove.

@ Arm rest

a

/ t \

v

t

Power switch

@ ouartz lock

indicator

@ Arm ctamp

@ seeeo

@ otsc slZE switch

A

-

19, I onearm

(!) R EPEATswitch

( O A R M E L E V A T I O Ns w i

r)-

@ srnnr/sroP switch

V

@ Remote operation knob

POWER

SWTTCH

e

Used to switch on and off the power to the turntable.

(ON).

P o w e r i s s u p p l i e dw h e n t h e s w i t c h i s d e p r e s s e d

T h e S P E E Ds w i t c hi n d i c a t o r( 3 3 ) c o m e so n . T h e p o w e ri s

switchedoff when the POWERswitch is released.

NOTES:

r

.

.

The platter doos not rotate when tho tonearm is positioned at

the far right oven if the sl,lritch is depressed and the powgr

supplied.

With each push, this switch alternates between the ON and

OFF positions.

Keep the POWER switch at the OFF position when you are

not using the turntable.

@ euARTz LocK rNDrcAToR

T h i s i n d i c a t o ri l l u m i n a t e sw h e n t h e p l a t t e r i s r e v o l v i n g

at the specified rateof 33-1/3 or 45 rpm.

\.

NOTE:

lf the platter speed varies, such as when the speed s:witch is

changed from one position to another or when you press momantarily on the platter, ths indicatorwill go off. As the platter

ro/olution returns to the specified sped, the indicator will illuminate again.

swrrcH

@ sPEED

33 . . . . . . Set the switch to this positionwhen playing

a 33-1/3 rpm recordsuch as an LP. Whenit

is depressed

t h, e 3 3 i n d i c a t o rl i g h t su p , a n d

the platterrotatesat a speedof 33-1/3rpm.

45 . . . . . . Set the switch to this positionwhen playing

a 4 5 r p m r e c o r d l i k e a n E P . W h e ni t i s d e p r e s s e dt,h e 4 5 i n d i c a t o rl i g h t su p , a n d t h e

platter rotatesat a speedof 45 rpm.

a

PL-L1

t

@ DrscsrzEswrrcH

Selectsthe switch that corresponds

to the sizeof the record you want to hearfor auto play operation.

12"30 . . . For 30cm records

10"25 . . . For 25cm records

7"17 . . . ForlTcmrecords

o Usedto selectthe recordsizewhen depressed.

For instance,when the 30cm indicatorlights up, depressthe

switch for the 25cm position,and depressit againfor

the 17cm position. Depressing

the switch once more

setsit to the 30cm position.

o When the power switch is turnedON, the turntable

will always be set for records with a diameter of

3 0 c m a n dt h e c o r r e s p o n d i nl igg h tw i l l c o m eo n .

NOTE:

This sruitch will not work if depressed when the tonearm is

m o v i n g ( a u t o l e a d - i n ,a u t o - r e t u r n , a u t o c u t ) .

@ REPEAT

swtrcH

Pressthis switch for repeat play. When pressedthe indic a t o r w i l l l i g h t u p , a n d t h e r e c o r dw i l l b e p l a y e da g a i n

(refer to page 12 for further details on repeat play).

Pressthis switch againto releaseit. The indicatorwill go

off and the repeatplay function will be released.

NOTE:

n

This slitch will not work if depressed wh6n the ton€arm is

moving (auto-return, auto cut).

@ enru ELEVATIoN

swtrcH

n'

t,

Use this switch to interrupt play temporarily or to perform manuap

l lay.

When the DOWN position is depressedthe tonearmwill

descendand when the UP position is depressed

the tonearm will rise.Thesetwo operationswill be performedalternatelyeverytime the switch is pressed.

NOTES:

r

r

o

When th€ POWER switch is set to ON, the tonearm will start

in the UP position.

This switch will not work if depressed when th€ tonearm is

moving (auto lead-in, auto-return. auto cutl.

When the switch is at UP, tho auto-return cancelling mechanisrn is actuated and so there will be no auto-roturn.

O sranr/sropswtrcH

Pressthis switchfor auto play. The platterwill startto rotate, the tonearm will automaticallymove over to the

edgeof the recordand play will begin(auto lead-in).

lf this switch is pressedduring play, the tonearm will

automaticallyreturn to the arm clamp position,the platter will stop rotating and play will be suspended(auto

cut).

I

NOTE:

This saritch will not work if depressed when the tonearm is

moving (auto lead-in).

Clclc'

@ REM oTEopERATtoNKNoB

Used when moving the tonearm by remote control.

Rotatecounterclockwise

to movethe tonearmto the left.

Rotateclockwiseto movethe tonearmto the right.

NOTE:

Whon the arm elevation switch is at DOWN or auto lead-in, auto

cut and auto-return, the tonearm does not move even when the

remote operation is releasedand th6 knob rotated.

@ ToNEARM

The tonearm function is to apply the correct tracking

f o r c e t o t h e c a r t r i d g em

. a i n t b i nt h i s v a l u ep r e c i s e lay n d a l low the stylusto tracethe recordgroovesaccurately.

The tonearmcan be operatedmanuallywith your handor

remotelywith the remoteoperationknob. lt is coupledto

the motor switch and when it movesacrossto the record,

the platter rotatesand it stops when the tonearm is ret u r n e dt o t h e a r m c l a m pp o s i t i o n .

NOTE:

When the POWER switch is at OFF, the ton€arm cannot

be moved by either manual or remote operation. lf it is forced

at tho OFF position, this may result in damage so always remember to set the POWER switch to ON when moving it.

@ ARM cLAMp

Usedto securethe tonearm.

To securethe tonearm,move it to the right and then push

down on the clamp.When you do not intend to usethe

turntable,securethe tonearm in this way. The tonearmis

released

when the clamp is raised.

@ anru REsr

T h i s s e c u r e st h e t o n e a r mp i p e . W h e n p l a y i n ga r e c o r d ,

rotate the arm rest counterclockwiseand releasethe

c l a m p .W h e n n o t p l a y i n ga r e c o r d ,s e t t h e a r m e l e v a t i o n

switch to UP ( ! ) and then rotate the arm restclockwise

and securethe pipe.

NOTE:

When the arm elevation sritch is at DOWN (l l, ttre tonearm

pipe cannot be secured. Make sure this sl,tritchis set to tho UP

( ! l position.

@ p I R I I E R / R U B B E R p L A T T E RM A T

Whenthe tonearm is movedand power is suppliedto the

turntable,the platter will start rotatingat the set rotation

speed.The rubber platter mat stabilizesthe recordsand

alsoabsorbsexternalvibration,

@ ousr covER

Keep this closedunlessoperatingthe controlsor tonearm,

or changingrecords.This servesto keepdust off of the records during record play. When fully openedand pulled

straight up, this dust cover can be removedfrom the

cabinet.

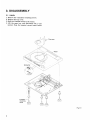

3. DISASSEMBLY

3.1 PANEL

1. Remove the 4 insulator mounting screws.

2. Remove the top cover.

3. Shift the tonearm acrossto the center4. Lift the panel up, and disconnect the B con_

nectors from the printed circuit board below.

Top cover

I

)

a

F i s .3 - 1

Ei

FL-LI

t

Oclcl

3.2 D.D MOTOR

1. Remove the 3 D.D motor securing screws.

2. Disconnectthe D.D motor connector.

)

l"

a

3.3 TONEARM

1. Remove the plate pressing against the tonearm output cable.

2. Remove the coil & rail ass'y.

3. Disconnect the ground lead connected to

the front rail from P.C.B.

4. Remove the E-type washers and screw holding

the gear and rail of the elevation mechanism.

The front rail may then be removed by pulling

Fis.3-2

out towards the right.

5. The other rail may also be removed by pulling out to the right after loosening the securing

screw.

6. The tonearm may be removed once both rails

have been pulled across to the right by at

least 15cm.

E

C o i l & R a i la s s ' y

E-type

washer

!t

G r o u n dl e a d

F i g .3 - 3

Fig.3-4

3.4 CdS DETECTOR AND LAMP

1. After removing the tonearm, remove the CdS

detector and lamp in the way indicated in

Fig. 3-5.

2. Remove the shutter before removing the spacer

securingthe CdS detector.

)

I

Shutter

\

@

F i g .3 - 5

a

4. PARTS LOCATIONS

o The l\ morh found otr some component parts itldicates

Ihe importance of the sately lactor of the parl. Therefore, @hen replacing, be sure Io use parts of id.enlical

designation.

Tonearm assembly

PPD€01

t

PNR.I26

ri

Dialunit

PXT.391

P u s hb u t t o n u n i r A

PAD-058

Pushbutton unit C

PAD{60

al

Pushbutton unit B

PAD-061

PL-LI

Clclc'

tcotes

lhere

'ntlcal

BtER

rw-339

E V m e c h a n i s ma s s e m b l y

(Coil assembly)

PXB{ 18

nel

\tR.l26

D.D. motor

PX B-061

Controlassembly

PWM{32

ialunit

xT-391

PL-L1

oclcl

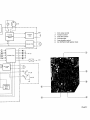

5 . B L O C K D I A G RA M

-l

I

33

45

QUARTZ

I

I

D.D. motor control

Rest sensor

Lead in

|If End signal

Display driver

End sensor

REP

sw

Lowering

1q

1 7 7

I

L-_

____l

I

30 cm

1 1

position

control

rooo

?

I, l r -$-€

Cds

I

J i rl f;

Tracking

sensor, power

supPlY.

I

I

I

Tonearm

drive

l

l

uoll

<

'

I

I

I

I

Manual drive

i €

1

2

3

4

5

6

D.D. motor control

Tonearmcontrol

Arm drivecontrol

Full auto logic

Arm elevationcontrol

E V , R E P E A T,S IZE sel ectori n put

Photo5-1

BLOCKDIAGRAM OPERATIONS

5.1 TONEARM CONTROL STAGE

a. Lead-in FF and Return FF

Lead-in FF . . . . This FF is set by pressingthe

S/S (START/STOP) switch

when the tonearm is on the

arm rest, and is reset by a

descend signal, or when the

power switch is turned on.

Return FF . . . . This FF is set by pressingthe

S/S switch when the tonearm

is not on the arm rest, and

also by the end detector. It

is reset when the power is

turned on, or by the descend

signal, or when the tonearm

returns to the arm rest.

b. When either of the above 2 FFs has been ser, an

"AUTO

on" signal is generated (as well as

AUTO on), resulting in the arm elevator being

set to the UP position, and inhibition of manual

drive.

I

5.2 END DETECTOR STAGE

The end sensor input signal is rectified and then

applied to the detector stage consisting of a differential circuit, integration circuit, and a monostable multivibrator.

When the detector stage detects the arrival of 2

consecutive input signals within the fixed time

constant period, an output signal is generated.

This output, however, is inhibited by the EV Up

signal when the arm elevator is in the Up position.

OUTPUI

E Vu p s q n a

Fig. 5_1

5.3 ARM ELEVATION CONTROL STAGE

This stage consists of a J-K-type FF with a reset

(clear) input and preset input.

The arm elevator is raised (Up position) as a

result of the initial resetting, or by the AUTO

operation signal from the tonearm control stage.

The eleyator descend again (DOWN position)

when the FF is preset by the descend signal.

Furthermore, whenever the EV switch is pressed,

Q and Q are generated alternately, resulting in the

arm elevator being raised and lowered correspondingly.

The FF output is applied to a logical ,,and"

circuit with the outputs from the elevator Up and

DOWN switches,the resultant output being applied

to the EV motor drive stage.

s.iA SIZE SELECTORSTAGE

This stage consists of a J-K FF 2-stage ring

counter and the QUQ2 logical ,,and,' gate. As a

result of the initial resetting, Ql = Q2 = L for automatic switching of the size selector to the B0cm

position. Every time the size selector switch is

pressed after that, the selector is switched from

the 30 to 25 and 17 positions in turn, and then

back to 30 again. Note, however, that switching

is inhibited when AUTO operation signals are

received from the tonearm control stage (i.e.

during lead-in, return, and repeat operations).

5.5

R E P E A TC O N T R O L S T A G E

Consisting of a T-type FF, e and Q are inverted

by Repeat switch operation. Note that the FF is

also turned off by the initial reset, and that there

is no inversion while the tonearm control stage

return FF remains set (i.e. during return and

repeat operations). Furthermore. the FF is also

turned off as a result of auto-cut operation during

repeat mode.

5.8

By

motol

senso

f,onea

opera

is DC

return

5.9

Thr

CdS r

voltag

ment.

the d

to pa

the to

EITOT

senso

./

7V

5.6

LOWERING

POSITION DETECTOR,

PLUNGER CONTROL STAGE, AND

D E S C E N DS I G N A L G E N E R A T O R

When the tonearm shutter passesbetween the

sensors corresponding to the designated record

size (sensors being mounted in positions corresponding to each record size), a lowering position

detector output signal is generated. This signal is

then applied to the plunger control stage (a monstable multivibrator), resulting in a fixed time

constant pulse signal being generated to activate

the plunger (during lead-in and repeat modes).

The down stroke of the pulse signal is differentiated and a descend position signal generated. Each

of the tonearm control stageFFs is also cleared.

5.7 DISPLAYSTAGE AND PLUNGER

DRIVER

This stage is responsible for the LED display

of elevator position, repeat mode, and selected

record size, in addition to plunger drive.

\

PL-L1

5.8 MANUAL DRIVE STAGE

By amplifying the input to the power generator

motor mounted in the locate stage, the tracking

sensor stage balance is upset, permitting the

tonearm to be moved back and forth.

Such

operation is inhibited, however, when the elevator

is DOWN during auto operation modes (lead-in,

retum, and repeat).

5.9

T R A C K I N G S E N S O RS T A G E A N D

TONEARM DRIVER STAGE

The tracking sensor stage (consisting of lamp,

CdS element, and shutter) generates * and voltage differences in response to tonearm movement. These output signals are then applied to

the driver stage where they are amplified, and

to pass a current through the drive coil to drive

the tonearm in such a way as to eliminate tracking

elror (i.e. to avoid the generation of tracking

sensoroutputs).

000

5.10 D.D. MOTOR CONTROL STAGE AND

D.D. MOTOR STOP CONTROL

The phono motor stop control stage stops the

motor when the rest sensor detects the presence

of the tonearm back on the arm rest. As long as

the tonearm remains off the arm rest, the motor

will continue to rotate. The phono motor control

stage employs 3 specially designed ICs - PA2005,

PA2OA4, and PD1003. These control stagesalso

include the speed selector, speed indicator, and

qtartz lock indicator circuits.

End detector

Loweringpositioi

detector

Restsensor

Fis.5-2

PL-L1

c,Clc'

€i. C I R C U I T D E S C R I P T I O N S

6.1 FULL AUTO LOGIC

-rt

O.7nS

g

STAFTJULSE

fL

*es-t

Lolr

LEAD IN.FETURN

REPEAT

--t__f-

STOP

PULSE

o30 |

r TPS60S0

ARM

REST

SENSOF

R E T U R NF . F .

c38

t/5o

r3

/lazt

END

VR4

6 8 0 I ( B ) D E T E C T O FA D J

oN ARMI

/

l'u

R E S T I o U To F I

AFM RESTJARM

REST

OUT OF ARM REST

I

OF ARM REST-,

aRv nEStl

ON ARM REST

ON

OUT

orr *xot.tltl

-t !

ts

8V

t.S/3S t5k

R60 took

I r

lK.liJ_-r\_

R59

Q3O5L-t TPS6050

END

.

TP5

R66

560k

SENSOF

io

,urtt'

rk

c3s +i"9

'

,, o.ol

VR9

3.3k(8)

END SENSOF ADJ

o.gv I

fy--j l-r

'l+

oruo

O.lnS

8V

R54

rok

c27

RrOl3.3k

ocizz \ y-,

c?a

t/5o

\

I

l

#

e.zrs

fr__..iFuu

o.6v

I

8V

A

I

o.o I

rok

c45

LOWERING

AND FESET

o.o?7

c46

t/50

16r-owEntruc

16

-

a._fl-L

.o jaslrziro

BV

|

c m i c mc m i c m

{nss

q55 1.51 | ssr

:"t

S I GN A L

TII\,4INGADJ

VR3

680k(B)

8V

1.5!Ols

R5l

IM

R52

R65

tok

3:"1 r's

?

fi

:J---r_

-lt7

o.o2'

ic3?

t/50

REPEAT

REPEAT

ON

(L)

r L 0 w E R r N GS t c N A L

I CONTR0L

F.F

LEAD

BEPEAT

STOP

IN (H)

1 clclcl

LEAD IN

ra)

tI

REPEATST0P

@

T O A F M D R I V ES E C T I O N

o

MANUAL OPERATION

PROHIBIT SIGNAL

+H

6)

TO D.D.MOTOR

STOP SECTION

-3ov,-4ooma,3oomw

r;\

\9

y' tzoN 24o

Y

2 S4 5 6 2

or

x?

2 SA 5 6 2 T M - Y

c47

to/t6

UP SW

PXM-069

NC

25c735 -Yo r x

2 5 C 1 9 5 9- Y

\

3 O V , 4 OmOA , 3 Om

Ow

tzo-zAo

? ( 9

l .

ONSW

swt

swz

NO

NC

NO

I

I

l

r

3OV,4OOmA

5OOmW

l?Q* 24O

1

l

L - - -

_ _ _ _ _ J

8V

II

swl

o.o I

LOWEF ING

AND FESET

16

:"t

3.t"t, r 's

R37 t.2k

15

6mA

R39 r.2k

sw2

I

I

REP

.t€3

loweRtnc

srcNAL

6mA

l(l

x?

5

.^

r+ -tga

,u

*4

tto

I

I

0209

DN

,(6

ra

6mA

R46 r.2k

R47 t.zl

?5

rr -9i1A

t k

0304

r -- --]

l T c mS E N S O R

30

1

D?

Q303

lsr885

<L

M A X8 m A

g1_-_/ to 1 coNTROr

1 6 . 0 5n A

t

S O L EN OI D

PXP-OO3

6 . 0 5m a

fi

'_r-L_

J L . o w E R l N cs r c N A L

rPS60so

D3O2-3Oa T L R I 2 1

MAx.25Oma ol_zeRt ,e

I

1 . 5+ O . ls

I rc bl

8V

UP

t7

.n5

Q 3 0 2- 3 0 a

R38 r.2k

+

i

,o.r1?

D3O3

2 5 c mS E N S O B

8V

M A X8 m A

| 6.O5mA

t

M A x8 m A

Q3O2

+4.

LOWERING POSITION SIGNA.

t k

tk

0302

3 0 c nS E N S O R

PL-L1 clc'cl

*

x

*

*

Number in parenthesis are the IC pin numbers.

LdenotesLlevel.

HdenotesHlevelEV denotes arm elevator, UP denotes that arm

elevator is in UP position, while DN that

elevator is in the DOWN position.

The Full Auto Logic section is made up of the

following 5 main stages.

(1) Tonearm control stage

(2) End detector stage

(3) Elevation control stage

(4) Record size selector stage

(5) Repeat control stage

6 . 1 . 1 T O N E A R M C O N T R O LS T A G E

1. When the power switch is turned on . . . .

. . . . the lead-in FF and retum FF are reset

by the initial reset signal (passed from

C29lF-55 to IC16,-+ICI7,->IC9, and IC10).

. . . . the phono motor will remain stationary

if the tonearm is on the arm rest, but

commence to rotate if it has alreadv been

moved away.

2. When the START/STOP switch is then pressed

with the tonearm on the arm rest,

* Pin (8) of IC8 is switched to L level.

* Pin (10) of IC8 is switched to H level, and this

appears at pin (3) of IC10, resulting in the

lead-in FF being set (and pin (10) of IC10 also

being switched to H level).

* Once pin (10) of IC10 is switched to H level,

pin (3) of IC8 is switched to L level, resulting

in pin (8) of IC1L being likewise switched to

L level, thereby inhibiting manual drive (locate

operation).

Pin (13) of IC14 is also switched to L level,

resulting in pin (12) of IC12 being switched to

H level, and the elevator being consequently

raised to the UP position.

* Pin ( ) of IC11 is switched to H level, resulting in the inhibition of any further START/

STOP switch inputs after a delay of about lms

(in order to prevent the return FF from being

set when the tonearm leavesthe arm rest). At

the same time, pin (12) of IC18 is switched to

H level to inhibit switching of the size selector.

Hence, the relevant FFs are set, the arm

elevator raised, and record size selector switching inhibited.

Pin (11-) of IC10 is switched to L, and this is

transferred to pin (6) of ICS. Once the elevator

is properly in the UP position, the UP detector

switch is switched to the NO position, resulting

in pin (5) of IC8 being switched to L level, and

pin (4) of IC8 switched to H level.

This IC8 pin (4) H level signal then turns Q7 on,

resulting in a current being passedfrom VR8 to

VRb and R99 via R93. If the potential at TP8

drops below the potential at TP10, the difference is amplified and a current passed

through the coil to subsequently drive the

czrlrier.

The carrier is thus shifted across towards

the record. (Assume size selector set to 30cm).

When the carrier reachesa position about 20mm

in front of the 30cm position, the carrier shutter

will block the light of the 30cm sensor.

Pin (13) of IC9 is thereby switched to L level,

and pin (10) of IC9 switched to H level. This

serves as a trigger for the monostable multivibrator incorporated in IC13, resulting in the

generation of an H level signal of r = 2.2 sec.

This is applied to TP3 and pin (9) of lCL2,

presetting the EV FF for lowering of the tonearm.

The TPB H level signal is used to drive IC7, and

in turn attracts the plunger and raise the index

plate.

The carrier continues to move further, coming to a stop when the swing pin strikes the

index plate.

TP3 is switched back to L level 2.2 seconds

later, the signal being differentiated by C34

and R44 to provide the tonearm descend signal

which is passed via IC1-7, IC9 and IC10 to

clear the FFs and stop the carrier drive current.

The elevator UP, locate inhibition, and size

selector switching inhibition are dlso cancelled

at the sametime.

As a further result of TPB being switched to L

level, the charge held by C35 is dischargedvia

R43 and the IC7 base resistance. During this

discharge period (0.3 to 0.5 sec.) the plunger

is maintained in the attracted position, but is

forced back (by a spring) once the discharge

has been eompleted. The elevator is thereby

retumed to DOWN position for start of play.

l

3. START/STOP switch pressed when tonearm

is not on the arm rest

x Pin (8) of IC8 is switched to L level.

* The IC8 pin (10) change to H level results in

pin (4) of IC10 being changed to L level for the

retum FF to be set.

* This then results in the elevator being raised,

and inhibition of size selector switching, S/S

switch input after a delay of 1ms, and locate.

* The L level signal on pin (9) of IC9 is transferred to pins (5) and (6) of 1C72, thereby inhibiting inversion of the repeat FF. Furthermore,

the IC10 pin (4) L level change is transferred to

pin (4) of IC12 via pin (8) of IC14 to clear

the repeat FF. The purpose of the 1ms delay

circuit referred to above is to permit sufficient

time for the generation of the time pulse employed in clearing this FF.

* In a similar fashion to the lead-in operation,

the L level signal appearing at pin (9) of IC9

once the elevator has been completely raised,

is converted into an H signal at pin (11) of IC8,

resulting in Q8 being turned on. In this case,

however, the TP10 potential drops below the

TP8 potential, resulting in the carrier being

retumed towards the arm rest.

x When the shutter cuts across the sensor light

beam during the retum motion, pin (10) of IC9

is switched to H level, but since the repeat mode

has been switched off, pin (1) of IC13 will be

at H level, thereby preventing operation of the

monostable multivator.

t Once the carrier reaches the arm rest position,

the rest sensor transfers and L level signal to

pin (3) of IC16, resulting in pin (11) of IC11

being switched to L level to stop the phono

motor.

+ When pin (11) of IC11 is switched to L level,

the charge stored on C43 is discharged via R71,

the return FF being cleared after the potential

on pin (1) of IC9 is reduced to 1/2Vcc (delay

circuit). During this period, the cauier remains

pressedagainst the arm rest.

4. End detector operation

* When the repeat mode is off, pin (3) of IC9 is

switched to L level by the end detector, and the

retum FF is consequently set. Subsequent

steps are the same as during normal return

mode.

* When the repeat mode is on, the retum FF is

again set in the same way for normal return

operation.

However, when the shutter cuts

across the size sensor, the plunger is activated

(TP3 switched to H level), followed by the

generation of the descend signal in the same

way as during lead-in. The elevator is thus

lowered for recommencement of play.

.Jl

6 . 1 . 2 E N D D E T E C T O RS T A G E

1. Detector Principle

* Shutter structure

hhnin

"n

ff""

I

.IE;

i

Fis.6-1-1

-r\4'

#

F i g .6 - 1 - 2

[1

-l-LlE

Fis.6-1-3

Fis. 6-2

That is, the detector circuit (outlined in the

above block diagram) has been designed to

detect the presence of 2 rising edges of the

Schmitt circuit output within 1.0610.1 seconds

2, Circuit Description

The end sensor is mounted at a position

R49mm from the spindle. When the left edge of

the shutter slits reaches that position, the stylus

tip will be at the R62.5mm position. That is,

there is 20mm between the 62.5mm position and

the point of entry into the detection range. Once

the detection range is entered, the sensor commences to generate output signals with a waveform like that shown in Fig. 6-1-2 above. This out

put is applied to the Schmitt trigger clcuit composed of 2 inverters in IC16 where it is rectified

into the square wave as shown in Fig. 6-1-3. This

output is then differentiated by C39/R61 and

applied to pin (5) of IC14, while another portion

of the same output is integrated by R62|C4O

and applied to the monostable multivibrator composed of 2 NOR gates in IC18, resulting in the

generationof a 1.06 1 0.1 secH level signal.(TPb).

Although this signal is applied to pin (6) of IC14,

there is no detection by pin (5) because of the

delay by the integration circuit.

If, however,

the next differential pulse is applied to pin (5) of

IC14 while the H level signal is being generated at

TP5, that pulse will be detected. Apart from this

case, there is no detection because the differential

pulse involves a slight delay before switching TP5

q

FL-L1 clclcl

to H level.

Furthermore, when the elevator FF Q is connected to pin (6) of IC18 to make Q = H (i.e. Up

-position), the monostable multivibrator is inhibit_

ed, thereby inhibiting the detector circuit. Q = H

also when the power switch is tumed on, again inhibiting the multivibrator.

6 . 1 . 3 E L E V A T I O N C O N T R O LS T A G E

x When the power switch is turned on,

an initial

reset sigrral is passed to pin (12) of IC14 from

R551C29, resulting in pin (11) of IC14 and pin

(14) of IC12 being switched to H level (Q = H).

This corresponds to the elevator being in the

UP position, or in other words, Up priority is

given when the power is first turned on.

* Since Q = H, one of the ICZ transistors

will

be turned on to light up the Up indicator lamp.

x Until the elevator reaches the Up position

the

UP detector switch remains in the NC position,

resulting in pins (13) and (I2) of IC1Z being

both switched to L level, and e13 and e16 of

the elevator drive stage being both turned on

to start up the motor.

x Once the elevator is properly in the Up position,

the UP detector switch is switched to the NO

position, resulting in pin (18) of IC1? being

switched to H level, and pin (11) of IC1Z being

switched to L level. Q1B and e16 are both

turned off and the motor stopped.

x If the elevator switch is then pressed,

a falling

edge differential pulse is generated on pins

(1) and (2) of lCL4, and a rising edge clock

pulse on pin (13) of IC12. This results in

Q = H and Q = L for lowering of the elevator

(DN).

* And since = H, the DN indicator lamp

will be

Q

lit up, and the UP indicator turned off.

x The DN detector switch remains in

the NC

position until the elevator is right down. During

this period, pins (9) and (8) of IC1T will be

both at L level, while pin (10) of IC1? will be

at H level. The elevator drive stage e14 and

Q15 will thus be on and the motor rotating.

x If the elevator switch is pressed during

this

condition, Q will switch to L and Q to H (Up)

to reversethe motor.

The above description relates to the opera_

tion of the elevator circuit itself. In addition,

* automatic mode UP (as

described under the

tonearm control stage),and

* DN at the lowering position,

may be controlled via the elevator FF preset

and clear terminals.

6 . 1 . 4 R E C O R DS I Z E S E L E C T O RS T A G E

x When the power is turned on, the initial

reset

signal from P"55lC29 is passed to IC16 to

switch pin (11) to H level, resulting in IClb

being cleared.

* Pin (1) (Q1) and pin (15) (e2) of rClb

are

both switched to L level, this then being transferred to pins (8) and (9) of IC18. pin (10) of

IC18 is thus switched to H level and the BOcm

indicator lamp is lit up.

* If the size selector is then pressed, the falling

' edge differential pulse applied

to pin (18) of

IC18 when pin (12) of this IC was at L level

(i.e. when none of the lead-in, return, or repeat

modes was operative), is instead applied to pin

(11) of IC18 as a rising edge clock pulse, thereby

activating the ring counter in IC1b. As a result,

Q1 = H and Q2 = L. The BOcm indicator lamp

is turned off, and the 2bcm indicator lamp

turned on.

* If the size selector is pressed

again, the 17cm

indicator lamp is turned on. Every time the

selector is pressed, the size is switched in a

cyclic order 30 -->25 -> L7.

6 . 1 . 5 R E P E A TC O N T R O L S T A G E

* When the power is turned on,

the intial reset

signal from R55/C29 is applied to pin (g) of

ICI4, resulting in pin (10) of this IC being

switched to H level, and pin (1) (e) of. lCL2

being switched to L level.

* The repeat indicator lamp will

thus be turned

off(sinceQ=L).

x If the repeat switch is then pressed,

a falling

edge differential pulse will be applied to pins

(5) and (6) of lCL7, and a rising edge clock

pulse generated at pin (4). As long as the

repeat or return modes are not operative at

this time, pin (5) (K) and (6) (J) of IC12 will

both be at H level, resulting in e - H, and Q

= L for the repeat indicator to be

turned on.

At the same time, pin (13) of IC13 is switched

to L level, thereby enabling the monostable multivibrator consisting of 2 gate circuits in IC1B

to operate during repeat.

x If the repeat switch is then pressed

again, the

J = K = H status will be inverted.

In addition to the above repeat control stage,

x The START/STOP switch may be pressed

to

activate return mode. In this case, a falling

edge pulse is generated on pin (4) of IC10,

and then applied to pin (S) of ICL . pin

(10) of IC14 is thus switched to H level, and

the IC12 FF cleared (repeat off), resulting in

Q=LandQ=H.

* When the retum FF is set (during return or

repeat mode), pin (9) of IC9 is switched to L

level, this being transferred to the J and K

terminals of the repeat FF, thereby inhibiting any inversion.

I ,

6 . 2 T O N E A R MD R I V E

24V

TP8

tczz !PC78LOB

1 5 . 4- 1 6 8 V

TP9

Tracking "O"

t?v

I o S H O R T: t 5 0 m A

3

EEBr',

IJ;:j;"'

"O"

TPII

Po:lW

7 . 7- 8 . 5 V

Q.o1o/o / oC

rc?t t/2

adj.

R93

t.?k

TH I

R89 68k

Tracking

sensor gain

cq,.t?!',l33Tl

adi.

M A X€ E

22.3V

(otVcc:24

, .c50 0.ol

TH 2

RgB 6Bk

8 V

TOmA

MAX

5.3mA

PEL- 04 I

?4v

Tracking "O"

t?v

5

rczt t/2

Lead in

speed adj.

o'13mA

Full auto section

| @-@

Tracking "9" --within several mV.

Tracking error 4mm ----1.2 - 1'.25V (ref. Fig. 6-4)

R9l

?.

25C945-PorQ

o l3mA

Full auto sectaon

tok (250c)

P C X -O 5 4

Rgz

Gain of 25oC

68+tO+68+tO

+t=2O.O

4.2

tl.Bh

o:

2 5 C l5 8 3 - F r

R80 4.7k

R82 4.7k

5,v 2OO rpm

7mY/ rom l9o/o

ltj

D6

152473

D5

xq

ts 2473

1 5 ? 4 73

PXM- 076

24t!

MAX

2.7mA

took

R79 47r

R 81 4.7k

TC20 t/2

MAX

3.6 mA

MAX

3.6mA

Full auto section

q4

Q4,5

25C945-PorQ

FL-L1

I ceg

to/35

roc

|

|

uAx

3OOmA

( 250 Cl

TP I?

M A X€ E

?2.3V

( o t V c c= ? 4 Y I

--within several mV.

error 4mm --- -,1'.25V (ref. Fig.6-4)

+ t=20.o

2 SC l 5 8 3 - F o r G

1S?473

MAX

2.7mA

t?5A671-Bor C \

\ esclo6l -Borc) x 2 or

t 2 5 A 8 1 6 - O o r Y\ - ^

\ z S c 1 6 ? 6 - o o r Y) ^ '

ClClCl

The tonearm drive stage contains the following 3

major component circuits.

(1) Tlacking sensor circuit

(2) Tonearm drive circuit

(3) Manual operation circuit (locate operation

circuit)

6 . 2 . 1 T R A C K I N G S E N S O RC I R C U I T

An outline of the tracking sensor circuit is

shown in page 21. When the stylus is positioned

exactly at right angles to the carrier, the lamp

Coil Ass'y

beam is directed practically equally onto both

P X B - I I 8

CdS elements, which means that the resistance in

R=73t5rl

(or 25('C)

both elements will also be more or less equal.

These 2 elements form part of a Wheatstone

bridge with R93, R94, and VR8, this latter variable

control being adjusted so that no potential difference is generated across TP8 and TP10 when

the stylus is located at right angles to the carrier.

If the stylus should happen to move to either

left or right, the amount of light striking the CdS

elements will change, resulting in the resistance of

one element being increased, and the resistance in

the other element being decreased. A potential

difference will thus be generated across TP8 and

TP10.

The relation between stylus movement

and the potential difference generated is shown in

grasp form in Fig. 6-4. VR? is used for adjustment

purposes.

i< When the stylus is positioned at right angles

to the carrier, the bridge is balanced, and the

carrier remains stationary.

* If the stylus should tend towards the left of the

ca"rrier, a (+) potential will be generated across

TP8 and TP10: This signal is amplified in the

tonearm drive circuit (sec. 2.2 below), resulting in a coil current to move the carrier to the

Ieft. (During record trace, or when moved to

the left by hand).

* If the stylus should happen to tend towards

the right, a (-) potential will be generated

TPlO@

across TP8 and TP10. After amplification in

vol t

the tonearm drive circuit, the resultant coil

current serves to move the carrier to the right.

(During record trace, or when moved to the

right by hand).

{€ During lead-in Q7 is turned on, and a current

is pumsedfrom R93 to R99 via VR5. A (+)

potential difference is generated between TP8

and TP10 by the voltage drop across R93,

resulting in the carrier being moved to the left.

Speed is controlled by adjusting the current

Fis.6-4

passingthrough VR5.

R

PL-L1 clclcl

* During return and repeat modes, Q8 is turned

on, resulting in a current being passed from

R94 to R98 via VR6. Consequently, a (-)

potential difference is generated between TP8

and TP10 by the voltage drop across R94,

thereby moving the carrier to the right. In

this case, speed is controlled by adjusting the

current passingthrough VR6.

6.2.2 TONEARM DRIVE CIRCUIT

The tonearm drive circuit consists of a current

booster formed by a differential amplifier and

Qe - Q12.

1. Differential amplifier

Consisting of a pair of op amps.

6.2.3 MANUAL OPERATION CIRCUIT (LOCATE OPERATIONCIRCUIT)

x When elevator not completely in UP position

(UP detector switch in NC position).

x During automatic modes (lead-in, return, repeat).

Under the above conditions, pin (10) of IC1l in

the full auto logic stage is switched to H level,

thereby tuming Q4 and Q5 on. The collector

voltage of these 2 transistors will thus be almost

zero. Current will also flow through the D10 R82 - Q4 and Dg - R81 - Q5 routes, resulting

in the base of Q6 being biased in the reverse

direction due to the voltage drop of Vp of D9

and D10 in respect to the emitter. eO is this

tumed off to inhibit locate operation.

* When locate dial is rotated.

* When the motor generatespower.

* When the motor rpm is low (slow rotation of

the dial), the amplifier gain is determined by

R76 + R7? +

1, but once the motor rpm is

R7g

increased to a certain rate, the gain will be

clamped by the voltage determined by D7 and

D8, or D5 and D6.

* When the differential amplifier is activated,

one side of Q6 is turned on according to the

rotational direction of the dial, resulting in

a voltage drop across R93 or R94, and the

generation of a potential difference between

TP8 and TP10. This is subsequently ampli

fied, and results in a current being passed

through the coil to move the carrier.

Coil current

Fis.6-5

7. ADJUSTMENTS

Adjustmentposition

VRl VR2

vnz@@ vna

vno@)@)vns

Fis.7-1

)

)

)

Preparation

1. Disconnect the panel according to the disassembly nrethod outlined earlier.

2. Use extension leads to connect the panel to the

printed circuit board located in the basesection.

3. Remount the turntable platter (but without

tightening the securing screws).

7.1 D.D. MOTOR OPERATING POINT

ADJUSTMENT

1. Connect the TP1 and TP2 terminals to the CH1

and CH2 inputs of a dual-trace oscilloscope.

2. Start the turntable platter turning by shifting

the tonearm over towards the center of the

record from the arm rest position.

3. Observe the waveforms in the oscilloscope, and

adjust the corresponding controls so that the

rising edge of the TP2 output waveform lies

within the TP1 output waveform.

4. VRl is the control to adjust for 4brpm speed,

while VR2 is the control for 33rpm adjustment.

10v

TP1

_,1-l_

TP2

_Fis.7-2

)

7 . 2 A U T O L E A D - I NT I M I N G A D J U S T M E N T

1. Set the record size selector to the 30cm position.

2. Pressthe START/STOP key to start the tonearm

lead-in movement.

3. When the tonearm is about 20mm away from

the outer edge of the record, an output pulse

signal will appear at TP3 (see Fig. 7-3). Adjust

VRB to obtain a time constant of 2.2 - 2.5 sec.

for this pulse signal.

7.3

END SENSOR SENSITIVITY ADJUST.

MENT

1. Connect the oscilloscopeto the TP4 terminal.

2. Set the arm elevator to the UP position, and

shift the tonearm across to near the lead-out

gloove.

3. Hold the tonearm carrier by hand, and move

the tonearm back and forth at a rate of 5 to

1Ocm/sec.

4. During this operation, adjust VR9 so that the

TP4 output saturates at H and L levels at about

'

50% duty.

\

7.5

1.S

a

j

2.S

t

a

a

c

f,

7.6

1.

t"

|\l,l/l/l

JU\/UV

\.

Fis.7-4

7.4 END TIMER ADJUSTMENT

1. Connect the oscilloscopeto the TP5 terminal.

2. Secure the tonearm to the arm rest. and remove

the turntable platter.

3. Insert a piece of paper (or any other light

shield) into the end sensorstage.

'4. As soon as the piece of paper (or light shield)

is removed, an output signal appears at Tpb.

Adjust the time constant of this output to

1.06 10.1 secby meansof VR4.

p

t

r

2.S

a

a

3.V

s

{,

4.7

1

5.f

t,

ti

n

s

* 1 .I

li

ir

v

*2.

h

li

Fis.7-3

F i g .7 - 5

25

PL-L1 clclcl

7.5

TRACKING SENSOR ZERO POINT

ADJUSTMENT

1. Set the arm elevator to the UP position, and

adjust VR8 to obtain of voltage of less than

t0.1V betweenTPg (-) and TP12 (+).

2. Set the arm elevator to the UP and DOWN positions repeatedly, and also perform each of the

automatic mode operations. Finally set the

arrn elevator back to the UP position, and

check that the voltage across the TP9 and TP12

terminals remains below t0.35V.

7.6

TRACKING SENSOR GAIN ADJUST.

MENT

1. Disconnect the drive coil connector, and insert a

piece of paper (or any other light shield) into

the rest sensor stage and stop the DD motor

rotation.

2. Shift the tonearm across to any desired position

above the turntable platter, and then fix the rail

and roller to secure the carrier.

3. With the arm elevator in the DOWN position,

shift the tonearm across to a position 4mm to

the left of the tonearm center position.

4. Then adjust VR7 so as to obtain a voltage of

7.2 to L.25V acrossthe TPS and TP10 terminals.

5. Next shift the tonearm to a position 4mm to

the right of the tonearm center, and check that

the voltage across TP8 and TP10 varies by no

more than 10.L5V from the value measured in

step 4 above.

*1. Because of the "ghost" tendency caused by

light from the tracking sensor lamp (as shown

in Fig. 7-8), this adjustment must be performed

with care.

*2. Perform the above tracking sensor adjustment

procedures(7.5 and 7.6\ at least twice.

F i g .7 - 6

Fig.7-7

1.2V--

I

I

I

Ghost

Fis.7-8

LEAD-IN AND RETURN SPEED ADJUST.

MENT

1. Set the record size selector to the 17cm position.

2. Press the START/STOP key to commence the

tonearm lead-in operation.

3. Adjust VRb so that the time required to reach

the 17cm position is 5.5 to 6.5 seconds.

4. Then adjust VR6 so that the time required for

the tonearm to retum to rest from the 17cm

position is also 5.5 to 6.5 seconds.

7.7

PL-LI

clclcl

8. TIMING CHART

(1 )

LEAD IN PLAY

(3 ) REPEAT

30cm DISC SIZE

I

(A)

Rest signal

t

L

(A)Rest signat

,

( B ) 30 Srze ind.

L

( B ) 30 size rnd

I

( c) s/s sw

(C)30"' sensor

(lOa1

- 2)

( D ) Lead in F.F.Q

(tcto_to)

L

(E)EV SWI

(up detector)

L

( G)

( H'

(F)

L

R e t e r nF . r . e

(r c s - 6 )

(G)EVswl

(up detector

)

2.2s-2.5s

timims

sisnal

(DN oelector)

( J ) Repeat

L

( ( ) Arm operal on

UP

(2 ) neLrcr

Restsignal

I

L

L

(C)S/S SW

5

L

i

i

( D ) R e t e r nF . r . Q

(|c9-5)

t

r

l

I

(E)EV swl

(up detector)

L

(F)EV SW2

(DN detector)

L

(G)Retern signal

( l c 8 -rr)

(H)Arm

operation

L

UP

DN

l

I

l

l

l

Play

Rejecl

Armup

27

I

\IUIJ-J]

DN

( B ) 30 srze ind.

nd.

, r i Solenotd timrng srgnal

tv J r,^,-^r

( f ) Lead in signal

(A)

L

(H)r.v sw2

:lJ::"$

(J ) Arm operation

]-/]_/l

( E ) f n o d e r e c t o rs r g n a l

( t c I4 - 4 )

L

(rc8-4)

L

I

30cmsensor

( r c g -1 2 )

-

( D ) End sensor

( F) EV SWZ

(DN detector)

L

U

- P

D N -

Play -

,o

srgnal

ze ind.

sens0r

tz)

sens0r

d e t e c t o rs i g n a l

, - 4)

'n F.F.Q

6)

SWI

j e t e c t o)r

lw2

d e t e c t o) r

rt rnd.

L

DN

UP

L

) o r dr m r n g s r g n a l

l-1\

operatlon

I

;

l<-l

N O T E S:

.

t\

-z.cs

UP -

A r m e l e v a t i o nD o W N

S T A R TS T O P S w i t c h

FLip Flop

A r m e l e v a t i o nU P

E l e v a t i o n( T o n e a r m )

DN F . F-

S/SEV -

PL-L1 ctctcl

9 . T R O U B L ES H O O T I N G

9 . 1 C I R C U I TB L O C K

9.1.1

No elevator operation

Auto mode in operation ?

Is pin (15) of IC12 inverted every time the elevator

switch is pressed?

Recheck after cornpletion

of present operation

Defective

(rc1,2)

Is there a voltage applied

across the elevation motor

terminals ?

Is there any fault in the

elevator mechanism ?

(Dislodged belt, or poor

gear inter-meshing).

s.1.2

No repeat switch on/off

switching

Return or reoeat mode in

Is pin (1) of IC12 inverted every time the repeat

switch is pressed?

Does the LED lamp light

up when pin (16) of IC7

is connected?

Defective

(rc12)

elevator

FF

9.1.3

No record

switching

^

size selector

Auto mode in operation?

Is pin (10) of IC18 and

pins (1) and (15) of IC15

switched to H level every

3rd time that the record

size selector switch is

pressed?

Do the corresponding LED

lamps light up when pins

(11), (12) and (13) of IC7

are connected (separate-

lv) ?

Recheck after completion

of present operation.

Defective size selector

stage(IC15 ).

t,t

9.1.4

No 33/45 switching

Is pin (13) of ICb inverted

every time the 33/45

switch is pressed?

Does IC6 function correctly as an inverter ?

Defective LED / Defective

P A2OO4| Defective

PD1003

?

l

PL-LI

9.1.5

Lead-in failure

START/STOP switch presafter

sed immediately

completion of return operation ?

Wait a few seconds before

pressing again,

Has the UP det€ctor

(elevator

switch

mechanism) been properly

depressed?

Defective elevator mechanism or defective elevator

control stage

Does the voltage drop

across TP9 and TP12 read

a little above 10V ?

Defective drive coil, defective drive transistor, or

incorrect magnetic polarity.

Is there a voltage difference of about 0.7 to

1,4V between TP8 and

TP1O?

Does a voltage difference

exist between TP8 and

TP10 when the tonearm

is moved bv hand ?

Has pin (10) of IC10

been switched to H level ?

Has pin (6) of IC9

switched to H level ?

Defective lead-in FF stage

(IC10), defective START/

STOP switch.

Defective tracking sensor

stage

Clc'cl

Tt

9.1.6

Retum failure

Has the elevator mechanism UP detector switch

been properlY dePressed?

Does the voltage difference between TP9 and

TP12 register a little above

10v ?

---------(No auto cut)

Defective elevator mechanism Defective elevator

control stage

Defective drive coil / Defective drive transistor /

Incorrect magnet polaritY

Is the voltage difference

between TP8 and TP12

about 0.7 to 1.4 ?

q

Is there a voltage difference between TP8 and

TP10 when the tonearm is

moved by hand ?

Has pin (6) of IC9

switched to H level ?

DefectiveIC8, Q8

4,

Has pin (10) of IC10 been

switched to H level ?

Defective retum FF stage

(ICg) or START/STOP

switch

?r,

;{

9.1.7

--------(normal

auto cut)

Does the end sensor oPerate normally (is there

sufficient outPut width

when passing the slit section)?

Out of adjustment, or defective sensor

Does the unistable multivibrator operate normally (including the time

constant) ?

Defective IC18 or surrounding comPonents

q(

PL-L1 clclc'

Repeat failure

Is the repeat FF (IC12)

inverted every time the

repeat switch is pressed?

l

i

h

,,?

Are pins (11), (12) and

(13) of IC9 switched from

H to L level (separately)

when the tonearm passes

the corresponding record

size position when the

repeat switch is on?

Designatedsize

36sm __,pin (12)

Designated size

25qm __,pin (18)

Designated size

17srn .+ pin ( 11)

Is TP3 switched to H

level during the above H

to L level switching?

9.1.9

Tonearm fails to stop at

designated lowering positlon

Are pins (11), (12) and

(13) of IC9 switched from

H to L level when the

tonearm passes the designated lowerins nositions ?

Is TP3 switched to H level

during the above H to L

level switching ?

Defective IC13

-

'r'

9.1.10

Tonearm fails to move

Does a voltage difference

(of at least 1V) appear between TP8 and TP10 when

the tonearm is moved back

and forth?

Is there a voltage difference between TPg and

(around 10 to

TP12

1 5 V )?

Defective tracking sensor

stage (defective lamp or

CdS element, or disconnected lead wire).

Defective drive coil / Defective drive transistor /

Incorrect magnetic polari

ty

;d

'I

9.1.11

1

Abnormal tonearm movement

Has the zero adjustment

been properly performed?

Can proper zero adjustment be obtained ?

Defective CdS element,

disconnected lead wire,

dislodged tracking sensor.

?n

Correct carrier inclination

to horizontal position

1F

:"J

tiA

PL-L1 clctcl

9.1.12

^.|.

II

I

Phono

rotate

motor

fails

to

Do pins (1) and (16) of

ICG respond correctly to

the rest sensor output ?

Defective IC6 / Defective

IC16 or IC11

Is there a 10V output on

pin (15) of PA2005 ?

Defective PA2005, or defective component connected to pin (15).

Is there a voltage difference of 0.5 to 1V between pins (16) and (18)

of PA2005 ?

I'l,,rlo

\ I :'ff

Is there a voltage of about

1.5V on pin (19) of

PA2005 ?

Are each of the Hall

element output terminal

voltages about 4V ?

Tum the power off, and

check the resistanceacross

pins (1) and (2), (1) and

(3), and (2) and (3) of

PA2005. Do they read

about 45 ?

Defective Hall element, defective Hall element resistors R101 - R103, or

defective PA2005

7-

a,

9.1.13

lock failure

Is there a 10V output at

pin (15) of PA2005 ?

Defective PA2005, or defective surrounding component

27 .7 8Hz signal

of 10V ampli

0.66ms Pulse

pin (15) of

Defective crystal oscillator

(PD1003)

Is there a

(at 33rpm)

tude and

width at

P D 1 0 0 3?

9.1.14

Is there a 10V output

pin (15) of PA2005?

Defective PA2005, or defective surrounding component

(,,

Does the stipulated voltage

register on pin (10) of

PA2004?

Is there a differential pulse

on pin (13) of PA2005?

Defective C33 component

Does a delta wave signal

appear at pin (14) of

PA2005 when the tumtable is rotated bv hand ?

Defective PA2005, R12'

or C17

?r.

\ {

llf

PL-L1 clclcl

Motor runaway

Is there a 10V output

pin ( 15) of PA2005?

Defective PA2005 or surrounding component

Is there a 55.5H2 square

wave signal on pin (5) of

PA2004 when the motor

speed is held to 33-1/3rpm

by hand ?

Is there an input from the

FG circuit board?

Is there a 55.5H2 square

wave signal on pin (10)

of PA2004 when the motor is held to the same

speed (33-1/3rpm) in the

Defective wiring, or defective speed detector circuit board

Defective PA2004 or defective R3, R4 C6- C8

component

While measuring the voltage between pins (12) (-)

and (14) (+) of PA2004

with the motor stopped bY

hand, let the motor speed

(rpm) increase gradually.

Does the voltage vary

gadually from -0.5 to

+2V ?

Is there a 27 ,7 8Hz signal

(at 33-1/3rpm) on pin

( 1 5 ) o f P D 1 0 0 3?

Is there any abnormality

in the waveforms observed

in the oscilloscope (see acdiagrams)

companying

when measuring the waveforms at each of the Hall

element output terminals

while keeping the motor

speed steady at 33-1/

3mm?

Defective Hall element or

Hall element resistance

DefectivePD1003

PA2OO4

Defective

related component

IHall elementoutput waveforms]

A.

Normal wav.form

C.

3oomVp-p {max.)

Exampl6

Ex.1

Approx.DC 4V

B.

Low outprrt wav€forrn{AC outpuil

Below 30OmVpf

+ff:re

EX.2

of dinort6d

wav€form

(bul normsl output

levol)

7-

4r'

9.2 MECHANISMBLOCK

9.2.1

Sigrrificant dif ference in

left and right direction

speeds when operating

the locate dial

Is the platter

horizontal?

perfectly

Is there any "play" in the

tonearm ass'y or elevator

shaft ?

Defective tonearm ass'Y,

elevator shaft or bearing

lr

Is the tonearm movement

too "free" ?

Does the speed remain

constant during lead-in

and retum?

Do the lead wires below

the carrier base (A) ass'y

scrape against the guide

bar ?

Does the carrier float ?

Rearrange wires to Prevent

any interference

?n

Proceedto section 9.2.2'

Q-s

9.2.2

L.

Does the carrier float

The damper bearing has

big play in it (backward

and forward).

tf^

PL-L1 clclc'

9.2.3

A

?

Irregular movement in

canier base

Is the platter

horizontal?

perfectly

Is the suide bar clean?

Damper bearing silicon has

been forgotten

e?l

r

!l-

Is there a gap between

the elevator shaft unit

and elevator bar when the

elevator is Iowered ?

Elevator mechanism not

properly adjusted

Do the lead wires below

the carrier base (A) ass'y

scrape against the guide

bar ?

Rearrange the wires to

prevent any interference

Does the carrier float ?

el"

Proceedto section 9.2.2.

Defective damper bearing

or roller

9.2.4

Carrier basefails to move

Do the damper bearing

and roller move smoothly?

Defective damper bearing

or roller

Defective CdS element or

lamp, or disconnectedlead

wire, or loose soldering

Does the tracking shutter

operateOK?

YES

Has the carrier clamper or

tonearm clamper been removed ?

ES

Removethe clamper

Do the relevant parts move

smoothly when moved by

hand?

Foreign matter in the carrier base, or jammed lead

wire

Loose magnet mounting

Defective circuit

:--ls l

Defective magnet mounting

-

^l

9.2.5

Carrier base moves too

freely

Is the platter

horizontal?

PerfectlY

"play" in the

Is there any

tonearm ass'y or elevator

shaft ?

Defective tonearm ass'Y,

elevator shaft or bearing

Is there a gap between

the elevator sheet and

tonearm rubber tip?

Readjust the height of the

elevator sheet

9.2.6

When tonearm shifts

across and traces record

groove

(r'

Does the tonearm shift

when the elevator is

raised?

Does gouging occur in the

darnper bearing and roller?

Defective damPer bearing

and roller

lr-r

1",l

Is the euide bar clean?

Carrier base (B) shifts but

fails to trace

Defectivecarrier base(B)

Circuit not properly adjusted.

fr

PL-L1 clclcl

A

9.2.7

?

Howling noise

Has the AC cord been

stretched tight?

Have the safety screws

(tightened during transport) been removed ?

e,p

9.2.8

9.2.9

l$r

Locate

right

dial

does feel

Problem with the actual

locate base?

Check sections9.2.L & 9.2.3.

4ffi)

['l ,f

9.2.10

Difference in stylus tip

height when in rest

position and when on

the record exceeds4mm

Defective elevator bar

Let the cord lie loose

I

I

iI

I

'f

9.2.11

Abnormal

speakers

Set the lead wires in correct arrangement

Are the lead wires arranged correctly?

EJr

Clean the guide bar

Defective roller damPer

bearing or guide bar

Noise like tumbling roller?

Do the PU leads and/or

shield tubing strike against

the guide bar under carrier

(A) ?

YES

Reset lead wires and tubing in correct position

PU cable ground floating

noise

9.2.12

Abnormal noise direct

from tumtable platter

Are there any magnetic

materia.lsbelow the platter

or in the linear arm

portion?

Is the noise generated

when tonearm is moving

to the lowering position ?

generated when

Noise

elevator moved uP and

down?

l

I

noise from

Foreign matter on guide

bar ?

)

Stopper unit dislodged

from stopper rubber or

plunger rubber

Fr

9.2.13

Elevator does not move

Does guide bar A rotate ?

Flash or foreign matter in

the canier base (A) ass'y

elevator bearing.

Clean

out and/or remove flashes

from the bearing.

Does the driver (E) ass'y

motor rotate ?

Clean off any oil on the

rubber belt

Does the elevator start to

move when the large pulley is rotated ?

Gear (F) and worm stuck

together,

or defective

driver (E) ass'y

Does the elevator bar

strike against the stater

base?

9.2.14

A\f

Lowering position not

attained

Is the platter

horizontal ?

$'

perfectly

Do the roller and damper

bearing operate without

gouging?

Are the lead wires in the

correct position?

Return the lead wires to

the correct position

Does the swing plate move

without gouging?

Defective swing plate

Return to section 1.d.

A f?

position

Lowering

properly adjusted

not

PL-L1 Clclcl

9.2.15

Tonearm fails to lower

on to record after stopping at lowering position, or if it does lower

onto the record it continues to trace the same

one groove

Is the platter

horizontal ?

perfectly

Does the lowering position

sensorfunction properly ?

Is there an unusual meta.llic sound?

Stopper unit stopper rubber or plunger rubber

needs readjustment

Does stopper

against

the

spring?

Stopper unit

position

needs readjustment

unit rub

plunger

Does the index plate move

normally when plunger is

tumed on and off?

s.2.16

Return failure

Defectivedriver 1E) ass'y

Is there gouging in the

damper bearing?

PL-L1 oclcl

1

2

3

1 0 . E X P L O D E DV I E W S

10.1 EXTERIOR

A

B

c

D

1

2

3

{ ooo

iz

6

5

4

.ta

A

-, tK

ry"'

B

)

>,

l

@

ilM

I

' @ l

f

__l

51

c

N

4

5

6

t

PL-LI

;

t

PartsList of Exterior

I

Kay No.

Psrt No.

3.

4.

Doscription

Washertacedalutite screw3 x g

1.

PRW-O68

PNR-126

Caution label

Panel

Control case assemblY

S1

5-2

5-3

$4

6.

7.

PAD{58

PAD{59

PAO-O60

PNX-I35

PDE-O65

GL-2PRl

Clc'Cl

Pushburtonunil A

Pushbutton unir E

Pushbufion unir C

ControlcaseA

CS type washer20

Connectorassembly

LED

Washer faced alutite screw 3 x8

The ! marh found on some component parts indicotes

the importonce of the safet! factor of the part. merefore, when replocing, be sure to use parts of identical

designotiotr.

a Parts without port number connot be supplied.

K.y No.

37,

38.

39.

40.

41.

.42.

rj-43.

,14.

P.C, Board

PT3x8

Part No,

PXT-4O3

Dccription

Motor

Washer faced alutite screw 3 x 8

PNW"338

PNW-339

PDGO21

IH ET, HBTI

PDG{04 (S/cl

PECO51

{HET, HBT)

E32{56 {S/Gl

PlareL

PlateR

PSB3X8

AC powercord

Strain relief

Angle

11,

12.

PBA-104

PNX-092

Screw

Lever

PSG{'|7

Washerfaced alutite screw 3 x 8

Pushswitch

13.

14.

15.

16.

1\17.

.l tA.

' ^j l

-i,20.

a

Wash€r feed alutite screw 3 x 6

PECOs2{HET, HBT) Insulator

eSf-Olz {HeT, HBT) Microswitch

DcE mo rs/G)

rs-l

19-2

r

Switch base

21,

1i 22.

PsA3xls

{H€T, HBT)

Plasticscrew3 x 15

(s/G)

PsA3x15

PTT{97 (HET, HBT)pow€rtransformer

PTT_I00(s/cl

PSB4x8

(HET, HBTI Lin€vottasesetector

PSB.Oo2

PSB{O7(S/c)

24-1

24-2

24-3

PAD-06'|

PAD{62

PAO"O63

244

24-5

25,

26,

27.

PNX-'130

28,

It, X.

30.

PDe{71

PwnOSt

(HET, HBT)

PWR-Osg(S/G)

PDE{67

31.

;

,t'l

32.

33.

34,

PNX{94

PECO63

PBH-257

Washerlaced alutite screw 3 x 8

Control caseB asaembly

Pushbutron unit B

Pushbutron unit D

Purh burton unit F

Control caseB

CStype washer20

Washerlaced alutite screw 3 x 8

Connectorassembly

P.C.Board

pT3 x I

power supptyassembty

Connectorassemory

PSA 2.6 x 6

Base

Nylon batt30

Spring

SF4x5

Washerlaced alutite screw 3 x 8

46,

47.

47-1

47-2

47-3

Label

Dust cover assembly

PXA-463

PNB-105

Hingeassembly

plate

DCM4x8

474

49.

49.

50,

51.

pNV{35

pEA{36

pXB-134

PNR-|21

Dust cover

Rubbermat ass€mblv

Screw

Turntableplatterassembly

53.

PNX-lO8

P l v3l x 5

EV gear

55.

56.

PLBOsl

PLB"OsO

Guidebar B

Guide bar A

57.

58.

59.

60.

61.

PLB{67

EV bar

PXT-391

PRW{46

Dial unir

Label

1

'

1O.2 TONEARM

I

^-.S

,

t-u-l

i

$

a-b

l 1 -: 3

I

|

;t

P

-l-r

yzl

l

ll__t

1

,l

-r

h:rF

:

\r

$.n

F\,r

o

Parts List of Tonearm

Key No.

I

2

s

4

S

6.

7,

7-1

7-2

73

7-4

8.

9.

10.

11.

Part No.

Elescription

PXA€04

PPD6O1

Weightassembly

Tgnearm assembly

Headshellassembly

PXB-116

PNR-127

PXT-414

11-1

1 1-2

11-3

12,

13.

14.

15.

16.

17.

18.

1 8 - 1.

18-2.

18-3

184

19.

PN X-1 03

PCX-051

PNX-1O2

PE L-041

Key No.

31'

32'

33.

34'

35.

Partswithout part number cannot be supplied.

Part No.

Description

PBE{17

PXB-121

PNC-145

PLB-046

BaseB

Washer

Bearing

Spacer

Roller

36.

37'

38.

39.

40.

PXB-120

PLB'O47

PBEO17

PXB-120

Bearing

Shaft

Magnet

Washer

Bearing

EV sheetunit

HS 3x5

BaseA

Screw

41 '

42.

43.

4445'

PLB-O59

PXB-121

Shaft holder A

Bearing

PXT-394

PEB-158

Shaft holder B unit

Rubbercap

S e n s o rb o a r d

Spacer

Cds

PM 2.6 x 6

T r a c k i n gs h a t e r

46.

47.

48.

49.

50.

PADO64

EV adjustscrew

PM 2.6 x 5

Terminal

Fw2.6x5x0.5t

PM 2.6 x 6

51.

52.

53.

PBH-255

EV sPring

EV sheetassembly

StoPPer

Spring

Cramper

Cupler base

LamP

S e n s o rb o a r d

PT 2.6 x 8

PT 2.6 x 8

20.

PSA 3x5

21 .

22.

23.

24.

Shutter

25.

PBA-094

Washer faced alutite screw 3 x 6

Plate

Pinunit

Screw

26.

27.

2829.

30.

PDAO13

PBH-254

PBH-29

P EB - 17 1

PLB-060

S h i e l dt u b e

Spring

Sprins

Rubber Pad

Screw

EV shaft

Pfastic washer 4Q x 0.1 3t

FL-L1 c'clo

ilied.

10.3 EV MECHANISM

\'

h

14

-k

q

16

,6{18

o Parts without part number cannot be supplied.

PartsList

Key No.

1.

2.

3.

4.

5.

6.

7.

8

9

1O

Part No.

PBE-018

PBE-014

PNW418

PNW-390

PSFOos

PDE{68

P EB € 9 7

Description

EW3

Washer

Washer

Key No.

Gear F

Plate

11

12

13

14

15

Cam

PT 2x10

Microswitch

Connector assembly

Belt

16.

17

18

19

20

Part N o.

Description

PNW-393

PNW-391

PNW485

PNW-391

Pulley

Collar

Worm gear

Collar

Chassis

PNW-392

P EB - 16 7

PXM-073

PSA 2.6x5

Frame

Motor pulley

Tube

Motor

PL-L1 clclcl

1

2

3

10.4 BOTTOM PLATE

A

B

c

D

1

2

3

tooo

5

4

d

,

*zz

6

A

[\

\ \ni\*

B

\

.11

-\

c

\

g

x

#Lq,

''F-u,

H

@

\

4

D

5

6

PL-LI

l*.(f

PSA4x16

Key No.

Prrt No.

Dorcription

PDE{66

Case

Washertacedalutite screw3 x 8

Connectorassembly

S€nsorboard

PT3xa