Download Life Fitness 9500 Series Cross Trainer Service Manual

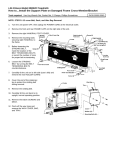

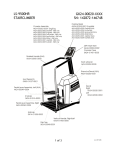

Transcript