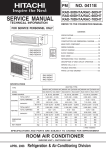

Download SERVICE MANUAL COMMERCIAL Single DC-Inverter

Transcript