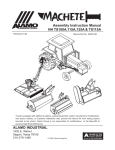

Download Maverick Boom Mower

Transcript