Download SERVICE MANUAL - Copy Finishing Systems

Transcript

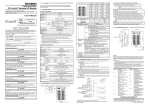

SERVICE MANUAL Standard Horizon PF-P330 Suction-Feed Paper Folder Read this manual, and thoroughly familiarize yourself with its contents before operating or servicing this equipment. PF-P330/SM FOREWORD Paper Folder PF-P330 Important Information This service manual is designed to help you to repair and maintain the PF-P330 in order to keep it in good operating condition. Please read and understand the instructions in this service manual before performing any repair or maintenance. - Horizon International Inc. shall not be liable for incidental or consequential damages resulting from: improper or inadequate maintenance by the customer; unauthorized modification or misuse; or operation outside of the environmental specifications for the product. - Horizon International Inc. follows a policy of continuing improvement in design and performance of the product. Therefore, the product design and specifications are subject to change without prior notice and without our legal obligation. - All rights are reserved. No part of the manual may be photocopied, reproduced or translated to another language without the prior written consent of Horizon International Inc. 031021/PFP330/00E/NO/HF/HO I US503009-00 Safety Precautions - Please read and understand all safety instructions with include the terms instructions are ignored, personal injury may result. WARNING, and CAUTION. If these safety - The repair, maintenance and safety instructions in this manual are valid only when the repair or maintenance work is performed according to the procedures described in this manual. - The term WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. - The term CAUTION indicates a potentially hazardous situation which, if not avoided, may result in damage on machines. It may also be used to alert against unsafe practices. - Horizon International Inc. cannot anticipate every possible situation that might involve a potential hazard. The instructions in this manual and the warning labels on the machine are therefore not all-inclusive. - All equipment shall be locked out or tagged out to protect against accidental or inadvertent operation when such operation, repair or maintenance could cause injury to personnel. Do not attempt to operate any switch, valve, or other energy isolating device when it has been locked or tagged out. - Some of the drawings in this manual show the machine uncovered for explanations of details inside the machine. II Abbreviations 1. Abbreviations for wire colors BRN RED ORN YEL GRN = = = = = Brown Red Orange Yellow Green BLU VIO GRY WHT BLK 3. Other Abbreviations = = = = = Blue Violet Gray White Black CON = DSW = NF = BRN(#) = the character (#) that follows the wire color indicates the attached gray sticker. The sticker is to identify the wire in case there are two wires of the same color. RED/BLU = "/BLU"; the color that follows slash indicates the base color of the wire. In this case, the wire is striped red on the blue color. 2. Abbreviations for electrical parts Axx Bxx Fxx Gxx Kxx Lxx Mxx = = = = = = = Inverter/Driver Sensor Fuse Power Supply Contactor LED Motor Qxx = QPM = QPW = S/SWxx = Xxx = Yxx = Circuit Protector/Breaker (Multi Layer) P. C. Board (Single Layer) P. C. Board Switch Terminal Board/Connector Solenoid/Clutch/Brake III Connector Dip Switch Noise Filter R/VR = SL/SOL= SSR = Volume Solenoid Solid State Relay Heading Precautions for P.C.Board and ROM P.C.Board and ROM can be damaged by humanly inperceptible static electricity. Handle P.C.Board and ROM with following care. Keep P.C.Board in a shield bag. Acrylic Cover Shield Bag P.C.Board Conductive Sponge Do not put P.C.Board and ROM on the machine, especially on the acrylic cover. (No problem on the conductive plate.) And keep the P.C.Board and ROM away from the insulators. Insulators: Plastic, form polystyrene, chemical fiber fabric, dry paper, etc. Clip Put the ROM on a conductive sponge and keep in a shield bag. Machine Frame Shield Bag Wrist Strap IV When replacing the P.C.Board and ROM, or setting the dip switches and volumes on the P.C.Board, wear a wrist strap, and connect the clip to the machine frame (not painted surface). Contents 3. Adjusting and Checking Procedures 1. Mechanism 1-1 1-2 1-3 1-4 1-5 1-6 1-7 1-8 1-9 1-10 Feed Table Unit .......................................................................... 1-2 Table Up/Down Unit .................................................................. 1-3 Table Height Detect Unit ............................................................ 1-4 Feed Rotor Unit .......................................................................... 1-5 Double Feed Stop Unit ............................................................... 1-6 Fold Roller Unit .......................................................................... 1-7 Deflector Unit ............................................................................. 1-8 Delivery Unit .............................................................................. 1-9 Buckle Chute Unit .................................................................... 1-10 Air Circuit Unit ......................................................................... 1-11 3-1 3-2 3-3 3-4 3-5 3-6 3-7 3-8 3-9 3-10 Sheet Guides Right Angle and Parallel Adjustment ................... 3-2 Rack and Pinion Position Adjustment ........................................ 3-3 Lower Guide and Fold Roller Gap Adjustment ......................... 3-4 Deflector Position Adjustment ................................................... 3-5 Buckle Chute Stopper Level Adjustment ................................... 3-6 Belt Tension Adjustment ............................................................ 3-7 Stopper (Roller Lever) Position Adjustment .............................. 3-8 Table Upper Limit Switch S01 Position Adjustment ................. 3-9 Feed Rotor Check ..................................................................... 3-10 Feed Ring Replacement ............................................................ 3-11 4. Mechanical Troubleshooting 2. Service Mode 2-1 2-2 4-1 4-2 4-3 4-4 4-5 4-6 4-7 4-8 4-9 4-10 4-11 4-12 Operations of Service Mode ....................................................... 2-2 Calibrating the Home Position (Buckle Chute Stopper) ............ 2-3 V Error Code 01 Is Indicated (= Feed Table Does Not Lower) ..... 4-2 Error Code 02 Is Indicated (= Feed Table Does Not Lift) ......... 4-3 Buckle Chute Sounds Loudly and Q01/02 Are Actuated ........... 4-4 Feed Rotor Does Not Suction the Sheets ................................... 4-5 Feed Rotor Does Not Drive ........................................................ 4-6 Fold Rollers Do Not Rotate ........................................................ 4-7 Delivery Conveyor Belt Does Not Drive ................................... 4-8 Deflector Malfunctions ............................................................... 4-9 Buckle Stopper Does Not Move ............................................... 4-10 Motor Does Not Drive .............................................................. 4-11 Display Does Not Show Any Image ........................................ 4-13 Error Message “Close Buckle” Is Shown (Even though it is closed) 4-14 5. Folding Quality Troubleshooting 5-1 5-2 5-3 5-4 5-5 5-6 Wrinkled Sheets .......................................................................... Folded Corners ........................................................................... Sheet Edges Do Not Align ......................................................... Sheet Is Folded Askew ............................................................... Sheets Are Not Arranged On the The Delivery .......................... Sheet Jams at the Deflector ........................................................ 5-2 5-3 5-4 5-5 5-6 5-7 6. Electrical Circuit 6-1 6-2 6-3 6-4 6-5 6-6 6-7 Electrical Parts Leyout and Descripton ...................................... 6-2 Electrical Chassis Layout and Description ................................. 6-3 P.C.B. Layout and Description ................................................... 6-4 Control P.C.B. QPM-192 ........................................................... 6-5 6-4-1 QPM-192 P.C.B. Layout ............................................ 6-5 6-4-2 QPM-192 LED Layout .............................................. 6-6 LCD P.C.B. QPW-677 ............................................................... 6-7 24V/5VDC Wiring Diagram ...................................................... 6-8 6-6-1 Buckle Chute Section ................................................. 6-8 6-6-2 Main Section ............................................................... 6-9 Power Circuit Wiring Diagram ................................................ 6-10 VI 1: Mechanism 1. Mechanism 1 Mechanism 1-1 1-2 1: Mechanism 1-1 Feed Table Unit Window for Sensor Sheet Guide The screw works as the fulcrum of sheet guide angle. Feed Angle Adjusting Mechanism Angle is adjustable within the range of this square. Sheet Guide Fixing Knob The sheet guides rotate on this fulcrum. Sheet Guide 1 2 Fulcrum Screw Guide Shaft Adjusting Screw Link This rod is eccentric. Slide Bracket Eccentric Rod Feed Angle Adjusting Mechanism Nut Plate Sheet Guide Angle Adjusting Mechanism 1: Mechanism 1-2 Table Up/Down Unit Rack (rear) Joint Rack (front) Bearing Pinion Side Plate (rear) Guides Side Plate (front) Table Fixing Hole Joint Table Bracket (Rack) Pinion Pinion M02 Table Up/Down Motor Guides Pinion Side View Top View 1-2: Table Up/Down Unit 1 Mechanism 1-3 1-4 1: Mechanism 1-3 Table Height Detect Unit Adjusting Lever Sensor L : Table Height Low B06 O : Table Height Standard H : Table Height High L O H Height Detecting Bar When the top of the loaded sheets pushes up this bar, the sensor detects the metal attached on the back of the bar. Fulcrum Height Detecting Bar Adjusting Lever Fulcrum for both 1: Mechanism 1-4 Feed Rotor Unit Vacuum Pipe This pipe does not rotate. This suctions the air through the holes at the bottom. Feed Ring Vacuum Rotor Vacuum Rotor This ring rotates and suctions the sheet through the radial slits. Vacuuming Mechanism A Drive Motor M01 Fold Rollers Clutch Electromagnetic Valve Vacuum Rotor Unit Driving Mechanism Viewing from A Vacuuming Mechanism 1-4: Feed Rotor Unit 1 Mechanism 1-5 1-6 1: Mechanism 1-5 Double Feed Stop Unit Gate Plate Up/Down Slide Plate Urethane When installing the gate plate, push it down and screw it. Double Feed Prevention Unit Fulcrum Gate Lever Moves Up/Down within the range of this slot. Vacuum Roller Blower (exhale) Square Pipe Blowing Outlet Double Feed Stop Plate The double feed stop unit moves Up/Down on this fulcrum. Gate Lever The bending and friction of this urethan prevents the double feeding of the sheets. Urethan Gate Plate When the flat disappears, replace to a new one. Worn out 1: Mechanism 1-6 Fold Roller Unit The gap between the first roller and guide plate = 1 mm (0.04") 1 [CHECK] 1mm 1 Remove the second and fourth rollers. (0.04") 2 After removing the rollers, raise the buckle 2 fixing lever and reset the roller lever level. (If the buckle fixing lever is left lowered, the roller lever pushes the guide plate up.) 3 Insert an 1 mm (0.04") allen wrench from the infeed side, and check the gap. Roller Lever Buckle Chute Side Solenoid ON = When the deflector is Up. 4 2 3 Mechanism 3 4 1 2 4 2 1-6: Fold Roller Unit 1 5 4 Solenoid OFF = When the deflector is Down. - When the solenoid turns OFF, the deflector lowers and makes a space between the deflector and the third roller. - The sheet that comes through the second and third roller goes over the deflector, then goes to the second buckle chute through the third and fourth roller. Vacuum Rotor 3 - When the solenoid turns ON, the deflector goes up and closer to the third roller. - The sheet that comes through the second and third roller goes under the deflector and is delivered. (As shown with the arrow to the right.) Guide Plate 1-7 1-8 1: Mechanism 1-7 Deflector Unit Deflector Unit Deflector Fulcrum Shaft Deflector Side Plate Deflector Holder Deflector Lever Solenoid ON: The upper/lower limit of the deflector is decided by the 15 hole on the side plate. 15 hole on the side plate Solenoid OFF: Deflector Lock the deflector with this screw. Deflector Holder Deflector Lever (front) Adjust the tilt of the deflector by adjusting the deflector holder with these two screws. 1: Mechanism 1-8 Delivery Unit M01 Drive Motor Delivery Belt Adjust the belt tension by fixing the shaft within the range of the slot. Tension Adjustment of the Delivery Belt O Ring 1-8: Delivery Unit 1 Mechanism The O ring contacts the shaft directly and drives the delivery shaft. (The motor does not have reduction gear. This wheel makes large reduction ratio.) 1-9 1-10 1: Mechanism 1-9 Buckle Chute Unit Buckle Chute Unit Idle Gear Screw Shaft Drive Gear Motor Gear Sensor Plate M03 M04 Stopper Encoder Sensor B01 Home Position Sensor Sensor Plate Encoder Unit Stopper Drive Mechanism 1: Mechanism 1-10 Air Circuit Unit Blower Box Vacuum Rotor M05 This ring rotates and suctions the sheet through the radial slits. Blower Motor - Inside the box, the motor M05 is installed. - The air comes from top goes out through the coil of the motor. The coil is also cooled down by the air blow. Electromagnetic Valve Open/Close Vacuum Air Vacuum Plug IN OUT Separation Air Outlet Carbon Brush Separates the suctioned top sheet from the rest of the sheets. [CAUTION] The carbon brush can not be replaced singly. Replace the whole blower box. Blower Air Outlet Blows the top of the loaded sheets and flips it up. 1-10: Air Circuit Unit 1 Mechanism The carbon worn out 1-11 2: Service Mode 2. Service Mode 2 2-1 Service Mode 2-2 2: Service Mode 2-1 Operations of Service Mode In the service mode, the operations listed on the chart to the right can be performed by pressing the power switch and the other switches together. To quit the service mode, turn OFF the power switch. While the PF-P330 is performing the service mode operations listed on the chart to the right, the sheet sensor B08 is deactivated. Therefore, the PF-P330 can run without sheets on the feed table. On the numeric key pad, press the button and turn ON the power switch. The first and second buckle chute stoppers move Up/Down at full stroke. Buckle Chute Single Moving Mode On the numeric key pad, press the button and turn ON the power switch. The total counter is indicated. (Total counter: The total number of the folding that is counted since the machine has been shipped. This is not cleared by pressing the [C] button.) Total Counter Indication [1] [2] On the numeric key pad, press the button and turn ON the power switch. [3] 1 Buckle chute stopper Up/Down 2 Drive motor drives 3 Feed table Up + Blower ON + Clutch ON + Valve ON 4 Feed table Down + Repeat Blower OFF + Clutch OFF + Valve OFF 3 4 Non-Production Run Mode 1 On the numeric key pad, press the button and turn ON the power switch. 1 Drive motor drives + Feed table Up and stops 2 Clutch repeats ON/OFF Clutch Unit Single Operation Mode On the numeric key pad, press the button and turn ON the power switch. 1 Drive motor drives 2 Feed table Up + Blower ON + Clutch ON + Valve ON 3 Feed table Down + Blower OFF + Clutch OFF + Valve Repeat 2 OFF 3 Non-Production Run Mode Except Buckle Chute Unit On the numeric key pad, press the button and turn ON the power switch. All stored memories are cleared. Memory All Clear [O] & [C] and turn ON the power switch. Total counter is reset to “0” Total Counter Clear When the folding pattern is NOT the Single Fold, press the [0] button and [Feed Gap] button. Solenoid Y02 and Y03 turn ON and the deflector closes. Deflector Close [4] [5] [C] On the numeric key pad, press the 2: Service Mode 2-2 Calibrating the Home Position (Buckle Chute Stopper) On the PF-P330, the home position of the buckle chute stopper only should be calibrated manually. Fold one sheet and adjust the home position depending on the shift of the folded sheet. Delivered with this face top. The First Stopper Raise the B01 by the half of the shift. Single Fold Perform the single folding. Measure the shift of the fold position. (Fig.1) Adjust the first buckle chute home position sensor B01 by the half of the folding shift. (Fig.2) Perform the parallel folding. Measure the shift of the fold position. (Fig.1) Adjust the second buckle chute home position sensor B02 by the half of the folding shift. Delivered with this face top. Parallel Fold Raise the B02 by the half of the shift. Fig.1 Adjusting Amount The sensor position is adjustable within the range of this slot. B02 B01 The Second Buckle Chute Home Position Sensor 3 4 B01 Fig.2 The First Buckle Chute Home Position Sensor B01 The First Buckle Chute Home Position Sensor Buckle Chute Side 5 [Additional Information] After the fold pattern and sheet size are selected, the stopper lowers. When the home position sensor detects the stopper, the motor reverses and the stopper lifts. The stopper moving amount is calculated from the fold pattern and the sheet size. Therefore, if the sensor position is shifted upward, the stopper position is also shifted upward by the same amount. The Second Stopper 1 2 Deflector Fig.3 Folding Unit 2-2 Adjusting the Home Position (Buckle Chute Stopper) 2 2-3 Service Mode 3: Adjusting and Checking Procedures 3. Adjusting and Checking Procedures 3 3-1 Adjusting and Checking Procedures 3-2 3: Adjusting and Checking Procedures 3-1 Sheet Guides Right Angle and Parallel Adjustment PF-P330 has the mechanism that the sheet guides F and R turn together to feed sheets to the feed rotor at right angle. (Fig.1) Sheet Guide R The screw works as the fulcrum of sheet guide angle. Sheet Guide F This section describes instructions to correct the angle of the sheet guides F and R in case their angle differs each other (Fig.2) Guide Fulcrum Loosen the fulcrum screw on the sheet guide. (Fig.2) Angle is adjustable within the range of this square. Eccentric Rod - Do not remove the screw completely, just loosen it by the half of a rotation. Loosen the adjusting screw. - Do not remove the screw completely, just loosen it by one rotation. Fig. 1 Feed Angle Adjusting Mechanism Sheet Guide Fixing Knob Sheet Guide Front Stop Adjust the sheet guide angle at right angle and parallel. (Fig.3) - Load a square sheet on the feed table. - Place the sheet so that sheet edge touches the front stop. - Align the sheet guide F and R with the sheet and tighten the screws described in step and . Slide Bracket 1 2 Fulcrum Screw Adjusting Screw Nut Plate Sheet Fig. 3 Right Angle and Parallel Adjustment Fig. 2 Sheet Guide Mechanism 3: Adjusting and Checking Procedures 3-2 Rack and Pinion Position Adjustment The feed table moves Up/Down by the rack F/ R and the pinions. If the position of the rack and pinion differs at the front and rear, the feed table can not move smoothly. - Slide guides 2 and 3 are identical. Rack R Fig2,3 2 Fix the slide guide at inner (exit) side. 3 At last, put the slide guide on the rack and fix it. Pinion Remove the feed table. Side Plate Spacer Loosen the fixing screws on pinion. - Release the pinion so that it can turns freely. Insert the rack into the slot on the side plate. Apply grease (back as well) 1 Put the rack on infeed side of the slot. Set the rack. (Fig.2) - Place two slide guides on both side of the rack and fix the rack on the infeed side. 1 The slot on the side plate is wider than the plate thickness of the rack. Put the rack on the infeed (entrance) side of the slot. 2 Fix the slide guide at the inner (exit) side of the machine. 3 Fix the other slide guide at the infeed (entrance) side. Fig. 1 Rack and Pinion Rack is at the upper limit. Lock the pinion. (Fig.3) Enough grease is applied on the rack that is installed between the slide guides. The rack that is installed between the slide guides moves Up/Down smoothly. Raise the rack to the upper limit. (Fig.3) - Keep the rack at the upper limit during performing the next step . Hold the rack using a rope or magnet. Fig. 2 Rack and Slide Guide - Tighten the fixing screws on pinion here. (Front side as well) - The screw should be put on the flat face of the pinion shaft. The tops of rack F and rack R are at the same height. Grease is applied on the mesh of rack and pinion. Set the rack at front side as well. Check the items listed in Fig.4. Fig. 3 Lock the Pinion Fig. 4 Check List 3-2: Rack and Pinion Position Adjustment 3 3-3 Adjusting and Checking Procedures 3-4 3: Adjusting and Checking Procedures Lower Guide and Fold Roller Gap Adjustment The shape of the lower guide is easy to be deformed as shown in Fig.1. 1mm (0.04") Lower Guide Sheet goes to the fold roller after passing through between the upper guide and lower guide as shown in Fig.3. 1mm (0.04") The First Fold Roller 1mm (0.04") 3-3 The gap between the lower guide and the first fold roller should be 1 mm (0.04”.) Check the gap. These fronts align, and there is 1 mm (0.04") gap between the lower guide and the fold roller. - Looking from the infeed entrance, use a small light and check if the three gaps between the lower guide and fold roller are 1 mm (0.04” .) (Fig.2) Fig. 1 Lower Guide and First Fold Roller [Note] Fig. 2 Amount of the Gap . Open the feed section cover. (Fig.4) Upper Gudie The First Fold Roller Feed Roller Cover 1mm - If the gap is not correct, go to the next step (0.04 ") Use a 1 mm-thick strip of sheet to check the gap accurately. Remove the feed roller cover. (Fig.4) - The lower guide positions under the upper guide. Adjust the front edge of the lower guide to adjust the gap. Lower Guide Sheet Feed Section Cover Fig. 3 Upper and Lower Guides Fig. 4 Feed Section Covers 3: Adjusting and Checking Procedures 3-4 Deflector Position Adjustment .3 No The deflector decides if the sheet is delivered or folded again. Deflector Fulcrum Shaft The upper or lower limit of the deflector is defined by the 15 hole on the side plate. (Fig.2) Deflector Side Plate Deflector Deflector Holder Deflector Lever Remove the second and fourth rollers. Deflector Holder Solenoid ON: 15 Side Plate Hole Deflector Lever (front) Loosen the fixing screws on the deflector holder. (Fig.3) Insert a 0.5 mm (0.02”) thickness of the sheet between the third roller and the deflector. (Fig.3) Y02 Solenoid Solenoid OFF: Fig. 1 Deflector Drive Mechanism Fig. 2 Solenoid ON/OFF and Deflector Position 0.5 mm (0.02") thickness of the sheet Lock the deflector holder. 5 - Hold up the deflector holder and tighten the fixing screws. - Remove the inserted sheet. Adjust the solenoid position. (Fig.4) - Position the solenoid so that when the plunger is pushed in, the deflector touches the 15 side plate hole. Tighten the fixing screws in that position. 5 3 4 3 4 1 2 Push In 1 2 Little gap at this side Deflector Holder Check - These screws set the position of the deflector. Fix the solenoid with this side touches the side plate. - Remove the fold roller drive belt. Keep pressing plunger on the solenoid and turn the third roller manually. Check that the roller turns silently (the deflector does not touch the roller.) - These screws can also adjust the tilt of the deflector. Solenoid Fixing Screws Fig. 3 Deflector Holder Fig. 4 Solenoid Position Adjustment 3-4: Deflector Position Adjustment 3 3-5 Adjusting and Checking Procedures 3-6 3: Adjusting and Checking Procedures 3-5 Buckle Chute Stopper Level Adjustment Check the sheet guides. Front Stop Sheet Guide - Place a sheet so that the sheet edge touches the front stop and check that the sheet guides are parallel to the sheet. (Fig.1) If the sheet guides are askew, see Section 3-1: Sheet Guides Right Angle and Parallel Adjustment and correct the sheet guides angle. Remove the cover on buckle chute section. - Lay down the buckle chute section and loosen the fixing screws at the bottom of the buckle chute. (Fig.2) Sheet Guide No gap between the sheet guide and the sheet that is aligned with the front stop. Remove the rear cover. Fig. 1 Sheet Guide - In later procedure, the motor belt will be driven manually to feed a sheet. Fig. 2 Remove the Covers Load a sheet on the feed table. - Load a square sheet and place the sheet guides on both side. Two screws adjust the tilt. Feed a sheet. - Drive the motor belt manually and feed a sheet. - Stop the belt at position where the sheet front edge touches the stopper. Stopper Stopper Adjust the stopper angle. - Adjust the stopper angle within the play made by the two fixing screws so that the stopper is parallel to the sheet. (Fig.3) Sheet Slide Guide Fig. 3 Stopper Fixing Section 3: Adjusting and Checking Procedures 3-6 Belt Tension Adjustment Drive Timing Belt Tension Fold Roller Drive Timing Belt Tension The tension of the drive timing belt is adjusted by the fixing position of the drive motor (M01.) Too much belt tension may result in that the timing belt vibrated by the motion of the machine. Do not tense the belt too much. The tension of the fold roller drive timing belt is adjusted by the fixing position of the tension roller. The hole on the side plate to fix the tension roller is slot. Delivery Belt Tension The delivery belts are flexible, therefore, the belt tension is not adjustable. Fix the delivery roller shaft at the center of the slot on the side plate. If the delivery belt slips, set the delivery roller shaft at exit side of the slot. Tension Roller The fold roller drive timing belt bends by about 1 mm (0.04") When the belt is pushed by 200 g at its center, the belt bends by 3-4 mm (0.12"-0.16".) Delivery Belt Feed Roller Drive Timing Belt Fold Roller Drive Timing Belt Power Timing Belt Fix at the center of the slot. M01 3-6: Belt Tension Adjustment 3 3-7 Adjusting and Checking Procedures 3-8 3: Adjusting and Checking Procedures 3-7 Stopper (Roller Lever) Position Adjustment The stopper of the roller lever prevents the removable rollers (the second and fourth rollers) from compressing the other rollers (the first, third and fifth rollers) too much. (Fig.1) If the rollers are compressed each other for a long time, the roller lever is raised gradually. To avoid that, limit the pressure of compressing the rollers by the stopper position. Spring 5 3 A B 2 Stopper Roller Lever Fig.1 Roller Unit When the stopper positions as shown in the Fig.2-B, the second and fourth rollers compress the first, third and fifth rollers too much. If the rollers are left as such for a long period, they may be deformed. Adjust the eccentric stopper angle. Eccentric Min. 1 4 When the stopper positions as shown in the Fig.2-A, the second and fourth rollers can not touch the first, third and fifth rollers and can not fold a sheet. Install the second and fourth rollers. Eccentric Max. Fig.2 Eccentric Stopper Position Eccentric Stopper Hole for Wrench 5 3 4 1 0.05 0.15 mm 0.002" 0.005" 2 - Set the stopper so that the hole for Allen wrench positions at the delivery (exit) side. Set the gap between the stopper and the roller lever. - Fix the stopper so that the gap is 0.05 -0.15 mm (0.002” -0.005”.) - In case of 64 gsm sheet, insert one or two sheets in between and fix the eccentric stopper. (When the eccentric stopper positions as Fig.2 -B, the rollers compress too much and are deformed.) Roller Lever Fig.3 Roller Compressing Fig.4 Correct Gap 3: Adjusting and Checking Procedures 3-8 Table Upper Limit Switch S01 Position Adjustment The table upper limit switch S01 (Fig.1) detects the upper limit of the feed table. B06 When the feed table is Up, the sheet loaded on the feed table is detected by the sheet upper limit sensor B06 (Fig.2) and the feed table stops there. If the sensor B06 malfunctions or the feed table lifts with an object on it, the upper guide is raised and the S01 activates to stop the feed table. Upper Guide S01 Sheet Upper Limit Sensor S01 Feed Table Magnet Loosen the fixing screws on table upper limit switch S01. Fig.1 Table Upper Limit Switch S01 Fig.2 Sheet Upper Limit Sensor B06 Lock the S01 in position that its actuator positions as shown in Fig.3. Check the followings. 1 Load a couple of sheets on the feed table. 2 Turn ON the power switch. 3 Press the test feed button. The feed table moves Up. 4 Raise the upper guide manually. If the table stops and starts lowering, the S01 is installed correctly. S01 When the actuator is pushed, there is still 0.5 mm (0.02") space. Nut Plate Fig.3 S01 Actuator Position 3-8: Table Upper Limit Switch S01 Position Adjustment 3 3-9 Adjusting and Checking Procedures 3-10 3: Adjusting and Checking Procedures 3-9 Feed Rotor Check PF-P330 has the same feed rotor that is installed on collating machine VAC-100. Check Wave Washer Feed Ring Profile Vacuum Rotor 1 The cutouts on both edge of the vacuum pipe face the bottom. (Fig.2) 2 4 The shrink amount of the wave washer is 2 mm (0.08”.) (Fig.3) [Additional Information] The stretching force of the washer removes the gap in the thrust direction. 5 6 Vacuum Rotor Vacuum Pipe Thrust Ring This ring rotates and suctions the sheet through the radial slits. Setting Block Fig.1 Feed Rotor Unit 2 This parts (front /rear) are at the same angle. Grease does not come out. 6 Can be turned smoothly by hand. Thrust Ring Wave Washer WW-30 N4 60 mm 3 (2.4") The torque on the setting block is 11kg/cm. (Fig.2) The installed feed rotor rotates smoothly. This pipe does not rotate. Suctions air the holes at the bottom. Holes at the bottom The setting blocks (front and rear) faces at same angle and level to each other. (Fig.2) 3 The edge of the pipe positions 60 mm (2.4”) ahead from face of the setting block. (At front and rear) (Fig.2) Vacuum Pipe WW-30 SB4-20 5 Torque 1 Cutout at the bottom 11kg / cm Fig.2 Feed Roller (front) 4 Shrink = 2 mm amount (0.08") Setting Block (rear) Fig.3 Wave Washer 3: Adjusting and Checking Procedures 3-10 Feed Ring Replacement The external diameter of the feed ring is bigger than the that of feed rotor by 0.3 mm (0.01”.) [Diameter: by 0.6 mm (0.02”)] When the feed ring is worn out and becomes smaller, it can not feed sheets correctly. (Fig.1) B4-6ZP X 4 B4-8ZP 0.3 mm (0.01") Setting Block When replacing the feed ring, do not dismantle the feed rotor unit. Feed Ring Remove the rear cover. Remove the hoses and conntecting parts. Fig.1 Feed Ring Fig.2 Valve AS - Remove the hoses and connectors to the pump. Remove the valve unit. (Fig.2) Rear Vacuum Plug Feed Rotor AS Remove the vacuum plug. (Fig.3) Feed Ring Pull out the feed rotor. Front - Displace the timing belt and pull out the vacuum roller. Cut the feed ring using a nipper. When installing the feed rotor AS, adjust this cutout on the notch Install new feed rings. (Fig.4) - After installing the new feed ring, fit the ring on the groove. Fig.3 Vacuum Plug [Note] - To install the feed ring easily, push this rotor to the rear side. - After installing the feed ring, fit the ring on the groove. Fig.4 Feed Rotor AS 3-10: Feed Ring Replacement 3 3-11 Adjusting and Checking Procedures 4: Mechanical Troubleshooting 4. Mechanical Troubleshooting 4 4-1 Mechanical Troubleshooting 4-2 4: Mechanical Troubleshooting 4-1 Error Code 01 Is Indicated (= Feed Table Does Not Lower) The error code 01 is indicated when the feed table lower limit sensor B07 does not detect the feed table within 7 seconds after the signal to lower the table has been sent. Table Up/Down motor M02 does not drive. The feed table Up/Down mechanism malfunctions. Rack 1 Joint When the feed table lowers and sounds loudly, the sensor B07 has a problem. QPM-192 2 Pinion X02 M02 4 Pinion Shaft QPM-192 Slide 3 Guide 2 CON8 B07 1. The fixing screws on the joint and the motor are fully tightened. 2. The fixing screws on two pinions are fully tightened. 3. The rack moves smoothly between the two slide guides. 4. The bearing for the pinion shaft positions correctly. Check the followings: When a ferrous object is put on the detecting part of the B07, the LED L12 illuminates. 2. B07 is installed correctly. 3. The wiring and connection between B07 CON10 on QPM192 is OK. 5 6 [ Moving Up/Down the Feed Table] Check the following mechanism functions: 5 CON10 6 CON8 Table Up/Down Motor 24VDC Geared Motor L12 YEL 1 2 GRN 3 BLU B07 1. M02 Table Up/Down Motor GRN BLU Turn OFF the power switch. Keep pressing the [5] button on the numeric key pad and turn ON the power switch. The blower, valve, clutch and table Up/Down motor repeat the cycle of feeding operation. (To stop, turn OFF the power switch.) If the M02 does not drive, or does not try to drive, check the followings: 1. When the fixing screw on the joint is loosened and unloaded, the M02 drives. 2. The connectors of X02 and CON8 on QPM192 are OK. 3. The voltage of the X02 at the QPM192 side is 24VDC. 4. The voltage between the Pin5 and Pin6 of the CON8 on QPM192 is 24VDC. 4: Mechanical Troubleshooting 4-2 Error Code 02 Is Indicated (= Feed Table Does Not Lift) The error code 02 is indicated when the feed table upper limit sensor B06 does not turn ON within 7 seconds after the signal to lift the table has been sent. Table upper limit switch S01 malfunctions. The upper guide is raised. Upper Guide The height detect lever of the sensor B06 is raised. QPM-192 L9 S01 Sensor NC ORN NO YEL C 3 4 CON3 S01 B06 Magnet 1. S01 is installed correctly as shown in Section [3-8: Table Upper Limit Switch S01 Position Adjustment] , Fig.3. Check the followings: 2. When raising the upper guide manually, the LED L9 on QPM192 lights OFF. 1. An object on the feed table raises the upper guide. 3. 2. An object sticks on the magnet that is installed under the upper guide, and it raises the upper guide. When raising the upper guide manually and pushing down the actuator of the S01, L9 illuminates. 4. Wiring and connection between the S01 and Pin3,4 of CON3 on QPM192 is OK. 3. The upper guide is deformed and positions apart from the S01. Fulcrum On the back of the height detect lever, a thin iron chip is attached. When the lever is raised by the sheets and detected by the sensor B06, the feed table stops. Check the followings: 1. Installation and function of the height detect lever. 2. The installation of the iron chip on the back of the height detect lever, and the B06. 3. Wiring and connection between the B06 and Pin1, 2 of CON10 on QPM192. Check the followings: The upper guide is held by a magnet. When the upper guide is raised and remains there, the table upper limit switch S01 works and stop the feed table. Height Detect Lever The feed table Up/Down mechanism malfunctions. See Section [4-1: Error Code 01 Is Indicated] and check the same heading. 4-2: Error Code 02 Is Indicated 4 4-3 Mechanical Troubleshooting 4-4 4: Mechanical Troubleshooting 4-3 Buckle Chute Sounds Loudly and Q01/02 Are Actuated Buckle stopper stops at the lower limit. Buckle stopper stops at the upper limit. Buckle chute home position sensors B01/ 02 malfunction or are installed incorrectly. A set of sensors on the encoder P.C.B. QPW422 malfunctions. Buckle stopper stops on the way. The guide shaft and the bushing of the stopper Up/Down mechanism malfunction. Second Buckle Chute Encoder P.C.B QPW-422 B02 Pointer B01 Screw Shaft First Buckle Chute Encoder P.C.B QPW-422 QPW-422 BRN 1 BLK 2 B01 BLU 3 The First Buckle Chute Home Position 1 2 3 CON2 CON1 BRN 1 BLK 2 BLU 3 The Second Buckle Chute Home Position 1 2 3 CON2 B02 1 2 3 4 6 QPW-422 QPM-192 BRN RED ORN YEL GRN 1 CON1 2 L3 3 4 6 1 BRU 1 CON2 VIO 2 2 3 GRY 3 WHT L6 4 4 6 BLK 6 BRN/WHT 8 CON1 8 Then, circuit protector is actuated. Check the followings: 3. 4. 1 CON1 2 L1 3 4 L2 6 The Second Buckle Chute Side 1 2 3 4 6 8 BLU VIO GRY WHT BLK BRN/WHT 1 CON2 2 3 L4 4 L5 6 8 The couble of optical sensors on the encoder P.C.B. QPW422 read and counts the rotation. If the sensor malfunctions and they can not count the rotation, the stopper goes father than the set position until it stops at the upper limit. Then, the circuit protector is actuated. If the buckle chute home position sensors B01/02 malfunction, the stopper goes farther than the home position until it stops at the lower limit and overloads. B01/02 are installed correctly. When a ferrous object is put on the detecting part of the B01/02, the sensor LED illuminates. At the same time, LED L3 or L6 illuminates on QPM192. Wiring and connection between B01/02 QPW422 - CON1/CON2 on QPM192 is OK. The First Buckle Chute Side BRN RED ORN YEL GRN Bushing Check the followings: QPW-422 QPW-422 1. 2. QPM-192 1 2 3 4 6 1. The bushing is not deformed and installed correctly. 2. The screw shaft is inserted into the bushing correctly. 3. The screw shaft does not bend and is not deformed. Check the followings: 1. 2. 3. Installation of the QPW422 Installation of the sensor plate When the sensor plate is rotated manually, the LED L1 and L2 or L4 and L5 on QPM192 illuminates by turns. If the sensors malfunction, replace the sensors and QPW422 together. (Check the guide shaft by turning it manually.) 4. The pointer in the stopper position checking window is not caught with the buckle frame and stopped. 4: Mechanical Troubleshooting 4-4 Feed Rotor Does Not Suction the Sheets When the M05 does not drive at all, go to Section [4-10: Motor Does Not Drive] Valve Y04 malfunctions. When the vacuum is weak, check if the air hose is installed correctly or it is not torn. The valve spring is weakened. Y04 Valve Spring The rotation of the blower motor is set low. 17 mm (0.7") QPM-192 CON7 3 4 ORN YEL X06 RED BLK Y04 Upper Stopper 2 Moving Button 2nd Stopper Stopper Position Display 1st Stopper 1 2 3 4 5 6 7 8 9 0 Memory C [Activating the Valve] Mode Turn OFF the power switch. Keep pressing the [5] button on the numeric key pad, and turn ON the power switch. The blower, valve, clutch and table Up/ Down motor repeat the cycle of feeding operation. (To stop, turn OFF the power switch.) Mode Selecting Button Air Press the mode selecting button to show the [Air] screen on the display. By pressing the upper stopper 2 moving button, the rotation of the blower motor M05 is increased and vacuum becomes stronger. - When the mode selecting button is pressed again, the setting is entered and the display goes back to the counter screen. The valve spring prevents the pump from choking when the vacuum hose is clogged. Check the followings: Check the followings: 1. The valve spring is installed correctly. 1. While the machine is performing the feeding operation described above, the valve sounds working. 2. The length of the valve spring is 17 mm (0.7”) as shown above. 2. While the machine is performing the feeding operation, 24VDC is measured at the connector X06. 3. Wiring and connection between Y04 - X06 Pin3,4 of CON7 on QPM192 is OK. 4-4: Feed Rotor Does Not Suction the Sheets 4 Mechanical Troubleshooting 4-5 4-6 4: Mechanical Troubleshooting 4-5 Feed Rotor Does Not Drive Checking the feed rotor: Drive motor M01 does not drive - Remove the feed rotor cover and the rear cover. - Turn OFF the power switch. Keep pressing the [5] button on the numeric key pad and turn ON the power switch. The blower, valve, clutch and table Up/Down motor repeat the cycle of feeding operation. (To stop, turn OFF the power switch.) Clutch Y01 malfunctions X10 Q03 X12 Y01 2A S00 X11 Capacitor SSR Drive belts are installed incorrectly. QPM-192 K02 1 2 CON7 11 22 BRN 1 RED 2 M01 X05 11 22 BLK BLK Y01 Y01 Clutch M01 Check the followings: Check the followings: Drive Motor 1. The circuit protector Q03 for M01 is not actuated. 1. While the machine is performing the feeding operation, the clutch sounds working. 2. The fixing screws on timing pulley of the M01 are fully tightened. 2. While the machine is performing the feeding operation, 24VDC is measured on connector X05. 3. The voltage on the SSR terminal Pin2 and BL connector X11 is 115/230VAC. 3. Wiring and connection between Y01 - X05 Pin1,2 of CON7 on QPM192 is OK. Tension Check the followings: 1. The four drive timing belts are installed and work correctly. 2. The tension presses the belt correctly. 4. Wiring and connection between S00 - M01 (shown above) is OK. 4: Mechanical Troubleshooting 4-6 Fold Rollers Do Not Rotate Checking the fold roller rotating Drive motor M01 does not drive - Remove the rear cover. - Turn OFF the power switch. Keep pressing the [5] button on the numeric key pad and turn ON the power switch. The blower, valve, clutch and table Up/Down motor repeat the cycle of feeding operation. (To stop, turn OFF the power switch.) X10 Q03 X12 2A S00 X11 Capacitor SSR Drive belts are installed incorrectly. K02 1 2 Fold Rollers M01 11 22 M01 Drive Motor Check the followings: 1. The circuit protector Q03 for M01 is not actuated. 2. The fixing screws on timing pulley of the M01 are fully tightened. 3. The voltage on the SSR terminal Pin2 and BL connector X11 is 115/230VAC. 4. Wiring and connection between S00 - M01 (shown above) is OK. Tension Check the followings: 1. The drive timing belts are installed and work correctly. 2. The fixing screws on the timing pulley are fully tightened. 3. The tension presses the belt correctly. 4-6: Fold Rollers Do Not Rotate 4 Mechanical Troubleshooting 4-7 4-8 4: Mechanical Troubleshooting 4-7 Delivery Conveyor Belt Does Not Drive The tension of delivery belt is loosened. O ring is cut, or slips on the grease. Delivery Belts Delivery belt drive mechanism malfunctions. Idle Shaft M O Ring Delivery Roller Shaft Adjusting Screw O Ring Delivery Pulley Idle Shaft Fix the screw at the center of this slot. [Profile] Check the followings: 1. Drive Shaft Power is transmitted from the idle shaft to the drive shaft through the O-ring, to make large reduction ratio. The adjusting screws for belt tension are set in correct position. - If the delivery belt is loosened even though the adjusting screw is set at the farther edge (exit side) of the slot, replace the belt. Check the followings: 1. 2. Delivery Roller Pulley Check the followings: 1. The fixing screw on the timing pulley of the idle shaft at motor side is fully tightened. 2. The fixing screw on the delivery roller pulley is fully tightened. 3. The delivery roller pulley and the drive shaft do not run idle. O ring is not cut or deformed. Idle shaft does not slip on the grease. 4: Mechanical Troubleshooting 4-8 Deflector Malfunctions Deflector mechanism malfunctions. Solenoids Y02, Y03 malfunction. Deflector closes = Solenoid Y02 and Y03 turn ON during the single folding operation. To perform the single folding, the deflector is raised (closed) and the folded sheet is delivered to the conveyor. Fulcrum Deflector Deflector Holder A jammed sheet is left inside. Y02 Deflector Solenoid (front) QPM-192 3 4 CON9 2 Deflector Lever (front) Y03 1 2 3 4 Deflector Solenoid (rear) BRN RED ORN YEL 1 1 BRN 2 2 WHT X04 1 1 BRN 2 2 WHT [Additional Information] Y03 In case either of Y02 or Y03 malfunctions, the deflector can be switched by the other solenoid. Although, that makes the space between the deflector and roller at the side where the solenoid malfunctions, and causes sheet jam. While the fold pattern is NOT set to single fold, keep pressing the [0] button and press the [Feed Gap] button. The Y02 and Y03 turn ON. To turn OFF the Y02, Y03, turn OFF the power switch. Check the followings: There is a jammed sheet between the deflector and the fold roller. [Check] Turn OFF the power switch. Remove the second and fourth rollers and put your hand from the delivery side. Insert your nail between the roller and the deflector on the other (infeed) side, and slide to check the gap. Check the followings: Check the followings: 1. 2. 1. When activating the Y02 and Y03 (described above), the plungers are pulled in. 3. 2. When activating the Y02 and Y03, 24VDC is measured on the connector X03 and X04. 4. 3. Wiring and connection between the Y02, Y03 X03, X04 - Pin1, 2, 3, 4 of CON9 on QPM192 is OK. 5. 4-8: Deflector Malfunctions 4 Lever Bracket Plunger Y02 [Activating the Y02, Y03] Deflector 1. Y02 X03 Mechanical Troubleshooting Fulcrum screw is fully tightened. The connection of the lever bracket and the plunger. While the power is OFF, the plunger can be moved manually and smoothly. The spring on the plunger is not cut. The spring is not deformed nor fall into the plunger hole. The fixing screws of Y02 and Y03 are fully tightened. 4-9 4-10 4: Mechanical Troubleshooting 4-9 Buckle Stopper Does Not Move The circuit of the motors M03 and M04 that moves the buckle stopper includes the circuit protector Q01 and Q02. Buckle Chute Mechanism Malfunctions. When the buckle chute sounds loudly, see Section [4-3: Buckle Chute Sounds Loudly and Q01/02 is Actuated] The voltage on M03 and M04 is not 24VDC. Screw Shaft Drive Gear Idle Gear QPM-192 CON6 Sensor Plate Motor Gear Encoder Sensor The circuit protector Q01 or Q02 is actuated. Motor 1 2 3 4 5 Circuit Protector Q01 Q02 X08 X07 11 22 33 44 M03 M04 1 2 X09 1 2 The First Buckle Chute M03 The Second Buckle Chute M04 Power Cable Plug Circuit Protector For the First Stopper Q01 0.3A 0.3A For the Second Stopper Q02 For Control The motor gear is fixed with the screw SS3-4. [Moving the buckle chute stopper singly] If the motor M03 and M04 does not drive even when this screw is loosened, there is a problem in the electrical circuit. Turn OFF the power switch. Keep pressing the [1] button on the numeric key pad, turn ON the power switch. The machine starts moving the buckle chute stopper. (To stop, turn OFF the power switch.) Check the followings: For Pump 1. The fixing screws on the motor gears are fully tightened. 2. The cog of the gears mesh correctly. 3. The circuit protector is the heat accumulating type. To reset the circuit protector, wait until it is cooled down. - In case the circuit protector is actuated again after resetting, the motor drive section locks or the M03 or M04 is short circuited. 4. Check the followings: 1. The motor gear can be turned manually and smoothly. During moving the buckle chute stopper (described above), 24VDC is measured on X08 and X09. 2. The screw shaft is not deformed and it is inserted into the bushing correctly. 24VDC is measured between the Pin1 and 2, or Pin3 and 4 of CON6 on QPM192. 3. There is a continuity between the terminals of the circuit protector when it is pushed in. 4: Mechanical Troubleshooting 4-10 Motor Does Not Drive 1 Drive motor M01 does not drive Table Up/Down motor M02 does not drive Buckle Chute Motors M03/M04 do not drive X10 Q03 X12 QPM-192 2A S00 X02 X11 M02 Capacitor SSR 11 22 M01 Check the followings: 1. The circuit protector Q03 for M01 is not actuated. 2. The fixing screws on timing pulley of the M01 are fully tightened. 3. The voltage on the SSR terminal Pin2 and BL connector X11 is 115/230VAC. 4. Wiring and connection between S00 - M01 (shown above) is OK. CON8 5 6 Q01 Q02 X08 X07 11 22 33 44 1 2 X09 1 2 The First Buckle Chute M03 The Second Buckle Chute M04 [ Moving Up/Down the Feed Table] [Moving the buckle chute stopper singly] Turn OFF the power switch. Keep pressing the [5] button on the numeric key pad and turn ON the power switch. The blower, valve, clutch and table Up/Down motor repeat the cycle of feeding operation. (To stop, turn OFF the power switch.) Turn OFF the power switch. Keep pressing the [1] button on the numeric key pad, turn ON the power switch. The machine starts moving the buckle chute stopper. (To stop, turn OFF the power switch.) If the M02 does not drive, or does not try to drive, check the followings: Check the followings: 1. When the fixing screw on the joint is loosened and unloaded, the M02 drives. 2. The connectors of X02 and CON8 on QPM192 are OK. 3. The voltage of the X02 at the QPM192 side is 24VDC. 4. The voltage between the Pin5 and 6 of the CON8 on QPM192 is 24VDC. 4-10: Motor Does Not Drive 4 1 2 3 4 5 Table Up/Down Motor 24VDC Geared Motor K02 1 2 GRN BLU QPM-192 CON6 Circuit Protector Mechanical Troubleshooting 1. During moving buckle chute stopper (described above), 24VDC is measured on X08 and X09. 2. 24VDC is measured between the Pin1 and 2, or Pin3 and 4 of CON6 on QPM192. 3. There is a continuity between the terminals of the circuit protector when it is pushed in. 4-11 4-12 4: Mechanical Troubleshooting 4-10 Motor Does Not Drive Blower motor M05 does not drive. X10 Q04 3A S00 SSR 2 The motor for cleaner shown as 13 to the right is used for the blower motor. This motor has limited longevity and needs to be replaced by about 1,000 hours. This is because that the carbon brush inside the motor is worn out. K02 1 2 X11 Blower Motor X14 11 22 33 6 The blower motor can not be replaced singly. Replace the whole blower box. 4 M05 3 [Driving the Blower Motor M05] Turn OFF the power switch. Keep pressing the [5] button on the numeric key pad and turn ON the power switch. The blower, valve, clutch and table Up/Down motor repeat the cycle of feeding operation. (To stop, turn OFF the power switch.) M05 13 Check the followings: 1. The connecter between the M05 and the machine is fully connected. 2. Circuit protector Q04 is not actuated. 3. The voltage between the BL terminal X10 and X11 is 115/230VAC. 4. When the air amount is set at maximum, the voltage between the Pin1 and 2 of terminal X14 is about 115/230VAC. 2 5 Fig.1 Blower Box 4: Mechanical Troubleshooting 4-11 Display Does Not Show Any Image The volume for panel brightness is turned to Min. 1 1 CON4 CON5 VR1 CON6 BZ DSW1 1 VR2 CON12 CON8 1 1 CON9 CON11 1 Display 1 When selecting sheet size or fold pattern, the machine does not sound activating. C10 C11 1 1 CON10 TP5 1 CON2 CON1 CON1 CON1 QPW-422 CON2 CON3 QPW-422 CON2 CON3 GND TP4 5V BZ Control P.C.B QPM-192 Check the followings: The brightness of the display panel is adjusted by the volume VR1 on QPM192 (shown above.) The flat cable (shown above) is fully connected. When replacing the QPM192 and the VR1 is turned to Min, the display can not show any image. When no sound can be heard 1. VR1 CON12 1 Flat Cable 1 CON5 CON11 QPM-192 1 IC2 1 CON3 1 CPU ROM CON7 LCD P.C.B QPW-677 - The display panel is assembled with the LCD P.C.B. QPW677. Therefore, to replace the display panel, replace the QPW677. If the problem is still not resolved, replace the control P.C.B. QPM192. [Additional Information] Rotary Switch DSW1 Setting 0 1 2 3 Not Used Japanese English English /mm /inch /mm 4-11: Display Does Not Show Any Image 4 Mechanical Troubleshooting 4-13 4-14 4: Mechanical Troubleshooting 4-12 Error Message “Close Buckle” Is Shown (Even though it is closed) The buckle cover sensor B03 malfunctions. The buckle cover sensor B03 is installed incorrectly. Buckle Fixing Lever QPM-192 CON2 B03 QPW-422 B03 CON1 BLK 6 6 8 BRN/WHT 8 1 2 CON3 1 2 Buckle Cover Sensor Magnet Check the followings: 1. The buckle fixing lever is fully closed. 2. The fixing screw on the sensor B03 is fully tightened. 3. The sensor connector is fully connected. 4. Magnet is installed correctly. Check the followings: 1. Remove the magnet that holds the buckle fixing lever, and put it on the sensor B03 directly. Check that the LED L7 on the QPM192 illuminates. 2. Wiring and connection: - Between the B03 and CON3 on QPW422 - Between the Pin6, 8 of CON1 on QPW422 and Pin6, 8 of CON2 on QPM192 PAGE INTENTIONALLY BLANK 5: Folding Quality Troubleshooting 5. Folding Quality Troubleshooting 5 5-1 Folding Quality Troubleshooting 5-2 5: Folding Quality Troubleshooting 5-1 Wrinkled Sheets The buckle chute guide is installed incorrectly or deformed. The deflector is deformed. The Third Fold Roller Buckle Chute Guide At Center The sheets are curled or concave. Fit on the infeed (entrance) side of the slot. Curled Concave - The sheets immediately after printed or left in the humid place may shape as shown above. If those shaped sheets pass through the rubber rollers, that may cause wrinkles on the folded sheet. Instruct the operator to flatten out or dry the sheets before folding. [Additional Information] - The wrapping of the sheets blocks the humidity. If the wrapping is opened and left for a long time, the sheet becomes damp around but dry inside. Therefore, the sheet becomes concave. - The recycled papers are more likely to be effected by the humidity. Deflector Correct Incorrect Not deformed like this. - When the buckle chute at the infeed (entrance) side is deformed as shown above, the sheet may hit the guide and cause wrinkles. If the buckle chute guide is deformed by more than 0.5 mm (0.02”), correct the buckle chute guide. If the jammed sheet is pulled by force to remove, that may deform the guide. - The buckle chute guide is installed on the side plate by inserting the edge of the 1.6 mm (0.06”) thickness spacer into the 2 mm (0.08”) width slot. The spacer should be fixed on the infeed (entrance) side of the slot. If not, that changes the position of the buckle chute and results in the wrinkles on the folded sheet. - If the deflector is deformed and does not align with the fold roller at the center, the sheet path is blocked there and may cause wrinkles. Remove the deflector and flatten it out. [Distortion: within 0.1 mm (0.004”) ] - When removing the jammed sheet on the deflector, if it is pulled by force, that may deform the deflector. Instruct the operator how to remove the jammed sheet. 5: Folding Quality Troubleshooting 5-2 Folded Corners The deflector is deformed. The Third Fold Roller At Center The jammed sheets are left on the sheet path. Deflector Correct Piece together the jammed sheet. - When removing the jammed sheet, remove it completely without any scraps left inside. When the scrap of paper is left on the sheet path, the delivered sheet hits it and the corners is folded (dog ear.) Incorrect - If the deflector is deformed and does not align with the fold roller at the center, the sheet path is blocked there and may cause wrinkles. Remove the deflector and flatten it out. [Distortion: within 0.1 mm (0.004”) ] - When removing the jammed sheet on the deflector, if it is pulled by force, that may deform the deflector. Instruct the operator how to remove the jammed sheet. - Instruct the operator to piece together the torn scraps and make sure to remove all the jammed sheet completely. 5-2: Folded Corners 5 Folding Quality Troubleshooting 5-3 5-4 5: Folding Quality Troubleshooting 5-3 Sheet Edges Do Not Align The sheet edges do not align even though it is folded in correct setting. Jammed sheet is left in the buckle chute. Stopper drive mechanism malfunctions. 1 - When removing a jammed sheet, if a scrap of sheet is left on the back of the buckle chute, it works as a stopper and the sheet is folded incorrectly. 2 3 - The sheet immediately after printed by the laser printer at high printing speed is hot and dry because it is compressed and delivered by the toner transferring rollers. Especially in winter season, the sheet described above becomes static and it sticks on the metal part, such as buckle chute, and can not reach the buckle chute stopper. In case of the short folding pattern that the large part of the sheet enters the buckle chute, the sheet is more likely to be effected by the statics. [Remedy] - The sheet printed by the high speed laser printer should be left for a while to cool it down and adapt to the temperature and humidity before folding. - The static is reduced by jogging the sheet using the jogging machine. - Lower the printing speed on the laser printer. - Reduce the statics on the laser printer. 6 4 The sheet is static. The sheet has the cross grain direction. 5 Check the followings: 1 The fixing screw on the drive gear is fully Cross Grain Direction 2 3 - The cross grain direction sheet is easy to break against the feed direction. If there is another problem such as static, the sheet may not reach the stopper and cause incorrect folding. 4 5 6 Sheet size is incorrect. - Measure the sheet. The correct sheet size: (Long Edge) A3 A4 B3 B4 420 mm 297 mm 515 mm 364 mm tightened. The fixing screw on the gear collar is fully tightened. The sensor plate and 1 is tightly connected. The fixing screw on idle block is fully tightened. The fixing screw on the motor gear is fully tightened. The fixing screw on the stopper home position sensor is fully tightened. [Additional Information] The stopper home position is set using the 64 gsm sheet as a standard. Therefore, when using thinner sheet or cross grain direction, home position does not match. It is useful to memorise the stopper setting that is adjusted for the other types of sheet using the stopper adjusting knob. 5: Folding Quality Troubleshooting 5-4 Sheet Is Folded Askew Roller pressure (spring force) is not even at front and rear. 5 3 4 The sheet guide is not at right angle against the front stop or not parallel each other. Stopper is askew. 1 2 Stopper Spring Stopper Roller Lever Sheet Guide Sheet Front Stop - The pressure of the fold roller is produced by the spring of the roller lever. When installing the second and fourth fold rollers, if the roller lever positions incorrectly but is pulled up by force, the spring will be extended. In case that, replace the spring. - To adjust the stopper tilt angle, fold a sheet and adjust the stopper depending on the shift of the folded sheet. See Section [3-5: Buckle Chute Stopper Parallel Adjustment]. Sheet Guide - When a sheet is loaded so that the sheet edge touches the front stop and the sheet guides are aligned with the sheet edge, the guides should be parallel to the sheet. - If the sheet guides are not parallel to the sheet, see Section [3-1: Sheet Guides Right Angle and Parallel Adjustment] and adjust the sheet guide. - There should be a gap of 0.1 mm (0.004”) between the stopper and roller lever (at front and rear), when the lever is pulled up. If there is no gap in-between, the pressure of the fold roller changes. See Section [3-7: Stopper (Roller Lever) Position Adjustment] . Fold rollers are contaminated. Especially the stencil printed sheet, if the sheet is folded before it drys out, the ink adheres to the fold roller and changes the friction and results in incorrect folding. - Instruct the operator to clean the fold rollers following the instruction of “Maintenance” in the operation manual . 5-4: Sheet Folded Askew 5 Folding Quality Troubleshooting 5-5 5-6 5: Folding Quality Troubleshooting 5-5 Sheets Are Not Arranged On the The Delivery Delivery conveyor belt slips. Antistatic tapes come off. 1 Delivery Conveyor Belt Deflector 3 O Ring Folded sheets stick each other because of static. 2 Antistatic Tape 4 Idle Shaft Check the followings: Feed Gap Sto Po Di 2nd Stopper 1 The delivery conveyor belt is not cut. 2 The delivery conveyor belt is tensed correctly. (See Section 3-6 Belt Tension Adjustment) 3 The O ring on the delivery roller pulley is not - If the sheets are static, they stick each other and do not arrange. cut. 4 Grease is not applied on the O ring or idle Fan the sheet well before folding and reduce the static. If the sheet is still effected by the static, run the machine by Feed Gap operation. shaft causing slip. Antistatic Tape [On the infeed (entrance) side] - The antistatic tapes are attached on the infeed (entrance) side of the deflector and delivery (exit) side of the delivery conveyor. 5: Folding Quality Troubleshooting 5-6 Sheet Jams at the Deflector Antistatic tape on the deflector comes off. Deflector mechanism malfunctions. 2 Fulcrum The Third Fold Roller The Third Fold Roller Deflector 3 Antistatic Tape 3 Deflector Holder Plunger 5 Deflector 3 4 4 1 2 Lever Bracket Y02/Y03 Deflector 5 1 The fixing screws on the deflector are fully 2 When the deflector is raised (when the solenoid Y02 is ON), the edge of the sheet that comes through the second and third fold roller touches the antistatic tape and is delivered. - Check the attachment of the antistatic tape by inserting hand from the delivery conveyor side and touching the rear (infeed) side of the deflector. 3 4 5 At Center 1 Deflector Lever (front) Check the followings: - The antistatic tape is attached on the deflector as shown above. The deflector is deformed. tightened. The fulcrum screw on the deflector lever is fully tightened. The connecting screw on the deflector lever is fully tightened. The screw connecting the plunger of the solenoid Y02/Y03 and the lever bracket is fully tightened. The fixing screws on the solenoid Y02/Y03 are fully tightened. Correct Incorrect - If the deflector is deformed and does not align with the fold roller at the center, the sheet path is blocked there and may cause wrinkles. Remove the deflector and flatten it out. [Distortion: within 0.1 mm (0.004”) ] - When removing the jammed sheet on the deflector, if it is pulled by force, that may deform the deflector. Instruct the operator how to remove the jammed sheet. - When pushing in the plunger of the Y02/Y03 manually, the deflector moves smoothly. - When changing the fold patterns by pressing the fold pattern selecting button, the Y02/Y03 moves correctly. 5-6: Sheet Jams at the Deflector 5 Folding Quality Troubleshooting 5-7 6: Electrical Circuit 6. Electrical Circuit 6 6-1 Electrical Circuit 6-2 6: Electrical Circuit 6-1 Electrical Parts Leyout and Descripton 3 1 2 M04 The Second Buckle Chute Motor B02 The Second Buckle Chute Home Position Sensor B01 The First Buckle Chute Home Position Sensor B03 M03 The First Buckle Chute Motor Buckle Cover Sensor Code Name B01 1 The First Buckle Chute Home Position Sensor B02 3 The Second Buckle Chute Home Position Sensor B04 B03 3 Buckle Cover Sensor Count Sensor (Projector) B04 4 Count Sensor (Projector) B05 4 Count Sensor (Receiver) B06 5 Sheet Upper Limit Sensor B07 7 Table Lower Limit Sensor B08 8 Sheet Detect Sensor M01 11 Drive Motor Single Phase 90W M02 10 Table Up/Down Motor 24VDC Geared Motor M03 2 24VDC DC Motor M04 2 4 B05 Count Sensor (Receiver) 6 Y01 12 11 Feed Clutch Y04 M01 Feed Valve Drive Motor Y03 10 Deflector Solenoid (rear) Y02 M02 Deflector Solenoid (front) Table Up/Down Motor M05 The Second Buckle Chute Motor 24VDC DC Motor Single Phase 14 Blower Motor Commutator Motor Y01 12 Feed Clutch 24VDC Y02 6 Deflector Solenoid (front) 24VDC Y03 6 Deflector Solenoid (rear) 24VDC Y04 12 Feed Valve S00 13 Power Switch S01 9 9 S01 13 S00 Table Upper Limit Switch 8 Main Switch 7 B07 Table Lower Limit Sensor 5 B06 Sheet Upper Limit Sensor B08 Sheet Detect Sensor 14 M05 The First Buckle Chute Motor Blower Motor Table Upper Limit Switch 24VDC 6: Electrical Circuit Electrical Chassis Layout and Description 24VDC G02 Power Supply 5VDC BLK K01 SSR Relay For Blower Motor M05 BLK K02 SSR Relay For Drive Motor M01 Q01 Circuit Protector For the First Buckle Chute Motor M03 Q02 Circuit Protector For the Second Buckle Chute Motor M04 Q03 Circuit Protector For M01, G01, G02 Q04 Circuit Protector For Blower Motor M05 WHT 115/230VAC 24VDC BL WHT VIO 3 (For M01) 4 To QPM-192 CON9 6 To QPM-192 CON9 5 GRN Ground To M01 3 SSR K01 (For M05) To Q03 2 1 BLU To X07 M03 To QPM192 CON6 1 To QPM-192 CON8 7 SSR K02 M05 Ground To Q04 BL X11 BL 2 To M05 Q04 4 Q01 1 GRY To QPM-192 CON8 8 X12 For M03 (0.3A) BLK To X07 M04 To QPM192 CON6 3 5VDC Q02 BLK For M04 (0.3A) G02 GRY VIO X10 For M05 230VAC: 3A 115VAC: 5A To QPM-192 CON7 8 To QPM-192 CON7 7 115/230VAC S00 K02_1 G01 To X10 To X12 BLU Power Supply Q03 To QPM-192 CON7 6 G01 230VAC: 2A 115VAC: 3A GRN ORN Name For M01 To QPM-192 CON7 5 To B08 connector X01 1 Code To K01_1 To X10 S00 6-2 6-2: Electrical Chassis Layout and Description 6 6-3 Electrical Circuit 6-4 6: Electrical Circuit 6-3 P.C.B. Layout and Description QPW-422 E n c o d e r P. C. B. P.C.B. for the encoder that decides the buckle stopper position. QPW-677 QPM-192 QPW-307 L C D P. C. B. C o n t r o l P. C. B. Deliver y LED P.C.B. P.C.B. that receives the signal from the buttons and shows images on the panel. Main P.C.B. that controls the machine. P.C.B. for the LED that guides the delivery roller position. 6: Electrical Circuit 1 CON9 To Delivery LED P.C.B. QPW-307 To LCD P.C.B. QPW-677 1 CON8 VR 1 CON4 CON5 CON6 DSW1 VR2 1 To M04 To M03 IC2 Brightness Adjustment VR2 Not Used DSW1 0 Not Used 1 Japanese /mm 2 English /inch 3 English /mm ROM 1 CPU 1 1 To B07 CON10 To B06 To B05 To B04 To S01 To B08 C11 CON3 To G02 +5V To G01 +24V To Y04 To Y01 CON7 C10 VR1 1 QPM-192 BZ 1 Control P.C.B. 1 VR1 CON11 CON12 1 To K02 To B06 To B07 To M02 QPM-192 P.C.B. Layout To Y02 To Y03 6-4-1 Control P.C.B. QPM-192 To K01 6-4 TP5 1 CON2 CON1 CON1 CON1 QPW-422 CON2 CON3 QPW-422 CON2 CON3 GND Encoder P.C.B. TP4 5V For details on connectors, see Section [6-6: 24V/5VDC Wiring Diagram]. To B02 To B03 To B01 6-4-1: QPM-192 P.C.B. Layout 6 6-5 Electrical Circuit 6-6 6: Electrical Circuit QPM-192 LED Layout LED Illuminating Condition 1 CON9 1 CON8 1 CON4 CON5 CON6 BZ 1 VR1 DSW1 L1 Sensor A on the first stopper encoder P.C.B. QPW-422 does not receive light. L2 Sensor B on the first stopper encoder P.C.B. QPW-422 does not receive light. L3 The first buckle chute home position sensor B01 is ON L4 Sensor A on the second stopper encoder P.C.B. QPW-422 does not receive light. L5 Sensor B on the second stopper encoder P.C.B. QPW-422 does not receive light. L6 The second buckle chute home position sensor B02 is ON L7 Buckle cover sensor B03 is ON. L8 Sheet detect sensor B08 is ON. L9 Table upper limit switch S01 is ON. L10 Count sensor (receiver) B05 does not receive light (sheet is passing.) L11 Sheet upper limit sensor B06 is ON. L12 Table lower limit sensor B07 is ON. 1 1 VR2 CON11 CON12 1 CON7 C10 QPM-192 C11 IC2 ROM 1 CON3 1 CPU 1 1 CON2 TP4 TP5 1 CON1 5V GND TR2 TR3 CON10 L10 CON3 L9 1 1 CON10 L3 L2 L1 L7 L6 L5 L4 L8 L12 L11 6-4-2 Control P.C.B. QPM-192 1 6-4 1 CON2 CON1 6: Electrical Circuit LCD P.C.B. QPW-677 2nd Stopper Start/Stop 1st Stopper 11"x7" 81/2"x11" 81/2"x14" Counter / Preset Counter 51/2"x81/2" Feed Gap 2nd Stopper Stopper Position Display 1st Stopper 1 2 3 4 5 6 7 8 9 0 Memory C Mode Folding Pattern CON1 L1 SW3 1 6-5 SW6 SW8 SW10 SW12 SW14 SW15 SW24 SW19 SW5 SW7 SW9 SW16 SW17 SW18 SW4 SW2 SW11 SW13 SW1 L2 L3 L4 L5 L6 L7 SW20 Sheet Size Test Feed L8 SW23 L9 L10 L11 SW21 (Top) SW22 CON2 1 (Back) QPW-677 6-5: LCD P.C.B. QPW-677 6 6-7 Electrical Circuit 6-8 6: Electrical Circuit 6-6 6-6-1 24V/5VDC Wiring Diagram Buckle Chute Section The First Buckle Chute Home Position Sensor 1 2 3 Encoder P.C.B. (1st Buckle Chute) B01 QPW-422 The Second Buckle Chute Home Position Sensor 1 2 3 Encoder P.C.B. (2nd Buckle Chute) Control P.C.B. B02 Buckle Cover Sensor QPM-192 1 2 QPW-422 Circuit Protector 0.3A X07 Circuit Protector 0.3A 1 2 3 4 Q0 1 Q 02 B03 1 2 3 4 X08 Capacitor 1 2 The First Buckle Chute Motor M03 Terminal Board X09 Capacitor 1 2 Terminal Board The Second Buckle Chute Motor M04 6: Electrical Circuit 6-6 6-6-2 24V/5VDC Wiring Diagram Main Section X03 1 1 2 2 X01 Sheet Detect Sensor B08 Feed Table Upper Limit Switch S01 1 1 2 2 3 3 Y02 Deflector Solenoid Y03 Deflector Solenoid K01 SSR for Blower Motor M05 Y04 Feed Clutch Y01 Feed Valve X04 1 1 2 2 X05 Count Sensor (Projector) B04 1 1 2 2 Control P.C.B. X06 1 1 2 2 3 3 QPM-192 Count Sensor (Receiver) B05 X02 Table Up/Down Motor SSR For Drive Motor M01 1 1 2 2 3 3 M02 G01 24VDC G02 5VDC Delivery LED P.C.B. K02 QPW-307 B06 1 2 3 Sheet Upper Limit Sensor Cable Harness 1 2 3 Table Lower Limit Sensor LCD P.C.B. QPW-677 B07 6-6-2: Main Section 6 6-9 Electrical Circuit 6-10 6: Electrical Circuit 6-7 Power Circuit Wiring Diagram (#) means that gray label is sticked on the wire. Motor Capacitor AC115V AC230V K02 Q03 To Power Source X10 Noise Filter Main Switch Z01 S00 Circuit Protector (115V: 3A) BL Connector WHT 2A C01 SSR X12 M01 1 1 Drive Motor (#) 2 2 BL Connector WHT X11 X01 1 1 2 2 3 3 BL Connector BLK (#) (#) G01 G02 K01 To B08 QPM-192 SSR Q04 Circuit Protector (115V: 5A) 3A X14 1 1 2 2 3 3 M05 Blower Motor PAGE INTENTIONALLY BLANK PF-P330/PM Revision 0 Standard Business Systems 10 Connector Road, Andover, MA 01810 (978) 490-1920 Fax (978) 470-2771