Download User guide - SPM Instrument

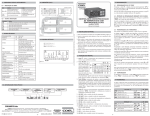

Transcript