Transcript

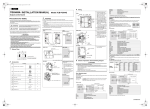

CH49921301.book Page 1 Monday, August 30, 2010 5:59 PM English 1 4 INSTALLATION MANUAL Wiring <SW07 (bit 2) OFF [2-stage switching]> SMMS-i Model:TCB-PCDM4E 6 -a 6 -b 7 1. Tie the output wiring using the 6 -b 1 8 8 Power peak-cut control board 3 4 7 3 Precautions for Safety • Read these “Precautions for Safety” carefully before installation work. • The precautions described below include important items regarding safety. Observe them without fail.Understand the following details (indications and symbols) before reading the body text, and follow the instructions. The meanings of indications Text set off in this manner indicates that failure to adhere to the directions in the warning could result in serious bodily harm or loss of life if the product is handled improperly. WARNING Text set off in this manner indicates that failure to adhere to the directions in the caution could result in serious bodily injury or damage to property if the product is handled improperly. CAUTION • After completion of installation, perform trial operation to check for any problems. Explain method of use and maintenance to the customer by following the descriptions in the manual. Ask customer to keep this Manual at accessible place for future reference. Installation 1. Before starting installation work, be sure to turn the power supply OFF. 2. Install the "optional PCB" at the position on the electrical components box shown in the [A] Input wiring Optional PCB figure below. Output wiring 3. Install the "optional PCB" at the specified location inside the electrical components box using the support ( 2 ). 4. There are four mounting holes for the fixing support at specified locations inside the electrical components box. 5. Connect the connector (PJ17) on the "optional PCB" to the connector (CN513) on the "interface PCB" using the connection cable. 6. The connection cable is long. Tie it using the binding band ( 6 ). 3. [PCB Installation Position] SMMS-i SMMS-i Connector Positions MMY-MAP080 to 120 1. Pass the binding band A ( MMY-MAP140 to 160 CN513(blue) Optional PCB [B] 3 4 ON OFF SW07 (bit 1) Bit 1 OFF Bit 1 ON 100% (normal operation) 100% (normal operation) Approx. 60% (upper limit 0% (forced stop) regulated) Display relay (L1) OFF ON For one input function (This function is possible only on the SMMS-i) Power peak-cut ON-OFF control is made possible on the SMMS-i on only the [ON] terminal input (SW1) by cutting the jumper lead (J16) of the center outdoor unit interface PCB. (Wiring example) L1: Display lamp suring power peak cut control Header outdoor unit Locally procured Optional PCB Display relay Outdoor unit interface PCB J16 Cut TB1 [OPERATION] PJ17 TB2 COM [ON] ON COM [OFF] OFF CN513 SW07 ON OFF 1 2 3 4 Bit 2 ON Power supply L1 Shield wire SW 1 Shield wire Connection cable ( 1 ) Power peak-cut control turns ON when SW1 in the wiring example is ON (continuous make). [A] Jumper lead J16 Output wiring MiNi-SMMS 1. Tie the output wiring with the wire clamp ( 3 ). (max. number installed: 1 pc) SMMS, SHRM Incorrect SW07 (bit 1) Input SW1 Bit 1 OFF OFF 100% (normal operation) ON 0% (forced stop) Cut Display relay (L1) Bit 1 ON 100% (normal operation) Approx. 60% (upper limit regulated) Electric component box SMMS, SHRM Connector Positions OFF ON Enhanced Functions Conect (Wiring example) CN513(blue) Outdoor unit interface PCB PCBs 4-4 mm dia. mounting holes Terminal block (M3) SW2 ON <SW07 (bit 2) OFF [2-stage switching]> Optional PCB External View Input SW1 OFF 6 ) through securing hole [B] shown in the figure on the left and tie the output wiring together with other wiring. 2. Fix the wire clamp ( 3 ) using the screw ( 4 ) holes at location [A] in the figure on the left. 6 Optional PCB SW07 1 * When more than one optional PC boards are installed, band all the connection cables and attach one clamp filter. Fix the wire clamp ( 3 ) using the screw ( 4 ) holes at location [A] in the figure on the left. SMMS, SHRM WARNING • Only a qualified installer or qualified service person is allowed to do installation work. If installation is carried out by an unqualified individual, fire or electric shock may result. • Perform installation work reliably according to this installation manual. Incomplete installation may cause electric shock, fire or abnormal operation. • Electrical work must be performed by a qualified installer or qualified service person in accordance with this installation manual. The work must satisfy all local, national and international regulations. Inappropriate work may result in electric shock or fire. • Connect the specified wires firmly and clamp them securely so that external force applied to the wires does not affect the connector pins. Improper wire connection or clamping may result in fire or malfunction. • Do not disassemble, modify, repair or move the product yourself. Doing so may cause fire, electric shock, injury or water leaks. • Ask a qualified installer or qualified service person to do any repairs or to move the product. binding band A ( 6 ) at the position in the figure on the left. ( 6 -a):Tie the output/input wiring togerther with other leads. ( 6 -b):Tie the output/input wiring after passing the upper fixation hole on of the bandling band. 2. Attach the clamp filter ( 7 ) to the output wiring, input wiring and connection cable as shown in the figure. Use binding band B ( 8 ) to fix the clamp filter ( 7 ) to the wirings. L1: Display lamp suring power peak cut control Header outdoor unit 3 4 Locally procured 71 61 Optional PCB Output wiring Outdoor unit interface PCB 2 2 Display relay TB1 L1 Power supply (max. number installed: 1 pc) 75 85 SW07 Screw Screw Accessories No. 1 Part Name Connection cable Interface P.C. board Q'ty 1 2 Support to fix the board 4 3 Wire clamp 1 4 Wire clamp fixing screw 1 5 Earth screw 2 Optional P.C. board • Optional PCB (left side) shown in the figure is removed and an upper right hook is slipped, an interface board will open. 2. Place this P.C. board by using the support of the electric component box. There are four installation holes to place the support of the electric component box. MiNi-SMMS Connector Positions Bit 2 ON Bindling band A 4 <Electrical Rating> 220 to 240 VAC, 10 mA or more, 1 A or less 24 VAC, 10 mA or more, 1 A or less (non-conductive load) ▼ Electrical Wiring Diagram Standard Specifications L1: Display lamp suring power peak cut control Locally procured 7 Clamp filter 3 Display relay [OPERATION] 8 Bindling band B 3 CN513 SW07 SW07 ON OFF 1 2 3 4 Bit 2 OFF TB2 PJ17 COM [ON] ON COM [OFF] OFF Connection cable ( 1 ) L1 TB1 SW 1 SW 2 For SW1 and SW2, be sure to provide no-voltage contacts for each terminal. <SW07 (bit 2) ON [4-stage switching]> When connecting a conductive load (e.g. relay coil) to the display relay load, insert a surge killer CR (for an AC power supply) or a diode for preventing back electromotive force (for a DC power supply) on the bypass circuit. Outdoor unit interface PCB (max. number installed: 1 pc) Connection cable ( 1 ) Specifications of display relay contact • The terminal for display output ([Operation] terminal) must satisfy the following electrical rating. Header outdoor unit Shield wire PJ17 TB2 COM [ON] ON COM [OFF] OFF Shield wire Optional PCB 6 SW07 ON OFF CAUTION (Wiring example) CN513(blue) CN513 1 2 3 4 Install this optional P.C. board to the back side of the Interface P.C. board on outdoor unit. 1. If the screw fo the position Hook part 2 Details of Operation By switching SW07 (bit 2) on the outdoor unit interface PCB, super module multi (MMY-) supports both standard specifications (2-stage switching) and enhanced functions (4stage switching). (max. number installed: 1 pc) MiNi-SMMS Terminal block (M4) [OPERATION] 5 Input SW07 (bit 1) SW1 SW2 OFF OFF ON OFF OFF ON ON ON Bit 1 OFF 100% (normal operation) Approx. 80% (upper limit regulated) Approx. 60% (upper limit regulated) 0% (forced stop) Bit 1 ON 100% (normal operation) Approx. 85% (upper limit regulated) Approx. 75% (upper limit regulated) Approx. 60% (upper limit regulated) Display relay (L1) OFF ON ON ON Power supply Shield wire SW1 SW 1 SW2 SW2 Shield wire For SW1 and SW2, be sure to provide novoltage contacts for each terminal. The input signals of SW1 and SW2 may be pulse input (100 msec or more) or continuous make. CH49921301