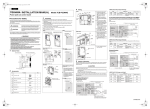

Download 4 Start up Controller

Transcript