Download XPRESS-MP USER GUIDE

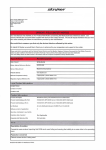

Transcript