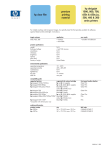

Download HP 1055CM User's Manual

Transcript