Download Chromalox PF450-5 User's Manual

Transcript

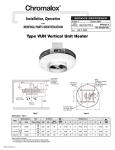

Installation Instructions SERVICE REFERENCE DIVISION and 4 SECTION SALES REFERENCE RENEWAL PARTS IDENTIFICATION VUH (Supersedes PF450-4) PF450-5 161-057822-001 JULY, 2002 DATE VUH Vertical Unit Heater 12" Min. 30" Min. 8-1/2" 4-11/16" Dia. Mounting Holes 3-7/8" Drop Ceiling 17" Position With Junction Box Facing Away From Walls For Easy Access 30" Min. F Approx. H D 4-11/16" Dia. Mounting Holes 12" Min. Anemostat** Diffuser Note: Knockout Location See Table 2 For Recommended Conduit Size. A E B M 4-11/16" Dia. Mounting Holes 7' Min. To Floor CL Warm Air Discharge C Figure 2 Figure 1 Specifications — Table 1 Heating Capacity Model Volts 1 3 Phase Phase kW BTUH 5 17,000 208 240 277 VUH-C-07 7.5 25,500 9.8 VUH-C-10 10 34,000 VUH-C-05 Air Delivery Data Max. Mtg. Outlet Height Temp.˚F* (Ft.) CFM FPM 208 240 480 450 703 102 208 240 277 208 240 480 550 880 208 208 240 277 240 480 712 1160 Dimensions (In.) A B C D E F H M 10 14 13-1/2 26 3-1/4 6-5/8 4 7-1/4 10-5/8 48 102 12 14 13-1/2 26 3-1/4 6-5/8 4 7-1/4 10-5/8 48 104 14 14 13-1/2 26 3-1/4 6-5/8 4 7-1/4 10-5/8 48 * Based on 60˚F entering air. ** For use with drop ceiling only. Installation in a drop ceiling should be in accordance with NFPA-90A and Article 300-22 of (NEC). *** For instructions on VUH units rated 15-25 kW refer to Bulletin PF451; VUH units rated 30-50 refer to Bulletin PF452. © 2010 Chromalox®, Inc. Mtg. Weight (Lbs.) Table 2 - Electrical Data Power Supply Circuit Model kW VUH-C-05 5 VUH-C-07 7.5 9.8 VUH-C-10 10 Volts 208 208 240 240 277 480 208 208 240 240 277 480 208 208 240 240 277 480 Phase 1 3 1 3 1 3 1 3 1 3 1 3 1 3 1 3 1 3 Notes: 1. Includes Fan Motor Amps. 2. Use 75˚C Wire - Copper Conductors only. Line Amps (Note 1) Line Wire Size (Note 2) No. Circuits 25 15 22 13 19 7 37 22 32 19 28 10 48 29 43 25 37 13 8 12 10 12 10 14 6 10 8 10 8 14 6 8 6 8 6 12 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 3. † Minimum Conduit Size † 3/4” 1/2” 1/2” 1/2” 1/2” 1/2” 3/4” 1/2” 3/4” 1/2” 3/4” 1/2” 3/4” 3/4” 3/4” 3/4” 3/4” 1/2” Contactor Holding Coil Volt Ampheres (Note 3) Inrush Sealed 60 9 60 9 60 9 Motor Volts 208/240 280/240 208/240 208/240 277 480 208/240 208/240 208/240 208/240 277 480 208/240 208/240 208/240 208/240 277 480 H.P. Phase 1/25 1 1/25 1 1/25 1 Standard units have one contactor. Units with separate fan motor control use two contactors. Conduit knockout location - top of Junction Box. IMPORTANT Failure to understand and follow these installation instructions and the “WARNING” notes therein may result in serious personal injury from electrical shock, or from the heater falling due to faulty installation. FIRE/EXPLOSION HAZARD. This heater is not intended for use in hazardous atmospheres where flammable vapors, gases, liquids or other combustible atmospheres are present as defined in the National Electrical Code. Failure to comply can result in personal injury or property damage. ELECTRIC SHOCK HAZARD. Disconnect all power before installing or servicing heater. Failure to do so could result in personal injury or property damage. Heater must be installed by a qualified per- sonal in accordance with the National Electrical Code, NFPA 70. The heater must be mounted at least 7’ above the floor to prevent accidental contact with the heating elements or fan blade which could cause injury. The ceiling structure, the brackets, hangers or chains used to suspend the heater, and the anchoring provisions must be of sufficient strength to support the combined weight of the heater installation (48 pounds for VUH-C-05, 07, 10 plus the weight of the supports). Prior to operating the heater verify that the fan hub setscrews are tightened and the push-on clip is secured to assure that the fan blade is securely fastened to the motor shaft. On models connected to three-phase power, fan blade rotation must be checked. If airflow is not downward, interchange any two of the three customer power leads. First stage of thermostat must be connected to terminals C1 and C2 to insure proper operation of overheat protective devices. INSTALLATION ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in accordance with the National Electrical Code to eliminate shock hazard. The heater must be mounted at least 7’ above the floor to prevent accidental contact with the heating elements or fan blade which could cause personal injury. 1. Heater should be positioned with the junction box facing away from walls to provide easy access for servicing relay(s) mounted within. See Figure 1. The ceiling structure, the brackets, hangers or chains used to suspend the heater and the anchoring provisions must be of sufficient strength to support the total weight of the heater installation (48 pounds for VUH-C-05, 07, 10 plus the weight of the supports). Mount the heater for down discharge only. Failure to comply may result in personal injury or property damage. 3. The heater to be mounted to the ceiling by attaching rigid angle brackets, hangers, or chains to the four mounting holes on the top of the heater case using four 5/8” bolts (by others). See Figures 1 and 2. Note: Brackets, hangers, or chains to support the heater are supplied by the customer. 2. It is important that the 12” minimum dimension shown in Figure 1 be maintained to make it possible for a serviceman to remove the fan motor, if necessary, without moving the heater from its mounting. 4. All wiring should be done in accordance with local codes and the National Electrical Code by a qualified person. MAINTENANCE 5. Rough-in wiring to heater. See Table 2 for line amperes, recommended wire size and conduit size. 6. Wire heater per wiring diagram supplied with this instruction sheet. 8. Air diffusers for deflecting the air are optional. See Instruction Sheet PF449 for installation instructions. Note: Power relay(s) are provided as standard on all heaters. ELECTRIC SHOCK HAZARD. Disconnect all power to heater before servicing or replacing heaters. Do not attempt to service heater while unit is operating as there is hazard of electric shock, injury from operating fan, and burns from hot heating elements. Prior to operating the heater, verify that the fan hub setscrews are tightened and the push-on clip is secured to assure that the fan blade is securely fastened to the motor shaft. Failure to comply could result in personal injury or property damage. 7. Carefully inspect the completed installation. Rotate the fan blade by hand to be sure that it turns freely. Investigate any binding, rubbing or interference. 1. Before activating for next heating season, vacuum or use compressed air to remove accumulated dust or lint, which otherwise may restrict proper air flow. 2. Periodically check all electrical connections and retighten to avoid electrical wiring difficulties. WIRING DIAGRAMS Transformer Color Code Index PRI XFMR 120V SEC. 24V SEC. LEAD CLRS LEAD CLRS LEAD CLRS VOLT H1 208 BLK 240 BLK 277 BLK H2 RED ORG X1 X2 BLK WHT BLK WHT BLK WHT X1 YEL YEL X2 BLU BLU YEL BLU 480 BLK BLK/RED BLK WHT YEL BLU BRN 208 - 240V Motor Hook-Up Elements Customer Wiring Factory Wire 277V Motor Hook-Up 208 - 240V Motor Hook-Up Elements 277V Motor Hook-Up BLU BLK BLU BLK M M M BLK WHT RED T2 T1 YEL WHT RED BLK T2 T1 YEL 480V Motor Hook-Up 480V Motor Hook-Up Cutout BLK M BLK Cutout RED RED Contactor X1 T2 T3 T1 C1 L1 L2 L3 BLK M 3ø Jumper Hook-Up XFMR Fusing Optional XFMR L1 L2 L3 T4 To Contactor 1ø Jumper Hook-Up TB2 C1 C2 TB1 Thermostat (By Others) L1 L2 L3 T4 Fused Switch (By Others) Customer Wiring Factory Wire Figure 3 Transformer Color Code Index 277V Motor Hook-Up VOLT BLU BLK M BLK BLK M T2 T1 WHT RED YEL 480V Motor Hook-Up Cutout BLK T1 T2 T3 C1 L1 L2 L3 M H1 208 BLK 240 BLK 277 BLK H2 RED ORG BRN X1 X2 BLK WHT BLK WHT BLK WHT X1 YEL YEL YEL X2 BLU BLU BLU 480 BLK BLK/RED BLK WHT Customer Wiring Factory Wire YEL BLU 277V Motor Hook-Up 208 - 240V Motor Hook-Up Elements BLU BLK M BLK M WHT BLK T1 Thermostat (By Others) YEL YEL 480V Motor Hook-Up RED XFMR X1 X2 T1 C1 L1 T2 T3 1ø Power BLK L1 L2 L3 H1 Heat H2 Fan TB2 C2 C1 3ø Jumper Hook-Up XFMR Fusing Optional YEL WHT T2 To Contactor 1ø Jumper Hook-Up L1 L2 L3 T4 TB1 Optional Heat Recovery Switch (By Others) BLU M C3 L2 L3 L1 L2 L3 T4 TB1 Fused Switch (By Others) T1 T2 T3 T1 C4 TB2 3ø Power 60 HZ Contactor Cutout 2 PDT Switch (By Others) Thermostat (By Others) T2 To Contactor 1ø Jumper Hook-Up TB1 L1 L2 L3 T4 T2 T1 RED BLU WHT 3ø Jumper Hook-Up 3ø Power 60 HZ Fused Switch (By Others) L1 L2 L3 T4 TB1 1ø Power Figure 6 Figure 5 Customer Wiring Factory Wire PRI XFMR 120V SEC. 24V SEC. LEAD CLRS LEAD CLRS LEAD CLRS RED Contactor TB2 C1 C2 1ø Power Figure 4 208 - 240V Motor Hook-Up Elements L1 L2 L3 T4 TB1 Fused Switch (By Others) 1ø Power Customer Wiring Factory Wire 1ø Jumper Hook-Up 3ø Power 60 HZ Control Power (By Others) L1 L2 L3 T4 TB1 To Contactor TB1 3ø Power 60 HZ Thermostat (By Others) YEL T2 T1 3ø Jumper Hook-Up TB2 C1 C2 BLU M WHT T2 T1 H2 BLK T1 T2 T3 C1 L1 L2 L3 Contactor YEL WHT X2 H1 BLU 208 - 240V Motor Hook-Up Elements BLU BLK M WHT YEL Note: For 208-240V motor wiring, red and yellow motor wires to be connected at T2 terminal. RED 2 PDT Switch (By Others) T1 C1 L1 Thermostat (By Others) Heat T1 T2 T3 T2 T3 Contactor MOTOR LUBRICATION Motors in VUH-C-05 through VUH-C-10 have sleeve bearings which are factory lubricated. Relubricate annually, if neccessary, with No. 10 non-detergent oil. Contactor C3 L1 L2 L3 L2 L3 Cutout 3ø Jumper Hook-Up Fan C4 C2 C1 TB2 L1 L2 L3 T4 TB1 3ø Power 60 HZ Optional Heat Recovery Switch (By Others) Fused Switch (By Others) Figure 7 To Contactor 1ø Jumper Hook-Up L1 L2 L3 T4 TB1 1ø Power Note: All fan motors are totally enclosed and internally thermal overload protected. RENEWAL PARTS IDENTIFICATION MANUFACTURER PART NUMBER BREAKDOWN (LOCATED ON UNIT NAMEPLATE) V U H C Common Parts Diagram Item No. Description Part No. 5 Grille 134-130456-001 6 Overheat Cutout 300-024283-003 Controls Elements, Motor and Fan Code kW Volts Phase Nos. 05-81 05-83 05-21 05-23 05-71 05-43 07-81 07-83 07-21 07-23 07-71 07-43 10-81 10-83 10-21 10-23 10-71 10-43 208 5 240 277 480 208 7.5 240 277 480 9.8 208 240 10 277 480 1 3 1 3 1 3 1 3 1 3 1 3 1 3 1 3 1 3 Element Part No. (Item No. 1) Motor Part No. (Item No. 2) Fan Part No. (Item No. 4) 118-130480-001 (3) 193-057699-001 118-130480-003 (3) 112-130398-001 118-130480-004 (3) 193-057700-001 118-130480-005 (3) 193-057699-001 118-130480-002 (3) 193-057699-001 118-130480-017 (3) 112-130398-002 118-130480-007 (3) 193-057700-001 118-130480-008 (3) 193-057699-001 118-130480-009 (3) 193-057699-001 118-130480-002 (3) 112-130398-003 Code Nos. Part Number Description Contactor-24V Coil (30A) 30-00 Contactor-24V Coil (50A) Transformer Contactor-24V Coil (30A) 31-00 Contactor-24V Coil (50A) Contactor-120V Coil (30A) 32-00 Contactor-120V Coil (50A) Transformer Contactor-120V Coil (30A) 32-45 Contactor-120V Coil (50A) Transformer Contactor-120V Coil (30A) 33-00 Contactor-120V Coil (50A) Contactor-208/240V Coil (30A) 34-00 Contactor-208/240V Coil (50A) Contactor-208/240V Coil (30A) 34-45 Contactor-208/240V Coil (50A) 118-130480-006 (3) 193-057700-001 118-130480-010 (3) 193-057699-001 Dia. Wiring Wiring Diagram Item Dia. Part No. No. Figure 072-303180-001 072-303180-002 315-304252-002 072-303180-001 072-303180-002 072-303180-007 072-303180-008 315-304252-001 072-303180-007 072-303180-008 315-304252-001 072-303180-007 072-303180-008 072-303180-013 072-303180-014 072-303180-013 072-303180-014 3 3 7 3 3 3 3 7 3 3 7 3 3 3 3 3 3 3 170-057688-001 4 170-057688-002 3 170-057688-001 6 170-057688-004 4 170-057688-002 5 170-057688-003 7 170-057688-005 Optional Transformer Fusing NOTES: Number in parenthesis ( ) indicates quanitity required of that part. Fuse Type Part Number KTK-3 128-047763-007 (2) Fan Motor Contactor Transformer Grille Heating Element Fan Blade Overheat Cutout Limited Warranty: Please refer to the Chromalox limited warranty applicable to this product at http://www.chromalox.com/customer-service/policies/termsofsale.aspx. 2150 N. RULON WHITE BLVD., OGDEN, UT 84404 Phone: 1-800-368-2493 www.chromalox.com