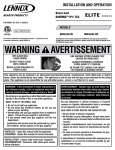

Download FS 925 OPERATORS MANUAL

Transcript