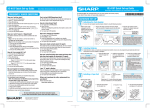

Download Sharp R-880S Operator`s manual

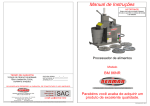

Transcript