Download RFI Emission OS-214plus Specifications

Transcript

Proprietary Statement

OS-214 plus

Desktop Barcode Printer

This manual contains proprietary information of Argox Information Co., Ltd. It is

intended solely for the information and use of parties operating and maintaining the

equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the expressed written

permission of Argox Information Co., Ltd.

Product Improvements

Continuous improvement of products is a policy of Argox Information Co., Ltd. All

specifications and signs are subject to change without notice.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that the interference will not

occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by the following measures:

•

Reorient or relocate the receiving antenna.

•

Increase the separation between the equipment and the receiver.

•

Connect the equipment into a different outlet on a different circuit.

•

Consult the dealer or an experience Radio/TV technician for help.

This unit was tested with shielded cables on the peripheral devices. Shielded cables

must be used with the unit to insure compliance. The user is cautioned that any changes

or modifications not expressly approved by Argox Information Co., Ltd. could void the

user’s authority to operate the equipment.

User’s Manual

Liability Disclaimer

Argox Information Co., Ltd. takes steps to assure that the company’s published

engineering specifications and manuals are correct; however, errors do occur. Argox

Information Co., Ltd. reserves the right to correct any such errors and disclaims any

resulting liability. In no event shall Argox Information Co., Ltd. or anyone else involved

in the creation, production, or delivery of the accompanying product (including

hardware and software) be liable for any damages whatsoever (including, without

limitation, damages for loss of business profits, business interruption, loss of business

information, or other pecuniary loss) arising out of the use of or the results of use of or

inability to use such product, even if Argox Information Co., Ltd. has been advised of

the possibility of such damages.

I

A Letter to Our Customers

Table of Contents

Dear Customers,

Getting Started .............................................................................1

Unpacking..................................................................................1

Package Contents...................................................................2

Connecting the Power Supply....................................................3

Getting to Know Your Printer ....................................................4

Parts and Features ......................................................................4

Controls and Indicators..............................................................7

Loading Ribbon and Media ........................................................9

Loading a Ribbon.......................................................................9

Loading Media.........................................................................14

Standard Mode .....................................................................14

Peel Off Mode......................................................................19

Cutting Mode .......................................................................23

Configuration .............................................................................25

Performing Calibration ............................................................25

Printing a Configuration Report ..............................................25

Resetting to Factory Default Settings ......................................26

Computer Connections..............................................................27

USB Interface Requirements ...................................................27

Serial (RS-232) Interface Requirements..................................28

Parallel Interface Requirements...............................................29

Serial and Parallel Cabling Requirements. ..............................29

Communicating with the Printer..............................................30

Before Installation....................................................................30

Installing the Driver (auto install driver) .................................30

Installing the USB Driver (Plug and Play) ..............................34

Setting Parameters ...................................................................39

Parameters for Win 98 .........................................................40

Parameters for Win 2000 .....................................................43

For NT 4.0............................................................................47

Congratulation on selecting an Argox OS series printer!

We believe soon you will find that you have made a

cleverest choice!

This booklet is a small gift from us. It is intended for

helping you to know your printer better, then further to

optimize it. Basically, this booklet contains two parts:

operation guidance and related valuable information.

In the part of the operation guidance, we will furnish you

with a lot of complementary illustrations, so you may pick

up those operation guides more quickly.

In the latter chapters of Trouble Shooting, Maintenance as

well as Reference Technical information, which we think,

you may need them just in case. Therefore, for your quick

reference, we try to table them as much as possible.

Enjoy your reading and have a good time with your printer!

Best wishes,

Argox Information Co., Ltd.

II

III

For Win XP ......................................................................... 49

Troubleshooting......................................................................... 53

LED Diagnosis........................................................................ 53

Miscellaneous ......................................................................... 55

Recovery ................................................................................. 56

Caring for Your Printer............................................................ 57

Cleaning .................................................................................. 57

Thermal Print Head............................................................. 57

Paper Sensor........................................................................ 57

Technical Reference .................................................................. 60

General Specifications ............................................................ 60

Fonts, Bar Codes and Graphics Specification......................... 62

Printer Programming Language A, PPLA .......................... 62

Printer Programming Language B, PPLB........................... 63

Interface Specifications........................................................... 64

Serial ................................................................................... 64

Connection with host: ......................................................... 65

Parallel (Centronics) ........................................................... 67

Auto Polling ........................................................................ 67

ASCII TABLE......................................................................... 68

Appendix I - Installing Dispenser Kit ..................................... 69

Top Cover................................................................................ 69

Middle Cover .......................................................................... 70

Base Housing .......................................................................... 71

Appendix II - Installing the Cutter.......................................... 74

Getting Started

Congratulations on choosing the Argox OS-214 plus desktop

barcode printer. This manual will help you get to know your new

printer. There are two parts to this manual, an operation guide

and related information. The operation guide is illustrated to help

you quickly become familiar with the printer. The related

information includes troubleshooting, maintenance and technical

information for your reference.

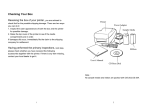

Unpacking

After receiving your printer, please check for possible shipping

damage:

1. Inspect the outside of both the box and the printer for

possible damage.

2. Open the top cover of the printer to see if the media

compartments are in order.

Note: If damage has occurred, contact your shipping company

immediately to file a claim.

3. Check whether you have received the following

accessories together with the printer. If there are any

items missing, please contact your local dealer.

IV

1

Printer

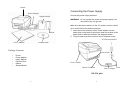

Connecting the Power Supply

Power Adapter

Sample Media

Connect the power supply as below.

WARNING! Do not operate the printer and power supply in an

area where they can get wet.

Ribbon

Make sure the power switch is in the "O" position, and be careful

not to touch the 36-pin parallel connector.

1. Insert the barrel connector of the Power Adapter into the

power jack on the back of the printer. Note the location of the

power jack for different models in the diagrams below.

2. Plug the other end of the cord into an AC electrical outlet.

AC Electrical Outlet

User’s Manual

CD Rom Disk

Package Contents

•

•

•

•

•

•

Power Jack

Printer

Power Adapter

User’s Manual

CD Rom Disk

Ribbon

Sample Media

Power Switch

Barrel Connector

Power Adapter

OS-214 plus

2

3

Cord

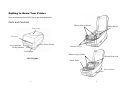

Getting to Know Your Printer

Parts and features of the OS-214 plus are illustrated below.

Parts and Features

Ribbon Pick-up Holder

Media Hanger

Top Cover

H Cover

Power Switch

Power Indicator

Release Levers

Ready Indicator

Feed Button

Ribbon Supply Holder

Thermal Print head

OS-214 plus

Platen Roller

Power Switch

4

5

Controls and Indicators

Peel-Off Option

Cutter Option

The printer’s controls and indicators are shown in the diagram

below. The following table explains control and indicator

functions.

Top Cover

Cutter

White Plastic Roller

Power Indicator

Power Switch

Ready Indicator

Feed Button

6

7

Loading Ribbon and Media

Control /

Indicator

Function

On: power on

•

Power Switch

•

Off: shut down

Note: Turn power off before connecting or

disconnecting cables

Power Indicator

Ready Indicator

Feed Button

•

Green light shows the power-on status

•

Light off shows the power-off status

•

Blinking light indicates error has occurred

•

Green shows printer is ready to operate

•

Blinking light indicates printer is paused or

data transferring

•

Light off indicates pack flash is under

processing

•

Press to advance labels to the first printing

position

•

Press to leave "pause" status

•

Press to back feed if a label is not properly

aligned

•

Press and hold while turning on the power

to print out a configuration profile

8

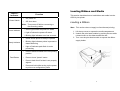

This section describes how to load ribbon and media into the

OS-214 plus printer.

Loading a Ribbon

Note: This section does not apply to direct thermal printing.

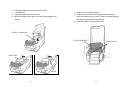

1. Lift the top cover to expose the media compartment.

2. Unlatch the print head module by pushing the two white

release levers on the sides toward the rear.

3. Turn over the print head module to expose the ribbon

supply holder.

9

Media Compartment

Print Head Module

Release Lever

Release Lever

4. Unwrap the ribbon roll pack and separate the ribbon roll

and the bare core.

5. Attach the edge of the ribbon on the bare core and wind it

a little bit onto the core.

6. Insert the ribbon roll into the supply holder. (First snap in

the left side and then the right side.)

Ribbon Supply Holder

Ribbon Supply Holder

Ribbon Roll

Bare Core

10

11

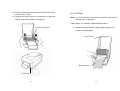

7. Put the print head module down and insert the bare core

into the pick-up holder. (First snap in the left side, and

then the right side.)

8. Turn the wheel of the print head module to ensure the

ribbon is tightly wound.

9. Press down the print head module firmly until you hear a

snap.

Wheel

Ribbon Pick-up Holder

Bare Core

Print Head Module

12

13

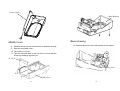

2. Remove the media hanger.

Loading Media

The OS-214 plus offers three different loading modes: standard,

peel-off, or cutting.

•

•

•

Standard mode allows you to collect each label freely.

Peel-off mode peels backing material away from the label

as it prints. After a label is removed, the next label prints.

Cutting mode automatically cuts the label after it prints.

Media Compartment

Media Hanger

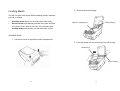

Standard Mode

1. Lift the top cover to expose the media compartment.

3. Load the media roll onto the hanger from left to right.

Media Roll

Media Hanger

14

15

4. Click the media hanger back into the media

compartment.

5. Align the media roll to the left end.

6. Move the shield from right to left until it leans against the

media.

7. Unlatch the print head module.

8. Hold the print head module upright with one hand to

allow the media to pass under it. Lead the media through

the media guides with the other hand.

9. Lead the media over the platen roller.

Media Compartment

Print Head Module

Media Guides

Media Roll

Shield

16

17

10. Put the print head module down and press down firmly

until you hear a snap.

11. Close the top cover and turn on the printer or press the

"FEED" button if the printer is already on.

Peel Off Mode

Note: For Peel-off mode you must first install the dispenser kit.

Please refer to Appendix I.

Follow Steps 1 to 8 listed in Standard Mode above.

Print Head Module

9. Remove enough labels to expose approximately a 6"

length of backing paper.

Peeler Sensor

Backing Paper

Feed Button

18

19

10. Trim the front edge of the label backing paper with

scissors or a knife.

11. Lead the backing paper over the dispenser bar, then

thread it back into the slot between the dispenser bar and

H cover, ensuring that it is inserted between the white

plastic roller and platen roller.

12. Press the "FEED" button for the label backing paper to

come out from the slot under the H cover.

13. To remove any slack, rewind the media onto the roll.

Press down the print head module firmly.

H Cover

Media Guides

Feed Button

H Cover

Dispenser Bar

Slot

14. Close the top cover and turn on the printer or press the

"FEED" button if the printer is already on.

20

21

Note: The "FEED" button does not make the printer peel.

Peeling occurs only when the software is properly set.

Cutting Mode

Note: For Cutting mode you must first install the cutter. Please

refer to Appendix I.

Follow Steps 1 to 8 listed in Standard Mode above.

9. Thread the media over the platen roller, then route the

media through the slot of the cutter module.

10. Press down the print head module firmly.

Label

Cutter Module

22

23

11. Close the top cover and turn on the printer or press the

"FEED" button if the printer is already on.

Note: The "FEED" button does not make the printer cut. Cutting

occurs only when the software is properly set.

Configuration

This section discusses calibration, printing configuration and

resetting the printer to factory defaults.

Performing Calibration

1. Press and hold the feed button while turning on the power,

until the printing motor is activated.

2. Calibration is performed while the printer automatically

feeds the label stock for a certain length.

Important!

You must always carry out calibration when

changing media. Failure to do so will result in

improper detection by the label sensor.

Printing a Configuration Report

1. Press and hold the "Feed" button while turning on the

power, until the printing motor is activated.

2. After feeding 12-inches of blank media, the printing motor

suspends for one second and then prints out a

configuration profile. The profile includes firmware version,

ROM checksum, RS232, thermal transfer/direct thermal

settings, hardware configuration, and font types.

3. At PPLB emulation, the printer enters character dump

mode. To exit from dump mode, press the feed button

again.

24

25

Resetting to Factory Default Settings

1. Turn on the printer and wait for 5 or more seconds.

2. Press the "Feed" button for 10 seconds, and the "Ready"

indicator and "Power" indicator will go off in order.

3. When the two indicators relight, release the feed button.

4. The printer feeds approximately 3 ~5 blank labels, and

then resets to the factory defaults.

Note: All settings are stored in flash and are retained even after

the printer is turned off.

Computer Connections

Note: You must insert the power supply’s barrel connector into

the power jack on the back of the printer before

connecting communication cables.

This printer comes with a USB interface, a nine-pin Electronics

Industries Association (EIA) RS-232 serial data interface and a

standard Centronics parallel interface. You must supply the

required interface cable for your application.

Note: This printer complies with FCC Rules and Regulations,

Part 15, for Class B Equipment, for use with fully shielded

six-foot data cables. Use of longer cables or unshielded

cables may increase radiated emissions above Class B

limits.

USB Interface Requirements

The Universal Serial Bus (USB) interface is version 2.0 and 1.1

compliant and provides a full-speed (12Mb/s) interface that is

compatible with your existing PC hardware. The USB’s “plug and

play” design makes installation easy. Multiple printers can share a

single USB port/hub.

26

27

Serial (RS-232) Interface Requirements

The required cable must have a nine-pin "D" type male connector

on one end, which is plugged into the mating serial port located

on the back of the printer. The other end of the signal interface

cable connects to a serial port on the host computer.

For technical and pin-out information, please refer to the

Reference Technical Information, Interface Specification.

Power Jack

RS232 Serial Port

Parallel Port

Parallel Interface Requirements

The required cable (IEEE 1284-compliant is recommended) must

have a standard 36-pin parallel connector on one end, which is

plugged into the parallel port located on the back of the printer.

The other end of the parallel interface cable connects to the

printer connector at the host computer. For pin-out information,

refer to the Reference Technical Information, Interface

Specification.

Serial and Parallel Cabling Requirements.

Data cables must be of fully shielded construction and fitted with

metal or metalized connector shells. Shielded cables and

connectors are required to prevent radiation and reception of

electrical noise.

To minimize electrical noise pickup in the cable:

•

Keep data cables short (6 ft or 1.83m recommended).

•

Do not tightly bundle the data cables with power cords.

•

Do not tie the data cables to power wire conduits.

USB Port

Notes:

1. Centronics allows a much higher communication speed

than serial.

2. The printer automatically detects parallel or serial port.

No need to set a switch or send a command.

3. Default settings are included in the configuration report.

28

29

Communicating with the Printer

The bundled printer driver can be applied to all applications under

Windows 98/2000/NT, and Windows XP. With this driver you can

run any popular Windows software applications such as MS-Word

and print to this printer.

Select a driver for your

printer and click "Next".

For 203 dpi modes with 4

inches print width, you

should select Label

Dr.200 (4 inch model).

Before Installation

1. Check the contents of the driver to ensure it is complete.

2. Make a backup copy of the driver.

Installing the Driver (auto install driver)

1. Double click the driver file (Label Dr. 200 or Label Dr. 300)

to execute in Windows.

2. Click "Next".

30

3. Select the port of the

printer and click "Next".

31

4. After the related files

are copied to your

system, click “Next”.

3. If you install new bar code application software such as

Bartender Ultra Lite, you should activate the seagull driver

for Argox printer.

ArgoBar

File → New→ Select Printer→ Label Dr. on LPT1: → OK

LabelView

File→ Select Printer→ Label Dr. on LPT1: → OK

CodeSoft

File→ Printer→ Windows→ Label Dr. on LPT1: → OK

5. After the installation

is complete, click

“Finish”.

LabelMatrix

File→ Printer Setup →Label Dr. on LPT1: → OK

Nicelabel

File→ Printer Setup →Label Dr. on LPT1: → OK

Bartender

File→ Printer Setup →Label Dr. on LPT1: → OK

Note:

1. If you are updating the driver, previous driver files are

overwritten automatically.

2. If you install new bar code application software such as

ArgoBar, LabelView or CodeSoft, you may activate the

Label Dr. 200 (or Label Dr. 300) driver and set it as the

current printer driver:

32

33

Installing the USB Driver (Plug and Play)

Note:

The printer driver needs to install version 1.4.00 or later

and support “USB Plug and Play” for Windows XP,

Windows 2003 and Windosw 2000.

5. Select “Search for the best driver in these locations” and

choose “Include this location in the search”. Input the location

of printer driver, click “Next”.

1. Extract the PrinterDriver.exe to the fixed route. (“C:\Label Dr.

200”, for example)

2. Connect the label printer to a computer with a USB cable.

3. Turn on the printer’s power and the system detects the device

automatically.

4. Select “Install from a list or specific location (Advanced)”, click

“Next”.

34

35

6. Select “Continue Anyway”.

7. Click “Finish”.

8. The Label Dr200 (4 inch model) printer is added in “Printers

and Faxes”.

9. Reboot the system.

36

37

10. The system assigns the USB port for Label Dr200 (4 inch

model) printer

Setting Parameters

After installing the driver, follow the path below to set parameters:

Start → Settings→ Printers→ Label Dr.→ Properties

Parameters include:

38

Ports

Select the IO port to link with the printer. The

port may be USB, parallel (LPT), serial

(COM), network port, or file.

Paper size

Select the proper size. If there is no desired

size, select "Custom" to define paper size.

Orientation

Set portrait or landscape.

Paper source

(Media type)

T/T stands for thermal transfer (ribbon)

mode and D/T for direct thermal mode

(without ribbon).

Media choice

(Darkness)

Set the heat value or darkness from this

field. Darkness values range from 0 to 15.

Copies

This function designates the number of

printed copies of each page.

More options

(Accessories)

To use the cutter or peeler function, enter

More Options and select one of the items.

Device options

(Speed)

Set print speed. For the OS-214 plus, the

speed ranges from 1~ 3 ips.

39

Parameters for Win 98

Output bin

(Accessory setting)

Ports

In the Properties menu:

→ Click "Paper"

→ Click "More Options"

→ Select Enable w/o

cutter, peeler

→ Click "OK"

In the Properties menu:

→ Click "Details"

→ Select the IO port.

→ Click "OK"

Paper size

Orientation

Paper source

(Media type)

Media choice

(Darkness)

Copies

Print quality

(Speed)

In the Properties menu:

→ Click "Device Options"

→ Select parameters

→ Click "OK"

In the Properties menu:

→Click "Paper"

→Click items to select the

desired parameters

→Click "OK"

40

41

Create a custom size

Parameters for Win 2000

In the Properties menu:

→ Click "Paper"

→ Select "Custom"

→ User-Defined Size

→ Set a custom size

→ Click "OK"

Ports

In the Properties menu:

→ Click "Ports"

→ Select the IO port

→ Click "OK"

Paper source

(Media type)

In the Printers menu:

→ Right click

→ Select "Printing

Preferences"

→ Click "Paper/Quality"

and select media type

→ Click "OK"

42

43

Orientation

Page order

Paper size setup

In Printing Preferences:

→ Click tag "Layout"

→ Click button "Advanced"

→ Click "button Customize”"

→ Select "paper size" or

add new paper size.

→ Click "OK"

In Printing Preferences:

→ Click "Layout"

→ Select "Portrait" or

"Landscape"

→ Click "Page order”"

→ Select "Front to Back"

or "Back to Front"

→ Click "OK"

Paper size

Copies

Print quality

(Speed)

Output bin

(Accessory setting)

In Printing Preferences:

→ Click "Layout"

→ Click "Advanced"

→ Click each item to select

parameters

→ Click "OK"

44

45

For NT 4.0

Create a custom size

Ports

In the Printers menu:

→ Right click

→ Select "Server

Properties"

→ Enter a form name for

in "Form Description for"

→ Reset paper size in

"Measurements"

→ Click "OK"

In the Properties menu:

→ Click "Ports"

→ Select IO port

→ Click "OK"

Paper size

Orientation

Paper source

(Media type)

Copies

Media choice

(Accessory setting)

In the Printer’s menu:

→ Right click

→ Select "Document

Defaults"

→ Click "Advanced"

→ Click items to select

desired parameters

46

47

Paper/Output

(Speed)

Print quality

(Darkness)

For Win XP

Ports

In the Properties menu:

→ Click "Ports"

→ Select the IO port

→ Click "OK"

In Default Document:

→ Click "Advanced"

→ Click item to select

desired parameters

→ Click "OK"

Create a custom size

Please refer to Create a

custom size in Win 2000 above.

Paper source

(Media type)

In the Printers menu:

→ Label Dr

→ Right click

→ Select "Printing

Preferences"

→ Click "Paper Quality"

→ Select media type

→ Click "OK"

48

49

Orientation

Page order

Paper size setup

In Printing Preferences:

→ Click tag "Layout"

→ Click button "Advanced"

→ Click button "Customize”"

→ Select "paper size" or

Add new paper size.

→ Click "OK"

In Printing Preferences:

→ Click "Layout"

→ Select "Portrait" or

"Landscape"

→ Click "Page order”"

→ Select "Front to Back"

or "Back to Front"

→ Click "OK"

Paper size

Copies

Print quality

(Speed)

Output bin

(Accessory setting)

In Printing Preferences:

→ Click "Layout"

→ Click "Advanced"

→ Click items to select

parameters

→ Click "OK"

50

51

Troubleshooting

Create a custom size

Normally, when the printer is in not working properly, the "Power"

LED blinks continuously; while printing and communication

between the host and printer stops.

In the Printers menu:

→ Right click

→ Select "Server

Properties"

→ Enter a “Form name”

→ Reset paper size

in the "Form description"

→ Click "OK"

LED Diagnosis

Power and Ready LEDs blinking continuously indicates printer

errors. To understand the problem, please observe the Power

and Ready LEDs and refer to the following solutions:

LED Indicators: Power and Ready LEDs blink at the same tempo

Power LED

ON

OFF

Ready LED

ON

OFF

Possible Problems

Solutions

Remarks

Miss-detect gap

Check the label path

If you use a

Check the label sensor continuous label roll

and run under

Windows, select

continuous media.

Label stock out

Supply the label roll

Label stock not

Install the label roll

installed

Label jam

Recover the jam

52

53

LED Indicators: Power and Ready LEDs blink alternately

Miscellaneous

Power LED

ON

OFF

If the host shows "Printer Time out"

1. Check if the communication cable (parallel or serial) is

connected securely to your parallel or serial port on the

PC and to the connector on the printer at the other end.

2. Check if the printer power is turned on.

Ready LED

OFF

ON

Possible Problems

Solutions

Ribbon out

Supply the ribbon roll

Ribbon jam

Recover the jam

Ribbon sensor error Replace ribbon sensor

Remarks

Not applicable to

direct thermal

type.

LED Indicators: Only the Power LED blinks

Power LED Ready LED

ON

ON

OFF

ON

Possible Problems

Serial IO error

Memory full

Cutter failed, or jam

at cutter

Hardware error

If the power cord is connected, the power switch is at position "I"

and the power LED is still not illuminated, check the fuse inside

the power adapter case.

If the data has been sent, but there is no output from the printer.

Check the active printer driver, and see if Label Dr. for your

Windows system and the label printer has been selected.

Vertical streaks in the printout usually indicate a dirty or faulty

print head. (Refer to the following examples.)

Solutions

Remarks

Check the baud rate

Not for Centronics

Add the extension RAM

Check the cutter

Occurs only when

Recover the jam

installing or setting the

cutter

Call for service

54

55

Clean the print head. If the problem persists, replace the print

head.

Poor printout quality:

•

The ribbon may not be qualified.

•

The media may not be qualified.

•

Adjust the Darkness (heat temperature).

•

Slow down the print speed.

•

Refer to the next chapter and clean the related spare

parts.

Recovery

Caring for Your Printer

After using eight rolls of label stock, clean the following areas of

the printer.

Note: Always switch off the power before cleaning.

Cleaning

Clean the following components of the printer using a cotton bud

dampened with alcohol. Do not soak the cotton bud excessively.

Thermal Print Head

After correcting problems, simply press the panel button or restart

the printer to continue your print jobs. Make sure the LEDs are not

blinking and remember to resend your files.

Thermal paper stock and the ribbon release debris on the print

head, which degrades printing quality. Clean the print head with

methanol or isopropyl alcohol and a cotton bud. Do not touch the

heater element with your fingers. Debris or dirt on the roller

should be cleaned with alcohol.

Paper Sensor

Debris or dirt on the paper sensor can cause a miss-read or

unstable detection of the label gap. Clean with a cotton bud

dampened with alcohol.

56

57

Replacing the Thermal Print Head

1.

2.

3.

4.

Switch off the power and wait for both LEDs to go off.

Unlatch the print head module.

Remove the ribbon.

Push the print head firmly into the casing and shift it to the

left. It will release from the module.

5. Disconnect the print head cable.

6. Disassemble the print head and the mounting bracket by

releasing screws.

7. Replace with a new print head. Reassemble the print head

module in reverse order. Be careful not to touch the print

head elements.

58

59

Technical Reference

General Specifications

Specification

Print method

Resolution

Max. print width

Max. print length

Max. print speed

Memory

CPU Type

Media Sensor

Display

Operation Interface

Communication

Interface

Fonts

Model

OS-214 plus

Direct thermal and thermal transfer

203 DPI (8 dots/mm)

4.1 in. (104 mm)

43 in (1092mm)

3 inches (76 mm) per second

8MB SDRAM / 4MB Flash ROM

32 bit RISC microprocessor

Reflective

LED indicator x 2

Button x 1

Centronics parallel, RS-232 serial, USB 2.0

(full-speed)

Int’l character sets standard

5 alpha-numeric fonts from 0.049” ~0.23” H

(1.25mm ~6.0mm)

All fonts expandable up to 24 x 24

4 direction 0°~270° rotation

Ribbon types &

Ribbon size

Soft fonts are downloadable

Wax, Wax/Resin, Resin ( Outside coated

ribbon)

Ribbon roll-OD 1.45” (37mm)

Ribbon length-max 3600” (91m)

60

Media Type

&

Media Size

Label indexing

Dimensions

Power Source

Agency Listing

Operation

Environment

Storage

Environment

Optional

Accessories

Roll-feed, die-cut, continuous, fan-fold, tags,

ticket in

Thermal paper or plain paper

Max width 4.25” (108mm)

Min width 1.0” (25.4mm)

Max length 43” (1092mm)

Min length 0.4” (10mm)

Thickness 0.0025”~0.01” ( 0.0635mm~

0.254mm)

Max roll capacity 4.3” (109mm) OD

Core size 1” (25mm) ID

Black stripe and gap

L 278 x W 186 x H 153 mm, 4.4 lbs( 2kgs)

Universal switching power supply

Input: 100V ~ 240 V, 1.8A, 50~60 Hz

Output: 24VDC, 2.1A, 50W Max

CE, FCC class A, UL / CUL, CCC, BSMI

32°F ~ 104°F (0°C ~40°C) ; 10~90%

non-condensing

-4°F ~122°F (-20°C~50°C)

Cutter, Dispenser kit, 4MB Flash card,

4MB Super card ( Combined card consists of

RTC and font, or RTC and 4MB flash), ArgoKee,

RTC board, External media stacker ( for media

roll with Max 8” OD)

61

Fonts, Bar Codes and Graphics Specification

Printer Programming Language B, PPLB

The specifications of fonts, bar codes and graphics depends on

printer emulation, which is a printer programming language (PPL)

through which the host communicates with your printer. There are

two PPLs for models OS-214 plus. They are PPLA and PPLB.

General fonts

Symbol sets

(Code pages)

Note:

Improper firmware updating may crash printer firmware. Please

contact your supplier for assistance.

Printer Programming Language A, PPLA

Specification

General fonts

Smooth fonts

Symbol sets for

fonts smooth

Courier fonts

Soft fonts

Font

expandability

Bar code types

Graphics

Model

OS-214 plus

7 alpha-numeric fonts, OCR A and OCR B ASD

4, 6, 8, 10, 12, 14 and 18 points

USASCII, UK, German, French, Italian, Spanish,

Swedish, and Danish/Norwegian

8 symbol set (PC, PC-A, PC-B EAMA-94, Roman8,

Legal, Greek and Russian)

Downloadable PCL fonts

1x1 to 24x24

Code 39, Code 93,Code 128/subset A/B/C, Codabar,

Interleave 2 of 5, UPC A/E/2/5 add-on, EAN-8/13,

UCC/EAN Code128, Postnet, Plessey,I25(standard/

modulo 10 checksum/ modulo 10 checksum and

shipping bearer bar), UCC/EAN Code 128 K-MART,

UCC/EAN Code 128 Random Weight, HBIC, Telepen ,

FIM. MaxiCode, PDF417, Datamatrix (2D

symbologies).

PCX, BMP, IMG and HEX format files

62

Specification

Model

OS-214 plus

5 fonts with different point sizes

8 bits: code page 437, 850, 852, 860, 863, 865, 857,

861,862, 855, 866, 737, 851, 869, 1252, 1250, 1251,

1253, 1254, 1255.

7 bits: USA, British, German, French, Danish, Italian,

Spanish, Swedish and Swiss.

Downloadable soft fonts

Soft fonts

Font

1x1 to 24x24

expandability

Bar code types Code 39(checksum), Code 93, Code 128/ subset A,B,C,

Codabar, Interleave 2 of 5(checksum), Matrix 2 of 5,

UPC A/E 2 and 5 add-on, EAN-8/13, Code 128UCC,

UCC/EAN, Postnet, German Postcode. MaxiCode and

PDF417 (2D symbologies)

PCX and binary raster

Graphics

Notes:

1. The bare core for the ribbon must be 11 cm in length. It should

have two opposite slits at two ends. If the ribbon itself is less

than 11 cm, it must be aligned with the bare core at the left end

when you install it.

2. Since this printer uses band buffer technology. If you just print

texts or barcodes the maximum length is more than 30 inches.

If you print many graphics the maximum length can only be a

few inches with standard onboard RAM. (Extension RAM, font

board and flash modules use the same connector and cannot

function at the same time.)

63

Interface Specifications

USB

Note: Pin 9 on the OS-214 plus is reserved for a KDU (keyboard

device unit). Do not connect these pins if you are using a

general host such as a PC.

Connection with host:

2

1

3

4

USB series “B” Receptacle Interface

Pin

1

2

3

4

Signal Name

VBUS

DD+

GND

Connector Terminal Pin Assignment

Serial

For the OS-214 plus, the RS232 connector on the printer side is a

female, DB-9.

Pin

Direction

Definition

1

In

DSR

2

In

RxData

3

Out

TxData

5

Ground

6

Out

DTR

7

Out

RTS

8

In

CTS

9

Out

+5V

64

Host 25S

Printer 9P

(PC or compatible)

Host 9S

Printer 9P

(PC or compatible)

DTR 20

DSR 6

TX 2

RX 3

CTS 5

RTS 4

GND 7

DTR 4

DSR 6

TX 3

RX 2

CTS 8

RTS 7

GND 5

……

……

……

……

……

……

……

1 DSR

6 DTR

2 RX

3 TX

7 RTS

8 CTR

5 GND

……

……

……

……

……

……

……

1 DSR

6 DTR

2 RX

3 TX

7 RTS

8 CTS

5 GND

Alternatively you can connect the 3 wires as follows:

Host 25S

Printer 9P

(PC or compatible)

Host 9S

Printer 9P

(PC or compatible)

TX 2

RX 3

GND 7

pin 4

pin 5

pin 6

pin 20

TX 3

RX 2

GND 5

pin 4

pin 6

pin 7

pin 8

…… 2 RX

…… 3 TX

…… 5 GND

65

…… 2 RX

…… 3 TX

…… 5 GND

The simplest way to connect to other hosts (not PC compatible) or

terminals is:

Printer

Pin 2- RxData ………

Pin 3- TxData ………

Pin 5- Ground ………

Terminal/Host

TxData

RxData

Ground

Parallel (Centronics)

The parallel port is a standard 36-pin Centronics, which complies

with IEEE 1284 standard (compatibility mode). Pin assignments

are as follows:

Pin

1

Direction

In

Definition

n/STROBE

Pin

16

Direction

-

In general, as long as the data quantity is not too large and you

use Xon/Xoff as flow control, it will be problem free.

2~9

In

Data 1~8

17

-

Baud rate:

10

Out

nACK

18

-

11

Out

BUSY

19~30

-

12

13

14

15

Out

Out

In

-

1200, 2400, 4800, 9600, 19200, 38400, 57600,

115200 bauds. (Programmable by command)

Data format: 7 or 8 bits

Parity:

Odd, Even, or None

Default Parameters:9600 bauds, no parity, 8 data bits, 1 stop bit

Handshaking:

XON/XOFF as well as CTS/RTS (hardware

flow control).

If you run an application with the bundled printer driver under

Windows and use the serial port, you should check the above

parameters and set the flow control to "Xon/Xoff "or "hardware".

66

PE

31

SELECT

32

nAUTOFEED 33~35

N.D.

36

In

Out

In

Definition

Ground

Chassis

Ground

Peripheral

High

Signal

Ground

nINIT

nFAULT

N.D.

nSELECTIN

Auto Polling

Both the serial port and parallel port of this printer can be

activated at the same time, i.e the printer can simultaneously

communicate with two PCs via different ports. However as no port

contention is made for this printer, if both PCs transmit data at the

same time the data may become damaged in the receiving buffer.

67

Appendix I - Installing Dispenser Kit

ASCII TABLE

NUL

SOH

STX

XON

XOFF

NAK

ACK

BEL

BS

LF

ESC

FF

CR

SO

SI

RS

US

!

"

#

$

%

&

‛

(

)

*

+

,

.

/

0

1

2

3

4

5

6

7

8

9

:

;

<

=

>

?

68

@

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

[

\

]

^

_

'

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

P

q

r

s

t

u

v

w

x

y

z

{

I

}

~

DEL

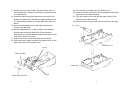

1. Turn off the printer power and unplug the printer.

2. Unwrap the dispenser kit and take out screws, the shaft,

the plastic roller, the dispenser bar, the direction label, and

the peeler sensor cable.

Top Cover

3. Take off the top cover of the printer.

4. The peeler sensor cable has a sensor board at one end

and a connector at the other end.

5. Mount the two little holes of the sensor board on the two

spines at left upper corner inside the top cover, keeping

the cable at the left.

6. Route the peeler sensor cable through the guides along

the left side of the top cover.

7. Fix the sensor cable and sensor board with Loctite-444

instant adhesive or equivalent.

69

Sensor Cable

Base Housing

Base Housing

Middle Cover

8. Release the two screws at the bottom of the base housing.

9. Remove the middle cover.

10. Take off the H. Cover.

11. Tape the direction label on the top of the H. cover with the

arrow sign heading opposite you.

12. Release the screw on the left bracket of the chassis.

H. Cover

Screw

Middle Cover

70

71

13. Unlatch the print head module. Hook the white roller on

the brackets of the chassis, ensuring the long thinner end

is on the left side.

14. Guide the shaft through the respective holes on the left

bracket, the white roller and then the right bracket in order.

(To smooth this procedure, hold the white roller with one

hand.)

15. Secure the attached screw to the right bracket of the

chassis to fix the shaft.

16. Hook the dispenser bar on the brackets of the chassis,

positioning it above the white roller. Ensure that the

dispenser bar is parallel with the black platen roller and its

long thinner end is on the left.

17. Secure the screw on the left bracket of the chassis.

18. Guide the sensor cable connector through the hole on the

upper left corner of the middle cover.

19. Click the top cover back onto the middle cover.

20. Insert the sensor connector into its receptacle on the main

logic board of the base housing.

21. Click the middle cover back into the base housing. First

click in the front then the rear.

22. Secure the two screws at the bottom of the base housing.

H. Cover

Middle Cover

Screw

Dispenser Bar

4 mm Gap

Shaft

White Plastic Roller

72

73

Appendix II - Installing the Cutter

1. Turn off the printer power and unplug the power cable and

Centronics / Serial cable.

2. Remove the top cover.

3. Remove the two screws under the base housing.

4. Remove the whole print head assembly by releasing the 4

screws at its feet.

Print Head Assembly

5. Add the cutter IC baby board to J16 on the main board.

74

75

6. Secure the four screws attaching the cutter.

Cutter

7. Plug the cutter's connector into the PCB's header

connector (JP16).

8. Reattach the print head assembly by securing the 4

screws.

9. Click back the middle cover.

10. Secure the two screws for the base housing.

11. Click the top cover into place.

76