Download Craftsman 502.255193 Owner`s manual

Transcript

o_vne

1

Model

No.

502.255193

, ,i i iil,ii

12 HP. LECTRIC START

40" MOWER

SPEED

LAWN TRACTOR

CAUTION:

Read And Follow

All Safety Rules

And Instructions

Operating

This

Equipment.

Before

® Assembly

o Operation

e Maintenance

e Service

® Repair

F-91726

12-01-90

and Adjustment

Parts

Sears, Roebuck and Co, Chicago, IL 60684

UoS.A.

Printed

inUSA

SAFETY

Safe Operation

As Recommended

RULES

Practices

by American

for Riding

National

Vehicles

Standards

Institute

This cutting machine is capable of amputating

hands and feet and throwing objects. Failure to observe

safety instructions

could result in serious injury or death to the operator or bystanders.

GENERAL

1o

the following

OPERATION:

Read, understand,

and follow

all instructions

in the instruction

Book, on the machine,

on the engine,

and with any attachments

before starting_

2

Only aliow responsible

adults familiar

3..

Clear the area of objects

4o

Be sure the area is clear of other people

5.

Never carry passengers.

6.

Disengage

all attachment

7,_

Disengage

power

8.

such as rocks, toys, wire,

ctutches

to the mower

look down and behind

before

the mower

not operate

the mower

without

9.

Slow

before

100

Never leave a machine

remove

unattended

Disengage

12.

Stop the engine before

13.

Mow

14.

Do not operate

15,.

Watch

Use extra

Always

from

/

18,

power

to start the engine_

up. Do not mow

in reverse

untess absolutely

necessary.

Always

at anyone

or at places where people may bee Do

backing.

the entire grass bagger

orgood

when

caution

the unit, Aiways

artificial

loading

glasses

wear

puliing

loads

ao

Use oniy approved

transporting

the grass bagger

while

operating

when

wear safety

when

removing

the machine

Use care when

before attempting

before backing

from the mower

or the mower

with the engine running, Always

to attachment(s)

only in daylight

17,.

if anyone enters the area°

guard

in place,

disengage

the blade(s),

set the parking

brake, stop the engine and

dismounting

1 1,

16.

by the b|adav

Stop the machine

discharge_ Do not point discharge

either

the machine.

turning.

the key before

for traffic

and shift into Neutral

and while

to operate

etc_ which could be picked up and thrown

before mowing.

or any attachments

Be aware of the directlon

down

with the instructions

or not {n use,, Disengage

or unclogging

the influence

near or crossing

not mowing°

or unloading

of alcohol

or drugs

the machine

when

using

a trailer

you operate

eye protection

you make an adjustment

when

or using heavy

or when

very tired,,

roadways,

or an eye shield when

hitch

when

light,

under

drawbar

the blade(s)

the chute.

or truck

for transporting.

the unit to protect your eyes from foreign

or repair

objects

that can be thrown

to the machine,

equipment°

points.

b.,

Limit loads

c.

Do not turn sharply,.

to those you can safely

Use care when

d.

Use counterweights

or wheel

control

backing.

weights

when

suggested

in the Instruction

Book.

CHILDREN:

Tragic accidents can occur if the operator is not alert to the presence of children, Children are often attracted to the machine and the

mowing activity. Never assume that children will remain where you last saw them,

1.

Keep children

2,

Be alert

out of the mowing

and turn the engine

3

Before

4.

Never carry

machine,

children

or any passengers

5,

Never

children

to operate

6

Use extra care when

F-91726

and when

allow

backing,

area and in the watchful

off if children

look behind

approaching

enter

and down

They

the machine_

blind

care of an adult

for small children,

may fall off and

Instruct

corners,

other than the operator.

the area.

shrubs,

chitdren

be seriously

in the dangers

trees or other

2

objects

injured

or interfere

with

of the machine

that

may obscure

vision.

the safe operation

of the

SAFETY

RULES - continued

SLOPE OPERATION:

Slopes and rough terrain are major factors related to loss of control and tip over accidents which can result in severe injury or death.

All slopes require extra caution. If you cannot back up the slope or if you feet uneasy on the slope, do not mow ito See the "Slope

Guide" in the back of this book to check for safe operation,

DO

1.

Mow

up and down

2o

Remove

slopes, not across.

3

Watch

4.

Use slow

5,,

Follow

6.

Use extra

7.

Keep all movement

8

Avoid

1o

Do not turn on slopes

Z,

Do not mow

obstacles

such

for holes,

as rocks,

speed,

Choose

care with

etCo..

Uneven

a low enough

the manufacturer's

starting

limbs,

ruts or bumps°

terrain

recommendations

grass baggers

or other

on the slopes

slow

or stopping

on a slope.

could

overturn

gear so that you will

for wheel

weights

attachments,

and gradual.,

the machine.,

or counterweights

they can change

Do not make sudden

If tires lose traction,

Tall grass can hide obstacles

not have to stop or shift

disengage

while

on the slope°

to improve

the stability

changes

the blades

stability.

of the machine.

in speed or direction

and proceed

slowly

straight

down

the slope,

DO NOT

injury

unless

near drop-offs,

absolutely

ditches

necessary,

then only turn slowly

or embankments.

and gradually

downhill,

A wheel over the edge or an edge caving

if possible,

in could cause a sudden

overturn

and an

or death.

3.

Do not mow

4.

Do not try to stabilize

on wet

grass.

5,

Do not use a grass bagger

Reduced

the machine

traction

could

by putting

or other

cause sliding.

your foot

rear mounted

on the ground.

accessories

on steep

slopes

(greater

than

10 °}

SERVICE:

1,

Use extra care when

a

Use only

b

Never remove

handling

an approved

gasoline

and other fuels,

Fuels are flammable

and the vapors

are explosive,

container,,

the gas cap or add fuel with the engine

running,

Allow

the engine to cool for several

minutes

before

refueling

Do

not smoke.

c,

Never

refuel

the machine

d°

Never

store

the

indoors

machine

with

fuel in the

tank or fuel

container

inside

where

there

is an open

flame,

such

as a water

heater,

2.

Never

3o

Keep all nuts and bolts,

start

and nicks

or run the engine

4,

Never tamper

5.

To reduce

years.

with

Stop

Never make adjustments

and inspect

Mower

blade(s)

housing

area.

Check

Wait

in good

Check their

replaced

a factory

for wear or damage

reptacement

such as cracks

blade. For safety,

replace

the

condition

proper

operation

regularly,

settings

parts

the brake

when

are sharp

operation

for all movement

or overspeed

are subject

always

an object,

Repair,

if necessary,

with the engine running,, The carburetor

Clean uP oil or fuel sPilfage

Allow

the machine

to

make

before

re-starting

can be adjusted

with the engine

running,

Do not change

the engine,.

to wear, damage

sure the grass

and deterioration,

bag is empty

which

Frequently

could

check

expose

moving

components

parts or allow

and replace

with

objects

to be

manufacturer's

necessary

and can cut

frequently,

to stop before

Wrap

the blade(s)

or wear

Adjust

and service

as required,

servicing

gloves

and use extra

caution

when

any part of the uniL

Look for this symbol

precautions,.

Become

F-91726

check the blade(s)

with

free of grass, leaves or other debris build-up

if you strike

or repairs

components

For storage,

recommended

11

the equipment

governor

Grass bagger

10,

nuts tight. Frequently

storing

7.

9,

devices.

keep the machine

6,

the engine

area

must be immediately

Keep the equipment

the safety

fire hazards

cool before

thrown,

an enclosed

the blade attachment

A blade that is bent or damaged

blade every two

8

inside

especially

This

Alert!

3

to indicate

symbol

Your

Safety

important

indicates:

safety

"Attention!

Is At Risks _

servicing

them

or the blade

Congratulations

on your

purchase

of a Sears Tractor.

designed, engineered and manufactured

ible dependability

and performance.

to give you the best poss-

If you experience

any problem

you cannot

see your nearest

Sears Service

Department.

well trained

this unit.

technicians

and the proper

Please read and retain this manual.

to assemble and maintain

"Safety

Rules".

CUSTOMER

easily

remedy,

tools

to service

please

or repair

The instructions will enable you

Always

observe

the

RESPONSIBILITIES

Carefully

the unit

•

Follow all the assembly

unit.

=

Know

how to operate

the

unit°

operate

all standard

Make

sure

that

Correctly

adjust

and accessory

the

operator

the

correctly

the unit.

Operate the unit only with guards, shields, and other safety

items in place and working correctly..

t

Complete

with

all maintenance

authorized

on the unit. Service

or approved

This unit is equipped

replacement

with

an internal

brush-covered

is equipped

or state

laws

maintained

in the

4442

or grass-covered

State

with

(if any).. If a spark

in effective

of California

of the California

have similar

Authorized

working

laws_ Federal

Service

Center

MAINTENANCE

A Sears Maintenance

nearest Sears Store

be

laws

apply

on federal

(Section

states

Model

may

lands., See an

Serial

for the muffler.

AGREEMENT

to the back of the frame

Number:

502.255193

Number:

on this unit

See the

Keep these numbers

for future

i,,111, ,, i,

reference.

ii

TWO YEAR WARRANTY

START

RIDING

EQUIPMENT

AND GRASS BAGGER ATrACHMENT

the date of purchase,

when this

riding equipment

and grass bagger

excludes

blade(s),

and the date

Date of Purchase:

Agreement

is available

for information..

blade adapter(s),

instructions

equipment

attachment

are maintained,

lubricated,

and

in the Owner's Manual, Sears will repair free of charge any defect in

and grass bagger attachment°

spark plug(s), air cleaner, and belt(s), which are expendable

arrd become

worn during

does not cover:

- tire replacement

or repair

caused

by punctures

from outside

- repairs necessary because of operator' abuse or negligence,

instructions

contained

in the Owner's Manual; and

- riding

TRACTOR

the serial number

The model number and serial number are found on a decal

attached

by law

tuned up according to the operating and maintenance

material or workmanship

in this electric start riding

This warranty

Record in the space below

of purchase of this unit.

loca|

it must

LIMITED

This warranty

normal use.

LAWN

exhaust

applicable

Code). Other

for a spark attester

..........................

forest-covered,

is used,

is required

Resources

ON ELECTRIC

For two years from

iiiiii

engine

order by the operator:

the above

Public

meeting

arrester

30 foot pounds

4 bushels

parts.

land unless the englne's

a spark arrester

Blade Nut Torque

Grass Bagger Size

the unit only

combustion

and must not be used on or near any unimproved

system

Tilt Seat

The seat tilts forward for easy access to the battery.

Mower Housing

The full=floating suspension and twin blades

give an even cut,,The lift lever has six height positions from 2 to

4 inches,

equipment

can

=

NOTE:

Tire Air Pressure

Front and Rear 12 psi

All Gear Transaxle

Six forward speeds and one reverse.,

Ground Speed

Forward 0-5,4 MPH.

Reverse 0-1 _6 MPH.

read and foilow the rules for safe operation.. Inspect

instructions_

SPECIFICATIONS

Briggs & Stratton Engine

12 HP,.

Charging System

3 amperes at 3600 rpmr.

Fuel Tank Size

1 gaIIon

Type Of Fuel

Unleaded Regular

Oil Capacity

3 pints

Oil Type

Above 32 °

SAE 30 or 10W30

Below 32 °

SAE 5W30

Spark Plug (Gap 0,.030")

Champion J 19LM

Sears 71-33312

STD361458

We have competent,

your unit properly.

o

on

PRODUCT

It has been

equipment

and grass bagger

attachment

FULL 90-DAY

objects

including

used for commercial

WARRANTY

(such as nails, thorns,

the failure

or rental

to maintain

stumps,

or glass);

the equipment

and

according

to

purposesv

ON BATTERY

For 90 days from the date of purchase, if any battery included with this riding equipment

proves defective in material

and our testing determines

the battery will not hold a charge, Sears will replace the battery at no charge.

or workmanship

WARRANTY SERVICE IS AVAILABLE BY CONTACTING THE NEAREST SEARS SERVICE CENTER/DEPARTMENT tN THE UNITED

STATES, This warranty applies only while this product is in use in the United States_

This warranty

gives you specific

legal

Sears. Roebuck and Coo, D/731CR-W,

F-91726

rights, and you may also have other rights

Sears Tower, Chicago, IL

60684

4

which

vary from state to state.

i

i

TABLE

OF CONTENTS

SAFETY RULES ...............................................

2-3

CUSTOMER RESPONSIBILITIES

.........................

4

PRODUCT SPECIFICATIONS

...............................

4

WARRANTY

......................................................

4

TABLE OF CONTENTS

.......................................

5

INDEX ...............................................................

5

TRACTOR ATTACHMENTS

................................

6

ASSEMBLY

..................................................

7-20

OPERATION

...............................................

21-26

MAINTENANCE

..........................................

SERVICE AND ADJUSTMENT

......................

STORAGE ........................................................

TROUBLE SHOOTING CHART ..........................

ELECTRICAL SCHEMATIC

................................

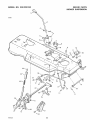

REPAIR PARTS, MOWER ............................

REPAIR PARTS, GRASS BAGGER ...............

27-34

35-41

41

42

43

44-57

58-59

REPAIR PARTS, TRANSAXLE

.....................

REPAIR PARTS, ENGINE .............................

60-61

62-66

PARTS ORDERING/SERVICE

................

Back Page

iNDEX

F

A

......................................................................

P

Parking Brake

21, 22

Parts Bag, Grass Bagger ...........................

11 - 12

Parts Bag, Lawn Tractor .........................................

7

............................

........................

R

........................................................

....

...........................................................

Filter Air .................................................................

34

Adjustments:

Filter Fuel

34

Blade Engagement Control 29 .....................

Fuel

25

Brake, Drive

30

Carburetor ....................................................................

35

Fuel System Storage ...............................................

41

Fuse ..........................................................

4t, 43, 54

Clutch .........................................................................

30

G

Mower Housing Level ......................................

38

Throttle Control Cable ................................ 35

Grass Bagger:

Assembly ............................................................

13 20

Assembly

7 - 20

Operation ..................................................................

24

Attachments ...................................................................

6

B

Service and Adjustment ................................

40

Replace Motion Drive Belt

38

Replace Mower Drive Belt .................................

37

..............................

S

Safety Rules .......................................................

2 -3

Seat, Install ...............................................................

9

Service and Adjustments .........................35 - 40

I

Battery, Emergency Start ...............................

40

Bagging Tips ...................................................................

26

Carburetor ........................................................

35

Ignition Switch .........................................................

21

Battery:

L

Fuel Filter

34

Charge ..............................................................................

8

Fuse ....................................................................

41

Lift Lever

21 23

Clean and Check .............................................

32

Level Mower Housing .......................................

38

Lights

21 40

Emergency Start

41

Lubrication ...................................................................

27

Light Bulb, Replace

40

Install .......................................................................

20

Motion Drive Belt ................................................

38

M

Storage ............................................................................

41

Mower Ddve Belt ..................................................

37

Maintenance .....................................................

27 34

Belt:

Air Filter

34

Mower Housing, Install ......................................

36

Motion Drive, Adjust

30

Mower Housing, Remove ............................36

Battery .................................................................

32

Motion Drive, Replace

38

Blade ...........................................................................

28

Sharpen Blade ..............................................................

28

Mower Drive, Adjust ......................................

29

Shift Lever ................................................

21, 22 31

Blade Engagement Control .............................

29

Mower Drive, Replace ...........................

37

Brake

30

Shift Gate, Adjust ..............................................31

Rooting, Check ................................................

10

Clutch ......................................................................

30

Slope Guide

67

Blade, Remove and Install .......................................

28

Spark Arrestor .............................................. 4 34

Engine 011

33

Blade, Sharpen ........................................................

28

Lubrication .........................................................

27

Spark Plug ...........................................................................

34

Blade Engagement Control:

Specifications, Product ............................................

4

Muffler, Check

34

Adjust

29

Speed Control Chart .............................................

22

Spark Arrestor ...........................................4 34

Operatlon

23

Spark Plug

34

Start Engine .....................................................................

25

Brake, Check and Adjust Drive .............................

30

Tires

32

Steering Whee! ..........................................................

9

Brake Pedal, Operation .................................. 21

C

Maintenance Schedule ................................... 27

Stop Unit ..................................................................

22

Storage

41

Mower Housing

Carburetor Adjust .................................................

35

T

Clean ......................................................................

40

Charge Battery ................................................................

8

Throttle Control .....................................................

23

Level Adjustment ...............................................

39

Clutch/Brake Pedal ............................................21

Throttle Control Cable Adjust ..........................

35

Remove and Install .........................................

36

Controls .........................................................................

21

Tire Pressure

10, 32

Cutting Height ......................................................23

Mowing and Bagging _t_ps ...............................26

E

Trouble Shooting Chart ......................................

42

W

Oih

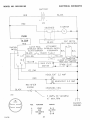

Electrical Schematic

43

Check ..............................................................33

Warranty ........................................................

4

Engine:

Wheel Align Front ....................................... 41

Carburetor .....................................................35

Change ...................................................

33

Wiring Schematic .......................................... 43

Operating Tips ................................................... 26

Oil, Change ................................................ 33

Operation ............................................................

21 - 26

Oil Level, Check

33

Grass Bagger .................................................24

Oil Type ...............................................................

33

LiftLever .......................................

21, 23

Operation Speed Chart .................................

22

Mower Housing ............................................23

Starting ....................................................... 25

Operation On Hills ...................................... 23

Stopping ................................................... 22

Parking Brake .................................... 2I, 22

Storage ...........................................................41

Shift Lever .............................

21 22

Throttle Control ..........................

21, 35

Start Engine ...................................

25

Trouble Shooting Chart ..................

42

Stop The Unit .....................................

22

....

......................................................................

.....................................

........................................................

............................

.........................................

............................................

......................................................................

.......................................................

..........................................

..........................................

.........

.......................................................................

...................................................

..............................................................

.......

................................................

....................................................................

................................................................

............................................................

..........................................................................

................................

....................................

....................................

........................................

.....................................

v

F 91726

5

4,

ii

TRACTOR

Attachments

That

illl

iiiiiillllllllllll

ATTACH

Add

Craftsman

to the

Lawn

M ENTS

Usefulness

of Your

Tractor

Sears offers a wide variety of attachments that fit your iawn tractor Many of these are listed below with brief explanations of how they can

help you°This list was current at the time of publication; however, it may change in future years- more attachments may be added, changes

may be made in these attachments, or some may no longer be available_

Most of these attachments do not require additional hitches or conversion kits (those that do are indicated) and are designed for easy attaching

and detaching° You may order these attachments at most Sears retail stores, catalog sales offices and thru the catalog,

PERMANEX BAGGER lets you collect grass clippings and leaves for a healthier, neater-looking lawn. Two Permanex containers hold

33-gallon plastic bags.

LAWN SWEEPERS let you collect grass clippings and leaves_ Select from these:

=

=

=

=

30-in,

32-in_

32=in

38-in,

Path with a capacity of

Path with a capacity of

High Performance Path

High Performance Path

9.0 cu. ft,

10_0 cu_ ft_

with a capacity of 10=0 cu=ft.

with a capacity of 12_5 cuoft_

LAWN MAC for powerful collection of heavy grass clippings and leaves Accepts optional wand attachment to pick up debris in

hard-to-reach places Has a 3hp. engine with 12 bushel capacity° Requires a Chute Adapter.

CARTS make hauling easy. Choose from these:

=

=

=

=

=

4 cubic foot Dump Cart with a capacity of 400 Ib,

10 cubic foot Hauling Cart with a capacity of 1,000 {b=

I0 cubic foot Dump Cart with a capacity of t,000 ib.

14 cubic foot Dump Cart with a capacity of 1,250 Ib=

17 cubic foot Dump Cart with a capacity of t,500 Ibo

ROLLER for smoother lawn surface. 36-1nch wide, 1B-inch diameter water-tight drum holds up to 390 Iboof weight. Rounded edges prevent

harm to turf_ Adjustable scraper automatlcally cleans drum°

SPREADER/SEEDERS

=

=

o

=

make seeding, fertilizing, and weed killing easy. Broadcast spreaders also useful for granular de-lcers and sand°

Drop type, 36-inch. 12-1nch semi-pneumatic wheels. I00 lb=capacity steel hopper.

Broadcasts a 4 to 12 foot swath 70 lb. capacity steel hooper= Non-corrosive spreading

spinner.. Nylon gear box. Stainless steel shaft_

Broadcasts t0 to 12 foot swath. 160 lb_ capacity (covers 40,000 sq. ft°) No-rust

polypropylene hopper and impeller. Vinyl hopper cover.

Broadcasts t 0 to 12 foot swath. 100 Ibo capacity_ No-rust polypropylene hopper and

impeller, Vinyl hopper cover.

AERATOR promotes deep root growth for a healthy lawn. Tapered 2_5-inch steel spikes mounted on 10-inch dia meter discs puncture holes

in soil at close intervals to let moisture soak in. Steel weight box for increased penetration_

CORING AERATOR takes small plugs out of soil to allow moisture and nutrients to reach grass roots., 36-inch swath. 24 hardened steel

coring tips. 150 lb capacity weight tray.

DETHATCHER loosens and flips thatch and matted leaves to lawn surface for easy pick up. Twenty spring steel tines (t 0 pairs) dethatch

40-inch swath. Useful to prepare bare areas for reseeding and for seed bed preparation after tilling. Rear mount

DETHATCHER loosens and lifts thatch to fawn surface for easy pick up (with bagger, sweeper or vac). Ten spring steel tines, each with two

"teeth", dethatch 3B-inch path_ Front mount_

TRACTOR COVER protects tractor from weather. Made of Evolution 3 fabric (water repellent, extremely breathable, lightweight, soft, non

abrasive, pliable over a wide temperature range, durable, stain-tear-and puncture-resistant, wilf not shdnk or stretchL

SEAT COVER is dense polyester shag, machine washable. Provides cooler, more comfortable

longer lifeo

ride in the summer heat. Protects seat for

SPRAYERS uses 12-volt DC electric motor that connects to tractor battery or other 12 volt source, Includes booms for automatic spraying

when pulling, and hand held wand for spot spraying. Wand has adjustable spray pattern_ For applying herbicides, insecticides, fungicides,

and liquid fertilizers.

'_

=

50 psi maximum pressure with 12 foot wand length

25 psi maximum pressure with 10 foot wand length

SNOW BLADE for snow removal only. t 4-inch high, 42-inch wide blade clears 38-inch path when angled left or right, Raises, lowers with

side lever_ Adjustable skids; replaceable, reversible scraper bar. (Use with tire chains, wheel weights.)

SNOW THROWER has 40-inch swath. Dru m-type auger handles powdery and wetJheavy snow_ Mounts easily with simple pin arrangement,

Discharge chute adjusts to 210 ° arc from tractor seat. 6-inch diameter spout discharges snow 10 to 50 feet. Lift controlled at tractor seat.

(Use wlth tire chains, rear wheel weights)

CART-N-VAC

Large 12 bushel capaclty. Converts to 4 cuo ft. hauling cart. Load capacity 250 lbs.

TIRE CHAINS ere heavy duty; closely-spaced extra-large cross links give smooth rlde, outstanding traction_

WHEEL WEIGHTS for rear wheels provide needed traction for snow removal. In pairs. (30 Ibs ea )

NOTE: Do not use pull-behind attachments

F-91726

on slopes that are greater than 10 degrees,

6

ASSEMBLY

i

,,,,,,,

,u ,,,,,,,,,

i,,,

u

...................,

, i ,,,,,,,,,,,,,,

i,

,, ,,, ,,,

PREPARATION

Before being put in the carton,

carton

was

made to protect

The unit is comptetety

the unit was carefu[iy

the unit during

assembled

except

inspected

The

shipment,

for the items shown

on

this page These items are in the carton with a parts bag which

contains the fasteners to assemble the unit Find and remove these

items,, The fasteners

are shown

Bellows

on the next page,

Owner's Manual

HOW

TO REMOVE

To remove

FROM

THE CARTON

the unit from the carton, follow

1.

Open the top of the carton,,

2.

Remove

the wood

3,,

Remove

the boxes

Remove

sleeve.

frame

the instructions below,.

at the top of the carton_

labeled

(A) and

(B) from

the seat,, NOTE: the seat is covered

Remove

connector

tube

the Grass Bagger

Cover,

and the protective

pad,

the

carton,.

with a protective

the outer

tube, the

4.,

The items shown at the right are in a small unmarked

box.

Remove and check each item Remove the small box°

5.

Cut each corner of the carton

a knife,

NOTE:

See the

the controls,,

Operation

from the top to the bottom

section

6o

Move

7,

Move the lift lever to the HIGH position

the shift lever to the NEUTRAL

for

the

with

location

of

position

TOOLS YOU NEED TO ASSEMBLE

1. Adjustable wrench (2 required)

2. Open end wrench 1/2" - 9/16"

3, Open end wrench 7/16" - 1/2"

4. Blade type screwdriver

CAUTION:

Check the bottom

of the carton for staples,,

Remove any staples that are in the path of the tires.

9,

From the back of the unit, carefully

off the wood frame,

pull the unit backwards

___. PARTS

BAG - contents

The fasteners and other loose parts are shown below,, The fasteners

® @ ©

for Lawn Tractor

THE UNIT

5 Phillips screwdriver

6, Low Tire pressure gauge

7o Knife

8 Socket Set (Optional)

........

are shown at full size with the quantities

in brackets

{ ),

@

(2) Locknut

(1) Flange Hax Nut

(2) Lockwasher

For Battery Terminals

1/_'2B

For Steering Wheel

5/t 6"-24

For Seat

I.Do 5116"

15×66

15x90

18xl 6

[Not shown rut}slzti)

(4) Hub Cap

24582

(2) Ignition Key

91275

(Notshawn full

Size)

(1) Battery

91941

Clip

12) He× Bolt

For Battery

Termlnais

V_"-20x%"

1 x38

F-91726

{2} HBx Bolt

For Seat

(t) Hex Bolt

For Steering

5116"_18x_ls "

tx45

B/16'L24x1

lx66

7

_J_

Wheel

¥0"

(1) Screw

For Battery Clip

26x 184

ASSEMBLY

ii

HOW TO PREPARE AND

CHARGE THE BATTERY

ii

Remove and discard

NOTE; Before you install the battery, add the battery acid

the meta_

(Electrolyte) and charge the battery° Battery acid will damage

paint and parts,

WARNING:

Vent Cap

Read the instructions included with

the battery acid container. Protect your hands

_

1.

nd eyes

fromyou.

the battery acid_ Use clothing that

will

protect

If the vent caps are not installed

vent

caps

included

from

with

the

If metal

bag

Read

remove

the

the

instructions

Battery

the vent caps_ Your unit will have one or the

other types of batteries

2_

on the battery,

plastic

tape covers

the vents. Discard

as shown.

the vents,

the metal

remove

the metal tape from

tape.

ii ...................

3.

Pour battery

touches

battery

acid into each battery

the bottom

the battery

4.

Wait

of the vent as shown.

acid above

much battery

the bottom

you charge

20 to 30 minutes

battery

5o

The

the

level

of

described

battery

battery

Discard

with

the battery

Add baking

more

the

solution

Destroy

the container

with

drop

vent

battery

below

the

Correct

Liquid

Level

acid until the correct

any battery

and any battery

soda and mix together

Discard

you can continue

Fill the container

soda

Vent

Install the vent caps_ Wash the

acid container

baking

tf you add too

acid will flow from

water to remove

was not used as follows.

Add

can

in step 3, Add more

top of the battery

6.

acid

acid level is reached.

until

using

the

acid that

half full with watery

the solution

and wash

acid._

a piece

does

container

DANGER

of wood,

not

with

BATTERY

foam.

CAUSE

8o

To prevent accidents, neutralize the battery acid that was not used To

The fumes

neutralize, fill the container half full with water Add baking soda and

mix using a piece of wood until the solution does not foam, Discard the

solution and wash the container with water Destroy the container

from

the battery

charger

a rate of 6 amperes

for 1 hour,

the battery

acid can cause

an

to charge the battery.

is charged,

check

Charge

Do not

add battery

battery

can be

to a charged

External = Wash the area with water, then wash with a solution of

water and sodium bicarbonate

the level of the battery

acid falls, add water.

acid

ANTIDOTE:

at

acid. If the level of the battery

The engine has a 3 amperes

charging

start the engine or frequently

the battery

battery,

BURNS

WARNING;

smoke,

KeepWhen

the battery

you chargethe

away from

battery,

any sparks_

do not

or the result

Internal = Drink large amounts of water milk, or milk of magnesia

Drink water mixed with the whites of eggs_ Call a Doctor

immediately

an explosion.

9.

WILL

Contains sulphuric acid.

Do not let the battery acid come in contact with the skin, the eyes. or the

clothing

Use a 12 volt battery

After

ACID

SEVERE

water..

explosion.

7,

VIEW

you put the vent caps on the

battery° While you wait for the battery,

of the unit°

CUT AWAY

the battery.

before

the assembfy

acid

Do not add the

of the vent.

acid, the excessive

when

cell until the battery

will not stay fully

charge

the battery

system

use the headlight

charged.

every three

Eyes - Flush with water for t5

medical help

If you frequently

minutes

and then get immediate

(if equipped),

For longer

life of the

- KEEP AWAY

months.

POISION

FROM

CHILDREN

D-5213

F-91726

8

ASSEMBLY

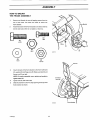

_OW TO ASSEMBLE

rilE STEERRNG WHEEL

Jse the fasteners shown below to install

;asteners are shown at full size

the steering

wheeE The

@

S1eedng

B

ix66

B

t 5×90

Bellows

1

Make sure the front wheels

point forward.

Slide the bellows

over the steering post. Make sure the collar of the bellows

on top. Push on the top of the bellows.

2,,

Attach

the

fasteners

HOW

steering

wheel

as shown

to the

Tighten

TO INSTALL

Use the fasteners shown

shown at full size°

steering

post

is

with

the

the seat, The fasteners

are

e 5699

the fasteners

THE SEAT

below to install

(A)

Ix45

(8)

18×16

1.

Carefully

remove

the protective

from the seat, Do not

bottom of the seat.

2.

3,

Align

the holes

Fasten

the

shown

Tighten

in the

seat

to the

sleeve and the

damage

seat hinge

seat

the

wire

plastic

attached

to the holes

hinge

with

the

to

bag

the

in the seat..

fasteners

as

the fasteners

Check the operating

position

Seat

of the seat. If the seat needs to

be adjusted, loosen the seat adjusting nuts on the seat hinge.

Slide the seat forward or backward along the adjusting holes

as shown.To

keep the seat straight,

align the rear edge of the

seat hinge with the marks on the top of the console_ Tighten

the hex nuts.

4"

Connect

the wire

harness.

Make sure the tab part of the connector,

seat switch

connector,

from

sensor,

the seat switch

sensor

to the wire

Jocks into the latch of the wire

from

the

harness

WARNING:

For correct and safe operation ofthe

unit, connect

the wire from the seat switch

sensor

F-91726

to the wire

harness.

9

Steering Posl

Wheel

= == =l= H =l=l,====,l,l,l,l,l==l,l=ll=l===

ASSEMBLY

= 111i= iH ,lliHi,i,ll

HOW

TO ATTACH

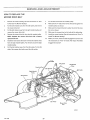

CHECK THE DRIVE

THE HUB CAPS

BRAKE

The drive brake can be easily checked as foHows_ Set the parking

brake Move the shift lever to the neutral (N) position Push the unit.

Push each hub cap onto the center' hub of each wheel, Make sure

the washer holds the hub cap in place_

If the rear wheels rotate, adjust the drive brake. Seo "How To Chock

And Adjust

CHECK

The Drive Brako'_

THE TIRES

CHECK THE LEVEL OF

THE MOWER HOUSING

Check the air pressure in the tireSr.Tires with too much air pressure

will cause the unit to ride rough. Also, the wrong air pressure will

keep the mower housing from cutting level, The correct air

pressure (PSI) is 12 PSI (0,B5 kg/cm2),

The lever of cut was set at the factory,, After the u nit is fully assemble,

completely

read the Operation

Section.

Make sure the level of cut is set at the height you like for your lawn,.

CHECK

THE BELTS

Check the operation

of the mower housing° Mow a short distance

and look at the area that was cut. If the mower housing does not cut

Check the routing of the belts.

Make

sure the belts

Make sure the belts are not twisted.

are inside

level, see the instructions

on "How

To Level The Mower

Housing"_

all the belt guides_

HOW

SHIFT

TO CHECK

THE ALIGNMENT

OF THE

GATE

Follow the instructions

The Shift

_nstructions,

in the Operation

Lever"., If it is difficult

"How

To Check

Section

to change

And Adjust

on "How

To Use

gears, first check the

The Clutch". Then, adjust

the shift gate.. See the irrstructions, "How To Check And Adjust The

Shift Gate",

Belt Guides

Blade Drive

Pulley

Transaxle Pulley

Belt Guides

idler Pulley

Mower Drive

Belt

Stack

Pulley

Idler Put{ey

Belt Guides

F-91726

t 0

iMPORTANT:

Remove

and identify

the contents

CONTENTS

of each box as shown

OF BOX

below:

A

Containers

Weight Bracket

Hin_

Frame

Mount

Bracket

_L=_

CONTENTS

OF BOX

B

Window

Parts Bag

(In paper bag_

Extension Tube

and Plate Assembly

Fr°ntWi_"

(2) Plastic Bags

(Not shown)

\

Channel

Elbow

D-81_8

F_91726

I 1

PARTS

BAG - conterlts

for Grass Bagger

The fasteners and other loose parts are shown below. The fasteners are shown full size with the quantities

NOTE:

Some

of the fasteners

will

not be required

for your modoLi_.,

in brackets ().

..,..

_,_"-20 x ½"

(5)Bolt,Special

3

For Outer Tuba (3)

(2) Bolt, Carriage

For Extension Tube

5/16"-18 x ¾"

2x64

(1) Screw

For Rubber Latch

1/_-20 x 1 _

ForFor

Cover

Hinge

Handle

(1) (4)

L4x24

For Center Tube (2)

5/16"-24 x 1% _

6x93

@

(1) Bolt, Hex

For Frame Bracket

½"-13 x t¼_

lx125

(2) Bolt, Hax

For Frame Bracket

5/t6"-1B x 1 _

I x84

4x71

(1_)

(4) Bolt, Carriage

For Front Weight

5/16_-18 x ¾_

#10-t6 x ½" AB

For Window

26x246

2x74

(2) Hex Nut, Flanged

For Latch Pin (1)

For Rubber Latch (1)

¼"-20

@

15x89

For Window

Q

(t) Locknut

For Frame Bracket

(4) Locknut, Flange

For Front Weight

5/16"-18

15x88

151Washer

121 Washer

(Not ShownFullSize)

For Frame Bracket

LD. °39"

17x51

(I) Handle, Plastic

For Cover

54537

;;

(Not

Full Size}

15x109

121 Nut -Flange, Hex

For Frame Bracket

5116"-18

15xl 08

(2) Nut, Wing

For Extension Tube

5/16'_18

@

{Not Shown

#10-24

(4) Nut, Jam

For Front Weight

5/16"-t8

_;_143

For Outer Tube (3)

For Center Tube (2)

18xl 5

For Cover Handle (2)

For Window Ctip (1)

#10-24 X %"

4x21

Clip (1)

15x81

For cover Hinge [4)

For Handle (2)

¼"-20

15x66

131 Screw

(3) Nut, Hax

For Cover Handle (2)

(6) LocknQ

(1) Bolt, Carriage

For Latch Pin

1/4"-20 x s/a"

2x39

Screw

For Elbow

¼" x ¾" AB

26x239

14x83

ShownFull

Size)

(1) Plug, Weight

24863

_

(Not ShownFull

Size)

(3) Cap

For Outer Tube (2)

For Center Tube (1)

54695

(1) Latch, Rubber

{Not Shown

Futl Size|

(1) Pin, Latch

54563

2

(Not Showni_[t Size)

(1) Pin, Hinge

54407Z

For Connector Tube

54416E7011

ForCover Hinge

31x6

(Not shown actual size)

(8} Fastener, Plastic

For Containers (4 each)

193xl

F-91726

151Nut, Hex

For Outer Tube (3)

For Center Tube (2) 5/16"-24

16X32

{NotShownFullSizel

(1) Clip, Window

54571Z

12

(NotShownFullSize}

(1) Bracket

For Extension Tube

54566

(1) Expansion Nut

For Window

28x56

ASSEMBLY

HOW

TO ASSEMBLE

Assemble

the front weight

THE FRONT

support

with

WEIGHT

the fasteners

shown

full

size below,

©

1,

(B)

(A)

(c)

15x 109

2x74

15x88

Assemble

the tractor

the four carriage

as shown,,

bolts

C_

.3_

Weight

Support

(A) and four jam nuts (B) to

Make sure jam nuts (B) are tight°

2,

Fit the front weight

3o

the plug on top as shown,

Set the weight and weight support

into the weight

support

with the hole for

in position

on the carriage

bolts you assembled

in Step 1- Fasten the weight

support

with the four Iocknuts (C} as shown, Make sure Iocknuts (C}

4_

are tight,

Fill the front weight

with

sand,, Install the plug in the front

weight.

on a slope

WARNING:

even.

or where the lawn is rough or not

Use the front weight when you mow

WARNING: Do not ride up or down slopes that

are too steep to back straight up. Never ride the

unit across a slope. See the "Slope Guide" in the

back of this book for information on how to

check slopes_

F-91726

O-e130

13

Weight

Support

iii

iiiiiii1,,111

ASSEMBLY

H =l= =H,N

::::::::::::::::::::::::::::::::

HOW TO MOUNT

THE FRAME ASSEMBLY

Remove and discard the two self=tapping screws from the

rear of the framer Use these two holes to mount

the

frame bracket_

2.

Frame Bracket

Attach the bottom of the frame bracket to the frame with hex

,

bolt (A} and Iocknut (B) Do not tighten at this t_me=

(A)

lx125

(A)

0-8t19

15x41

(D)

17x51

__

(E)

15x108

Channel

3_

Attach the back of the frame bracket to the frame with bolts

(C), washers (D) and flange nuts (E)._Make sure botts (C) and

flange nuts (E) are tight.

NOTE: For easier assembly, use a ratchet and socket to

"U" Shape

tighten bolts (C).

4_

Tighten bolt (A) and Iocknut (B}.

5..

Slide the channel in to the "U" shape opening in the top oftha

Opening \

frame bracket as shown,

D-8_20

F-91726

14

Frame Bracket

From the right side of the unit, install

6,

the channel

channe_

Mount

7_

as shown,

Rotate

the channel

the channel

pin throug

(F)

h

pin to lock the

in place,

the outer tube to the channel

as shown,

Make sure the

holes on one end of the outer tube are on the right side of the

unit, Use the fasteners

fasteners

shown

full size below

Make sure the

(G)

are tight_

CAUTION:

If the fasteners

are tightened

outer tube

can be damaged.

© @

IF)

(G)

6xg3

t8x 15

too much,

the

(H)

15x32

Make

sure

these

holes are to the

right side of the

unit

Channel Pin

Rotate

Channel Pin

Counterclockwise

e-8!21

8

Mount

the center tube to the channel

the fasteners

CAU'flON:

9.

as shown

Make sure

are tight,

If the

fasteners

are tightened

center

tube

Attach

the caps to the end of the tubes

too

much,

the

can be damaged,

as shown

Channel

Center Tube

(F)

(F}

6x93

G Q

(G)

! 8x 15

F-91726

(H)

15x32

15

IIIHII=I=IIIll i= i

ASSEMBLY

HOW

1o

TO MOUNT

Assemble

THE COVER

the hinge

to the cover with the fasteners

full size below,. Push tire hinge toward

Make sure the screws

hinge,, Tighten

2

Attach

are at the bottom

the fasteners

(a)

4x24

(c)

(D)

4x21

15x81

nut (F) into the slot in the cover as shown,,

the window

to the cover with the fasteners

as shown°

Make sure the cover fits between

the plastic

cover,

Push on each side of the

at the end of the window°

window

until

Fasten

with

the two

screw

on the inside

window

clip with

screw

plastic

channel.

with

flange

are locked

Align

the hole in the cover°

and the

in position°

Put the window

of the window,.

clip

in

the hole in the

Fasten

the window

(C) and nut (D) as shown,

Set the cover in the operating

tube assembly

tabs

(E) as shown,

position

clip with

4.

15x66

Push expansion

Mount

as shown.

the fasteners,

_(A)

3_

of the holes in the

the fasteners.

the handle to the cover with

Tighten

shown

the top of the cover,,

as shown.

position

D-S124

on the top of the outer

Align the holes in the hinge and the

Fasten the cover and hinge assembly

hinge pin and hair pin shown

to the channel

full size below.

),

W_ndow

Plastic Tab

31x6

Pfastic Flange

(El

26_.46

IF)

28x56

O

(H)

54407Z

F-9t726

(H)

!6

................................

i,, ,lui un,lllli,l_Jii

ASSEMBLY

HOW

1,,

TO MOUNT

Assembfe

latch

fasteners

shown

THE EXTENSION

pin (A)

to

the

TUBE

extension

tube

with

the

below

A

54563

15x89

2x39

A

B

C

2,

Move the lift lever to the highest cut position,

3.

Disconnect

the wire to the spark plug. Raise the deflector,

Rotate the blade away from the discharge openir;g, Remove

the carriage

shown.,

bolt and

Iocknut

from

the

mower

housing

as

Deflector

Bracket

D-B126

_

4,

Slide

the extension

tube

under

shown_ Fasten the extension

housing

5-

Mower Housing

has of

sharp

edges_ Always

b eARNING:

careful ofThe

the blade

position

the blade.

with

the bolt (D) and wing

sure the wing nut is tight,

ff not assembled

to the extension

position at the back of the

extension tube and the bracket

as shown.

Make

the deflector

bracket

as

tube to the front of the mower

sure the wing

nut (E) as shown.

tube,

Extension Tube

Make

put the bracket

in

extension

tube_ Fasten the

with bolt (D) and wing nut (E)

nut is tlght,,

Deflector

Bracket

2x64

D

14x83

E

a-8151-2

F-91726

17

ASSEMBLY

HOW TO MOUNT

THE CONNECTOR

Mount

the

connector

TUBE

tube

with

the

fasteners

shown

full

size

1

below,,

Assemble

the handle

tube

the fasteners

with

screwdriver

15x89

and tighten

the

3,

Fasten the elbow

4x24

4,

5_

cover,

(E)

the

in the hole of cover

NOTE: To help the elbow

with

the hole

in the

tube with the self=tapping

screw

until

the head

of the

put wax or polish

efbow

7

rubber latch is aligned whh

Slide the bottom

end of

tube

and

you open

or close the

on the elbow,

Rotate

extension

the

as shown,,

slide when

6.

15x66

connector

tube

assembly

the latch pin

the connector

Lock in place with

tube

the rubber

until

the

over

the

latch,

Elbow

hole in

with hole in elbow

Conoector

Tube

Slide elbow into

hole in cover_

Lock in piece

whh rubber latch

D-8133

CoRRecter

Tube_

Handle,

Rubber Latch

(D)

D-S129-f

F-91726

18

a

Move the lift lever to the lowest cut position_

Hold tire handle on the connector

tube,, Put the end of the

elbow

4x71

tube

to the connector

as shown

Tighten

touches the elbow,

with

Iocknuts,

Atign the hole in the connector

elbow as shown_

screw

screw

latch to the connector'

as shown,_ Hoid the screws

2,

(B)

26x239

and the rubber

ASSEMBLY

HOW

TO ASSEMBLE

THE CONTAINERS

NOTE: There is only one way that these containers can be put

together. Carefully read and follow the instructions below_,

1

Separate

the six container

have 2 tops, 2 middle

2,

Look

for a number

numbers

3.

into two

on

one

side

groups

pieces

of each

You will

top

piece

The

for the two top pieces are I arid 3. Set the two top

with

Look for two

on one side of each middle

piece

numbers

the numbers

the flange

has the numbers

piece has the numbers

piece_ One

1 and 2, The other

3 and 4. Match

1 and 2 with

part up as shown,

top piece

the middle

middle

piece with

1. Set the middle

piece

inside the matching

top piece as shown

Match the middle piece with numbers 3 and 4 with top piece

3 as shown

piece

Set the middle

piece

inside

the matching

top

as shown,,

5,

Look for a number

6,

numbers for the two bottom pieces are 2 and 4o

Match bottom piece 2 with the top piece 1 and middle piece1

that

on one side

has the numbers

piece inside

7

Match bottom

of each bottom

piece

1 and 2. Set the matching

the middle

piece

bottom

piece 4 with the top piece 3 and middle piece

bottom

TOP PIECES

Put one foot inside the three pieces and lift the top piece until

the three pieces connect

together

of each piece are locked

9,

The

as shown

that has the numbers

3 and 4, Set the matching

piece inside the middle piece as shown_

8,

PIECES

as shown,

pieces on the ground

middle

4.

pieces

and 2 bottoms

BOTTOM

D_8177

Make sure all four corners

i

together.,

Fasten the top and middle

Flange

of Top

GROUND

pieces of each container

together

using four fasteners for each container

Push each fastener

into the hole in each side of the container

from the inside

as shown,

Fasteners

(No_ shown

_ctua!

s_ze}

BOTTOM PIECE

MIDDLE PIECE

TOP PIECE

F-91726

19

i

ASSEMBLY

i

HOW

1

TO ATTACH

Tilt the

seat forward

Two

3,.

4,

plastic

bag

Hold

linings,

included

with

optiona]

accessories

the handle

not shown

that

on the back

of the

in the illustration,

The plastic

are

bag linings

can be used for easy removal

Put the plastic bag linings in to the containers

Slide the containers

on to the frame tubes as shown

5,

are

of

Make

is to the rear' as si_own

Lower the cover Pull back on the handle and push the cover

the grass,,

down unti_ it locks into place

IMPORTANT:

For the grass bagger to work

must be in the down position,.

FINAL

1,

correctly,

I

the cover

ASSEMBLY

The grass bagger

has two containers.

For easy removal of the

grass, use a plastic lining inside the container

following

Check

2+

Use one ofthe

sizes°

e

33 gallons

e

4 bushels

e

145 litres

the fasteners°

0-8131

;_

Make

sure that

alt bolts

and nuts are

TO INSTALL

THE BATTERY

Use the fasteners shown below

are shown at full size,

(A)

lx38

1o

to install the battery,

The fasteners

(B)

(C)

t 5x66

26x184

Tilt the seat forward Install the battery tray_ Make sure the

drain on the bottom ofthe battery tray goes through the hote

in the frame as shown,

Set the battery in the battery tray, Make sure the battery

terminals are toward the front of the unit,

NOTE: Make sure the battery fits under the tabs at the

back of the unit.

Fasten the battery clip in the slot in the frame,, Attach the

battery clip with the fastener as shown,

2,,

3°

cable

to theTopositive

terminal

before

WARNING:

prevent(+)sparks,

fasten

the you

red

connect the black cable,

_

4.

Fasten the red cable

fasteners as shown_

to the positive

(+) terminal

5,

Fasten the black cable to the negative

fasteners as shown,

(--) terminal

F-91726

with

Caution

to

tight,,

HOW

i

and lift to raise the cover

the grass bagger

sure the "CAUTION"

illll

THE CONTAINERS

cover,, Pull back on the handle

2

lllll

the

with the

2O

rear

i

,

,

OPERATION

KNOW

THE

PRODUCT

Before you operate the unit, read this instruction

When

you read this instruction

follow

the operating

Position

book° If you understand

book, compare

instructions

the illustrations

and the safety

rules

the unit and how the unit operates,

to the unit. Learn the location

Keep this

instruction

book for future

you will get the best performance.

of the controls.

To help prevent an accident,

reference

w _en Enga(

Button

!

Parking Brake Lever

Clutch/Brake

lgnitloniLight

Pedaf

Switch,

Blade Engagement

Control

O

Q

Position when Disengaged

ill

ill,ii

u i

i

ii ii

ii

MEETS

Sears Mowers

Commission,,

conform

i illlUHlll

BLADE

to the safety

i Hu,

.ll

ENGAGEMENT

lever to start

standards

and stop

CONTROL

the rotation

LEVER:

UUlmlIHH

National

Use the control

SWITCH:

The switch

PARKING

The first

has two funct}ons

The second

Standards

when

IGNIT|ON/LIGHT

function

ii ,i,,ll

i ,, illUll,,i

,,i

i

Institute,

and the US

Consumer

Product

Safety

I I III,H

of the blade

the engine

ii

REQUIREMENTS

'llHJl

PEDAL:

The pedal has two functions

The second function is a brake

is for starting

ii

of the American

CLUTCH/BRAKE

function

is a clutch

first function

i ,llllll,lll,ii

CPSC SAFETY

BRAKE:

you leave

LIFT

LEVER:

attachment

The

SHIFT

unit

is to

Use the parking

brake

to engage

the brake

the unit

Use

the

lift

lever

to

change

the

height

of

the

LEVER: Use the sh_ft lever to change the speed of the

turn on the headlight

THROTTLE

CONTROL

LEVER: Use the throttle control to

increase or decrease the speed of the engine

F191726

2t

OPERATBON

The operation

foreign

thrown

result

in severe

safety

glasses

your

lawn

eye

the

spectacles

available

at Sears

TO USE THE

can result

eyes,

damage°

shields

and

Wide

over the

mower

in the

or eye

mower

recommend

HOW

of any lawn

objects

Retail

wear

Safety

Completely

for

3,

Remove

your

t

from

release the paddng

will hold the unit,

I

To

release

the

clutch/brake

automatically

parking

FUNCTION

pedal

and

brake,

completely

The

brake

Trimming

Snow

the

control

HOW

1,

unit

2

brake.

Move

the blade

to the DISENGAGE

position.

and remove

the ignition

Bagging

the

blade

forward

grass

,,! or 2

mowing

to stop the

3.,

Move

4_

Set the parking brake,.

5.

Move the throttle

&

To stop the engine,

Remove

control

to the

Light

DISENGAGE

mowing

lever to the NEUTRAL

control

position,,

to the SLOW

turn the ignition

Snow

TO US[ = TH[= SHIFT

HOW

TO CHANGE

1.

the direction

Completely

CHOKE

key to the OFF position,

"°7"

Attachments

L[=V[=R

push the clutch/brake

the steps

HOW

below:

pedal _orward

I.

3

depress

Before

the

you clutch/brake

change directions

pedal,,

of

Make

sure the shift

Slowly release the clutch!brake

foot on the clutch/brake

pedal

F-91726

2 or3

TO USE THE SHIFT-ON-THE-GO

While the unit moves forward,

you can select any forward.

speed Just move the shift lever to the next faster or next

lever engages

pedal

2,

into the shift

Do not ride with

speed,

You

do

not

have

to use the

clutch/brake

pedal

Pull the shift lever toward the seat until the lever disengages

from the shift gate_ Move

the shift lever to FIRST or

REVERSE,

gate

6

SLOW-F_:r

slower

2.

""

DIRECTIONS

of the unit, follow

WARNING:

travel,

fully

O5

position,

the key,

HOW

4or5

Blade

Pull Behind

To change

,2o!3

on the pedal.

engagement

position.

the shift

i --

key.

Normal

pedal completely

Keep your foot

Move

mm

CHOKE

TO STOP THE UNIT

Push the clutch!brake

I

Thrower

:z

Set the parking

Stop the engine

THROTTLE

will

WARNING:

Before

you leave

the operator's

position, move the shift lever to the neutral

(N)

engagement

LEVER

,, =,,,,u

brake

push

parking

SHIFT

then

Make sure the parking

pedal

forward.

release,

position+

i J

e-5732

pedal forward.

the clutch!brake

brake lever

Ga

I

brake lever_

foot

Shift

!

Stores.

MOWER

push the clutch/brake

Lift the perking

tShlftLever

glasses.

HOW TO SET THE PARKING BRAKE

2

i[

We

Mask

safety

or Catalog

1

starting

mowing.

or standard

in

can

Always

before

while

Vision

which

The shift lever positions

in the chart

for operation

of your unit are shown

NOTE: Belt noise can occur when the clutch is engaged_ This

noise is normal and does not affect the operation of the unit°

your

22

OPEBATnON

i

HOW

TO USE THE THROTTLE

Use the throttle

control

engine_

1

To start

a cold

CHOKE

2,

The

to increase

engine,

position

lever

HOW TO OPERATE WITH

THE MOWER HOUSING

the speed of tile

to the

For transport

throttle

with

a detent,

using a grass bagger,

For maximum

also for a cooler

FAST position,

The

the

is marked

and when

the FAST position

4,,

CONTROL

or decrease

move

,

START

WARNING: The deflector is a safety device,, Do

not remove the deflector° The deflector forces

the discharged material toward the ground.

Always keep the deflector in the down position.

If the deflector is damaged, replace it with a

factory replacement part.

or

position

FAST

operations

3,

ii

running

charging

engine,

For normal

move the lever to

of the battery

aperate

the engine

and to tow pull behind attachments,

control

engine

to the needed

governor

performance,,

move the

speed,

is set at the

Do not

and

in the

adjust

factory

for

the governor

to

TO CHANGE

THE CUTTING

HEIGHT

button

the

forward

to release the lever. Move

to lower the mower

can be set from

2 to 4 inches

you ride on a sidewalk

or a road, move the lift lever to the hightest

position

the

and

DISENGAGE

move

blade

engagement

control

to

to a lower

5o

position,

Push the clutch/brake

6o

Move the shift lever to one of the speed

When

bagger,

control to the SLOW position°

engagement

Control

to the

pedal

you mow

put the shift

completely

in heavy

lever

Slowly

Move the throttte control to the FAST position

the

move

of the blade engagement

Use the blade engagement

the blade

1

Make sure the level of cut, set at the factory,

If the mower

ENGAGEMENT

on "How

section.

speed

housing

is still correct,

look at the area that was cut.

does not cut level, see the instructions

To Lever The Mower

Housing"

in the maintenance

control in the illustration.

control to start and stop the rotation

WARNING: For better control of the unit, always

select a safe speed.

of

position

Move the control

the blade°

Note:

If the

lever to the ENGAGE

engine

stops

when

position

you engage

to rotate

the blade{s),

HOW

TO OPERATE

Move the control lever to the DISENGAGE position to stop

the rotary blade. Before you feave the operatoKs position,

make sure the blade has stopped

4,

Ifyouneedto

lever to another

setting,

the seat switch is not activated.

Make sure you sit in the

middle of the seat. Also, make sure the wire is connected

to the seat switch,

3

a

Before you start the engine, make sure the centre! lever is in

the DISENGAGE

2,

with

speed,

pedal.

the shift

After you mow a short distance,

See the location

or mow

B°

9

BLADE

settings°

grass

in the slowest

release the clutch/brake

ENGAGE

forward,

7°

go faster or slower,

position

HOW TO USE THE

CONTROL

position°

Move the throttle

Move

the blade

lever

When

housing

in high or thick

first and then lower

3.

4°

NOTE:

housing and back to raise the mower

housing. The cutting height

the engine_

the mower

the

Push the

of the lever

Move the lift Iever to a height of cut position,

maximum

increase

To change the cutting height, raise or lower the lift lever

on top

Start

grass, cut the grass in the high position

speed of the engine

HOW

1

2+

Before

controI

lever to the DISENGAGE

or a road,

move

the

position,,

WARNING: Always keep your hands and feet

away from the blade, deflector opening, and the

mower housing when the engine runs,

HOW

TO TRANSPORT

To transport

the unit, follow

1.

the

Move

blade

14

the steps

2+

Do not stop or change

parking

3+

to the

DISENGAGE

Raise the lift lever to the HI position.

3,,

Move the throttle

and FAST

4

To go faster,

control

move the shift

to

a position

4+

between

lever to a faster

SLOW

5

23

settings

on a hill

If you must

ke pedal forward

and set the

brake,

speed,

Slowly

the pedal

If you must stop or eta rt on a hill. always

you release

have enough

the brake

space

and engage

Be very careful when you change directions

on a hill, When

on a slope or in a turn on a hilt, move the throttle control to the

SLOW

F-91726

speed

push the clutch/bra

for the unit to roll when

the clutch.

speed

lever to the

To start again, make sure the shift lever is the slowest

Move the throttle

control

to the SLOW position,

release

position.

2

a hill, move the shift

speed.

stop, quickly

below,

control

Before you ride up or down

slowest

THE UNIT

engagement

ON HILLS

WARNING: Do not ride up or down slopes that

are too steep to back straight up. Never ride the