Download Craftsman 351.226711 Owner`s manual

Transcript

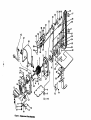

SAVE THIS MANUAL FOR FUTURE REFERENCE OWNER'S MANUAL MODEL NO. 351.226711 .A/P /CRR FTSMRN l"x 6" BELT & DISC SANDER CAUTION: READ ALL INSTRUCTIONS CAREFULLY! • • • • Sold by SEARS, ROEBUCK Part NO. 3899.00 safety Instructions assembly operating instructions replacement parts AND CO., Chicago, IL 60684 U.S.A. © May 1991 FULL ONE YEAR WARRANTY ON SEARS/CRAFTSMAN 1" x 6" BELT & 015C SANDER If Within one full year tom the date of purchase, this Sset_ Cmfleman 1" x 6" Belt & Dlso Sender fells due to e defect in material or wodunanchlp, Seam will repair It, free of r,hafge, WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS STORE OR SERVICE CENTER THROUGHOUT THE UNITED STATES. This warranty glvm; you specific legal rights, and you my have other rigMs which vary from elate to stats. BEARS, ROEBUCK AND CO., DEPT. 690/'731A SEARS TOWER, CHICAGO, GENERAL SAFETY INSTRUCTIONS BEFORE ANY WORK IS DONE READ THE CAUTIONS LISTED BELOW CAREFULLY. WORKING SAFELY PREVENTS ACCIDENTS. e. f, OPERATOR SHOULD BE PREPARED FOR JOB: g. n. b. c. d. Wear proper IpporeL Do not wear loose clothing, gloves, neolclles, dngs, mcelsts or other Jewelry which may get ,-,ught In moving parts el machine. Wear proteoth_ halr layering to contalnlong hair. Wear safety shoes with nOn-slip soles. Wear ealeW glasses. Everyday glasses have only impact mldstant lenses. They am not safety glass- h, IL 60684 FOR POWER TOOLS Keep ell guards In place end In working order. Keep ell parts In woddng order. Check to determine that the guard or other parts will opamte propedy end perform their intended fun_on, Check for damaged parts. Check for allgnment of moving parts, blndlng of moving parts, breakage of parts, mountlng and any other cond#lon that nay efle¢l a tool's operation. A guard or other pert that [11damaged should be properly repaked or replaced. Do not perform makashitt repairs. (Use the part8 list providedto order replasament parts.) as. e. f. OPERATOR SHOULD KNOW HOW TO USE TOOL: Wear face mask or dust masklf sanding oberstlon is dusty. Be alert and Udnk olemty. Never operate power tools when tired, Immdcm_ or when taking medIsatlons that cause drown. e. signed, b. WORK AREA SHOULD BE READY FOR JOB: S. =. o, d. f. g. 0. Keep work area clean. CkJ_.ered work areas and workbem:he: _ ecclder_. Do nOt use POWer tools In d-ngeroua em4ronmenta. Do n_ use power tools In damp or wet kxmtlona. Do not e:q)oea power toofe to rain. Work am Ihould be ixofxmly llgMed. Proper olectrlccl outlet should be available for tool Three-prong plug should be plugged directly Intoprope_f grOUnded,lhrea-p_g e. d. e. re_p_e. g, Extenefon cords should have • grounding prong end tha throe wlnm of the e_enelon oord should be the correc_ gauge, Keep vlaimre • safe distance from work area. Keep children out of workplace. Make workshop chlM-proof. Use padlocks, master switches and remove starter keyl to prevent any unintanlJonal h. I. J. TOOL SHOULD BE MAINTAINED: c. d. Olsconneot tool when changing ecceseerlal, such es belt, disc, miter gauge and the like. Avoid accidental start-up. Make sure that the machine Is In the *off" posItion before plugging In. DO nOt force • tool, K we11 work most affldently at the rata for whlch It was designed. Usa rscommended eok-easorlea. Refer to page 1 t. Use of improper e_sorles may cause risk of Inlmyto persons. I. useofpo_r ton_. a. b. Use right tool for the Job. Do not force tool or attachment to do • Job for whk_.hIt was n_ de- k. Alvmys unplug power tool prior to Inspection. Consult owner'a manual for specific maintaining end adjusting procedures. Uae clean born end keep me tool clean for safest operation. Remove adjusting keys end wrenches. Form I'mblt Of checking to see that keys and adjusting wrenches ere removed before turning tool on. I. m. -2- Handle the workplece Oorreotly. Use alter gauge when requlred. Protect hands from passlMe Injury. Dlreotlon of feed. Feed work Into • bar or dlso against dlro_lon of rotation of the ben or dlso. Turn the ma¢hlne off If It Jams. Disconnect plug from power _uroe before servicing tool. Never leave • too4 running unattended. Turn the power offend do not leave sander until it comes to e complete atop. Do not overreach. Keep proper footing and Imlanoe. Never stead on tool. Serious Injury oould occur If tool Is Upped or If abraslve belt or dlsc Is unlntentlonally contacted, Keep hands away from moving parts and earKllng surfaces, Know your power tool. team its operation, applk:ation end specific limitations. CONTENTS Wmmmty ................................ Goal 8eloty Immmotkme for Power Tcolo ...................... Salety InIWmotlene for Bolt & Disc Sender ................. Motor Speclfk:atlone end Ei$Ctlrlsal Requirements ............ Eieotrk:al ConnecUone .................. a Unpaeldng end Checking Contents ........... TOOLSNeeded ............................ 8 $ 2 As_mb_ ............................... s Operetlon ............................... Malntermr_e .......................... Trouble Shooting ......................... RepMcament Perta Illustration .............. Roplasement Parts Usl ................... S 4 4 &S 0 0 &0 9 10 11 WARNING LABEL The bolt and d_ sander has beam marked with • warning lehegma_ seeds to be obs_ved for esfe operafloe, The operator should be aware of the locatlon end contents of this label. SAFETY INSTRUCTIONS WARNING: 1. This wemlng label Is placed In • speclflc looatlon so It Is vislble to the operator when stanlng and operating the belt and disc sander. FOR l"x 6" BELT & DISC SANDER IX) NOT ATI"EMPT TO OPERATE BELT & DISC SANDER UNTIL IT IS COMPLETELY ASSEMBLED ACCORDING TO THE INSTRUCTIONS. Know general power toot sefety. Make sum all precautlorm am understood end provided to( Loa0o z). 2. Secure aU Motener$. FmquenW check that nuts and bo_,4are tight and heve not viaroted Iocoe. 3. _et_mdlonlnwuotl_e. Operate me be_ Be eure motor rum €lockwise on dllm side. Abrasiveb_ mu,,t_1 down. 5. Perform dhm eandlng on down ekle (right side). The dl_ should p_l work towards the table. 6. Do not forse work. Slowing or stallIng the motor wUloverhset 8. DO not overlmot work. Move metal across the abmslve end (:xx_ Itwhen It becomes hot. 9. DO not wet grind or polish. Never use a steady stream of water on the wodq_eca. Only quench the wod(pleca in water to cool It. 11. Koep sender maintained. Instructions" (Page 9). 12. Dleconneot IX:.wor. Tum swRch off and disconnec_ power whenever sender Is not In use. Follow "Maintenance Be certain to follow proper operating proeedursa decpfle familiarity gelned from frequent uso of your lea end disc sander. Always remember that beklg careleec for even m fraotlon of • second IS sufll_ent time to Inflict severe InJu_,. The operation of any power tool can result in foreign being thrown into the eyes, whloh can result In e(wom eys damage. Always wear safety goggles complying with ANSI Z87.t (shOwn on package) before commencing power tool operation. Safety goggles am available at Sears ro_H or cetslog _ores, Support worlq:lece. Use baelmop or work _t_. The backstop forthe abrssJve _ is the bell platen (Key No. 25) as described In "Oper-sflng Instructions" (page 7), 7. Do not grind or polish magnesium, k could catch on fire. CAUTION: end dis(: sander eel deserl1>ed In this manual (r.,0es 6 through 8), 4, 10. THINK SAFETY: Safety is • combination Of operator common sense and alertness st ell times when the belt & disc sander is being used. --3- MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS PROPERLY GROUNDED MOTOR The belt and disc lander Is mmembled with motor 8nd wiringreadied ,., an _eTal i_t of the tool The 120 Volt AC permanent epla €_q_c_ motor has the renewingqx_ncatk_: M_ Devek¢_ Horsepower ................ 1/t Voltage .................................. Amperes .................... 120 3 ............... Phase ................................ RPM ................................... Rotation (viewed from left side) ......... This tOOl Is Intended for use on clrcult having e nominal mtlng lee8 than 150 volts whl, ',hhss an outlot that looks like the one ll=ed above. Single 34S0 Clockwise A temporary adapter, which looks like outlet lilustr_ed below, may be used to connect this plug to 8 two-pole recalXa_le If a propedy grounded outlet IS not avdable. The temporary adapter _lould be used only untl a pmpedy grounded outlet can be Installed by 8 qua,fled eleofrldan. POWER SOURCE CAUTION: 1. 2. 3. 4, Do not _nneot the heft and dlso sender to the power source until ,,11ummmly steps hsve been completed. The motor b designed for operatton on the voftage and frequor_y spodfled on motor nsmel_te. Normal loads wll be hendled safeb/on vdtages nof more than 10% el)ova or below nameplate voltage. Running the unlt on vo#ages whleh 8re not within range may cause overhaadng and motor bum-out. Heavy loads require thst voltage lit motor termlr.ds be not less than voltage specified on The green colored groundlng luo extending from the edalXer must be connected to a permanent Qfound such its 8 properly grounded outlet box. Mslm sine _IN_w Is nameplate. GROUNDING INSTRUCTIONS This tool Io equipped v/_th 8 _€onduc_o_ (x)rd end 7ot_J t_e pl_ w_dd_hee e gu_ncJ_g jx_O 8pprovedby Unden_ere Labondodu end theCanadian Standarda A_lodmUon. Do not remove or _er the grounding prong in any sel ¢ummt to reduce the rbk of electrical shock. NOTE: The adapter llu_nded IS for use only If you 81rcady have • properly grounded 2-Wong ru=epmde. ,,_la_er IS not ellowed In Cshada by the Canadian Eleotrlcal Code. EXTENSION CORD8 The plug mu= be plugged Into e mmddng ouUetth= 1. mmrmer. In.the m_nt of 8 _ o4"Ixmlkclown. 7oond_g IXovldese peth ofIse= rudmmca forqdoc_ • prop_ _ The use of amy e_enslon cord wRI cause some drop In the voltage end Io_ of power. 2. Wires of extension cord must be sufficient In idze to carry current and malnlaln 8dequste voltage, 3. Use the tame belowto determlne the minlmum wlre she (A.W.G.) extension cord. 4. Use only 3-wire extension cords whlcl_ haw 3prong grounding type plugs and 3-po_e receptacles which accept the tool plug. S. ff power €ord b worn, cut or damaged In any why, have It mpk_ced Immediately. Extonslon oon:l length Wlre Slze A.W.G. Upto 100 ft................................. 16 NOTE: Using extension cords over 100 ft. long b no_ recommended. WARNING: DO NOT PERMIT FINGERS TO TOUCH THE TERMINALS OF PLUG (= WHEN IN$TALUNG OR REMOVING THE PLUG TO OR FROM OUTLET. and70undod_ ===xde,x_w=h nglocal €odes amdordlrmno_ Do nof modifyme plug ixovlded,ff = v41 not _ In me o_let, hero the proper outlet _ by a qualH_l electtfcbR Improper OOnnectlonOf _.g_)undIng conductor can re_JIt In a risk of dectrkmJ ohock. The ¢ondu(_x wlh Insu_tlon having an outer surface whichb omen 18the equipmentgroundingconductor. If repair or re_(_mlent of the e/octlrk_ cord or i_ug IS _, rnako m the equipment g_ndlng c,onductor 18no( connected to a line terminal. WARNING: CHECK WITH A QUALIFIED ELECTRIClAN OR SERVICE PERSONNEL IF THE GROUNDING INSTRUCTIONS ARE NOT UNDERSTOOD OR IF IN DOUBT A8 TO WHETHER TOOL I$ PROPERLY GROUNDED. --4-- ELECTRICAL CONNECTIONS WARNING: MAKE 8URE THE UNIT 18 OFF AND DISCONNECTED FROM THE POWER 8OURCE BEFORE IN8PECTING ANY WIRING. •r_ motor wxl wlrl_ m k_mlled u _ _ U_ wr_ dk_ram(m F_re 1). The motor Is auen_ed with an apflrowd thnm oo_ ductor €old to be used on 120 volts u Indk:ated. The power su_ to the motor Is con(rolled by a double pole lockingrocker swltc_ Remove the key to prevent unauthorized use. The power flmm are Inse_ed dlmc_ly Into the swltch. WHIT£ The green ground line must remaln securely fa_ened Figure 1 to theframeto propedypro(ectagOrOt eleGmcdshodc UNPACKING C_k _ _)r_ AND CHECKING CONTENTS damsel Udam0e_ o_md a claim shoukl bo reed with tho carrktrfor fa_ action. Pane wh_ head to be futenod to the u_ _JId be kx_ed andm:_ounted for (m Figure2). A. Lower b_t guard B. Kltobs. 4 linch - 2 ellCh for idlachlng the belt guard and 2 each for stlachlng-tnmnlonsto diSCtabSe bracket C. Be_ tab4e D, Belt guard E. DI_ Tal_e F, Flatwa_r, 6116",2 each G, TablesupportIxao_ H. Wo_p HeK wmnc_ m_€_ C (3, 4 and 8ram) m idilo locsted In the see"Too_Nea_d." UnpJnted a_l sudac_ have been ooa_d v,_h a weoorv_ve.Removethe _ keroeamor penetmm: oa. w_ I_o_r'o 2 Usesoapand wa_r on rubl_ and pl_tl_ l_t_ CleanIng fluide tend to _ TOOLS NEEDED Non-flamn_ble solvente are recommended. Whle _,,Ttll,g or edJuC_g your _ & disc sander you wig need t_e fol_w]ng tools: 1. O. 10and 12mmWrencll 2. 3, 4 and 8ram Hex Wrenches (supplied) 3. CombinationSquare 4, PhElps S_ev_lriver -5- ASSEMBLY CAUTION: Lift the disc table so both tn.lnnions are shoulderod agelnst the guide pips and tighten the knobs. Position dtsc table so the edge of disc table end abrasive disc are parallel and the gap between them Is 1/16'. DO NOT A'rFEMPT ASSEMBLY IF PARTS ARE MISSING. USE OWNER'S MANUAL TO ORDER REPLACEMENT PARTS. FASTEN THE DISC TABLE BRACKET Refer to Figure S. The table support breckt Tlghten the hex bolts seoure_y. (Key No, 15) Is _lached to theleft hand endshleld(Key No. 5) withtwo he_ bolta FASTEN THE BELT GUARD and flatwashers (Key NOL 46 & 64'), Pos_lon the bracket and thread the bolts with washers The t_t through the blacker andlnto endshleld. the lapped I_ee guard (Key No. 28) is attached to the belt housing(KeyN_ 20) wth theOusrd_ 26) _._dtwokrx_ (KeyNO.17). In the (KeyNO. T_e. thegua_eurgo_ _o thetap_ ho_ Inthe T_tan the boassammy. hotmlng. PoeJtlonthe belt gua,d erd laslen t by t_,wlng twoknobe(KeyNO.t'r) _o_e ALIGN THE DISC TABLE The table IS mlamhad to the tmnnlons wlth 2 hax bolts and matwashem (Key NOL 65 & $'r). Loo_n the bolta so the _ can be allgned. Posltlon the disc table and move the trunnlons Into place over the gulde plne (Key NO. 18). Insart the knot,s wlth flatwwdle_ through the trunnlons and thread them Into the disc table I:xsc,keL the gu_d ATTACH THE BELT TABLE The belt table t)recket (Key No. 39) Is a=ttached to the belt table. The table and bmcke_ rare fMtaqed to the frame wlth the socket hal_ bo_tsnd flatwasher (Key Nos. 52 & 54). The t_t table Is angled snd poslloned 1116"away from thebeitatthe same tlmo. OPERATING INSTRUCTIONS SAFETY PRECAUTIONS WARNING: For opilmum pedomlance do not stall motor or reduce belt speed. Do not force the work Into the abrulve. ALWAYS OBSERVE THE FOLLOWING SAFETY PRECAUTIONS. Never push a sharp corner of the workpisce mpldly agalnst the belt Or dlsc. The abn_ive may tear. Replace a=br, uivee when they become loaded (glazed) or freyed. Whenever acl_ust_ or replacif_ any l_rts On the sander turn sw#ch OFF and remove the plug from j:_.ver Iourcoo When gdndlng metal move the workplece acro_ abrasive to prevent heat build up. Recheck table locking nu_s and bolts. They must be tightened secur_y. the Never attempt wet cunlng, If the workplece becomes too hot to handle, cool It In cold water. Make sure all guards are properly attae,hed. All guards should be fastenedeecumly. Nwsys weer eye prote_-,tlonor faoe shleld. Make sure all moving I_rts are free and dear ol any Interference. W_h power disconnected, test operation by hand for deamnce and adjust if necessary. Make sure abrasive belt alwaystracksprope_. Correct tracking gives optimum pedormance. /_ter turning switch on, alw=ys allow the belt to come up to full speed before sanding or grinding. Keep your hands dear of abrasive belt, disc and all movlno partL -8-- OPERATING INSTRUCTIONS (Continued) TENSIONING ABRASIVE BELT ADJUSTING BELT TABLE ANGLE Tension ks created by a spring loaded Cam shaft (Key TO adjust the angle of the belt tal_e, loosen the socket head bolt (Key NO` S2) and adJuetto d'm desired angle. Uee a combination square to set the belt table at 45" or i_"_ the abm_ve be_ No.32). Tho tracking whoel IS mounted tho shall on tim oppose side of The spring tenskm Is tmnsml_ed to tho trecldng wheal (Key NO_31) end maintains the ter.don on ben. Adjust for 1116" cleanince between the _ table. REPLACING ABRASIVE BELT Remove I_t No. 38) by removing socket When the beA table IS id the dealred ang_o, Iockt into pcaltk)n by eaoumly tJgr4enlng the socket heed bolt. ABRASIVE BELT FINISHING table _W _ed bon0_y No.r,2). The abras_ end the bait ash be uead to eand wood, debu_ rceud, orpd_ pW.o endCe_ Remove the her Otaud (Key No. 28) by removing thumb The belt le moa efficient whec uead with the table. Tho I" ben _ Is _for getting Into comem and k_0e (Kw Noot7). Rceacatheten¢o,on_M I:_ by puer_U_ _n_en hmSo (KeyN= a7) fonwd (_mn_ open.x). Remove_t Jnx. U_o_ w_d (KeyNo.3_). ooncavecurvededge_ ADJUSTING BELT PLATEN Releasetensionhandle and removebelt from sander. The 8t:,ud_ t_ has _n 8now printed on the Inskle Operallng with the belt platen In place wll altow Ihe operator to rand or grindszralghteven tines. which Jndlcetea tho dlreO_en of ravel The'platen ahould be adjusted so the belt does no( ride on the platen unll wod( ksfed Into the 10elt To adjustbelt platen, loosen two each 1/4 - 20 x 1/2" box head Iodte (Key No. SS) 8nd adjust TIgMon bob securely, The errow ehoUld polm down toward the bait table to ensure that tho 8pllGe Jntho bell wB not come epert. Pull on tension handJo to Insudl abrmdve belt. PIs_ the etxaslvo belt equsrely on tho whee_ Tho 8lxing ac_on wl tonsJen tho I:e#. Make sure me b_ b tracldng correo_. /_Ju_ the ._ing u .ecaseary. When the tit ISUaeldng wopedy Itrklea on the oer_er d each wheel Replacethe ben guard and beattable. TRACKING ABRASIVE Rguro 3 Toet the trecklng. Plug In power c_)rd. Turn sw#ch ON and_rned','te/OFF. POLISHING AND CONTOUR SANDING Iftho 8brsslve bolt did no( move to tho right or left. t ks tmoklng properly. If the belt moved to the dgh( or IMt, adjustment Is Remove platon (Key No. 25) by removing hex head bolts and washers (Key No_ 5_ & 57). The belt Is fle0dble(no dgld back) and ksable to follow the contour of ouwed partL necessary. To adjust the vacklng wheel loosen the lecknut (Key Move the workpleca 8gsleat be_t.The be_ wnlfollow the No.SS). contour(seeRguro 3), Use 8 4mm hex w_enoh to tLml the tracking adJuslrJng SHARPENING If the al_aMve bait move,_ to the left. turn the adjusting bolt countercleckwlea. Adjust belt tablo to the de_dred _-uarpe_lng angle and tlghten secu_ly. Use the belt sander to notch the back of an eu_llae/pleca of wood. Lockme po_k)n when the balt ksuack_ngpmpedy so Using a _. attach the auxlflary plece of wood to the tame. It acts as a support while 8harponing (sec the bell wB remaln centered en the wheels. F_wo 4). I-.Ioldthe pcal_on of the tracking edJuedmerd eorew with the 4ram hex wrench, Use a 8ram wre_ch to tighten Io¢,knuZto lock posltl_ Top edge of tho wood should be approximately _/_' Imm atxsslve -7- be_ OPERATING INSTRUCTIONS (Contlnued) _0o, abrasiveused can be changedtOa dlffarentgrit ro_acgnothe aJum_num €.8C. Addltlonslaluminumdlace are avsHable,Use I separate elumlnumdlsofor _ch gritslze used. Interal_nge the ilun_num dlscto el_nge _ size. Refll_e dlse table. ADJUSTING DISC TABLE ANGLE dll_ tal_e 18IKllUllllll01o from 45" to gO* for beveled work. To adjust the dlso table, Iooeen the two knobe and adJuu to the dselmd angle. When dleo table Is IR dulmd m_ie, lock II Into p(JUon bym_.r_y _e_n_ mekno_ ABRASIVE DISC FINISHING Figure 4 dlso sandingb well eultadfor finishingsmall HORrTONTAL BELT SANDING fist eurfacee encl conve0( curvad adges. 11_ belt houa_ _n be tired to a ho_zo_l pa_ Removethe belttabfaby mmovlngthe amcka headbolt Movethewodq:_ _ and_t wMher (KWNOL62 & S4). elxaslvedls_produces almostno sbnmlve e<:_Ion atthecen_er. Loo_m the socker hind bdt (Key No. 62); tlt lhe belt hou_g tothehortzor_poe_n, and_en e_head bait to =meumthe po_lon. TI_ drlvo wh_ of the b_t oan be u_l for _cllng _ sudac_ me ckMn_de (rloht)ofthe faceofthe abrulve dlso. me eoGk. The abraslve dlsc moves fastest and rernov_ more martial as _lta_ at the outor edge. If v_ Is fed withoul addltlonal ou_danca, more materl_l wlll be removad towarcls the ou_" adge of the disc. A wodaltop (Key No. 66) Is provlded to be uaad when stndgr,=ndV_ _ the hodzorsdpm_k_ For accuracy use the rnler gauge, Attach the workaop to me belt housing with ==¢ket head be. and wuher (K_/Noe, S2 & S4). USING THE Mrl'ER GAUGE (SeeRecommended Accessod_ page11.) Use a _ornblnstlon square to adjust the workstop at g0" to _ _ with a 1/16" gap between the belt and worl_op; The miter gauga Is used oNy on the disc tabSe,Use the mlter gauge for secudng work and haidlng the proper anglewhlledlsc _andln_ NOTE: For stabllity,mount the belt and dbc sander to the bendl top. Adjust the .angle by _g and locking It Into place washer. REPLACING THE ABRASIVE DISC Remove disc tab_ the relier gauge scale with thuml_¢rew and fiat- Remove aid 8braslve disc by peellng It from slumlnum dis(;. Removing 81umlnumdisc trom motor 8hall Is not necessary. Check the accuracy o_ the miter gauge scale. Use ii comblnatlorl square to adjust the miter gauge square to the face o( the dlsc. Clean aluminum dlsc If necee,ga_, Select the proper abrasive disc 8nd apply to aluminum clls_. Indlcator should be at zero. Loosen screw and reposllion Indlcator If necessary. MAINTENANCE WARNING: MAKE CERTAIN THAT UNIT IS DISCONNECTED FROM POWER SOURCE BEFORE AI"rEMPTING TO SERVICE OR REMOVE ANY COMPONENT. Keep the wheels dean. Dirt on wheels will ceuse poor tracking and belt sllppage. IMPORTANT: AFTER SANDING WOOD OR NONMETALLIC MATERIAL. ALWAYS CLEAN THE AREA OF SAWDUST BEFORE GRINDING METAL THE SPARKS COULD IGNITE THE DEBRIS AND CAUSE A FIRE. CLEANING Keep machine and workshop dean. Do nol aflow sewdust to accumu_te on belt and dtsc undm'. -8- MAINTENANCE LUBRICATION The shielded _ manomly IUl_ted further lubrlcelk)n, (Continued) Replace any damaged or mlsldng parts. Use the perte I_ to order parts. besdng_l In this sander are perlit the factory. They require no Any _lempt to repalr the motor may create e heze_ unless rel_r Is done by s qualified service technlclarL Repair service is available at your nearut Seers store. KEEP SANDER IN REPAIR If power cord Is worn, cut or damaged In any vmy, have , repaid _anmed_Cy, Replace worn abrasives when needed. TROUBLESHOOTING SYMPTOM M_orwlllnot Mint. POSSIBLE CAUOE(S) CORREC11VE ACTION 1. Low voltage. 2. Open ckcue, in motor or I. Che_,powMllnelurproperv_ 2. Inspeot Mleedoonne(:Uo_onmotorfor _lome _ Motto wm not etant; fusee or circuit breakers blow, looseor open€onnectk_ 1. Short drct,e In Une cord or r_u_ 2. Shah clrcull In motor or Io_e conne_k:m. 3, Inoorrecl fusse or dmult • breekors In powerllce. 1. Ir._pectnneoo_l Orplugfordamaged Insulation and shorted wlres. 2. Inoped all ieed ¢ormootiono on motor for k:xlo or sho_ed tormlr.ds or worn Ins_ on'w_ 3. Instail O:mot luses or c',mull brsekerL lie= Motor falls to develop lull power Loowsr IX_ of motor dram 1. Power I_ ovedceded with lights, appliances and other motom. rapidb/withdecre_e 2. Undendza In voltage M motor terminals). too long. 3. General ovedoad_g of power company's facaltles, 2. Ir_rease wire elze_ or reduce length 04 • wlrk_. 3. RiKNest a voltage d_eck fTOmthe power company. Motor overlheata. 1. MOtor ovedoedgd. 2. Ab"circulation through the motor restricted. 1. Reduce Iced on motor, 2. Clean out motor to provlde normal air drcuiatlon throt_h motor. Motor mils (resulting in blown fusn or tripped circuit). 1. Short c_cult In motor o_ loose connections. 2. Low voltagL 3. Incorrect fuses or drcult brukem In power line, 4. Motor ovedoaded. 1, Inspect connections In motor for loose or shorted termlrmle orwom Ineulatlon on lead wires. 2. Correct the low line voltage conditions. 3. Inst_ correct fuses or cimult breakers. wlre8 or ch'(_uils Machine slows down while opetatlng. Applylng too much pressure Abrasive belt tuna off lop wheeL No__c_ng proper_. P Reduce the load on the power line. 4, Reduce load on motor. Ease up on Ixusure. to workplace. _9- See Operating I_ "l"mcldn9 Abmelve Belt" section 42 65 50 4 I 3 62 S4 F_re S - F_:i_TW_ pam m_ REPLACEI NT KEY NO. 1 2 I I PART NO. DESCRIP'flON 3896.00 3897.00 Ro(o¢ Stzd_ 3896.00 38ge.00 3304.0O 330S.0O 3306.00 1603.00 3307.00 3308.00 330O.0O 3310.00 3311.0O 5 6 7 8 9 10 11 12 13 14 15 16 T7 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 Rutdxrfoot Disc _ _lt_ KEY NO, PART NO. 1 1 2 1 1 37 38 30 40 41 1 44 STD51100_ * dP10-24xS/16' Screw, pan head 6 4! _ STD5.0O_ _lO-_xlrZ'Scrow,pa.hoad STD5231_ : 5/16-18 x 1/2" Boltr hex 27 3329.00 333O.OO Z924.0O 1304.00 STD5110O; * 3334.00 331S.00 • /_lv_d 3316.00 3,317.00 Belt Iltousin_ _(6") .0o 3319.0o Ben_ 332O.OO _ DESCRIPTION QTY. Handle wjlmob Bolt table Bdl table bracket Switch with key #I0-24x 1/4" ScreWr I:Bnhud 1 1 1 I 1 3332.00 8TD50250_ • 114-20 x 5/16" Screw, set 33,2.oo _ STD522507 • 114-20x 3/4" Bolt, hex T_ Traddng whul cam sh_dt TraO_ng bracl_ 3325.0o 3327.1111 • • QI"_'. _scbcaclt 3313.00 3314.0O 3323.00 3324.00 3325,OO PARTS LIST 1 1 4 2 1 1 1 1 1 1 1 2 2 $ I 2 1 1 1 1 2 See Recommended Acoeasodes (below Standard handware item avalal_e locally. RECOMMENDED Sl 52 sOCl_t hood 333s.oo: ,m-24x3/4-so_d 1389.00 3/8-16 x 3Q4"Bolt, socket heel 1 1 53 54 3336.09 D 5/16-18 X 3/4" Screw, _ 8TD551337 * 3/r Washer, fiat 2 I 55 STOS2250E• II4-20 x 1/2"Bolt,box 4 58 57 58 59 60 61 62 63 64 65 STD04111Q STD55102E STD551111] STD04102E 1764.00 1902.00 1382,00 1474.00 STD551001 3337.00 1 6 4 I I I I I 4 1 es 67 68 69 70 •* ** * @10-24x 5/8" _ 333e.00 • " • " • * • • ' @10-24 Nut, hex 114"Washer, Ilat @10Washer, Io<:k 1/4"20 Nut, hex 10ram Rata/_ dng 1Gram Retalnlntj dng 3/8-16xl l/4"Bolt, sockethasd dll0 Washer, star 5/16" Washer, flax Motor shroud Work_op 8TD5410Ol * 5/16"-18 Nut, hex STD376004 * WIro nut 3339.00 Spacer 3193.00 _wer belt guard 3_.00 Owner's ManuaJ I 2 2 2 1 I Al_ays order by Part No_ not by Key No. Not shown ACCESSORIES The A¢oessedes aro cm'rent and we_ awillable at the time this monual was printed. ABRASWE BELTS 1" x 42" ABRASIVE DISCS 6' FINE ............................... 928409 MEDIUM......................... _928410 COARSE ........................ 9 28411 X-FINE ........................... _.28312 MEDIUM ........................ _928313 COARSE ....................... 9 29314 MITER GUAGE ........................... 924215 POWER TOOL HANDeOOK .......9 29117 BELT CLEANER .......................... 9 22744