Download Re-Verber-Ray LS Series Product Manual

Transcript

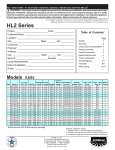

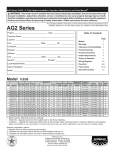

LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual* ! WARNING: This heater must be installed and serviced by trained gas installation and service personnel only! Improper installation, adjustment, alteration, service or maintenance can cause property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment. Protect yourself and others by observing all safety information. Retain instructions for future reference. LS Series * For complete installation instructions, see Generic IOM this piece was inserted within. Also available at www.reverberray.com. Project: ____________________________ Date: _________________ Location: _________________________________________________ City: ________________________ State: _______ Zip: ___________ Customer Name: ___________________________________________ Local Representative: ______________________________________ Contractor: _______________________________________________ Engineer: _________________________________________________ Address: __________________________________________________ City: _________________________ State: ________ Zip: ___________ Phone#: ___________________________ Install Date: ____________ Serial#: ___________________________________________________ Notes: ____________________________________________________ Commercial Models Model # LS 10-25 LS 10-30 LS 10-40 LS 15-40 LS 15-50 LS 20-40 LS 20-50 LS 30-50 (circle one) N or LP N or LP N or LP N or LP N or LP N or LP N or LP N or LP BTU's 25,000 30,000 40,000 40,000 50,000 40,000 50,000 50,000 Residential Models Length 12'-3" 12'-3" 12'-3" 17'-0" 17'-0" 22'-0" 22'-0" 31'-3" Model # LS 10-25 LS 10-30 LS 15-40 LS 20-40 LS 30-50 (circle one) N or LP N or LP N or LP N or LP N or LP Models 1 Warnings 2 Clearances to Combustibles 2 Product Summary 3 Mechanical Instructions 3 Heater Requirements 4 Theory of Operation 4 Wiring Diagrams 5-7 Flowchart 8-9 Parts Listing 10-11 Series Kit Contents 12 U-Tube Length N/A N/A N/A N/A N/A 13'-0" 13"-0" *17'-8" Weight 70# 70# 70# 85# 85# 100# 100# 120# Min. Mount Height 8 ft. 8 ft. 10 ft. 8 ft. 10 ft. 8 ft. 9 ft. 9 ft. Combustion Chamber Titanium Coated Titanium Coated Titanium Coated Titanium Coated Titanium Coated Titanium Coated Titanium Coated Titanium Coated Radiant Emitter "Type" Tube Pkg Baffle Tube #1 Pieces N/A 10-3 Titanium 3 N/A 10-3 Titanium 3 N/A 10-3 Titanium 3 Aluminized 15-3 Titanium 3 Aluminized 15-3 Titanium 3 Aluminized 20-3 Titanium 3 Aluminized 20-3 Titanium 3 Aluminized 30-3 Titanium 3 (Approved for both commercial and residential use) Gas Type Qty. Page (Approved for commercial use) Gas Type Qty. Table of Contents BTU's 25,000 30,000 15,000 40,000 50,000 U-Tube Length Length 12'-3" N/A 12'-3" N/A 17'-0" N/A 22'-0" 13'-0" 31'-3" *17'-8" Min. Mount Weight Height 70# 8 ft. 70# 8 ft. 85# 8 ft. 100# 8 ft. 120# 9ft. Combustion Chamber Titanium Coated Titanium Coated Titanium Coated Titanium Coated Titanium Coated *Model requires 5EA-Sub accessory package. Warranty registration options: 1. Register online at www.reverberray.com/warranty 2. Fill out this page and fax to Detroit Radiant Products Co. 3. Fill out this page and mail a copy to Detroit Radiant Products Co. Printed in U.S.A. © 2004 Detroit Radiant Products 21400 Hoover Rd., Warren, MI 48089 T. (586) 756-0950 F. (586) 756-2626 Form# LIOLS-1M-3/04 (LES) Replaces Form# LIOLS-2M-10/02 Radiant Emitter Tube N/A N/A Aluminized Aluminized Aluminized "Type" Tube Pkg #1 10-3 Titanium 10-3 Titanium 15-3 Titanium 20-3 Titanium 30-3 Titanium Baffle Pieces 3 3 3 3 3 LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual LS Series Warnings and Clearances to Combustibles ! WARNING! Only certain models are for residential use. Certified under American Gas Association (AGA) requirement for residential radaint tube heaters No. 7-89 Do not use in the home or sleeping quarters. ! WARNING! This heater must be installed and serviced by trained gas installation and service personnel only. Read and understand these instructions thoroughly before attempting to install, operate or service this heater. Failure to comply could result in personal injury, asphyxiation, death, fire, and/or property damage. Retain these instructions for future reference. WARNING! ! This is not an explosion-proof heater. Where there is the possibility of exposure to flammable vapors, consult the local fire marshal, the fire insurance carrier and other authorities for approval of the proposed installation. ! LS (10) - 25,30 W/1 side shield W/2 side shields 20 ft from burner LS (10,15,20) - 40 W/1 side shield W/2 side shields 20 ft from burner LS (15) - 50 W/1 side shield W/2 side shields 20 ft from burner LS (20,30) - 50 W/1 side shield W/2 side shields 20 ft from burner SIDE MOUNTING ANGLE FRONT BEHIND 0º 8 8 45º 39 8 0º 29 8 0º 9 9 0º NA NA 0º 15 15 45º 58 8 0º 42 8 0º 20 20 0º NA NA 0º 11 11 45º 39 8 0º 29 8 0º 16 16 0º NA NA 0º 11 11 45º 39 8 0º 29 8 0º 16 16 0º 7 7 TOP BELOW 4 10 4 4 NA 6 10 6 6 NA 6 10 6 6 NA 6 10 6 6 6 36 36 36 36 NA 45 45 45 45 NA 48 48 48 48 NA 48 48 48 48 30 *See cover page for models certified for residential use. SIDE SIDE FRONT BEHIND BELOW BELOW 0º MOUNTING ANGLE 0º W/1 SIDE SHIELD TOP TOP BEHIND FRONT WARNING! This heater should be installed so that the minimum clearances to vehicles, as marked on the heater, will be maintained. If vehicle lifts are present, ensure that these clearances will be maintained from the highest raised vehicle. TOP TOP WARNING! Failure to comply with the stated clearances to combustibles could result in personal injury, death and/or property damage. ! MODEL NO. WARNING! In locations used for the storage of combustible materials, signs must be posted to specify the maximum permissible stacking height to maintain the required clearances from the heater to the combustibles. Signs must either be posted adjacent to the heater thermostats or in the absence of such thermostats in a conspicuous location. ! LS CLEARANCES TO COMBUSTIBLES (IN.) * SIDE SIDE BELOW BELOW 45º MOUNTING ANGLE 0º W/2 SIDE SHIELDS 2 LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual LS Series Mechanical Instructions This supplement is designed to address the specifics of the LS Series - See page 12 for specific product features. Product Summary IMPORTANT LS Series commercial/residential tube heaters are available from 10 to 30 foot, 25,000 through 50,000 BTU’s, natural or LP gas. LS Series are positive pressure, single stage heaters and feature aluminized steel for it’s radiant pipes. LS MODELS APPROVED VENT PACKAGES 25,000 thru 50,000 BTUH 3-DSK RTVP-3 Figure 1 Specific Mechanical Instructions Be sure to identify the titanium combustion chamber and place as the first tube section. Do not use the aluminized steel radiant tubing as the first tube (combustion chamber). Radiant Tube For residential installations it is required that the appliance be vented. Venting must be 3 in. diameter (4 in. diameter for common venting). Refer to the flue venting guidelines, figure 1 and on page 19 of the General Manual. For residential installations mounted below 8 feet, it is required that Protective Guards (part # PG) are installed on heater (see figure 2). Reflector Protective Guard (part # PG) Figure 2 LS BAFFLE INSTRUCTIONS WITH TURBULATOR FINS Insert assembled baffles with HEAT Baffle preceeding the PRESSURE Baffles (fig. 1). Allow for turbulator fins so that the key hole is inserted first. All baffles must be placed vertically in the last radiant tube/heat exchanger (fig.2). Figure 1 HEAT BAFFLE 1st If the heater is installed with a U or Elbow fitting all baffle must still remain. There may be some instances where the baffle will be cut into two sections. Place as much baffle as possible downstream of the U or Elbow and the remainder of the baffle just before the U or Elbow fitting. Key Hole 2nd PRESSURE BAFFLE 3rd 3' BURNER BOX TOP VIEW Figure 2 IMPORTANT: NOTE FIN DIRECTION & BAFFLE ASSEMBLY 100º 80º Turbulator fins Key Hole LAST RADIANT TUBE HEAT BAFFLE PRESSURE BAFFLE END VIEW SIDE VIEW CROSS SECTION WITH BAFFLE Figure 3 3 LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual LS Series Theory of Operation Electrical Requirements ♦ 120 Volt - 60 HZ. ♦ Hot surface ignition. ♦ Starting Current 4.8 Amps. ♦ Running Current 1.1 Amps. ♦ 24V controls optional (24VAO). · Starting Circuit When voltage is applied to L1 and L2 (see diagram on right), a circuit is completed from L1 via the blower motor to L2. The blower fan is mounted in the control box and rated to supply sufficient air for combustion. Gas Requirements ♦ Manifold Pressure • Nat. 3.5’’ • LP. 10.0’’ ♦ Minimum Inlet Pressure • Nat. 5.0’’ • LP. 11.0’’ ♦ Maximum Inlet • Nat. 14.0’’ • LP. 14.0’’ Air pressure generated by the blower will cause the normally open burner pressure switch No. 1 to close. Another circuit is completed from L1 to the module ignition control and back to L2. There is a five second delay, then the glo-bar is powered. After the glo-bar has been powered for 45 seconds, the control module causes the gas valve to open and initiates the ignition trial. Ventilation Requirements ♦ Residential models must be vented. ♦ Consult the generic supplement for venting instructions and unvented operation. Power to the glo-bar is shut off during the last two or three seconds of the ignition trial. ♦ For unvented operation (commercial use only), there must be a positive air displacement of at least 4.0 CFM per 1000 BTU/H for natural gas or 4.5 CFM per 1000 BTU/H for LP gas. WVE-4 termination cap must also be used. · ♦ Maximum vent length for all models is 20 ft. Running Circuit After ignition, the flame rod monitors the flame. As long as a flame is present, the valve is held open. If the flame is lost, the control acts to close the valve within one second, and a new trial sequence identical to that at start-up is initiated. If proof of flame is not established within 8.5 seconds, the unit will lock out. If lockout occurs, the control can be reset by briefly interrupting the power source. Approved & Required Vent Caps Sidewall Single ♦ 3’’ Duravent sidewall vent kit (3-DSK). ♦ 3’’ Vent terminal (SWD-3). Sidewall Dual (Sharing common t-stat) ♦ 4’’ Duravent sidewall vent kit (4-DSK). ♦ 4’’ Vent terminal (SWD-4). Roof Single ♦ Approved 3’’ rooftop raincap (RTVP-3). Roof Dual (Sharing common t-stat) ♦ Approved 4’’ rooftop raincap (RTVP-4). Important: Do not use sidewall caps for roof venting and do not use roof caps for sidewall venting. 4 LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual Internal Wiring Diagrams LADDER DIAGRAM - MARK17DU-117 WITH THERMO L1 L2 120VAC BLOWER BK BK INDICATOR LIGHTS BK BK BK BK GAS VALVE BK BK THERMO SWITCH PRESSURE SWITCHES R BK O W BK W G GND NEUT VALVE NEUT TH LINE1 PROBE IGNITOR SIC1 W BR IGNITION MODULE IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, IT MUST BE REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE RATING OF AT LEAST 105 C. BLOCK DIAGRAM - MARK17DU-117 WITH THERMO BURNER TERMINAL BLOCK PRESSURE SWITCHES BK BK BK FLAME ROD IGNITOR BK BK THERMO SWITCH BK BK BK BK BR O INDICATOR LIGHTS BK L1 BK 120VAC BK L2 W W BLOWER W W M 1 C 2 P 3 M 1 C 2 P 3 MARK 17DU-117 W R GAS VALVE 5 IGNITION MODULE PROBE SIC1 LINE1 TH NEUT VALVE NEUT GND G LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual LS Series Field Wiring Diagrams G W R Common required for thermostats that require constant power. 24V HEATER BURNER BOX 24V WHITE L2 115V L1 TO HEATER BRANCH #1 BY OTHERS VIOLET WHITE 115V HEATER BURNER BOX TO HEATER BRANCH #2 BLACK NOTE: This Transformer Relay will handle up to 3 tube heaters per branch (6 tube heaters total) or up to 8 DR heaters per branch (16 DR heaters total) HEATER BURNER BOX NOTE: Brown and Yellow wires on the R8285 transformer relay are normally not used. POLE #2 POLE #1 R W W G Y B COIL C RED/YELLOW RED R 8285 Transformer Relay - Used in conjunction with any low voltage T-stat (i.e. XL411, T8600) when wiring tube heaters or line voltage DR heaters 24V T-Stat & Connection - Relay Tranformer Required FIELD WIRING INSTRUCTIONS HEATER BURNER BOX T-stat NOTE: Up to 4 line voltage tube heaters can be wired to most T-stats. Heaters on same vent must share the same t-stat. GRD NC HEATER BURNER BOX COM HEATER BURNER BOX L1 L2 120V Connection(s) FIELD WIRING FOR MULTIPLE LINE VOLTAGE HEATERS 6 L2 115V L1 LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual Alternative Wiring Diagrams MARK17DU-117 WITH THERMO TERMINAL BLOCK PRESSURE SWITCHES BK BURNER BK BK BK T-STAT TERMINAL BK BK BK 24V BK BR O BK BK FLAME ROD IGNITOR THERMO SWITCH INDICATOR LIGHTS L1 BK 120VAC BK L2 W W BLOWER W W M 1 C 2 P 3 M 1 C 2 P 3 MARK 17DU-117 W IGNITION MODULE R PROBE SIC1 LINE1 TH NEUT VALVE NEUT GND G GAS VALVE BLOCK DIAGRAM FOR INTERNAL RELAY OPTION THE INTERNAL RELAY ALLOWS FOR LOW VOLTAGE T-STAT OPERATION OF LINE VOLTAGE HEATERS COMMON REQUIRED FOR THEMOSTATS THAT REQUIRE CONSTANT POWER. N 24v N 24v N 24v COMMON C BURNER BOX WITH INTERNAL RELAY OPTION W R 24v DIGITAL T-STAT BURNER BOX WITH INTERNAL RELAY OPTION EXTERNAL TRANSFORMER 24V 120 V EXTERNAL TRANSFORMER IS NEEDED WHEN USING THE INTERNAL RELAY OPTION. A 40VA TRANSFORMER IS SUFFICIENT TO OPERATE 10 APPLIANCES L2 L1 FIELD WIRING FOR INTERNAL RELAY OPTION 7 BURNER BOX WITH INTERNAL RELAY OPTION 8 Does valve open? YES Does valve light come on? YES NO NO Remove obstruction & lubricate fan. Is the ignitor physically damaged? YES NO Correct problem. Replace valve. NO YES NO Temporarily place jumpers across the thermal fuse (be sure to reinstall the cover). Does the light energize? YES Replace thermal fuse. * Baffle(s) is in the tube(s) farthest from the burner. * Heater, fan blower, squirrel cage, intake and exhaust are clean and free from dirt and obstructions. * The 4” air intake pipe does not exceed 20 feet and/or 2 elbows. * There is not a negative pressure experienced at the area of air intake (i.e. attic space, high-winds, very tight building). Replace the appropriate switch after verifying the following: YES The heater is equipped with 2 safety pressure switches. The burner switch in the blower compartment is a normally open switch and the exhaust switch in the gas valve compartment is a normally closed switch. Temporarily place jumpers across the terminals of each switch, one at a time. (Be sure to reinstall the cover.) Does the light energize? NO Replace burned out light. The fan is faulty and must be replaced. Replace faulty light. Replace ignitor. NO Is resistance through the ignitor 45-400S. Repair wiring. YES The circuit board and/or wiring harness may be faulty and need to be replaced. Replace circuit board. NO Correct wiring. NO Is there 120V YES coming to the fan? Check for loose wiring or resistance in hose connection to pressure switch. Are they NO ok? NO Check voltage at ignitor during ignition sequence (usually 30-45 YES seconds after power to the heater). Is it 120V? Check to make sure pressure is within min. & max. inputs as indicated on AGA burner rating label. Are both ok? NO Does burner ignite at YES all? Replace ignitor. YES YES Is the blower obstructed? Is the inlet or the outlet of the unit obstructed NO (i.e. ice, birds nest, dirt)? YES Remove obstruction. NO Find the source of the electrical problem. Is the power at the heater 120V? NO Is the light burnt out? If so, replace. NO Does the ignitor warm NO up and glow red? YES Does the switch NO light energize? YES Does the fan turn on? Turn up thermostat LS Series Troubleshooting Flow Chart LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual 9 YES YES Test for 120V at valve during valve opening period (usually 30-45 NO seconds after power to the heater). Is there 120V to valve? NO NO Troubleshooting ends. The following can cause the heater to shut down: * Improper grounding. * High winds. * Taking combustion air from the attic. * Dirty environment. * Baffle not located properly. * Fluctuating gas pressure. NO YES WARNING: By-passing any pressure switch is for testing purposes only. Do not leave switch by-passed during normal operation or heater’s built-in safety mechanisms will be compromised. Sensing rod is faulty or flame is weak. Check to make sure heater is operating at proper gas pressure as indicated on AGA burner rating label and then replace sensing rod if needed. NO Check to make sure flame sensor wire is ok and then replace circuit board. YES With voltmeter, check DC voltage at flame rod. Is it greater than 30 Volts DC? Certain models have a separate glo-bar ignitor and flame rod sensor located next to the glo-bar. Other models have a glo-bar ignitor only, which acts as both an ignitor and flame sensor. Does model in question have glo-bar ignitor only? YES NO Consult factory for proper parts. Exhaust pressure switch may be faulty or there is a restriction in the exhaust. Correct problem. Correct problem. NO * Make sure gas lines were purged of air. Correct problem. Is the heater properly grounded? YES Is the heater’s polarity correct? NO Check to make sure that the pressure is within minimum and maximum inputs as indicated on the AGA burner rating label. Is gas pressure YES ok? YES Does the burner come on and then turn off immediately (1 or 2 seconds). NO Does the burner stay on for approx. 8 seconds and then shut off? Is the gas cock in YES an ON position? Check to make sure gas pressure is NO within minimum and maximum inputs, as indicated on AGA burner rating label. Is gas pressure ok? YES Replace gas valve. Correct problem. Possibly, the circuit board and/or wiring harness is faulty. These should be replaced. Check to make sure gas pressure is NO within minimum and maximum inputs, as indicated on AGA burner rating label. Is gas pressure ok? YES Does heater stay on until call for heat ends? YES Does the burner stay on? YES Does the burner ignite? YES After ignitor is warmed up, does gas NO valve open? YES LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual 328 70 10 333 329 334 44 264E 33B 122 351A 1064B 1002 264F 264D 31B 68A 352A 1063 1015 55A 76 212 83 208 223 209P 209 31B 330 1004 331 204 1060F 217 17 1062 1003 1033 1060D 1070 301 1 205 5 50 1080 1079 9 106 10 105 112 12 222A 20C 222 221 1078 11 1077 1081 mb Co n tio us 1086 be Tu rT itte Em 1082 e ub 1083 LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual Parts Breakdown LS Series TP# 11 ITEM CONTROL BOX COVER FLANGE GASKET CONDUIT COUPLING CONDUIT 4" X 1/2" GLO-BAR IGNITOR BOX GLO-BAR IGNITOR BOX COVER SIGHT GLASS KIT 120" ALUMINUM REFLECTOR CONTROL BOX BRACKET 1/2" GAS COCK AIR ORIFICE W/SCREEN - CONSULT FACTORY GLO-BAR IGNITOR FAN BLOWER (40, 50, 60 MBTU/H) STRAIN RELIEF BUSHING CONTROL BOX COVER GASKET (PER FOOT**) RUBBER GROMMET STAINLESS STEEL FLEX CONNECTOR REFLECTOR END CAP REFLECTOR CLIP 5' REFLECTOR GASKET FOR AIR ORIFICE & AIR COLLAR GAS ORIFICE - CONSULT FACTORY GLO-BAR HOLDER "Z" MOUNTING BRACKET 36E36A-246 GAS VALVE - NAT GAS ASSY 36E36A-240 GAS VALVE - LP GAS ASSY 1/2" X 3" PIPE NIPPLE PRESSURE BARB FITTING GLO-BAR HOLDER GASKET FLAME ROD FLAME ROD WIRE GAS MANIFOLD TP# TP-264D TP-264E TP-264F TP-301 TP-328 TP-329 TP-330 TP-331 TP-333 TP-334 TP-351A TP-352A TP-1002 TP-1003 TP-1004 TP-1015 TP-1033 TP-1060D TP-1060F TP-1064B TP-1062 TP-1063 TP-1070 TP-1077 TP-1078 TP-1079 TP-1080 TP-1081 TP-1082 TP-1083 TP-1086 ** 6’ TOTAL NEEDED TO COVER OUTER EDGES OF A BURNER BOX (TP-70). TP-1 TP-5 TP-9 TP-10 TP-11 TP-12 TP-17 TP-20C TP-31B TP-33B TP-44 TP-50 TP-55A TP-68A TP-70 TP-76 TP-83 TP-105 TP-106 TP-112 TP-122 TP-204 TP-205 TP-208 TP-209 TP-209P TP-212 TP-217 TP-221 TP-222 TP-222A TP-223 ITEM N.O. BURNER PRESS. SWITCH (30MBTU/H) N.O. BURNER PRESS. SWITCH (25MBTU/H) N.O. BURNER PRESS. SWITCH (40 MBTU/H) DIVIDER PANEL W/ P.S. MOUNTING TABS 120V INDICATOR LIGHT 1/4" NEUTRAL TERMINAL BLOCK DIVIDER GROMMET GREEN SELF TAP GROUND SCREW 3' BLACK 120V PLUG YELLOW 24V CONTROL WIRE MARK 17DU-117 POTTED CIRCUIT BOARD LONG WIRING HARNESS FOR 17DU-117 LEFT END PANEL W/ LIGHT HOLES RIGHT END PANELS - NO HOLES CONTROL BOX FAN BLOWER (25, 30 MBTU/H) THERMAL FUSE EXHAUST PRESS. SWITCH (25,30 MBTU/H) EXHAUST PRESS. SWITCH (40,50 MBTU/H) N.O. BURNER PRESS. SWITCH (50 MBTU/H) EXHAUST PRESSURE TUBE (VINYL) 1/4" ATMOSPHERIC & PRESSURE TUBES (VINYL) BURNER (25 TO 50 MBTU/H) TUBE CLAMP REFLECTOR CENTER SUPPORT WIRE HANGER W/ SPRING CLIP 16'' BURNER TUBE WITH FLANGE 10 FT. TITANIUM COMBUSTION TUBE 10 FT. STAINLESS RADIANT TUBE 3" S.S. INTERLOCKING 33" PRESSURE BAFFLE WITH TABS 3" S.S. INTERLOCKING 33" HEAT BAFFLE SECTION LS SERIES PARTS LISTING Basic Parts List LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual LS Series - 3” Tube Heater Installation, Operation, Maintenance and Parts Manual KIT CONTENTS AND PRODUCT FEATURES Kit contents for the LS Series are shown below. Reference the proper column for your particular models length. FILLED BY: LS SERIES KIT CONTENTS TP# DESCRIPTION 10 FOOT 15 FOOT 20 FOOT 30 FOOT TP-1077 TP-1079 TP-1078 TP-105 TP-106 TP-33B TP-83 3" TUBE CLAMPS 3" HANGERS 3" REFL. CNTR. SPRT. REFL. ENDCAPS REFL. ENDCAP CLIPS 1/2" GAS COCK 24" SS FLEX LINE 1 2 1 2 8 1 1 2 3 1 2 8 1 1 2 3 2 2 8 1 1 3 4 3 2 8 1 1 IOM INSTALL / OP MANUAL 1 1 1 1 3” Hanger TP-1079 3” Butt Clamp TP-1077 1/2” Gas Cock TP-33B Reflector End Caps TP- 105 3” Reflector Center Support TP-1078 24” SS Flex Connect TP-83 Bag of Reflector endcap clips TP-106 General IOM (LIOGT) AND Series Insert (LIOLS) Product Features APPROVALS • IAS, CGA, AGA, CSA. • Certain models are residentially certified to AGA No. 7-89. • Outdoor Approval with OD-KIT. BURNER SIGHT GLASS • For burner inspection. COMBUSTION AIR INLET & VENT • 4” air inlet duct. • 3” vent duct. ENAMELED CONTROL BOX • Outside air collar (4”) attached. • Totally enclosed components. EMMITER & COMBUSTION TUBES • 16ga. 3” O.D. titanium coated combustion chamber. • 16ga. 3” O.D. aluminized steel radiant tubes. OPTIONAL FEATURES • 24VAO - Used when operating heater with 24V thermostat. Includes internal relay, power cord and indicator lights. External transformer required. CONTROLS • 100% safety shut off. • Moisture and corrosion resistant GAS CONNECTION ignition module. • 1/2” gas cock included. • Dual differential pressure switches. • 24” x 1/2” flex connector included. • Silicon carbide hot surface igniter. • Flame rod sensing. • Pre-purge controls. • Indicator lights. 12 RADIANT SURFACE AREA (SQ. FT.) • 10’ models - 7.6 • 20’ models - 15.2 • 30’ models - 22.8 WARRANTY* • 1 year - Burner box components. • 3 years-Combustion and radiant tubes. • 5 years-Stainless steel burner. * See cover for warranty registration information. OTHER • One reflector center support per reflector. • Stainless steel turbulator baffle included. • Stainless steel upgrades (burner box and reflectors only) are available. • Silicone sealed control box available. • Made in U.S.A. • Visit www.reverberray.com for additional information & parts.