Download Briggs & Stratton 260700 Specifications

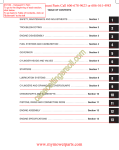

Transcript