Download FUEL SYSTEM - jholst.net

Transcript

FUEL SYSTEM—1

Group 14

FUEL SYSTEM

CONTENTS

F U E L PUMP

Paragraph

Page

F u e l P u m p Disassembly

Removal

Cleaning and Inspection

Assembly

7

5

Operation

5

4

Service Diagnosis

1

3

F u e l P u m p T e s t i n g (on Vehicle)

Pressure Test

V a c u u m Test

Volume Test

I n l e t V a l v e Test

6

4

(Fuel Pump)

BED S E R I E S C A R B U R E T O R S

A u t o m a t i c Choke - W e l l Type

19

15

Carburetor A d j u s t m e n t s

Accelerator P u m p

F a s t Idle A d j u s t m e n t

Choke Unloader ( W i d e Open K i c k )

Bowl Vent Valve Adjustment

Idle Speed A d j u s t m e n t { C u r b I d l e )

18

13

Carburetor

15

9

Cleaning C a r b u r e t o r

16

11

Inspection and Reassembly

Throttle Body

M a i n Body

Checking F l o a t S e t t i n g

Air Horn

17

11

8

7

14

9

Disassembly

Service Diagnosis

S e r v i c i n g the C a r b u r e t o r

AFB S E R I E S C A R B U R E T O R S

A u t o m a t i c Choke ( W e l l T y p e )

Carburetor Adjustments

Fast Idle Adjustment

Choke Unloader A d j u s t m e n t

Accelerator P u m p A d j u s t m e n t

Secondary T h r o t t l e Lever A d j u s t m e n t

Secondary T h r o t t l e L o c k - O u t A d j u s t m e n t

.

24

25

23

24

2 — FUEL SYSTEM

A F B S E R I E S CARBURETORS-Continued

CONTENTS—Continued

Paragraph

C a r b u r e t o r Assembly

M a i n and T h r o t t l e Body Casting

Accelerator P u m p Test

I n t a k e Check B a l l

Discharge Check Needle

A i r Horn-Assembly

F l o a t A l i g n m e n t Setting

F l o a t Level S e t t i n g

Float Drop Setting

~

Page

22

21

-

21

18

-

25

26

~-

20

18

26

28

Fuel Tank (Imperial)

Removal

Installation

27

29

F u e l T a n k ( T o w n and C o u n t r y )

Removal

Installation

28

30

A d j u s t i n g the A n t i - S t a l l Device

32

36

A d j u s t i n g the R a m M a n i f o l d

A F B 2903S Series C a r b u r e t o r

Idle Speed and M i x t u r e A d j u s t m e n t ( O n Vehicle)

Fast Idle Adjustment (On Vehicle)

I n d e x i n g the Choke Piston

33

36

29

32

30

34

31

35

A F B Carburetor — Disassembly

A i r H o r n — Disassembly

M a i n Body Disassembly

Cleaning and Inspection

-

I d l e Speed A d j u s t m e n t ( C u r b I d l e )

S e r v i c i n g the Carburetor

-

F U E L TANK

F u e l T a n k ( A l l Models Except T o w n and C o u n t r y

and I m p e r i a l )

Removal

Installation

RAM MANIFOLD

Ram Manifold -

Removal

Ram Manifold -

Installation

S e t t i n g the R a m M a n i f o l d T h r o t t l e L i n k a g e

P o s i t i o n i n g the Accelerator Shaft

P o s i t i o n i n g the Accelerator Pedal

- . -

FUEL SYSTEM —3

DATA AND SPECIFICATIONS

P

361 Cu. In. V-8

ENGINE

383 C u . I n . V-8

Make

-

Model

413 C u . I n . V Carter

-

M-2769S

Type

Diaphragm

N u m b e r o f Valves

Driven

By

3

.

Camshaft

P u m p Pressure (Pounds)

3% to 5

[FECIAL TOOLS

T109-43

Plug

C-3411.

Remover

Pressure Gauge

E DIAGNOSIS

1. FUEL PUMP LEAKS—FUEL

b. Leaks i n fuel line or

Possible Causes?

c.

a.

Loose housing screws,

c. Loose d i a p h r a g m m o u n t i n g plates.

e.

Frozen gas lines.

f.

I m p r o p e r l y seating valves.

g.

V a p o r lock.

h.

Weak m a i n spring.

i.

I n c o r r e c t fuel pump,

j.

Restricted fuel

fittings.

2. F U E L PUMP L E A K S — O I L

Possible Causes:

a.

D i r t or r e s t r i c t i o n i n fuel tank.

d. W o r n , r u p t u r e d , or t o r n diaphragm.

b. W o r n , r u p t u r e d or t o r n diaphragm,

d. Loose inlet or outlet line

fittings.

Cracked or deteriorated p u l l r o d oil seal.

filter.

b. Loose rocker a r m p i v o t p i n .

c. Loose p u m p m o u n t i n g bolts.

4. FUEL PUMP N O I S E

d. Defective pump t o block gasket.

Possible Causes:

3. I N S U F F I C I E N T F U E L D E L I V E R Y

a.

Loose m o u n t i n g bolts.

b.

Scored o r w o r n rocker a r m .

Possible Causes:

a. V e n t i n t a n k filler neck restricted.

also cause collapsed fuel t a n k . )

(This w i l l

c. W e a k or broken rocker a r m s p r i n g .

4 — FUEL SYSTEM

Group 14

FUEL SYSTEM

F U E L PUMP

F u e l p u m p Model M-2769S is used on a l l De Soto,

C h r y s l e r and I m p e r i a l engines. T h e service procedures f o r t e s t i n g , disassembly, overhaul, cleaning and

reassembly o f the fuel p u m p appears below.

5. OPERATION—FUEL PUMP

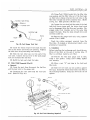

T h e fuel p u m p ( F i g . 1) is d r i v e n b y an eccentric

cam (cast i n t e g r a l w i t h the camshaft) t h r o u g h the

m e d i u m or a s h o r t push r o d .

A s the camshaft rotates, the eccentric cam presses

against the push r o d , f o r c i n g the p u m p rocker a r m

d o w n . T h i s a c t i o n l i f t s the p u l l r o d and d i a p h r a g m

u p w a r d s against the fuel p u m p m a i n s p r i n g , t h u s

c r e a t i n g a v a c u u m i n the valve housing, w h i c h opens

the i n l e t valves, f o r c i n g fuel i n t o the valve h o u s i n g

chamber. On the r e t u r n stroke, the m a i n s p r i n g

forces the d i a p h r a g m to the d o w n p o s i t i o n w h i c h

closes the i n l e t valves and expels the fuel i n the valve

h o u s i n g chamber, t h r o u g h the outlet valve to the fuel

filter and the c a r b u r e t o r .

t y and a l o w pressure r e a d i n g w i l l result.

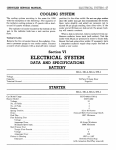

( 4 ) Connect a tachometer, t h e n s t a r t the engine

and r u n at 500 r . p . m . The r e a d i n g should be f r o m

3% t o 5 p.s.i. The pressure should r e m a i n constant

or r e t u r n to zero v e r y , v e r y slowly w h e n the engine

is stopped. A n i n s t a n t drop to zero indicates a leaky

outlet valve. I f the pressure is too low, a weak m a i n

s p r i n g or i m p r o p e r assembly of the d i a p h r a g m m a y

be the cause. I f the pressure is too h i g h , the m a i n

s p r i n g is too s t r o n g .

ROCKER ARM HOUSING

ROCKER ARM

FOLLOWER SPRING

T h e f u e l filter assembly should be changed every

10,000 miles, to i n s u r e h a v i n g a n u n r e s t r i c t e d flow

of fuel at a l l times. D O N O T A T T E M P T T O

CLEAN.

i.

— DIAPHRAGM

AND PULL ROD

ASSEMBLY

Mr

SCREW ASSEMBLY

TESTING FUEL PUMP—(On ¥ e M c l e )

I f the fuel p u m p f a i l s to s u p p l y fuel p r o p e r l y t o the

c a r b u r e t o r , the f o l l o w i n g tests should be made before

r e m o v i n g the fuel p u m p f r o m the vehicle.

VALVE-ASSEMBLY

(SERVICED ONLY

IN VALVE BODY)

VALVE B O D Y -

a. Pressure Test

SCREW ASSEMBLY

I f leakage is n o t apparent, test p u m p f o r pressure, as

follows :

(1) I n s e r t a "T" fitting i n t h e fuel line at

c a r b u r e t o r , as s h o w n i n F i g u r e 2.

the

•1

AIR DOME \

DIAPHRAGM

( 2 ) Connect a 6 i n c h piece o f hose between t h e

" T " fitting a n d gauge C-8411. ( T h e hose should n o t

exceed 6 inches. A longer hose m a y collect f u e l and

the a d d i t i o n a l w e i g h t w o u l d be added t o the pressure

of the p u m p and r e s u l t i n a n inaccurate r e a d i n g . )

( 3 ) V e n t t h e p u m p f o r a f e w seconds ( t h i s relieves a n y a i r t r a p p e d i n the f u e l c h a m b e r ) . I f t h i s

is n o t done, the p u m p w i l l n o t operate a t f u l l capaci-

-VALVE ASSEMBLY

(SERVICED ONLY

IN VALVE BODY)

-COVER

60x189

Fig.

1 - F u e l Pump M-2769S (Exploded V i e w )

FUEL

SYSTEM

—5

a. Removal

(1)

Remove the p i v o t p i n plug, u s i n g Tool T109-

43.

TACHOMETER

(ENGINE S P E E D )

6 INCH

MAXIMUM

( 2 ) Disengage t h e rocker a r m follower s p r i n g

f r o m the rocker a r m and the r o c k e r a r m housing.

( 3 ) T u r n t h e p u m p on i t s side ( p i v o t p i n hole

d o w n ) and t a p g e n t l y t o remove t h e p i v o t p i n .

( 4 ) Disengage t h e rocker a r m f r o m the diap h r a g m p u l l r o d , b y the s l i d i n g r o c k e r a r m o u t o f

the housing.

Fig. 2—Pressure Testing Fuel P u m p

b. Vacuum Test

The v a c u u m test should be made w i t h the fuel l i n e

disconnected f r o m the c a r b u r e t o r . ( T h i s w i l l a l l o w

the p u m p t o operate at f u l l capacity, w h i c h i t m u s t

do to p r i m e a d r y c a r b u r e t o r . )

The v a c u u m r e a d i n g should be at least 10" h.g.

v a c u u m at 500 r . p . m . w i t h the fuel line disconnected

at the c a r b u r e t o r .

( 5 ) Remove t h e screws a t t a c h i n g t h e valve body

to the r o c k e r a r m housing. Separate the valve body

and r o c k e r a r m h o u s i n g and l i f t out the d i a p h r a g m

and p u l l r o d assembly.

( 6 ) Remove t h e screws t h a t a t t a c h t h e valve body

to the valve h o u s i n g cover. Separate cover and valve

body and remove the outlet a i r dome d i a p h r a g m .

b. Cleaning and Inspection

( 1 ) Clean a l l fuel p u m p p a r t s (except d i a p h r a g m )

i n a suitable solvent, t h e n b l o w d r y w i t h compressed

air.

( 2 ) Check the condition of t h e valve seats and

p a r t s f o r g u m deposits.

c. Volume Test

The fuel p u m p should supply 1 q u a r t o f fuel i n 1

m i n u t e or less at 500 r . p . m .

d. Inlet Valve Test

To test the i n l e t valve, connect a v a c u u m gauge on

the i n l e t fitting w h i l e the line is disconnected.

( 3 ) I f g u m deposits are found, remove w i t h den a t u r e d alcohol.

( 4 ) I f t h e valves are badly w o r n or damaged, i n stall a complete new valve body assembly. T h e

valves are not serviced individually.

( 1 ) S t a r t t h e engine or t u r n over w i t h s t a r t i n g

motor.

( 5 ) Inspect t h e d i a p h r a g m f o r cracks, t o r n screw

holes or r u p t u r e s . Check the r u b b e r o i l seal on the

end o f the p u l l r o d f o r d e t e r i o r a t i o n .

( 2 ) There should be a noticeable v a c u u m present,

n o t a l t e r n a t e d b y blowback.

( 6 ) Inspect the o u t l e t a i r dome d i a p h r a g m f o r

cracks or d e t e r i o r a t i o n .

( 3 ) I f blowback is present, t h e i n l e t valves are

n o t seating p r o p e r l y and should be cleaned, o r a n e w

valve body installed.

( 7 ) Inspect t h e rocker a r m f o r scoring or g a l l i n g

on the camshaft or push r o d b e a r i n g surface.

c. Assembly (Fig. 1)

I f the fuel p u m p does not p e r f o r m to the above

test requirements, the fuel p u m p should be removed

f r o m the vehicle and reconditioned as f o l l o w s :

7. FUEL PUMP DISASSEMBLY (Fig, 1)

N O T E : Before disassembling the fuel pump, mark

the housings in such a manner that the "Inlet" will

be facing the inlet fuel line when reassembled. T h i s

is important!

(1)

the

Place t h e airdome d i a p h r a g m i n p o s i t i o n on

valve body

or

filter

housing

(depending

on

p u m p ) , w i t h i n l e t passage hole over passage.

( 2 ) A l i g n t h e scribe m a r k s on t h e cover ( o r filter

housing, depending on p u m p ) a n d the valve body,

t h e n i n s t a l l a t t a c h i n g screws. T i g h t e n securely.

( 3 ) Slide the d i a p h r a g m p u l l r o d up i n t o t h e

rocker a r m housing. Place the valve body i n posi-

6 — FUEL SYSTEM

t i o n on the d i a p h r a g m w i t h the scribe m a r k s aligned.

(Be sure the holes i n the d i a p h r a g m , rocker a r m

housing and valve bodies are aligned.) Compress the

u n i t together. T h e n i n s t a l l the a t t a c h i n g screws, b u t

do not t i g h t e n . N E V E R U S E S H E L L A C OR A N Y

OTHER ADHESIVE ON T H E DIAPHRAGM,

(4) Slide t h e rocker a r m i n t o t h e housing and

gage the d i a p h r a g m p u l l r o d . A l i g n the p i v o t

holes i n the a r m w i t h those i n the housing, t h e n

s t a l l p i v o t p i n . I n s t a l l new p l u g and d r i v e i n

curely.

enpin

inse-

(5) I n s t a l l t h e rocker a r m follower s p r i n g over

the tab on the rocker a r m and over the dimple i n the

housing.

(6) Engage t h e ends of t h e bowl r e t a i n i n g strap

i n the slots of the filter housing. T i l t the r e t a i n i n g

s t r a p to one side, f a r enough to i n s t a l l the ceramic

filter.

(7) I n s t a l l a new ceramic filter, s p r i n g and bowl.

Center the b o w l , then t i g h t e n the r e t a i n i n g screw

securely.

( 8 ) Place the pump i n a vise ( w i t h protector

j a w s ) and push on the rocker a r m u n t i l f u l l t r a v e l

is reached. H o l d i n t h i s position, w h i l e t i g h t e n i n g

the a t t a c h i n g screws. ( T h i s w i l l prevent t e a r i n g

of the d i a p h r a g m w h e n the p u m p is i n operation and

the p u m p a r m i n its f u l l stroke.)

(9)

Test t h e fuel p u m p as described previously.

BBD S E R I E S C A R B U R E T O R

DATA AND SPECIFICATIONS

CARBURETOR

Type

B a l l and B a l l D u a l T h r o a t

Model

BBD-2923S or BBD-2924S

BORE

-

VENTURI

-

MAIN METERING

1-9"16"

1-5/16"

JET

Standard

N o . 120-245S

No. 120-238S

One Size L e a n

N o . 120-248S

N o . 120-248S

Two

N o . 120-250S

N o . 120-250S

Sizes L e a n

ADJUSTMENTS

F l o a t S e t t i n g ( a t center o f f l o a t s )

Accelerator P u m p (top o f p l u n g e r to a i r h o r n )

Fast Idle

9/32"

1 - f or — 1/64"

1375 to 1425 r . p . m .

F a s t Idle S e t t i n g

Choke U n l o a d e r

.015"

( w i d e open k i c k )

I d l e M i x t u r e ( b o t h screws)

I d l e Speed ( c u r b i d l e )

( w i t h air conditioning)

Bowl Vent Valve Setting

1

/

4"

1 f u l l t u r n open ±

y

2

500 r . p . m .

575 r . p . m .

.060"

CHOKE

Type

Control

Setting

Well-Automatic

Thermostatic

Coil

On I n d e x

Spring

FUEL SYSTEM —7

SPECIAL TOOLS

T109-287S

E l e v a t i n g Legs ( 3 )

T109-288S

E l e v a t i n g Legs

T109-239

F l o a t Gauge ( 9 / 3 2 " )

) P a r t of T109-289U

(1)

T109-44

W i r e Gauge (.015" F a s t I d l e )

T109-22

B e n d i n g Tool

T109-31

Choke Unloader Gauge ( % " )

.060"

D r i l l (Bowl Vent Valve)

T109-213

B e n d i n g Tool

S E R V I C E DIAGNOSIS

8. POOH IDLING

v.

I n t a k e m a n i f o l d leak,

Possible Causes:

w . I n t e r n a l coolant leak.

a.

Incorrect a i r idle adjustment.

x.

L o w b o i l i n g p o i n t fuel ( w i n t e r fuel i n s u m m e r ) .

b.

Carbonized idle tube or poor seating shoulder.

y.

L o w grade fuel.

Co M a n i f o l d heat control valve stuck.

z. I n c o r r e c t valve t i m i n g .

d.

I d l e air bleed carbonized or o f incorrect size.

e.

Idle discharge holes plugged or gummed.

f. T h r o t t l e body

shaft.

carbonized

or

worn

throttle

g . A i r leak at m o u n t i n g between carburetor and

manifold.

h.

Damaged or w o r n idle needle.

i.

I n c o r r e c t fuel or float level.

j.

Choke does n o t completely open.

k. Loose m a i n body to t h r o t t l e body screws.

1.

9. POOR PERFORMANCE—MIXTURE TOO LEAN

Possible Causes:

a.

Damaged m a i n m e t e r i n g j e t .

b. Damaged t i p or bad top shoulder seat of m a i n

discharge j e t .

c.

V a c u u m p i s t o n w o r n o r stuck,

do Incorrect fuel or float level.

e.

A u t o m a t i c choke n o t operating properly.

f.

Incorrect fuel p u m p pressure.

Carburetor i c i n g .

m. D i s t r i b u t o r advance vacuum leak.

10. POOR PERFORMANCE—MIXTURE T O O RICH

n. Loose d i s t r i b u t o r base plate bearing.

Possible Causes:

o.

Corroded w i r e ends or d i s t r i b u t o r towers.

a.

p.

Incorrect d i s t r i b u t o r p o i n t gap.

b. Excessive fuel p u m p pressure.

q.

Fouled spark plugs.

c. H i g h float or fuel level.

r.

Incorrect ignition timing.

d. Damaged needle and seat.

s.

I n c o r r e c t spark p l u g gap.

e.

L e a k i n g float.

t.

Overheated spark plugs.

f.

Worn main metering jet.

u.

Compression n o t w i t h i n l i m i t s .

g.

S t i c k i n g choke.

Restricted a i r cleaner.

8 — FUEL SYSTEM

11. E X C E S S I V E FUEL CONSUMPTION

d.

W o r n needle valve and seat.

Possible Causes:

e.

L e a k i n g float.

f.

Excessive fuel p u m p pressure.

a.

Overloading ( p u l l i n g t r a i l e r s , etc.).

b.

I m p r o p e r rear axle r a t i o .

c. W r o n g speedometer pinion.

N O T E : Presence of fuel dye around carburetor gaskets does n o t necessarily denote a leak or a flooding

condition. T i g h t e n a i r h o r n a t t a c h i n g screws securely t o correct.

d.

Brakes d r a g g i n g .

e.

Detonation or pre-ignition.

f.

D r i v i n g at excessive speeds.

g.

L o w t i r e pressure.

h.

Short t r i p or heavy traffic d r i v i n g .

i.

D r i v i n g i n snow or m u d .

j.

D r i v i n g i n high winds.

k.

Unnecessary use o f accelerator.

c. F a u l t y acceleration p u m p discharge ball.

1.

S t i c k y choke.

d.

13.

POOR ACCELERATION

Possible Causes:

a. Step-up p i s t o n stuck i n down position (lean

m i x t u r e at wide open t h r o t t l e ) .

b. Accelerator p u m p piston (or p l u n g e r ) leather

too h a r d , w o r n or loose on stem.

Accelerator p u m p i n l e t check ball f a u l t y .

m. I n c o r r e c t i g n i t i o n t i m i n g .

e. Incorrect fuel o r float level.

n.

f.

W o r n accelerator p u m p and t h r o t t l e linkage.

o. H i g h fuel level i n carburetor.

g.

A u t o m a t i c choke n o t operating properly.

p.

Stuck m a n i f o l d heat c o n t r o l valve.

h.

Carburetor gummed up.

q.

Fouled spark plugs.

i.

F a u l t y coil.

r.

L o w engine compression.

j.

Loose d i s t r i b u t o r base plate bearing.

s.

W o r n camshaft lobes.

k.

D i s t r i b u t o r n o t advancing p r o p e r l y .

t.

S t i c k i n g valves.

1.

Incorrect ignition timing.

u.

E l e v a t i o n and atmospheric conditions.

m. I n c o r r e c t spark p l u g gap.

I n c o r r e c t d i s t r i b u t o r advance.

v. Restricted t a i l pipe or muffler causing exhaust

back pressure.

w. I n c o r r e c t valve t i m i n g .

12.

CARBURETOR FLOODS OR LEAKS

Possible Causes:

n.

Fouled spark plugs.

o. Overheated spark plugs.

p.

M a n i f o l d heat control valve stuck.

q.

L o w fuel pump pressure or vacuum.

r.

Compression n o t up t o specifications.

a.

Cracked body.

s.

L o w grade of fuel.

b.

Defective body gaskets.

t.

D e t o n a t i o n or p r e - i g n i t i o n .

u.

I n c o r r e c t valve t i m i n g .

c. H i g h float or fuel level.

FUEL SYSTEM — 9

C A R B U R E T O R MODELS

BBD-2923S OR BBD-2924S

14. SERVICING THE

CARBURETOR

D i r t , dust, w a t e r and g u m m y deposits are some of

the m a i n causes f o r poor c a r b u r e t o r operation.

P r o p e r cleaning, however, and i n s t a l l a t i o n of new

p a r t s , where required, w i l l r e t u r n the c a r b u r e t o r

to its o r i g i n a l l y designed performance.

W h e n o v e r h a u l i n g the carburetor, several items

of i m p o r t a n c e should be observed to assure a good

j o b . A l l p a r t s should be carefully cleaned i n a suitable solvent and inspected f o r damage and wear.

Replace questionable p a r t s w i t h N E W ones.

Use a i r pressure only, to clear the various orifices

and passages.

SERVICE PROCEDURES

15. CARBURETOR DISASSEMBLY (Fig. 3)

( 1 ) I n s e r t t h r e e Tool T109-287S and one Tool

T109-288S elevating legs t h r o u g h the c a r b u r e t o r

t h r o t t l e body stud holes. (These tools are used to

protect the t h r o t t l e valves f r o m damage and to p r o vide a suitable base f o r w o r k i n g . )

( 2 ) Remove the

h a i r p i n clip and

disengage

ACCELERATOR PUMP ARM

the

fast idle connector r o d f r o m the t h r o t t l e and

idle levers.

( 3 ) Remove the h a i r p i n clip and disengage the

accelerator p u m p r o d f r o m the t h r o t t l e lever and the

p u m p rocker a r m , as shown i n F i g u r e 4.

( 4 ) Remove t h e a i r h o r n r e t a i n i n g screws and l i f t

a i r h o r n s t r a i g h t up and a w a y f r o m the m a i n body.

D i s c a r d the gasket (2 screws recessed).

CHOKE VALVE

ACCELERATOR PUMP PLUNGER

BOWL VENT SEAL

CHOKE PISTON CYLINDER

AIR HORN

FAST IDLE SCREW

IDENTIFICATION TAG

FAST IDLE CAM

FAST IDLE LEVER -

. THROTTLE BODY

MAIN BODY

ACCELERATOR

PUMP ROD <

THROTTLE LEVER .

fast

FAST IDLE CONNECTOR

ROD

IDLE SPEED SCREW

ELEVATING LEG (TOOL)

58x240B

Fig. 3—Carburetor Assembly BBD-2923S or BBD-2924S

10 —FUEL SYSTEM

—FLOAT

STEP UP PISTON

.ACCELERATOR PUMP

CONNECTOR ROD

J

•IS

FAST IDLE

C O N N E C T O R ROD

/

CENTER HOLE

GASKET

"i

HAIRPIN C U P

58x241A

Fig. 4—Removing ©r Installing Fast Idle a n d

Pump Rods

( 5 ) Disengage t h e accelerator p u m p plunger f r o m

the accelerator p u m p a r m b y p u s h i n g up on b o t t o m

of p l u n g e r a n d s l i d i n g p l u n g e r shaft off hook, as

s h o w n i n F i g u r e 5. Slide p l u n g e r o u t o f a i r h o r n

and remove the compression s p r i n g a n d seat.

I f the old p l u n g e r can be used a g a i n o r i f a n e w

p l u n g e r is t o be installed, place t h e p l u n g e r i n a

j a r o f clean gasoline o r kerosene t o p r e v e n t t h e leather f r o m d r y i n g out.

_ _ NEEDLE

Ox*— V A L V E

r

111

w

58x242 A

Fig. 6—Removing or Installing Float

w e l l , as shown i n F i g u r e 7. L i f t out t h e step-up

p i s t o n s p r i n g . Remove the step-up p i s t o n gasket

f r o m the b o t t o m o f t h e w e l l .

STEP-UP PISTON

STEP-UP RODS

STEP-UP PISTON

SPRING

MAIN

' METERING

JETS

( 6 ) Remove t h e fuel i n l e t needle valve, seat and

gasket f r o m t h e m a i n body.

( 7 ) L i f t out t h e float f u l c r u m p i n retainer, and

l i f t out the floats a n d f u l c r u m p i n , as s h o w n i n

F i g u r e 6.

( 8 ) Remove t h e step-up p i s t o n and r e t a i n i n g

screw a n d slide the step-up p i s t o n a n d rods o u t o f

R E T A I N I N G SCREW

60x102

ACCELERATOR

PUMP SHAFT

ACCELERATOR

PUMP ARM

Fig. 7—Removing

m Girnsira.ling Step-Up Piston

SPECIAL TOOL

C H O K E PISTON

LINK

CHOKE

PISTON

PLUG

58x246A

Fig. 5—Removing

or Installing Accelerator Pump

MAIN

METERING JET

>

58x244A

Fig. 8—Removing or Installing Main Metering Jets

FUEL

(9) Remove t h e m a i n m e t e r i n g j e t s a n d gaskets,

as shown i n F i g u r e 8.

SPARK

IDLE T R A N S F E R PORTS

A

(10) Remove the v e n t u r i cluster idle bleed screws,

t h e n l i f t t h e v e n t u r i cluster and gaskets up and away

f r o m t h e m a i n body, as shown i n F i g u r e 9. Discard

the gaskets. Do not remove the idle orifice tubes or

the main vent tubes from the cluster. T h e y can be

cleaned i n a solvent and d r i e d w i t h compressed air.

(11) I n v e r t t h e c a r b u r e t o r and drop o u t t h e accelerator p u m p discharge check ball.

- \

IDLE

16. CLEANING C A I B U R E T O I

The recommended solvent f o r g u m deposits is den a t u r e d alcohol w h i c h is easily obtainable. There

are other commercial solvents, however, w h i c h m a y

be used w i t h satisfactory results.

IMPORTANT

I f the commercial solvent or cleaner recommends the

use of water as a rinse, it should be " H O T . " After

rinsing, all trace of water must be blown from the

passages with air pressure. I t is further advisable to

rinse all parts in clean kerosene or gasoline to be cer-

Fig.

9 - R e m o v i n g or Installing Venturi Cluster

ADVANCE

PORT

/

IDLE M I X T U R E

VALVES

SCREWS

SPEED

r

SCREW

(13) Remove t h e screws t h a t a t t a c h t h e t h r o t t l e

body to the m a i n body. Separate the bodies and

discard the gasket.

I t is usually not advisable to remove the t h r o t t l e

shaft or valves f r o m the t h r o t t l e body, unless wear

or damage necessitates the i n s t a l l a t i o n o f new parts.

V

THROTTLE

(12) Remove t h e idle m i x t u r e a d j u s t i n g screws

and springs f r o m the t h r o t t l e body.

The c a r b u r e t o r n o w has been disassembled i n t o

three sub-assemblies, the a i r h o r n , m a i n body and

t h r o t t l e body and the components of each disassembled as f a r as necessary f o r cleaning and inspection.

SYSTEM—11

.1'

Fig.

- GASKET

^-

60x104

1 0 — P o r t s in Relation to Throttle V a l v e s

tain no trace of moisture remains. Never clean jets

with a wire, drill or other mechanical means, because

the orifices may become enlarged, making the mixture too rich for proper performance.

17.

INSPECTION A N D 1EASSEMBLY

a. Throttle Body

(1) Inspect t h e t h r o t t l e shaft and t h r o t t l e body

for excessive wear. I f either or b o t h are w o r n t o

the p o i n t w h e r e the c a r b u r e t o r operation w i l l be

affected, replace as r e q u i r e d .

D u r i n g m a n u f a c t u r e , the location of the idle t r a n s fer p o r t and the spark advance c o n t r o l p o r t s t o t h e

t h r o t t l e valve, is carefully established f o r one p a r t i c u l a r assembly ( F i g . 1 0 ) .

I f a new shaft should be installed i n an old, w o r n

t h r o t t l e body, i t w o u l d be v e r y u n l i k e l y t h a t the

o r i g i n a l r e l a t i o n s h i p of the p o r t s to the valves w o u l d

Fig. 1 1-lnstalling Throttle V a l v e s

12 — F U E L

SYSTEM

be obtained. C h a n g i n g the relationship o f the valves

t o the p o r t s w o u l d adversely affect n o r m a l car opera t i o n between the speeds o f 15 and 30 miles per h o u r .

I f i t has been determined, however, t h a t a new shaft

o r valves is to be installed, adhere to the f o l l o w i n g

instructions.

( 2 ) M a r k t h e p o s i t i o n o f t h e t h r o t t l e valves i n t h e

bores. Be sure the i d l e speed screw is backed off.

( 3 ) Remove t h e screws t h a t hold t h e t h r o t t l e

valves t o the shaft and slide the valves out o f the

bores.

CAUTION

These screws are staked on the opposite side and care

should be used a t r e m o v a l so as n o t t o .break off i n

the shaft.

( 4 ) Slide t h e t h r o t t l e shaft and lever out o f t h e

body.

( 5 ) I n s t a l l new t h r o t t l e shaft and lever.

( 6 ) I n s t a l l t h r o t t l e valves i n t h e i r respective bores

( w i t h the valve numbers t o w a r d the m a n i f o l d

flange). I n s t a l l new screws b u t do n o t t i g h t e n . H o l d

the valves i n place, w i t h the fingers pressing on the

h i g h sides o f the valves, as shown i n F i g u r e 1 1 .

T a p the valves l i g h t l y w i t h a s c r e w d r i v e r t o seat

i n the t h r o t t l e bores. T i g h t e n the screws securely

and stake b y squeezing w i t h p l i e r s .

( 7 ) I n s t a l l t h e idle m i x t u r e screws and springs

i n the t h r o t t l e body. ( T h e tapered p o r t i o n m u s t be

s t r a i g h t a n d smooth. I f the tapered p o r t i o n is

grooved or r i d g e d , new idle m i x t u r e screws should

be i n s t a l l e d to insure h a v i n g correct idle m i x t u r e

control.) D O N O T U S E A S C R E W D R I V E R . T u r n

STEP-UP RODS MUST MOVE FREELY

60x106

Fig. 13—Step-Up Rod Free Play

t h e screws l i g h t l y against t h e i r seats w i t h t h e fingers.

Back off one f u l l t u r n f o r approximate adjustment.

b. Main Body

(1) I n v e r t the m a i n body and place a new gasket

i n p o s i t i o n and place the t h r o t t l e body on the m a i n

body and a l i g n . I n s t a l l screws and t i g h t e n securely.

( 2 ) I n s t a l l t h e accelerator p u m p discharge check

b a l l i n the discharge passage and check the accelera t o r p u m p system; fuel i n l e t and discharge check

balls as f o l l o w s :

( 3 ) Pour clean gasoline i n t o t h e carburetor bowl,

a p p r o x i m a t e l y / i n c h deep. Remove the p u m p

p l u n g e r f r o m the j a r o f gasoline, flex the leather

several times, t h e n slide d o w n i n t o the p u m p c y l i n der. Raise the p l u n g e r and press l i g h t l y on the

p l u n g e r shaft to expel a l l a i r f r o m the p u m p

passage.

l

2

( 4 ) U s i n g a s m a l l clean brass r o d , hold t h e discharge check b a l l d o w n f i r m l y on i t s seat. A g a i n

raise the p l u n g e r and press d o w n w a r d . N o fuel

should be e m i t t e d f r o m either the i n t a k e o r discharge passage, as shown i n F i g u r e 12.

I f any fuel does e m i t f r o m either passage, i t i n d i cates the presence o f d i r t o r a damaged check b a l l .

Check the passage again and repeat test. I f leakage is s t i l l evident, i n s t a l l a new check ball. The

fuel i n l e t check b a l l is located a t the b o t t o m o f the

p l u n g e r w e l l and should r a t t l e freely w h e n the

carburetor is shaken.

58x249B

Fig. 12—Testing Accelerator Pump Intake a n d

Discharge Check Balls

( 5 ) I n s t a l l new gaskets on t h e v e n t u r i cluster, and

i n s t a l l i n p o s i t i o n i n the m a i n body. (Refer t o F i g .

9 ) . I n s t a l l the idle bleed screws and t i g h t e n securel y . Test p u m p discharge b y pressing p u m p p l u n g e r

FUEL SYSTEM— 13

d o w n . T w o fine streams o f fuel should be forced

f r o m the cluster. I f e i t h e r s t r e a m is r e s t r i c t e d or

d i v e r t e d , remove cluster and reclean. A f t e r test,

p o u r the f u e l f r o m the b o w l and remove p u m p

plunger.

( 6 ) I n s t a l l t h e m a i n m e t e r i n g j e t s and gaskets.

T i g h t e n securely. (Refer to F i g . 8 ) .

( 7 ) Before i n s t a l l i n g t h e step-up piston, be sure

the step-up rods are able to move freely, each side

of the v e r t i c a l p o s i t i o n , as shown i n F i g u r e 13. The

step-up rods m u s t be s t r a i g h t and smooth.

FROM TOP O F

PUMP SHAFT TO

BOTTOM O F

AIR HORN

( 8 ) Slide t h e step-up p i s t o n gasket d o w n i n t o posit i o n i n the p i s t o n w e l l , t h e n i n s t a l l the step-up p i s t o n

s p r i n g , step-up p i s t o n and rods. C a r e f u l l y guide

t h e step-up rods i n t o the m a i n m e t e r i n g j e t s . (Refer

to F i g . 7 ) . I n s t a l l the r e t a i n i n g screw and t i g h t e n

securely. Check p i s t o n f o r free operation i n the

well.

THROTTLE VALVES SEATED ^ 3 . , .

A step-up p i s t o n stuck i n the U p p o s i t i o n w i l l

cause a r i c h m i x t u r e a t p a r t t h r o t t l e , whereas a

p i s t o n stuck i n the D o w n p o s i t i o n w i l l cause a lean

m i x t u r e at w i d e open t h r o t t l e and poor acceleration.

c. Checking Float Setting

(1)

I n s t a l l t h e floats and f u l c r u m p i n .

( 2 ) Assemble t h e fuel inlet needle valve, seat and

gasket a n d i n s e r t i n p o s i t i o n i n the m a i n body.

T i g h t e n securely. ( I f the needle valve is r i d g e d or

b a d l y w o r n , i n s t a l l a new needle valve and seat

assembly.)

( 3 ) U s i n g Tool T109-239 or a " T " scale, check t h e

float s e t t i n g , as shown i n F i g u r e 14. There should

be 9 / 3 2 " f r o m top o f the c r o w n o f each float t o t o p

FLOAT UP HELD AGAINST

NEEDLE VALVE

^

%^

^

^^^^^^

\

FLOAT G A U G E

60x107

71

4—Checking

FAST IDLE

SCREW O F F

FAST IDLE

CAM

58x255B

Fig.

15—Measuring Accelerator Pump Travel

of the m a i n body. E a c h float m u s t be adjusted t o

t h i s s e t t i n g a n d should not touch the sides o f the

b o w l . I n s t a l l float f u l c r u m p i n r e t a i n e r .

d. A i r Horn

( 1 ) Check the freedom o f t h e choke mechanism i n

the a i r h o r n . The shaft and p i s t o n m u s t float free

to operate c o r r e c t l y . I f the choke p i s t o n sticks i n

the c y l i n d e r , pierce the welsh p l u g and remove p l u g

and p i s t o n . Clean t h o r o u g h l y a n d r e i n s t a l l p i s t o n .

I n s t a l l new p l u g .

( 2 ) Remove accelerator p u m p p l u n g e r f r o m gasoline, slide compression s p r i n g and s p r i n g seat over

shaft. I n s t a l l assembly i n a i r h o r n a n d engage w i t h

accelerator p u m p a r m . (Refer t o F i g . 5 ) .

(3) Place a new gasket on t h e m a i n body, and i n s t a l l the a i r h o r n . I n s t a l l a t t a c h i n g screws and

t i g h t e n securely. ( W h e n i n s t a l l i n g a i r h o r n , be sure

the leather on the p l u n g e r does n o t w r i n k l e or f o l d

back.)

(4) Engage t h e accelerator p u m p r o d w i t h t h e

p u m p rocker a r m and i n s t a l l loose end i n the center

hole o f t h r o t t l e lever. (Refer t o F i g . 4 ) . I n s t a l l

h a i r p i n clip to secure.

•

Fig.

§

¥l©at

Setting

( 5 ) Engage the f a s t idle connector r o d i n t h e fast

idle lever and t h r o t t l e lever. I n s t a l l h a i r p i n clip t o

secure. (Refer t o F i g . 4.)

18. CABBURETOl ADJUSTMENTS

I t is v e r y i m p o r t a n t t h a t the f o l l o w i n g adjustments

are made on a reconditioned c a r b u r e t o r and i n the

sequence l i s t e d :

14 —FUEL SYSTEM

. UNLOADER

GAUGE

iHROTTLE VALVE

b#lf

LIGHT FINGER PRESSURE

' A G A I N S T CHOKE VALVE

T i l

THROTTLE VALVES IN

WIDE OPEN POSITION

^ ^ ^ ^ ^ ^ ^ ' ' . ^ ^ FAST IDLE C A M

\

INDEX MARK

FAST IDLE ADJUSTING S C R E W

58x252 A

58x254B

Fig. 16—Checking Fast Idle Setting

Fig. 18—Checking Choke Unloader Setting

a. Accelerator Pump

(1) Back off t h e idle speed a d j u s t i n g screw. Open

the choke valve so t h a t the t h r o t t l e valves can be

completely seated i n the bores. Be sure t h a t the

p u m p connector r o d is i n s t a l l e d i n the center hole

of the t h r o t t l e lever.

( 2 ) H o l d i n t h i s position, and i n v e r t t h e carburet o r . Slide w i r e gauge Tool T109-44 .015" between t h e

t h r o t t l e valves and the bore (side opposite p o r t s ) .

T i g h t e n the fast idle a d j u s t i n g screw u n t i l a s l i g h t

d r a g is f e l t as gauge is b e i n g w i t h d r a w n , as shown

i n F i g u r e 16.

( 2 ) Close t h e t h r o t t l e valves t i g h t l y . Measure t h e

distance between the top o f t h e a i r h o r n and the

end o f p l u n g e r shaft, as s h o w n i n F i g u r e 15. T h i s

measurement should be 1 " ± o r — 1/64 i n c h .

( 3 ) A g a i n , i n v e r t t h e carburetor a n d open t h e

valves to w i d e open position. Close the t h r o t t l e

valves and the choke valve t i g h t l y .

( 3 ) To adjust p u m p t r a v e l , bend t h e p u m p connector r o d , u s i n g Tool T109-213, a t t h e l o w e r angle

of r o d , u n t i l correct t r a v e l has been obtained.

( 4 ) Release t h e choke valve only. T h i s again posit i o n s the f a s t idle cam to fast idle. The i n d e x m a r k

on the cam should s p l i t the center o f the f a s t idle

screw shank, as shown i n F i g u r e 17.

b. Fast Idle Adjustment

(1) Open t h e t h r o t t l e valves and hold t h e choke

valve i n the f u l l y closed p o s i t i o n . Close t h e t h r o t t l e

valves. T h i s w i l l p o s i t i o n the f a s t idle cam t o the

fast idle p o s i t i o n .

I f an adjustment is necessary, bend the t a n g on

the choke shaft lever, u s i n g Tool T109-22 u n t i l the

i n d e x m a r k on the cam indexes w i t h the a d j u s t i n g

screw.

INDEX MARK

58x253B

Fig. 17—Fast Idle Index Mark A l i g n e d

•

-

~

58x256B

Fig. 19—Bending Fast Idle Lever Tang

FUEL SYSTEM—15

c. Choke Unloader (wide open kick)

( 1 ) H o l d t h e t h r o t t l e valves i n t h e wide open posit i o n . I n s e r t Tool T109-31 ( o r a

d r i l l shank)

between the upper edge o f the choke valve and the

i n n e r w a l l of the a i r h o r n , as shown i n F i g u r e

18.

( 2 ) W i t h a finger l i g h t l y pressing against t h e

valve, a s l i g h t d r a g should be f e l t as gauge is b e i n g

w i t h d r a w n . I f an a d j u s t m e n t is necessary, bend the

t a n g on the fast idle lever, u s i n g Tool T109-22, as

shown i n F i g u r e 19 u n t i l correct clearance has been

obtained.

C H O K E ROD

DUST S E A L WASHER

COVER

CALIBRATION

IOCK

M A R K S \

NUT

d. Bowl Vent Valve Adjustment

( 1 ) W i t h the t h r o t t l e valves held closely, i t should

be possible to i n s e r t a .060" d r i l l shank between the

b o w l vent valve and the a i r h o r n .

(2) I f an adjustment is necessary, bend t h e short

t a n g on the vent valve o p e r a t i n g lever, u s i n g Tool

T109-22 u n t i l correct clearance has been obtained.

e. Idle Speed Adjustment (curb idle)

The idle speed a d j u s t m e n t is made after the

b u r e t o r has been installed on the engine.

THERMOSTATIC C O I L ^ J ^ t ^

SPRING AND H O U S I N G

'

-INDEX MARK

57P55

Fig. 20—Well Type Automatic Choke Unit

be clean and move freely. O t h e r t h a n an occasional

cleaning, the choke requires no s e r v i c i n g . I t is v e r y

i m p o r t a n t , however, t h a t t h e choke c o n t r o l u n i t

w o r k freely i n the w e l l and at the choke shaft.

car-

( 1 ) W i t h the t h r o t t l e valves closed and t h e choke

valve w i d e open (engine at n o r m a l o p e r a t i n g t e m p e r a t u r e ) adjust the idle speed screw to give 500

r . p . m . u s i n g a tachometer, (575 r . p . m . on a i r condit i o n equipped c a r s ) .

( 2 ) A d j u s t the idle m i x t u r e screws u n t i l the engine operates smoothly. Recheck the tachometer

and again adjust the idle screw to give the correct

engine r . p . m .

19. AUTOMATIC C H O K E — W E L L TYPE

To f u n c t i o n p r o p e r l y , i t is i m p o r t a n t t h a t a l l p a r t s

Move the choke

movement on the

choke u n i t should

C H O K E U N I T is

a t t e m p t to r e p a i r

F i g . 20.)

r o d up and d o w n to check f o r free

p i v o t . I f the u n i t binds, a new

be installed. T H E W E L L T Y P E

serviced as an assembly. D o n o t

or change the index s e t t i n g . (See

W h e n i n s t a l l i n g the w e l l t y p e choke u n i t , be cert a i n t h a t the coil h o u s i n g does not contact the sides

of the w e l l i n the i n t a k e m a n i f o l d . A n y contact at

t h i s p o i n t w i l l affect choke operation.

D o not l u b r i c a t e any p a r t s o f the choke or the cont r o l u n i t . T h i s causes an accumulation o f d i r t w h i c h

w i l l result i n b i n d i n g of the choke mechanism.

16 — FUEL SYSTEM

AFB S E R I E S CARBURETOR

DATA AND SPECIFICATIONS

CARBURETOR

Type

Model (automatic t r a n s m i s s i o n )

4 Barrel Downdraft

AFB-2927S, 2950S AFB-2968S

AFB-2903S

T H R O T T L E BORE

Primary

Secondary

MAIN VENTURI

Primary

Secondary

LOW SPEED

Primary

.

.

1-7/16"

1-11/16"

1-3/16"

1-5/16"

1-3/16"

1-9/16"

JET

No. 67-.032"

ADJUSTMENTS

Accelerator P u m p S e t t i n g (top of plunger to a i r h o r n )

Choke Unloader ( w i d e open k i c k )

F a s t Idle A d j u s t m e n t

F a s t Idle Speed ( r p m )

Idle Speed A d j u s t m e n t ( r p m )

( w i t h air conditioning) ( r p m )

Secondary T h r o t t l e Lever A d j u s t m e n t

Secondary T h r o t t l e Lock-Out A d j u s t m e n t

F l o a t S e t t i n g (gasket to top of

floats)

Float Drop

Idle M i x t u r e ( b o t h screws-turns open)

A u t o m a t i c Choke U n i t S e t t i n g

*

1-7/16"

1-9/16"

N o . 67-.035"

7/16"

y±"

.020"

1775-1825

500

550*

19/64"

.020"

7/32"

%"

1-2

2 Notches R i c h

N o . 65-.035"

7/16"

A "

.010"

***1475-1525

**725-750

*550

19/64"

.020"

9/32"

%"

1-2

1 Notch Rich

l

550 r p m w i t h the transmission i n " D " or " R " and the a i r c o n d i t i o n i n g compressor " o n " .

** 725 to 750 r p m and constant w i t h the t r a n s m i s s i o n i n n e u t r a l ( N ) and the a i r c o n d i t i o n i n g compressor

" o n " ( i f so equipped).

***On R a m Charge De Soto A d v e n t u r e r and 1375-1425 on the Chrysler Model C300F.

S P E C I A L TOOLS

C-3400

T109-287S

T109-22

T109-29....

T109-31

T109-41

T109-58

T109-59

T109-106

T109-126

T109-200

T109-213

...

.

R e p a i r Stand

E l e v a t i n g Legs

B e n d i n g Tool

W i r e Gauge (.020" and .030") ( F a s t I d l e )

.Gauge

(Choke U n l o a d e r )

B e n d i n g Tool ( F a s t Idle E n d U n l o a d e r )

Screwdriver B i t

Screwdriver B i t

F l o a t Gauge ( 7 / 3 2 " )

.Float Gauge ( 9 / 3 2 " )

W i r e Gauge (.010" and .012") ( F a s t I d l e )

B e n d i n g Tool

FUEL SYSTEM—17

CHOKE VALVE

STEP-UP PISTON A N D

58x275 A

STEP-UP PISTON AND ROD COVER PLATE (2)

CHOKE

PISTON LINK

ACCELERATOR PUMP

CONNECTOR LINK

FUEL INLET C O N N E C T I O N

-f-V ACCELERATOR PUMP

SHAFT

MODEL NUMBER AND DATE

STAMPED O N BOSS

(AT CENTER O F CARBURETOR)

SECONDARY THROTTLE

OPERATING LEVER

.

^JLT,

*~

7

PUMP C O N N E C T O R

ROD IN CENTER

HOLE O F ARM

/

PRIMARY THROTTLE

SHAFT ARM (OUTER)

DISTRIBUTOR VACUUM FITTING

THROTTLE OPERATING ROD

PRIMARY THROTTLE SHAFT ARM (INNER)

PRIMARY THROTTLE SHAFT D O G

Fig. 21—Carburetor A s s e m b l y

58x276 A

18 — F U E L SYSTEM

AFB SERIES CARBURETOR

MODELS AFB-2927S, 2950S, 2968S, 2903S

The new A F B ( a l u m i n u m f o u r b a r r e l ) c a r b u r e t o r

contains m a n y new features, some o f w h i c h are a

new location f o r the step-up rods and pistons. The

step-up rods, pistons and springs are accessible f o r

service w i t h o u t r e m o v i n g the a i r h o r n , o r the carb u r e t o r f r o m the engine.

The v e n t u r i assemblies ( p r i m a r y and secondary)

are replaceable and contain m a n y o f the c a l i b r a t i o n

points f o r b o t h the h i g h and l o w speed system. One

fuel b o w l feeds b o t h the p r i m a r y and secondary nozzles on the r i g h t side w h i l e the other fuel b o w l takes

care o f the p r i m a r y and secondary nozzles on the

left side. T h i s provides i m p r o v e d performance i n

c o r n e r i n g , quick stops and acceleration.

A l l the m a j o r castings of the c a r b u r e t o r are a l u m i n u m , w i t h the t h r o t t l e body cast i n t e g r a l w i t h the

m a i n body. T h i s allows an overall h e i g h t r e d u c t i o n

i n the carburetor. The section c o n t a i n i n g the accele r a t o r p u m p is t e r m e d the p r i m a r y side o f the carb u r e t o r . The rear section is the secondary.

The five conventional systems are t w o float systems, t w o l o w speed systems ( p r i m a r y side o n l y ) ,

t w o h i g h speed systems, one accelerator p u m p syst e m and one automatic choke control system.

20. SERVICING THE CARBURETOR

D i r t , dust, w a t e r and g u m m y deposits are some of

the m a i n causes f o r poor carburetor operation. H o w ever, proper cleaning and the i n s t a l l a t i o n of new

parts, w h e r e required, w i l l r e t u r n the carburetor

to i t s o r i g i n a l l y designed performance.

W h e n o v e r h a u l i n g the A F B carburetor, several

items o f importance should be observed to assure a

good j o b .

The c a r b u r e t o r should be carefully disassembled

and a l l p a r t s should be cleaned i n a suitable solvent

and inspected f o r wear or damage.

A i r pressure only should be used to clean the

v a r i o u s orifices and channels. Replace questionable

p a r t s w i t h new ones.

SERVICE PROCEDURES

2 1 . DISASSEMBLING THE AFB CARBURETOR

(Fig. 21)

tons and rods out of the a i r h o r n , as shown i n F i g u r e

22. Remove the step-up p i s t o n springs.

( 1 ) Place t h e c a r b u r e t o r assembly o n repair stand

Tool C-3400 or T-109-287S e l e v a t i n g legs.

( 6 ) Remove t h e ten screws t h a t attach the a i r

STEP-UP PISTON AND ROD

( 2 ) Remove t h e h a i r p i n clip t h a t attaches the f a s t

idle connector r o d to the choke lever. Disengage r o d

f r o m lever, t h e n s w i n g r o d at a n arc u n t i l i t can be

disengaged f r o m the fast idle cam.

STEP-UP PISTON SPRING

( 3 ) Remove t h e retainer and s p r i n g t h a t holds t h e

t h r o t t l e connector r o d i n the center hole o f t h e

accelerator p u m p a r m . Remove the h a i r p i n clip t h a t

attaches the l o w e r end o f r o d i n the p r i m a r y t h r o t t l e

shaft lever. Disengage r o d f r o m a r m and lever,

t h e n remove f r o m c a r b u r e t o r .

( 4 ) Remove the screws a t t a c h i n g

p i s t o n and r o d cover plates.

the

step-up

N O T E : H o l d c o v e r d o w n w i t h a finger to p r e v e n t t h e

p i s t o n a n d r o d s f r o m flying o u t .

(5) L i f t off the plates and slide the step-up pis-

COVER PLATES 58x277

-~

STEP-UP PISTON

r

\

STEP-UP ROD

Fig. 22—Removing or Installing Step-Up

Pistons a n d Rods

FUEL

h o r n to the m a i n body ( 1 screw i n hole i n a i r h o r n ) .

L i f t a i r h o r n s t r a i g h t up and a w a y f r o m the m a i n

body.

N O T E : W h e n r e m o v i n g a i r h o r n , u s e c a r e so a s n o t

to bend o r d a m a g e t h e floats.

( 7 ) Remove t h e accelerator p u m p plunger lower

s p r i n g f r o m the p u m p c y l i n d e r .

SYSTEM—19

PRIMARY VENTURI

( C H O K E SIDE)

SECONDARY

VENTURI

(CHOKE SIDE)

PRIMARY

VFNTURI

(PUMP S I D E )

.

SECONDARY

VFNTURI

(PUMP SIDE)

^ '*

a. Disassembling the A i r Horn

Place the a i r h o r n i n an i n v e r t e d p o s i t i o n on the

bench (to p r o t e c t the floats).

(1) U s i n g a suitable tool, remove t h e float f u l c r u m

pins (left and r i g h t ) and l i f t t h e floats up and out

of bosses on a i r h o r n .

N O T E : I t i s s u g g e s t e d t h a t t h e float o n t h e p u m p

side be m a r k e d s o t h a t t h e floats c a n be r e - i n s t a l l e d

in their respective positions.

( 2 ) Remove t h e t w o needle valves f r o m t h e i r respective seats, a f t e r m a r k i n g the one on the p u m p

side f o r identification. U s i n g a w i d e blade screwd r i v e r , remove the needle valve seats. Be sure each

needle valve is r e t u r n e d t o i t s o r i g i n a l seat at reassembly.

( 3 ) Remove the h a i r p i n clip t h a t holds the accele r a t o r p u m p connector l i n k i n the p u m p a r m and

p l u n g e r shaft. Disengage l i n k f r o m p u m p a r m a n d

shaft.

Slide the accelerator p u m p p l u n g e r and

s p r i n g out o f the a i r h o r n . Remove the a i r h o r n t o

m a i n body gasket and discard.

( 4 ) Place the accelerator p u m p plunger i n a j a r

of clean gasoline or kerosene, to p r e v e n t the leather

f r o m d r y i n g out.

( 5 ) Remove t h e fuel i n l e t fitting and filter screen

f r o m the a i r h o r n .

DISCHARGE CHECK

NEEDLE (IN HOLE)

ACCELERATOR / PUMP CYLINDER

' ''

|L

l\

f*;

f%lf^^W

y

S E C O N D A R Y JET (2)

A PRIMARY J E T (2)

58*2/8

Fig. 24—Removing or Installing Main Metering Jets

( 6 ) U s i n g a p r i c k punch, pierce t h e welch p l u g

and remove i t f r o m the end o f choke p i s t o n c y l i n d e r .

Remove cotter p i n t h a t attaches the p i s t o n l i n k t o

the choke valve lever. Slide choke p i s t o n and l i n k

out o f cylinder.

b. M a i n B o d y D i s a s s e m b l y

(1) Remove t h e screws t h a t a t t a c h the accelerat o r p u m p j e t h o u s i n g to the m a i n body. L i f t out the

j e t housing and gasket, as shown i n F i g u r e 23.

D i s c a r d the gasket. I n v e r t the m a i n body and d r o p

out the discharge check needle f r o m the discharge

passage.

( 2 ) U s i n g Tool T109-58, remove t h e m a i n meteri n g jets ( p r i m a r y side), as shown i n F i g u r e 24.

N O T E : T h e p r i m a r y and secondary main metering

j e t s a r e not interchangeable.

I t is very important

t h a t t h e s e j e t s be i n s t a l l e d i n t h e i r r e s p e c t i v e locat i o n s i n t h e m a i n body a t r e a s s e m b l y .

GASKET

PRIMARY VENTURI (PUMP SIDE)

h?IMAKY VENTURI

C H O K E SIDE

/

/

'4 si-

MODEL NUMBER

A N D DATE

STAMPED

O N BOSS

<**

• 'f '

A

58x283

Fig. 23—Removing or Installing Accelerator

P u m p Jet Housing

Fig. 25—Removing or Installing Primary Venturi

20 — FUEL SYSTEM

SECONDARY VENTURI PUMP SIDE

GASKET

PUMP JET HOUSING

^

SECONDARY VENTURI

(CHOKE SIDE)

y

h

IDLE DISCHARGE PORTS

PRIMARY

THROTTLE

VALVES

ACCELERATOR

PUMP INTAKE

PASSAGE

CHOKE SIDE OF

CARBURETOR

PUMP SIDE OF CARBURETOR

SECONDARY VENTUF

NOZZLE BLEEDER TUBE

PRIMARY VENTURI

^

( 5 ) Remove the screws t h a t attach the secondary

v e n t u r i (choke and p u m p side) to the m a i n body.

L i f t the secondary v e n t u r i assemblies s t r a i g h t up

and away f r o m the body, as shown i n F i g u r e 26.

NOZZLE

\

BLEEDER TUBE

DO NOT REMOVE TUBES R O M

VENTURI

58x284

Fig. 26—Removing or Installing Secondary Venturi

( 3 ) A g a i n using Tool T109-58, remove the m a i n

m e t e r i n g jets (secondary side), as shown i n F i g u r e

24.

( 4 ) Remove the screws

v e n t u r i (choke and p u m p

L i f t the v e n t u r i s t r a i g h t

m a i n body, as shown i n

gaskets.

t h a t a t t a c h the p r i m a r y

side) to the m a i n body.

up and a w a y f r o m the

F i g u r e 25. D i s c a r d the

N O T E : The v e n t u r i assemblies are not interchangeable, side f o r side and m u s t be re-installed i n t h e i r

o r i g i n a l location a t reassembly.

VA INCH BIT

CHECK BALL SEAT

PLUG

^

58x287

Fig. 28—Ports in Relation to Throttle V a l v e s

MAIN BLEED TUBE %

IDLE TUBE

IDLE TRANSFER PORTS

58x286

Fig. 27—Removing or Installing Accelerator Pump

Intake Check Ball Seat

( 6 ) I n v e r t the m a i n and t h r o t t l e body casting, and

remove the accelerator p u m p i n t a k e check b a l l

p l u g . U s i n g Tool T109-59, s c r e w d r i v e r b i t , remove

the check b a l l seat, as shown i n F i g u r e 27. A g a i n

i n v e r t the body casting and drop out the i n t a k e

check ball.

( 7 ) Remove the t w o idle m i x t u r e a d j u s t i n g screws

and springs f r o m the t h r o t t l e body p o r t i o n of the

m a i n casting.

The c a r b u r e t o r now has been disassembled i n t o

t w o units, the a i r h o r n and m a i n and t h r o t t l e body

casting. The component p a r t s of each have been

disassembled as f a r as necessary f o r cleaning and

inspection.

I t is usually not advisable to remove the t h r o t t l e

shafts or valves, unless w e a r or damage necessitates

the i n s t a l l a t i o n of new p a r t s . D u r i n g the manufact u r e of the carburetor, the location of the idle t r a n s fer ports and the idle discharge p o r t s to the valve

is carefully established f o r one p a r t i c u l a r assembly,

as shown i n F i g u r e 28. The valves are m i l l e d to

give the proper p o r t relation.

I f new t h r o t t l e shafts should be installed i n an

old, w o r n body, i t w o u l d be v e r y u n l i k e l y t h a t the

o r i g i n a l relationship of these p o r t s to the valves

w o u l d be obtained. A v e r y slight change i n the p o r t

r e l a t i o n s h i p to the valves w o u l d adversely affect

n o r m a l c a r b u r e t o r operation, between the speeds of

15 and 30 miles per hour.

I t is recommended t h a t i f the t h r o t t l e shafts are

excessively w o r n , t h a t a new c a r b u r e t o r be installed.

FUEL SYSTEM

I f the t h r o t t l e valves, however, have become nicked,

b u r r e d or damaged, new valves m a y be installed,

p r o v i d i n g the f o l l o w i n g i n s t r u c t i o n s are carefully

followed.

N O T E : The screws t h a t a t t a c h the t h r o t t l e valves

are staked on the opposite side and care should be

used i n r e m o v a l so as not to break the screws i n the

t h r o t t l e shaft. Remove the staked p o r t i o n of the

screws w i t h a file.

Remove the screws t h a t attach the p r i m a r y

t h r o t t l e valves to the t h r o t t l e shaft and slide valve

(or valves) o u t o f the bores.

Remove the screws t h a t a t t a c h the secondary

t h r o t t l e valves to the t h r o t t l e shaft and slide valve

(or valves) out of bores.

T h e p r i m a r y valves and secondary valves are

not interchangeable and should be k e p t separate i n

order t h a t each m a y be r e t u r n e d to i t s respective

bore. (See F i g . 29.)

c. Cleaning and Inspection

22.

a.

—21

CARBURETOR ASSEMBLY

M a i n a n d Throttle B o d y C a s t i n g

(1) Slide t h e p r i m a r y t h r o t t l e valve (or valves)

i n t o t h e i r respective bores, i n s t a l l new screws, b u t do

not t i g h t e n . Be sure the idle speed a d j u s t i n g screw

is backed out. H o l d the valves i n place w i t h fingers

(fingers pressing on the h i g h side o f the v a l v e s ) .

( 2 ) Tap t h e valves l i g h t l y w i t h a screwdriver to

seat i n the bores. H o l d i n g the valves i n t h i s posit i o n , t i g h t e n the screws securely. Stake screws b y

squeezing w i t h pliers.

( 3 ) I n s t a l l the t w o idle m i x t u r e a d j u s t i n g screws

and springs i n the t h r o t t l e body p o r t i o n of the casting.

The tapered p o r t i o n m u s t be smooth and

s t r a i g h t . I f the tapered p o r t i o n is grooved or r i d g e d ,

a new idle m i x t u r e a d j u s t i n g screw should be i n stalled to insure h a v i n g correct idle m i x t u r e control.

N O T E : D o n o t u s e a screwdriver.

The recommended solvent f o r g u m deposits is den a t u r e d alcohol. There are other other commercial

solvents, however, w h i c h m a y be used w i t h satisf a c t o r y results.

The a d j u s t m e n t should be made w i t h the fingers.

T u r n the idle m i x t u r e a d j u s t i n g screws l i g h t l y

against t h e i r seats and back off one f u l l t u r n f o r an

a p p r o x i m a t e adjustment.

IMPORTANT

I f t h e commercial solvent or cleaner recommends the

use o f a w a t e r rinse, i t should be " H O T . " A f t e r

r i n s i n g , a l l trace of w a t e r m u s t be blown f r o m the

passages w i t h a i r pressure. I t is f u r t h e r advisable

to rinse a l l p a r t s i n clean kerosene or gasoline to be

c e r t a i n no trace of moisture remains. Never clean

j e t s w i t h a w i r e , d r i l l , or other mechanical means,

because the orifices m a y become enlarged, m a k i n g

the m i x t u r e too r i c h f o r proper performance.

( 4 ) Place new secondary v e n t u r i gaskets i n posit i o n , i n s t a l l the secondary v e n t u r i ( p u m p and choke

side) b y l o w e r i n g s t r a i g h t d o w n on gaskets. I n s t a l l

a t t a c h i n g screws and t i g h t e n securely.

s SECONDARY VAIVE

(THICK)

^^^K

^^^^

•

N O T E : B e s u r e a l l t h e m e t e r i n g holes a n d v e n t t u b e s

a r e c l e a n , i n b o t h t h e p r i m a r y a n d secondary v e n t u r i .

( 5 ) Place new p r i m a r y v e n t u r i gaskets i n position,

t h e n i n s t a l l the p r i m a r y v e n t u r i ( p u m p and choke

side) b y l o w e r i n g s t r a i g h t d o w n on the gaskets. (See

F i g . 2 5 ) . I n s t a l l a t t a c h i n g screws and t i g h t e n securely.

( 6 ) I n s t a l l the p r i m a r y and secondary m a i n meteri n g jets, u s i n g Tool T109-58. (See F i g . 24.) T i g h t e n

j e t s securely.

( 7 ) I n v e r t t h e carburetor and i n s t a l l the accelerat o r p u m p i n t a k e check b a l l . I n s t a l l seat and t i g h t e n

securely, u s i n g Tool T109-59 ( F i g . 2 7 ) . I n s t a l l

screw p l u g and t i g h t e n securely.

b.

Accelerator P u m p Test

(1) Pour clean gasoline i n t o t h e carburetor bowl

( a p p r o x i m a t e l y / i n c h deep). Remove the accelerat o r p u m p p l u n g e r f r o m the j a r o f gasoline. F l e x

the leather several times, t h e n slide onto the p u m p

cylinder.

l

2

PRIMARY VALVC-"

Fig. 29—Throttle V a l v e Identification

(2)

I n s t a l l t h e accelerator pump discharge check

22 —FUEL SYSTEM

needle i n the discharge passage. Raise the p u m p

p l u n g e r and press l i g h t l y on the p l u n g e r shaft t o

expel a i r f r o m the p u m p passages. U s i n g a s m a l l

clean brass r o d , hold the discharge check needle

firmly on i t s seat. A g a i n raise the p l u n g e r and press

d o w n w a r d . N o fuel should be e m i t t e d f r o m either

the i n t a k e o r discharge passage.

(8) I f fuel does e m i t f r o m the i n t a k e passage,

disassemble t h e i n t a k e check b a l l and reclean the

passage. F u e l leakage a t the discharge check needle

indicates the presence o f d i r t or - a damaged check

needle. Clean a g a i n and t h e n i n s t a l l a new check

needle. Retest f o r leakage.

( 4 ) I f either the i n t a k e check ball or discharge

check needle leaks a f t e r above test and service fix,

a t t e m p t t o reseat as f o l l o w s :

c. Intake Check Ball

Remove the screw p l u g , gasket, b a l l seat and b a l l

f r o m the b o t t o m o f the t h r o t t l e body flange. I n s t a l l

a new b a l l and b a l l seat. I n s t a l l screw p l u g and n e w

gasket and retest as described p r e v i o u s l y .

d. Discharge Check Needle

( 1 ) W i t h t h e discharge check needle installed, i n sert a piece o f d r i l l r o d d o w n on the needle. L i g h t l y

t a p the d r i l l r o d w i t h a h a m m e r to f o r m a new seat.

Remove and discard old needle and i n s t a l l a new one.

Retest as described previously. I f the service fix does

not correct the condition, a new c a r b u r e t o r m u s t be

installed.

( 2 ) I n s t a l l t h e 'accelerator p u m p discharge check

needle, j e t h o u s i n g and gasket. I n s t a l l h o u s i n g a n d

a t t a c h i n g screws. T i g h t e n screws securely.

(3)

Press, d o w n on t h e accelerator p u m p plunger

THESE SURFACES MUST BE PARALLEL.

AIR HORN FUEL BAFFLE .

FLOAT GAUGE

GASKET IN PLACE

57

x 802 A

Fog, 3 ii-Checking Float Height

shaft and as the p l u n g e r is being depressed, a clear

s t r a i g h t stream should e m i t f r o m each j e t . i f t h e

streams are i d e n t i c a l ( i f either one is d i v e r t e d o r

r e s t r i c t e d ) a new accelerator p u m p j e t housing

should be installed. A f t e r test, p o u r the gasoline

f r o m the c a r b u r e t o r b o w l and remove p u m p plunger.

e. Air Horn Assembly

(1) Slide t h e fuel inlet screen i n t o t h e fuel line

fitting,

t h e n i n s t a l l fitting i n a i r h o r n . T i g h t e n

securely.

( 2 ) Check t o see i f t h e leather on t h e accelerator

p u m p p l u n g e r is h a r d , cracked or w o r n . I f any s i g n

o f w e a r o r d e t e r i o r a t i o n is evident, i n s t a l l a new

p l u n g e r assembly.

( 3 ) Slide the accelerator plunger i n t o a i r h o r n ,

and i n s t a l l the accelerator p u m p l i n k . I n s t a l l the ret a i n i n g h a i r p i n clip t o secure.

( 4 ) Place a new a i r h o r n t o m a i n body gasket i n

position on the a i r h o r n and i n s t a l l the float needle

valve seats. (Re sure each needle seat a n d needle is

reinstalled i n i t s o r i g i n a l p o s i t i o n . )

(5) Slide t h e r i g h t and left floats i n t o position i n

the a i r h o r n and i n s t a l l the float f u l c r u m p i n s .

N O T E : Be sure the marked float is installed on the

pump side of the air horn.

( 6 ) A f t e r t h e floats have been installed, check t h e

float alignment, level a n d d r o p settings as f o l l o w s :

f. Float Alignment Setting

(1) S i g h t d o w n t h e side o f each float shell t o det e r m i n e i f the side o f the float is p a r a l l e l t o t h e

outer edge o f the a i r h o r n casting, as s h o w n i n F i g ure 3 0 .

I

\/

MINIMUM CLEARANCE WITHOUT BINDING-

57 x 801

Fig. 30—Checking Float Alignment

( 2 ) I f t h e sides of t h e float are n o t i n a l i g n m e n t

w i t h the edge o f casting, bend the float lever b y

a p p l y i n g pressure t o t h e end o f the float shell w i t h

the fingers w h i l e s u p p o r t i n g the float lever w i t h the

thumb.

FUEL SYSTEM — 2 3

N O T E : T o avoid damage to t h e float, apply only

enough pressure t o bend the float lever.

( 3 ) A f t e r a l i g n i n g the floats, remove as m u c h

clearance as possible between t h e a r m s o f the float

lever a n d the lugs on the a i r h o r n . T o do t h i s , bend

the float lever. T h e a r m s o f the float lever should

be p a r a l l e l as possible t o the i n n e r surfaces o f the

lugs or the casting.

g. Float Level Setting

(1) W i t h t h e a i r h o r n i n v e r t e d , t h e a i r h o r n gask e t i n place and the float needle seated, slide float

gauge Tool T109-106 ( 7 / 3 2 " ) between t h e t o p o f t h e

float (at outer end) and t h e a i r h o r n gasket, as shown

i n F i g u r e 3 1 . F l o a t should j u s t t o u c h gauge.

( 2 ) Check t h e other float i n t h e same manner.

I f an a d j u s t m e n t is necessary, bend the float a r m

u s i n g T o o l T109-22, u n t i l correct clearance has been

obtained. A f t e r b e n d i n g a r m , recheck the float

alignment.

h. Float Drop Setting

(1) H o l d i n g t h e a i r h o r n i n a n u p r i g h t position,

measure the distance f r o m the top o f the floats

(outer end) t o the a i r h o r n gasket, as s h o w n i n

F i g u r e 32. T h i s measurement should be % i n c h . I f

an a d j u s t m e n t is necessary, bend the stop tabs on

the float levers u n t i l the correct d r o p s e t t i n g has

been obtained. Bend t h e t a b t o w a r d s the needle

seat to lessen the d r o p , or a w a y f r o m t h e seat to

increase the d r o p .

( 2 ) A f t e r t h e floats have been checked and adjusted, continue t o assemble the c a r b u r e t o r as f o l lows:

( 3 ) Place t h e accelerator p u m p p l u n g e r lower

s p r i n g i n the p u m p c y l i n d e r , t h e n l o w e r the a i r

h o r n c a r e f u l l y d o w n on the m a i n body.

GASKET IN PLACE

\\

57 x 803 A

STOP TABS

Fig. 32—Checking Float Drop

cylinders, followed b y the step-up pistons and stepup rods. I n s t a l l the cover plates and a t t a c h i n g

screws w h i l e h o l d i n g the step-up pistons d o w n i n

position. T i g h t e n screws securely.

( 6 ) Slide t h e choke p i s t o n i n t o i t s c y l i n d e r i n t h e

a i r h o r n , g u i d i n g the l i n k i n t o the slot i n the choke

valve lever. A l i g n hole, t h e n i n s t a l l a t t a c h i n g cotter

p i n . Place a n e w welsh p l u g over c y l i n d e r opening

and secure b y r a p p i n g w i t h a hammer. Check the fit

of the choke valve i n a i r h o r n . The valve should be

evenly spaced on a l l sides. Loosen screws and rep o s i t i o n i f necessary.

( 7 ) Engage t h e t h r o t t l e connector r o d w i t h t h e

p r i m a r y t h r o t t l e shaft lever and i n s t a l l h a i r p i n clip.

Slide the flat washer over the other end o f r o d and

engage w i t h the accelerator p u m p a r m . I n s t a l l ret a i n e r s p r i n g and r e t a i n e r securely.

( 8 ) Engage t h e lower end. o f t h e fast idle connector r o d w i t h the fast idle cam, t h e n s w i n g i n a n

arc t o lock i n cam. Slide other end o f r o d i n t o the

choke shaft lever and secure w i t h h a i r p i n clip.

WIRE

GAUGE-

CAUTION

Be sure the fuel baffles on the a i r horn, slide down

in front (bowl side) of the float chamber baffles, or

the air horn will not index correctly with the main

body and can cause the floats to hang up. Be sure

the leather on the plunger does not curl or wrinkle.

Accelerator pump operation will be affected if this

precaution is not observed.

( 4 ) I n s t a l l t h e (10) a i r h o r n a t t a c h i n g screws and

t i g h t e n securely. ( T h e t w o l o n g screws should be

installed i n the holes t h a t are located a t the a i r

cleaner m o u n t i n g surface. T h e 1 i n c h screw a t the

f r o n t and the l / i n c h a t t h e r e a r . )

FAST IDLE

ADJUSTING S C R E W

'KIT

INDEX MARK O N C A M .

HIGH STEP O F FAST IDLE C A M '

l

2

(5)

Slide the step-up p i s t o n springs i n t o t h e p i s t o n

C H O K E VALVE TIGHTLY C L O S E D — - - ^

58x289 A

Fig. 33—Checking Fast Idle Adjustment

24 —FUEL SYSTEM

23. CARBURETOR ADJUSTMENTS

UNLOADER G A U G E

':•./• INCH)

The f o l l o w i n g adjustments should be made w i t h

the c a r b u r e t o r on t h e bench f o r ease o f w o r k i n g ,

and should be made i n t h e f o l l o w i n g o r d e r :

a. Fast Idle Adjustment

(1) W i t h t h e choke valve held t i g h t l y closed and

c a r b u r e t o r i n v e r t e d , t i g h t e n the fast idle a d j u s t i n g

screw ( o n t h e h i g h step o f t h e fast idle c a m ) u n t i l

w i r e gauge Tool T109-29 (.020 i n c h ) can be i n serted between the p r i m a r y t h r o t t l e valve a n d t h e

bore (side opposite idle p o r t ) , as shown i n F i g u r e

33. T h e index m a r k o n t h e fast idle c a m should be

i n d i r e c t line w i t h t h e fast idle screw shank.

( 2 ) I n v e r t t h e carburetor a n d open t h e t h r o t t l e

valves t o w i d e open p o s i t i o n . Close t h e choke valve

t i g h t l y a n d t h e n close t h e t h r o t t l e valves. Release

the choke valve. T h i s w i l l p o s i t i o n the fast idle c a m

to fast idle. T h e i n d e x m a r k o n t h e c a m should s p l i t

the center o f t h e fast idle a d j u s t i n g screw, as s h o w n

i n F i g u r e 34.

( 3 ) I f an a d j u s t m e n t is necessary, bend t h e fast

idle connector r o d a t t h e angle, u s i n g Tool T109-213,

u n t i l t h e i n d e x m a r k on t h e c a m indexes t h e fast

idle a d j u s t i n g screw.

b.

Choke Unloader Adjustment ..

\

V

^ ^ ^ ^ ^ ^ ^ ^ ^ ^ ^ ^ ^ M

j

I 58x291

.

LIGHT FINGER

PRESSURE

AGAINST

CHOKE V A L V I

B E N D

UNLOADER LIP

T H R O T T L E VALVES WIDE O P E N

k

Fig.

35—Checking Choke Unloader (wide o p e n kick)

Adjustment

c. Accelerator Pump Adjustment

(1) Move t h e choke valve t o wide open position, t o

release the fast idle cam. B a c k off t h e idle speed

a d j u s t i n g screw ( c u r b i d l e ) u n t i l t h e t h r o t t l e valves

are seated i n t h e bores.

(2) Measure t h e distance f r o m t h e t o p o f t h e a i r

h o r n t o t h e t o p o f t h e p l u n g e r shaft, u s i n g a " T "

scale, as shown i n F i g u r e 36. T h i s distance should

be 7/16 i n c h on A F B 29035.

( 1 ) W i t h t h e t h r o t t l e valves i n t h e wide open posit i o n , i t should be possible to i n s e r t Tool T109-31 ( %

i n c h ) gauge between t h e upper edge o f t h e choke

valve a n d t h e i n n e r w a l l o f t h e a i r h o r n , as s h o w n

i n F i g u r e 35.

(3) I f an adjustment is necessary, bend t h e

t h r o t t l e connector r o d a t t h e l o w e r angle, u s i n g T o o l

T109-213, u n t i l correct t r a v e l has been obtained.

( 2 ) I f a n a d j u s t m e n t is necessary, bend t h e u n loader l i p o n t h e t h r o t t l e shaft lever, u s i n g Tool

T109-41, u n t i l correct opening has been obtained.

(1) To check t h e secondary t h r o t t l e lever adjustment, block t h e choke valve i n t h e w i d e open p o s i t i o n

and i n v e r t t h e carburetor.

d.

Secondary Throttle Lever Adjustment

-SCALE

PLUNGER S H A F T s

HOKE VALVE

OPEN

*7/16

A1

THIS A N G J f

: 11

:

;

Ah-

SHAHK O F FAST

- IDLE ADJUSTING

•V

BEND THROTTLE

C O N N E C T O R AT

THIS A N G L E ,

V- Vv

34—Fast Idle C a m Indexing

IDLE SPEED SCREW

BACKED O F F

THROTTLE VALVES SEATED IN BORES

VALVfS CLOS

Fig.

INCH

Fig.

58*292

36—Checking Accelerator Pump Travel

FUEL SYSTEM —25

Fig. 39—Cross-Over Choke Control Unit

Fig. 37—Checking Secondary Throttle Opening

(2) Slowly open t h e p r i m a r y t h r o t t l e valves u n t i l

i t is possible t o measure 19/64 i n c h between the

lower edge of the p r i m a r y valve and the bore (opposite idle p o r t ) as shown i n F i g u r e 37. A t t h i s

measurement, the secondary valves should j u s t s t a r t

to open.

(3) The stop lugs on b o t h t h e p r i m a r y and secondary t h r o t t l e levers should contact the bosses on the

flange at the same t i m e .

(4) I f an a d j u s t m e n t is necessary, bend the seco n d a r y t h r o t t l e o p e r a t i n g r o d at the angle, u s i n g

Tool T109-213, u n t i l correct adjustment has been

obtained.

(5) A t wide open t h r o t t l e , the p r i m a r y and seco n d a r y t h r o t t l e valves should reach the f u l l v e r t i c a l

position.

( 6 ) W i t h t h e p r i m a r y and secondary t h r o t t l e

valves i n the t i g h t l y closed p o s i t i o n , i t should be

possible t o I n s e r t Tool T109-29 (.020 i n c h ) w i r e

gauge, between the positive closing shoes on the

secondary t h r o t t l e levers, as shown i n F i g u r e 38.

( 7 ) I f a n a d j u s t m e n t is necessary, bend t h e shoe

on the secondary t h r o t t l e lever, u s i n g T o o l T109-22,

u n t i l correct clearance has been obtained.

©. Secondary Throttle Lock-Out Adjustment

( 1 ) Crack t h e t h r o t t l e valves, t h e n m a n u a l l y open

and close the choke valve. T h e t a n g on the secondary

t h r o t t l e lever should freely engage I n the notch o f

the lock-out dog.