Download Brake Unit Overview

Transcript

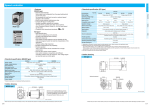

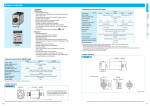

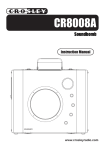

Brake Unit Contacting type • Features Outline of Brake Unit <SD type> <EX type> Product designation EX type 1 02 Voltage Type 1. Can be controlled using electrical signal. Electrical signal can be used for “run”, “quick stop” and “coast to stop” control of motors. 2. Operation time of the electric brake is adjustable. Operation time is set to a suitable value within the range from 0.1 to 2 sec 3. “Run” and “Instantaneous stop” lamps are provided. Index SD type • Separate type DZ9 Options 1. Compact 8P plug-in configuration. 2. Can be used in combination with other commercially available SSR (contactless relay). These combinations enable the use of electrical signals for “run” and “quick stop” control of motors. 3. The electric brake operates for approx. 0.5 sec. • These units are electric brakes that can stop motor immediately. • These brake units are divided into the contact (separate) type and contactless (48 mm sq.(1.89 inch sq.)) type. • Separate type brake units can be used with 3-phase motor. • The contactless 48 mm sq.(1.89 inch sq.) type brake units can be used with induction motor, reversible motor and electromagnetic brake motor. Brake Unit • These brake units are electric brakes used to instantaneously stop motors. • These electric brakes have longer life expectancy and can perform inching operation. Speed controller Brake Unit Overview SD type EX type 1: Single-phase 100 VAC 2: Single-phase 200 VAC 3: 3-phase 200 VAC • Names and functions • Braking time control Adjusts the time up to 2 sec (standard). Since longer braking current increases motor temperature, the shortest time necessary to stop the motor is the recommended setting. Separate type brake unit • Sq.48 mm contactless brake unit MODEL DZ9102 VOLTAGE AC100V • Brake lamp DVMB 48 1 L Brake unit Size Output Voltage 48 mm sq. (1.89 inch sq.) L : 100 V Y : 200 V Lights in red while the braking current is flowing. • Run lamp Lights in green while the motor is running. PHASE 1ø FREO. 50/60Hz CURRENT AC100V 3Amax DZ9113 EX type SD type 1: For induction motor 2: For reversible motor 3: For electromagnetic brake motor * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. C-46 C-47 Contacting type • Models and applicable motors SD type Brake Unit Contacting SD type The thick continuous lines in the circuit diagram below represent main circuit. Use conductor of approx. 0.75 mm2. The thin continuous lines represent signal circuit. Use conductor of size approx. 0.3 mm2. EX type Speed controller Brake Unit • DZ9102 and DZ9202 fundamental electrical wiring diagram (induction motor) DZ9102 DZ9202 DZ9302 DZ9113 DZ9213 Induction motor Reversible motor Rated voltage input SW3 3-phase 200 V CW RUN BRAKE White C1 DZ9202 DZ9302 Item SW2 RUN BRAKE RUN BRAKE SW3 Electric brake RUN BRAKE RUN BRAKE Motor T1 DZ9213 DZ9113 Single-phase 100 VAC Single-phase 200 VAC 50/60 Hz Power frequency 50/60 Hz Operation current 3 A Permissible current Operation current 3 A Applicable motor 3 to 90 W Applicable motor 3 to 90 W Braking method Feeds electric braking current for a specified time Braking method Feeds electric braking current for a specified time R2 7 8 Electric braking time 0.5 sec (typ) Electric braking time Variable up to 2 sec (typ) Operating temperature –10 to 50˚C Operating temperature –10 to 50˚C Storage temperature –10 to 60˚C Storage temperature –10 to 60˚C Gray SW1 100 V supply system Black SW2 200 V supply system SW3 R2 Capacitor Pin No. • When wired as shown above, the motor turns clockwise when viewed from the shaft end. To turn it counterclockwise, exchange brown and gray leads. [Notes] 1. Electric braking system has no holding torque. 2. For application requiring holding force, use Panasonic electromagnetic brake motor. 3. When braking a load with excessively large inertia, related issues are strength and life of motor shaft and gear. For these subjects, consult us. 4. When using motor other than compact geared motor, consult us. R2 R1+C1 DVOP008 (option) Motor 25 W or smaller 40 W or larger 100 V supply system 0Ω 30 Ω (approx. 100 W) 200 V supply system 0Ω 100 Ω (approx. 100 W) Control signal SD type Unit: mm (inch) EX type Unit: mm (inch) • When using power relay • When using contactless relay (SSR) RY3 HC relay (Panasonic Electric Works Co.,Ltd.), or equivalent 14.2(0.56) 50(1.97) 14.2(0.56) 36(1.42) 59(2.32) 93.5(3.68) 59(2.32) 50(1.97) 61(2.4) 36(1.42) NFB SW1 1 2 Rated voltage input R1 6 C1 R2 7 8 Gray Motor Vcc Capacitor RUN 5 4 33±3.0(1.3±0.12) 0.5(0.02) 8 6 2 1 3 7 ø29(ø1.14) 12.0(0.47) 5 39±0.1 (1.54±0.004) 48.4(1.9) ø3.8(ø0.15) 3.0(0.12) t0.8(0.031) 48±2(1.89±0.08) (2.2(0.087)) 10.5 –1.5 (0.41–0.059) 8.0(0.31) 6.0 (0.24) 4(0.16) 14.0(0.55) 20.8(0.82) 0.8 (0.03) 10.5 (0.41) 33(1.3) • External resistor for braking (for DZ9302 only) 5.2 (0.02) (ø2.5(ø0.01)) 9.0(0.35) 0.6(0.02) * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. Pin No. SSR INPUT CW White LOAD Brown R2 7 4 5 Vo • Socket (common to SD and EX) Connection for DZ9202 Gray Motor Black 8 R2 Ry3 Unit: mm (inch) Rated voltage input 6 Brown Black NFB SW1 1 2 White R5 Accessories SSR AQ2017 (Panasonic Electric Works Co.,Ltd.), or equivalent CW Connection for DZ9202 Ry3 4 6(0.24) 5 A or more at 250 VAC DC10V 10mA [Notes] 1. When SW2 and SW3 are switched from RUN to BRAKE, electric brake is applied for approx. 0.5 sec (T1) causing the motor to stop quickly. 2. Both SW2 and SW3 should be switched from RUN to BRAKE at the same time. 3. The wattage of R2 depends on frequency of start and stop operations. First check the power dissipation. • Outline drawing C-48 5 A or more at 125 VAC Index Power frequency Permissible current 3.2(0.13) T1 6 Part No. Rated voltage Braking Run ON Options DZ9102 Single-phase 100 VAC Single-phase 200 VAC 3-phase 200 VAC Rated voltage RUN Connection for DZ9202 <EX type> Part No. R1 Brown • Specification Item SW2 BRAKE 3 <SD type> Braking Run SW1 Single-phase 200 V 3-phase motor NFB SW1 1 2 Single-phase 100 V Brake Unit Rated voltage R5 R2 Vcc Capacitor If RUN Vo BRAKE BRAKE Pin No. [Notes] 1. Use 0 W R5 when Vcc is below 6 VDC. When Vcc is 6 VDC or higher, determine the value of R5 according to the equation shown below. Ripple of Vcc should be 5% or below. (Internal resistance 220 Ω) • Resistance of R5 R5 = Vcc – 6 V at If = 15 to 20 mA If Run SW1 • Example Vcc = 24 V If = 20 mA 24 – 6 R5 = = 900 Ω = 1 kΩ 20 x 10–3 Vo RUN Braking Braking Run ON BRAKE RUN BRAKE 2. Also refer to SSR handling precaution (see contactless relay catalog). * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. C-49 Contacting SD type The thick continuous lines in the circuit diagram below represent main circuit. Use conductor of approx. 0.75 mm2. The thin continuous lines represent signal circuit. Use conductor of size approx. 0.3 mm2. The thick continuous lines in the circuit diagram below represent main circuit. Use conductor of approx. 0.75 mm2. The thin continuous lines represent signal circuit. Use conductor of size approx. 0.3 mm2. • DZ9102 and DZ9202 standard electrical diagram (reversible motor) • DZ9302 fundamental electrical wiring diagram (3-phase motor) SW3 RUN BRAKE CW R1 SW2 SW4 RUN 3 6 RUN BRAKE C1 C1 White RUN 8 RUN Gray RUN BRAKE Black SW3 RUN RUN RUN SW5 CW R1 Ry5 6 NFB SW3 Ry4 Ry5 DV0P008 (option) Motor 25 W or smaller 40 W or larger 100 V supply system 0Ω 30 Ω (approx. 100 W) 200 V supply system 0Ω 100 Ω (approx. 100 W) 4 5 Pin No. R6 If Ry4 4 Vcc 5 Ry5 Vocw Vocw RUN LOAD White Gray R2 Black Capacitor R5 NFB SSR Black R2 Vcc Motor R6 R5 SW3 C1 Ry2 Ry1 Ry2 White Braking R1+C1 SW1 SW2 SW4 SW5 RUN BRAKE RUN SW3 RUN BRAKE RUN Motor Black Ry3 Ry2 Ry1 C1 Gray RY1, RY2 Run ON CW R1 SW1, SW6 AC250 V 10 A min. Accessory Braking 3ø AC200V Pin No. DC10 V 10 mA DV0P008 (option) R4 S T R BRAKE 7 R4 RY3 BRAKE Relay HP/HG (Panasonic Electric Works Co.,Ltd.) or equivalent DV0P008 (option) Accessory Twin contact or Au-clad contact relay Braking Run SW1 Braking Run ON T1 [Notes] 1. When SW2, SW3 and SW4 are switched from RUN to BRAKE, electric brake is applied for approx. 0.5 sec (T1) causing the motor to stop quickly. 2. Do not place these switches to RUN position while the electric braking is applied (T1). 3. A massive amount of current will flow through SW2, SW4 and SW5. Use a disconnecting device (switch or relay) rated at 10 A or more. When using a relay, use HP/HG (Panasonic Electric Works Co.,Ltd.) or equivalent. Capacitor SW6 RUN Ry2 ON ON Ry3 ON ON Ry1 Electric brake BRAKE RUN BRAKE ON ON T1 T1 [Notes] Ry1 and Ry2 should be interlocked to avoid simultaneous “ON”. Control signal Vocw Pin No. • When using power relay Voccw RUN BRAKE BRAKE SSR R6 RY1 Relay HP/HG (Panasonic Electric Works Co.,Ltd.) or equivalent NFB SW1 AQP107 (Panasonic Electric Works Co.,Ltd.), or equivalent 1 2 R4 6 R1 C1 Ry1 SW1 Vocw Voccw Electric brake RUN Braking Run ON White BRAKE BRAKE RUN T1 Gray 7 4 RUN BRAKE T1 R5 Vcc Ry1 If 5 RUN BRAKE RUN BRAKE Motor [Notes] 1. Use 0 Ω R5 when Vcc is below 6 VDC. When Vcc is 6 VDC or higher, determine the value of R5 according to the equation shown below. Ripple of Vcc should be 5% or below. (Internal resistance 220 Ω) • Resistance of R5 RUN Vo Pin No. Vo C1 Black Braking SW1 Braking Run ON CW R1 C1 Braking Run 3ø AC200V R1 Ry1 10 Ω Run S T R Ry1 * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. C-50 Ry2 C1 R1 AC250 V 10 A min. R1+C1 If [Notes] 1. Use 0 Ω R5 when Vcc is below 6 VDC. When Vcc is 6 VDC or higher, determine the value of R5 according to the equation shown in description for induction motor. Ripple of Vcc should be 5% or below. (Internal resistance 220 Ω) 2. Ry4 and Ry5 should be relay or electromagnetic contactor with the rated voltage two or more times the power supply voltage and the rated current 3 A or more. 3. Do not place Vocw and Voccw in RUN at the same time. 4. Be sure to use resistor R6 to protect relay, SSR and capacitor. Current will flow through R6 - 2 A 90 W; 1.7 A 60 W; 1 A 40 W; 0.6 A 25 W; 0.4 A 15 W. 5. Also refer to SSR handling precaution (see contactless relay catalog). R4 Ry1 Run AC100V LOAD INPUT SW6 RUN R1 Ry2 SW4, SW5 R1+C1 1 2 7 8 Gray R2 8 7 DC10 V 10 mA SW1 INPUT Ry1 Gray SW1, SW2 SSR Motor 7 3 6 C1 T1 • When using contactless relay (SSR) (Cannot be used for DZ9202) White R2 Motor Black SW4, SW5 200 V supply system 5 A or more at 250 VAC C1 C1 BRAKE SW1, SW2 100 V supply system 5 A or more at 125 VAC R1 Ry4 RUN Ry3 White T1 Rated voltage input Connection for DZ9202 C1 NFB SW1 1 2 Electric brake • When using power relay SW1 R4 CW R1 RUN Pin No. Control signal 1 2 C1 BRAKE Index CCW T1 R2 SW4 • For application using inching motion frequently If SW2 and SW5 emit long sparks, use of the following circuit is recommended. CW Electric brake [Notes] 1. When SW2 (SW4) and SW3 are switched from RUN to BRAKE, electric brake is applied for approx. 0.5 sec (T1) causing the motor to stop quickly. 2. Never place both SW2 and SW4 in RUN position at the same time. 3. Never select RUN while electric brake is applied (T1). 4. When using DZ9202, do not operate SW5 while the electric brake is being applied (T1). 5. The wattage of R2 should be determined based on frequency of start and stop operations. First check the power dissipation. R1 RUN R1 BRAKE Capacitor SW2 BRAKE 3 6 SW4 R2 Pin No. RUN Braking BRAKE 3ø AC200V SW3 BRAKE SW5 SW2 7 Run ON SW1 CCW R2 Braking Run Motor SW5 CW Clockwise T R CCW Counterclockwise R1 S 1 2 Options BRAKE Connection for DZ9202 CW NFB SW1 Rotating direction viewed from shaft end Rated voltage input Brake Unit NFB SW1 1 2 Speed controller Brake Unit BRAKE R5 = Vcc – 6 V at If = 15 to 20 mA If • Example Vcc = 24 V If = 20 mA 24 – 6 R5 = = 900 Ω = 1 kΩ 20 x 10–3 * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. C-51 Contacting EX type The thick continuous lines in the circuit diagram below represent main circuit. Use conductor of approx. 0.75 mm2. The thin continuous lines represent signal circuit. Use conductor of size approx. 0.3 mm2. Brake Unit Speed controller Brake Unit Contacting EX type • Stopping coasting DZ9113/DZ9213 • Coast stopping circuit wiring diagram • Operation • DZ9113/DZ9213 fundamental electrical wiring diagram (unidirectional rotation and braking) Input rated voltage 2 CW R7 • When wired as shown left, the motor turns clockwise when viewed from the shaft end. To turn it counterclockwise, exchange brown and gray leads. If 5 R7 6 Vo If V1 Vo RUN V1 FREE RUN Operation RUN Brake Unit NFB SW1 3 RUN BRAKE STOP RUN BRAKE STOP White 8 R2 Gray R2 Black 5 A or more at 125 VAC 200 V supply system 5 A or more at 250 VAC Motor Motor R2 Connection for DZ9113 1 100 V supply system 25 W or smaller R7 5 R7 If RUN If 6 Vo BRAKE Pin No. 100 V supply system 0Ω 30 Ω (approx. 100 W) 200 V supply system 0Ω 100 Ω (approx. 100 W) [Notes] 1. Use 0 Ω R5 when Vcc is below 6 VDC. When Vcc is 6 VDC or higher, determine the value of R5 according to the equation shown below. Ripple of Vcc should be 5% or below. (Internal resistance 90 Ω) • Resistance of R7 Braking Run SW1 ON Vo BRAKE RUN 2. The wattage of R2 depends on frequency of start and stop operations. First check the power dissipation. BRAKE RUN R7 = Vcc(MIN) – 6 V at If = 32 to 45 mA If • Example: Vcc (MIN) = 12 V If = 40 mA 12 – 6 R7 = = 150 Ω 40 x 10–3 Braking Run • DZ9113 application wiring diagram (normal/reverse rotation and braking) SW1 Motor Single-phase 100 V Reversible motor SSR AQP107 (Panasonic Electric Works Co.,Ltd.) or equivalent SSR INPUT White R2 7 8 R6 Gray R6 R2 4 Vcc Black Capacitor Voccw Vocw RUN BRAKE RUN 1 R7 I f 6 Pin No. Run Braking Run ON SW1 Vocw Voccw Electric brake Braking BRAKE RUN BRAKE RUN T1 • Contactless signal input driving • Wattage of fixed resistor (R2) 300 • These are internal equivalent circuits that may be used for contactless signal driving devices such as TTL and MOSIC. Electric power resistor 250 300 W 4 10 Ω 220 Ω RUN BRAKE [Notes] 1. For information on R2, SW1, etc., not found in this figure, refer to the fundamental electrical diagram shown above. 2. For information on the SSR, refer to the related documents available from the contactless relay manufacturer. 3. The rated voltage of SSR should be 2 times or more the power supply voltage and the surge rating should be 100 A or more. 4. Be sure to use resistor R6 to protect SSR and capacitor. Current will flow through R6 - 2 A 90 W; 0.7 A 60 W; 1 A 40 W; 0.6 A 25 W; 0.4 A 15 W. Determine the wattage by first checking the heat dissipation. 5. Never turn on the motor while the electric braking is operating (T1). 6. Do not place Vocw and Voccw in RUN position at the same time. 7. For Vcc and R7, refer to “Unidirectional rotation and braking” above. T1 * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. C-52 SD type, EX type The thick continuous lines in the circuit diagram below represent main circuit. Use conductor of approx. 0.75 mm2. The thin continuous lines represent signal circuit. Use conductor of size approx. 0.3 mm2. Motor R7 I f 5 Brake Unit NFB AC100V LOAD 1. Turning on and off of input voltage V1 on pin 6 causes coasting and braking, respectively. 2. For the resistance value of R7, refer to basic electric wiring diagram (negative direction rotation and braking) of DZ9113/DZ9213. 3. For the remaining wiring connections, refer to respective electric wiring diagrams. 5 SD type Required resistor wattage (W) 3 2 : Electric braking applied [Notes] Index Vcc Brake Free run 40 W or larger Capacitor 4 Pin No. 200 200 W 150 150 W With 200 VAC power supply R2 = 100 W (half-wave of 200 VAC) 1 sec ON, sec OFF 120 W 100 100 W 80 W 60 W 50 With 100 VAC power supply 4 Control circuit 7 SW1 Brown Options Connection for DZ9213 LED 150 Ω 220 Ω 40 W 12 14 16 18 20 OFF period (sec) 5 6 EX type R2 = 30 W (half-wave of 100 VAC) 1 sec ON, sec OFF 0 0 2 4 6 8 10 [Notes] The curves shown above are required wattage of electric power resistor R2 to maintain the surface temperature of it at 200˚C or below when it is driven with WR (average on/off cycle power) and 35% load factor. Load factor = 35% ON duration (braking time) = 1 sec (fixed) 1. When 100 VAC supply WR = 476/(Toff + 1) 2. When 200 VAC supply WR = 571/(Toff + 1) Example: 10 sec run; 5 sec stop; 1 sec braking; under 100 VAC WR = 476 / [(10 + 5 + 1) + 1] = 31.7 W * Please read your User's manual carefully so that you will understand the operation and safety precautions before attempting to operate the system. C-53