Download UM0379 User manual - STMicroelectronics

Transcript

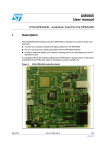

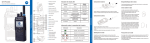

UM0379 User manual STM3210B-MCKIT and STR750-MCKIT 3-phase motor control power stage Introduction This manual describes the MB459B motor control evaluation board. The MB459B is an AC/AC power converter that generates a three-phase waveform for driving three-phase motors such as induction motors or PMSM motors. It includes: ● An input power stage with voltage rectification and auxiliary power supply, ● A 7A three-phase inverter based on IGBT and level shifter, ● A motor connector for linking with the control board, ● A connector for motors with Hall/encoder and tachometer input. The MB459B motor control evaluation board can be supplied in two ways: ● From a single power supply for motors requiring a voltage greater than 18 V; ● From a dual power supply for motors requiring a voltage less than 18 V. This manual describes where the various components are located on the motor control board, and the appropriate settings for driving a PMSM motor or an AC induction motor. The MB459B board is delivered with the STM3210B-MCKIT and STR750-MCKIT motor control kits. For more information on these kits, refer to www.st.com. December 2007 Rev 2 1/21 www.st.com Contents UM0379 Contents 1 Hardware layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3 Operational amplifier configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3.1 Three-shunt current reading configuration . . . . . . . . . . . . . . . . . . . . . . . . . 5 3.2 Single-shunt current reading configuration . . . . . . . . . . . . . . . . . . . . . . . . . 7 3.3 Jumper configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 4 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 5 Hardware settings for driving PMSM motors . . . . . . . . . . . . . . . . . . . . 11 6 Hardware settings for driving AC induction motors . . . . . . . . . . . . . . 12 7 Description of jumper and connector settings . . . . . . . . . . . . . . . . . . . 13 8 Schematic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 2/21 UM0379 1 Hardware layout Hardware layout This section illustrates the main connectors of the MB459B motor control board (see Figure 1), and describes their function. Figure 1. MB459B connectors 1 4 3 9 2 7 6 8 5 1. Motor and board input power stage, auxiliary power supply, and voltage rectification 2. Prototype area 3. J3 connector: power supply input 4. J1 connector: auxiliary supply input 5. J8 connector: Hall sensors / encoder input 6. J6 connector: tachometer input for closed-loop controlled AC motors 7. J5 connector: Three-phase output to motor 8. J7 motor connector: link to STR75x and to STM3210B-EVAL evaluation board, or other control board 9. 7A inverter and level shifter 3/21 Power supply 2 UM0379 Power supply The MB459B motor control evaluation board can be supplied from a single power supply or from a dual power supply. ● Single power supply for motors requiring a voltage greater than 18 V The power is supplied to the J3 connector. The voltage must not exceed 42V DC or 30Veff AC. It supplies both the motor and the motor control board. A 15V DC voltage is automatically generated for the motor control board logic. However, depending on the voltage supplied, two cases are possible: ● – If the supplied voltage is greater than 35V DC, the W1 jumper must be set in "HIGH VOLTAGE" position; – If the supplied voltage is between 18V and 35V DC, the W1 jumper must be set in the "<35V ONLY" position. Dual power supply for motors requiring a voltage less than 18 V The power for the motor is supplied to the J3 connector, while a separate power supply for the motor control board logic must be applied to the J1 connector (15V DC, 0.5 A). Caution: In the case of dual power supply, the W1 jumper must be removed and the D3 shortcircuit must be unsoldered (this is to avoid having reverse current in the linear voltage regulator). Note: On the J3 connector, the polarity of DC input is not important. Figure 2 shows where the power supply connectors are located on the board. Figure 2. MB459B power supply connectors 1 3 2 1. J1 connector: 15V DC, 0.5 A power supply input (used in dual power supply mode to supply the motor control board logic). 2. J3 connector: motor power supply (in dual power supply mode) or motor plus motor control board power supply (in single power supply mode). Up to 42V DC or 30Veff AC. 3. W1 jumper. In single power supply mode, selects the motor voltage; in dual power supply mode, it must be removed. 4/21 UM0379 3 Operational amplifier configuration Operational amplifier configuration The MB459B motor control evaluation board can be configured to run in two current reading configuration modes: ● Three-shunt configuration ● Single-shunt configuration Single-shunt configuration requires a single op-amp, three-shunt configuration requires three op-amps, and for compatibility purposes, one of them must be common to the two configurations. Jumpers W7, W8 and W9 allow you to set the common op-amp to achieve the compatibility between single-shunt and three-shunt current reading mode. The TSV994 used on the motor control board has a 20MHz gain bandwidth and operates with a single positive supply. Three-shunt current reading configuration Figure 3 gives the op-amp configuration for the three-shunt current reading mode. In this configuration, the alternating signal on the shunt resistor, with positive and negative values, must be translated to be compatible with the single positive input voltage of the microcontroller’s analog-to-digital converter used to read the current value. This means that the op-amp must be polarized in order to obtain on the output a voltage that makes it possible to measure the symmetrical alternating input signal. Three-shunt configuration U e shunt i1 r1 i2 +5V r3 v r2 7 Figure 3. 3 + 2 - 6 s 4 3.1 R r 5/21 Operational amplifier configuration UM0379 The op-amp is used in follower mode with a gain set by resistors r and R. G = s / v = (R + r)/r The relation between the input signal e and the signal v on the positive input of the follower is: v = (U/(k*r3) + e/(k*r1)) where k =(1/r1+1/r2+1/r3) The resistor values implemented on the MB549B board are: R=5400Ω \ r=1000Ω \ r1=660Ω \ r2=560Ω \ r3=4700Ω and U=5V Therefore, the gain is: G = 6.4 The response of the op-amp is represented in Figure 4. Figure 4. Voltage response in three-shunt configuration Op_Amp Output Vout Op_Amp 3.500 3.000 2.500 2.000 Series2 1.500 1.000 0.500 0.000 -0.6 -0.4 -0.2 0 0.2 0.4 0.6 V shunt With these settings, the output voltage of the op-amp is equal to 1.94V for a nil current. The peak current that can be measured in this configuration is: +/- 5A for R_shunt = 0.1ohms +/- 2.3A for R_shunt = 0.22 ohms 6/21 UM0379 Single-shunt current reading configuration In the single-shunt current reading configuration, the current sampling is done only when the value on the shunt resistor is positive. The only positive value read on the shunt resistor allows to set a higher gain for the op-amp than the one set in three-shunt mode. However, because the input of the op-amp is not railto-rail, in this configuration also, it is necessary to polarize the it to compensate for this limitation. Figure 5 shows the op-amp configuration used in single-shunt configuration. Figure 5. Single-shunt configuration +5V shunt U r1 i1 w r4 i2 v 7 e r2 3 + 2 - 6 s 4 3.2 Operational amplifier configuration r3 R r The op-amp is used in follower mode with a gain set by resistors r and R. G = s/v = (R + r)/r The relation between the input signal e and the signal v on the positive input of the follower is: v = ((U*h)/(k*r4) + f(e)) with: k =(1/r3+1/(r1+r2)+1/r4) h=r1/ (r1 +r2) f(e)=(e*r2)/ (r1 + r2) + (e*r1)/((k*(r1+r2)*(r1+r2)) The resistor values implemented on the MB549B board are: R=11000Ω \ r=1000Ω \ r1=1130Ω \ r2=1000Ω \ r3=22Ω \ r4=2200Ω and U=5V Therefore, the gain is: G = 12 7/21 Operational amplifier configuration UM0379 The response of the op-amp is shown in Figure 6. Figure 6. Voltage response in single-shunt configuration Vout Op_Amp Op_Amp Output 3.500 3.000 2.500 2.000 1.500 1.000 Series1 0.500 0.000 0 0.1 0.2 0.3 0.4 0.5 0.6 V shunt In this configuration, the output voltage of the op-amp is equal to 3.16V when the maximum peak current that is measured in R_shunt is reached: + 5A for R_shunt = 0.1Ω or + 2.3A for R_shunt = 0.22Ω 8/21 UM0379 Jumper configuration Based on the two current reading configurations for single-shunt and three-shunt, the final configuration of the common op-amp is summarized in Figure 7. Figure 7. Common op-amp configuration +5V W8 shunt 7 e 1_Shunt 3 + 2 - 6 s 4 3.3 Operational amplifier configuration W7 W9 U 3_Shunts 9/21 Electrical specifications 4 UM0379 Electrical specifications Table 1 provides the maximum ratings for the MB459B motor control board. Table 1. Motor control evaluation board electrical specifications Parameter Maximum ratings Motor types Three-phase PMSM or AC motor Main input voltage (J3) 42V DC or 30 Veff AC Auxiliary input voltage (J1) 15V DC, 0.5A Maximum output current on motor phases (J5) 7A The maximum current allowed on the motor phases is mainly dependent on the shunt resistor value and op-amp gain. For further information, see Section 3: Operational amplifier configuration on page 5. 10/21 UM0379 5 Hardware settings for driving PMSM motors Hardware settings for driving PMSM motors To drive the PMSM motor, you must simply ensure that the MB459B motor control board is driven by a control board that outputs the six signals required to drive the three-phase power stage. The MB469B STR75x evaluation board provided in the STR750-MCKIT or the STM3210B-EVAL evaluation board provided with the STM3210B-MCKIT are perfectly suited for this task. To drive any other generic high voltage PMSM motor, you must ensure that: ● your PMSM motor is connected on the motor control board in place of the PMSM motor provided, on the J5 and J8 connectors, ● the motor phases are connected to the board on the J5 connector, ● the encoder from the PMSM motor is connected to the board on the J8 connector For example, for the Shinano PMSM motor provided with the STR750-MCKIT and the STM3210B-MCKIT the connections are listed in Table 2. Table 2. Jumper settings for a PMSM motor (default settings) Jumper Settings for the supplied SHINANO 24V PMSM motor Settings for a generic high voltage PMSM motor W1 “< 35V Only” “< 35V Only” or “ HIGH VOLTAGE” W4 Present W5 Not present W6 Present W7 Present and set to default position of silk-screen printing W8 Present W9 Present W10 Present W11 Present W12 Not present W13 Not present W14 Not present W15 Not present W16 Present and set to reverse position of silk-screen printing W17 Present W18 Present W19 Present 11/21 Hardware settings for driving AC induction motors 6 UM0379 Hardware settings for driving AC induction motors To drive an AC induction motor, you must ensure that: ● The motor control evaluation board is driven by an adapted control board that outputs the six signals required to drive the three-phase power stage, ● The AC induction motor is connected on the motor control board in place of the PMSM motor, ● The AC induction motor phases are connected to the board on the J5 connector, ● The tacho generator is connected to the board on the J6 connector. Table 3. Jumper settings for an AC Induction motor Jumper 12/21 Settings for a generic AC motor with tachometer feedback W1 “< 35V Only” or “ HIGH VOLTAGE” W4 Present W5 Not present W6 Present W7 Present and set to default position of silk-screen printing W8 Present W9 Present W10 Present W11 Present W12 Present W13 Not present W14 Not present W15 Not present W16 Present - any position W17 Not present W18 Not present W19 Not present UM0379 7 Description of jumper and connector settings Description of jumper and connector settings Table 4. Jumper descriptions Jumper Selection Description “ HIGH VOLTAGE” Motor supply is greater than 35V DC or 25Veff AC. “< 35V Only” Motor supply is less than 35V DC or 25Veff AC. Not present Power motor supply is separate from motor control circuit.The motor control circuit must be supplied with 15V DC (0.5A) on J1 connector. In this case, the D3 short-circuit must be removed (unsoldered) from the PCB. Refer to Section 2: Power supply for details. Present Connects R3 shunt resistor to T2 IGBT source for the three shunt configuration. Not present Disconnects R3 from T2 IGBT source for the single shunt configuration. Present Connects the T2 IGBT source to R4 shunt resistor for the single shunt configuration. Not present Disconnects the T2 IGBT source from R4 shunt resistor for the three shunt configuration. Present Connects the output of thermal comparator on shutdown to the pin 2 input of the L6386 MOS-driver. In such cases, the thermal protection can also generate an emergency stop forcing the Fault signal to low. Not present Disables feedback of thermal comparator on L6386 MOS-driver. Set to default position of silk-screen printing Selects the input polarization of Phase B current op-amp for the three shunt configuration. Set to reverse position of silk-screen printing Selects the input polarization of Phase B current op-amp for the single shunt configuration. Present Sets the input resistor of Phase B current op-amp for three shunt configuration. Not present Sets the input resistor of Phase B current op-amp for single shunt configuration. Present Sets the gain resistor of Phase B current op-amp for three shunt configuration. Not present Sets the gain resistor of Phase B current op-amp for single shunt configuration. Set to default position of silk-screen printing Connects R5 shunt resistor to T6 IGBT source for the three shunt configuration. Set to reverse position of silk-screen printing Connects the T6 IGBT source to R4 shunt resistor for the single shunt configuration. W1 W4 W5 W6 W7 W8 W9 W10 13/21 Description of jumper and connector settings Table 4. UM0379 Jumper descriptions (continued) Jumper Selection Description Present Connects the output of diagnostic comparator to the Fault/MC EMGCY input of microcontroller pin P1.10 Not present Disconnects the output of diagnostic comparator from the Fault/MC EMGCY input of microcontroller pin P1.10 Present Connects the tachometer signal to Measure Phase A / TIM2_TI1 input P0.03. In that case, W17 is not present (removed). Not present Disconnects the tachometer signal from Measure Phase A / TIM2_TI1 input P0.03. Present The 3.3V Pow supply connected to Vdd_m is used to supply the microcontroller board connected on pin 26 of the motor control connector J7. Not present Vdd_m is not connected to the 3.3V Pow of power board. Present The 5V supply connected to Vdd_m, is used to supply the microcontroller board connected on pin 26 of the motor control connector J7. Not present Vdd_m is not connected to the 5V of the power board. Present Uses the 5V of the microcontroller board to supply the power board via the motor control connector J7. Not present The 5V of the power board is not supplied by the microcontroller board. Set to default position of silk-screen printing The +Vdd_m is used to supply the Hall sensor or encoder Set to reverse position of silk-screen printing The +5V is used to supply the Hall sensor or encoder Present Enables Hall1/A+ on Measure Phase A/ TIM2_TI1 input P0.03 Not present Disables Hall1/A+ for Measure Phase A/ TIM2_TI1 input P0.03 Present Enables Hall2/B+ on Measure Phase B/ TIM2_TI2 input P1.03 Not present Disables Hall2/B+ for Measure Phase B/ TIM2_TI2 input P1.03 Present Enables Hall3/Z+ on Measure Phase C/ TIM0_TI1 input P0.01 Not present Disables Hall3/Z+ for Measure Phase C/ TIM0_TI1 input P0.01 W11 W12 W13 W14 W15 W16 W17 W18 W19 14/21 UM0379 Description of jumper and connector settings Table 5. Name Connector pinout descriptions Reference 2 J1 J2 J3 2 1 1 2 3 1 J4 12 Optional 15V DC, 0.5A input connector to supply the motor control board logic separately from the motor power stage. 1) 15V DC power supply 2) Vss power 15V DC output connector to supply auxiliary board. This connector is not mounted. 1) 15 V DC power supply 2) VSS power Up to 42V DC or 30Veff AC power supply input connector. 1) Earth/ground 2) Power input (AC/DC) 3) Power input (AC/DC) BEMF daughter board connector 1) Phase A 2) Not connected 3) Phase B 4) Not connected 5) Phase C 6) Not connected 7) Bus voltage 8) Not connected 9) +5V 10) +Vdd_m 11) Vss board 12) PWM Vref Motor three-phase output. 1) Motor phase C 2) Motor phase A 3) Motor phase B 4) DC bus middle point (may be used for two-phase motors) 5) Earth 5 J5 1 J6 1 Description/pinout 2 1 Tachometer input connector for AC motor speed loop control. 1) Tachometer bias (0.6 V) 2) Tachometer input 15/21 Description of jumper and connector settings 2 34 Reference 1 Name Connector pinout descriptions (continued) 33 Table 5. J7 1 J8 16/21 UM0379 5 Description/pinout Motor control connector 1) EMERGENCY STOP ---------------- 2) GND 3) PWM-1H ---------------------------------- 4) GND 5) PWM-1L ---------------------------------- 6) GND 7) PWM-2H ---------------------------------- 8) GND 9) PWM-2L --------------------------------- 10) GND 11) PWM-3H ------------------------------- 12) GND 13) PWM-3L ------------------------------ 14) HV BUS VOLTAGE 15) Current PHASE A ---------------- 16) GND 17) Current PHASE B----------------- 18) GND 19) Current PHASE C----------------- 20) GND 21) NTC BYPASS RELAY ---------- 22) GND 23) DISSIPATIVE BRAKE PWM - 24) GND 25) +V Power ---------------------------- 26) Heatsink temperature 27) PFC Sync --------------------------- 28) Vdd_m 29) PWM Vref --------------------------- 30) GND 31) Measure Phase A ---------------- 32) GND 33) Measure Phase B ---------------- 34) Measure Phase C Hall sensors/ encoder input connector 1) Hall sensor input 1 / encoder A+ 2) Hall sensor input 2 / encoder B+ 3) Hall sensor input 3 / encoder Z+ 4) 5V DC power supply 5) VSS board UM0379 8 Schematic diagrams Schematic diagrams The MB459B motor control evaluation board schematics are split into two sheets: ● Sheet 1/2 Current Measurement (Figure 8), shows the op-amp wiring and configuration, the encoder/ Hall sensor adaptation, the tacho input stage and the motor control connector wiring. ● Sheet 2/2 Power Switch (Figure 9), shows the power converter with its associated level shifter and all auxiliary power supplies. The version of the board described in this manual is MB459-B01. The board version information can be found on a sticker on the component side of the PCB (the visible one), on the bottom left edge of the board when reading the serigraphy. The changes on this version of the board compared with the previous version MB459-B00 are summarized below: ● Operational amplifiers have changed, TSV994 replacing TSH24. ● The value of capacitors C37, C42, and C47 has increased from 10pF to 100pF. ● The value of resistors R13, R23 and R52 has decreased from 2.2kΩ to 1.8kΩ. ● The D3 diode is now short-circuited. ● The board can also be driven by the STM3210B-EVAL board. 17/21 1 +Vdd_m W14 2 2 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 All resistors 1% +3.3V Pow W13 1 1 3 5 7 9 11 13 15 17 19 21 23 25 1 27 29 31 33 34CONT J7 R29 1K C38 33P 560 R33 4K7 R31 R51 1K C46 33P 2 R49 560 R45 1K R39 4K7 R40 560 C41 33P +5V I Low Phase B W7 I Low Phase C Heatsink Temperature +5V 1 1K R58 R48 560 R59 470 I High Phase C HV Bus R57 22 R56 2K2 +5V 4K7 R55 I High Phase B 2 W8 I Low Phase A 1 3 - C37 9 2K7 R60 8 TSV994 PWM_Brake R68 2 +5V 47K W15 PWM Vref Measure Phase A Measure Phase B R66 47K R67 47K TP39 1 1K R54 47K R71 47K R70 TP43 TP25 47K R69 TP42 TP29 1K R62 1K R38 TP28 TP40 W9 R61 5K6 2K7 R27 2 TP38 2K7 R28 100P Measure Phase C 1 TSV994 U6C + Current Phase A Current Phase B Current Phase C Fault - U6A + 100N C43 4μ7 25V 2K7 R47 7 TSV994 C11 C47 100P 2 3 10 2K7 R50 R30 560 - 2K7 R46 C42 100P 6 +5V R41 560 U6B + +Vdd_m +Vdd_m PWM_2L PWM_Brake PWM_3L PWM_3H 100N 2 3 4 5 Hall3/Z+ +5V GND TP31 PWM_3LBuf PWM_3HBuf PWM_2LBuf PWM_2HBuf PWM_1LBuf PWM_1HBuf _ PWM_Brake Wrapping Area R65 1K - 220P R35 39K U6D + C62 13 3 14 R 2 3 Size A4 Date: U21A 6 4μ7 100N C51 TP33 R79 10K D17 BAS16 D18 BAS16 R75 10K TS372 MB 459 Wednesday, September 12, 2007 Document Number MCU Application Lab +Vdd_m 2 2 2 Sheet 1 of 2 R ev B-01 Drawn by: JM CHARRETON Vincent ONDE Approved by: Measure Phase A Measure Phase B 2 W19 W18 W17 W12 TP32 C54 2N2 1 C56 1 1 1 10P Measure Phase C R73 100 T7 BC817 R72 10K TP35 TP37 TP36 C57 10P C58 4K7 10P R77 4K7 +Vdd_m C55 100N R74 0(NC) 1 Thermal Protection R78 + U20A - 25V 74HC09 100N C60 3 74HC09 8 74HC09 3-Phase power stage MB459 C59 100N U21C U21B C14 +Vdd_m +5V 2 1 10 9 5 4 Organisation name: 2 1 J6 1K R64 +5V R82 4K7 Title: R81 4K7 C61 100N 50V Vref R80 TSH24 W16 C52 330P R32 10K 12 +5V 1 2 Heatsink Temperature R34 10K +Vdd_m Kontek-Comatel 1 Hall2/B+ J8 11 Hall1/A+ 74HC09 U21D Temp 13 12 74HCT7007 5 U8C 6 74HCT7007 9 U8D 8 74HCT7007 11 U8E 10 74HCT7007 13 U8F 12 74HCT7007 PWM_1L 3 U8B 4 PWM_2H 2 C50 1 U8A 74HCT7007 PWM_1H +5V Current Phase C BAR43 D14 Current Phase B BAR43 D16 TP41 +Vdd_m Current Phase A BAR43 D15 HALL SENSOR / ENCODER 5 4 11 +5V 14 7 14 7 4K7 TACHO METER R76 4K7 18/21 8 Figure 8. 4 I High Phase A Schematic diagrams UM0379 Schematics sheet 1/2: current measurement J1 100μF 25V C15 22N 10μ 25V C20 BAS16 fus5x20 4 FB VDD IN 3 + High Voltage TP8 SOURCE DRAIN RES SET 1.5KE18P OUT OUT OUT OUT 2 3 6 7 100μF 25V 1μ 25V C53 TP34 C3 TP3 R10 1K5 D2 +15V U3 VIPER12AS-E 0.23V GREEN LED LD1 C22 3 2 Y C2 4N7 Y C1 4N7 R Title: Size Custom Date: MB 459 Wednesday, September 12, 2007 Document Number MCU Application Lab 3-Phase power stage MB459 Organisation name: Z1 1μ C16 U1 2 L7805CP or CV +3.3V Pow C18 100N 1 WA627-003 Mounted on 30°C/W Heatsink X2 Sheet 2 of 2 C7 1000μF 200V WIRING 2 C8 1000μF 200V 1 2.54 linebar D3 1 C45 +15V 10μF 35V C9 C33 PWM_3LBuf 1.8K 2.2nF R23 PW M_2HBuf PWM_2LBuf 1.8K 2.2nF R13 C27 1 7 6 5 4 3 2 1 7 6 5 4 3 2 1 LIN U5 GND CIN DIAG VCC HIN SD LIN U4 GND CIN DIAG VCC HIN SD LIN VBOOT L6386D R20 1K GND LVG NC NC OUT HVG VBOOT L6386D R12 1K GND LVG NC NC OUT HVG VBOOT 14 8 9 10 11 12 13 14 8 9 10 11 12 13 14 C39 22 R14 220 D13 R44 BAS16 D10 R19 22 220 R17 BAS16 D11 R15 TP27 1μ 25V C29 C32 22N TP18 1μ 25V C30 22 220 R8 BAS16 220 R9 BAS16 D6 R11 22 R6 D7 TP19 1μ 25V C25 C26 22N TP9 1μ 25V C24 TP14 T1 TP23 R4 0R22 5% T4 STGF7NC60HD T3 STGF7NC60HD PWM Vref +5V +Vdd_m Bus Voltage Phase C with 1.27 & 2.54 footprint 5V, 15V, GND, Max CURRENT: 50mA PWM_Brake Pin WRAPPING AREA 1 W6 1N 10μF 35V C12 1.8K 2.2nF R52 C48 PWM_3HBuf 7 6 5 4 3 2 U7 GND CIN DIAG VCC HIN SD L6386D R43 1K GND LVG NC NC OUT HVG 8 9 10 11 12 13 1μ 25V C44 22N TP26 1μ 25V 220 BAS16 220 R36 BAS16 D12 R42 22 R37 22 C40 TP30 R25 100 C21 Temp I High Phase B W5 W4 C49 10N 2 R53 100 R5 0R22 5% W10 C13 10N 400V I Low Phase B 10N C36 C10 10N 400V to be soldered STGF7NC60HD C5 10N 400V STGF7NC60HD I High Phase C T6 STGF7NC60HD T5 10N R7 120R TP6 Phase B Phase C Phase C Phase B I Low Phase C to be soldered TP24 C31 10N I Low Phase A R3 0R22 5% TP16 Phase A Phase A To be soldered W2 X4 KM100-1 I High Phase A R16 100 TP10 Mounted on 2.9°C/W KM100-1 AAVID Thermalloy Heatsink NTC2 Mounted on 2.9°C/W KM100-1 AAVID Thermalloy Heatsink TP13 T2 +5V STGF7NC60HD 2 R26 47K 1N C34 +15V 10μF 35V C4 PWM_1HBuf PWM_1LBuf TP7 Mounted on 2.9°C/W KM100-1 AAVID Thermalloy Heatsink TP21 Vref 6 5 1K R24 1N C28 +15V Bus Voltage Phase B 1 +5V TP20 R63 3K3 R22 8.2K R21 470K HV Bus R18 470K + 2 7 U20B TS372 TP_0 TP2 C35 47N TP_0 TP1 CTN10K To Heatsink Phase A TP44 W11 NC (short) TP12 R1 47K 1W R2 47K 1W Thermal Protection Fault 2 1μ 25V U2 2 L7815CP or CV C17 1 2 3 4 5 6 7 8 9 10 11 12 J4 +5V TP5 R ev B-01 WA627-003 Mounted on 30°C/W Heatsink X3 BZW50-120B 50V Drawn by: JM CHARRETON Vincent ONDE Approved by: 1μ 25V C19 1mH (nc) L2 1 W3 BZW50-120B Z2 35V Max TP4 D1 3 TP17 1.5KE36A W1 Z3 BZW50-100B C6 100N 400V TOKO 8 R H B PANASONIC E L C 0 9 D 102 F 1mH L1 1 SW1: Must Be on 35V Max for 24V External Supply D4 STBR608 U10 LD1117D33 JACK 15V 1 2 3 Stick Supply J2 MKDSN 1,5/2-5,08 2 1 D8 F1 3.15A TEMP TV1505 Mounted on 17°C/W AAVID Thermalloy heatsink X1 NTC1 SG170 (4R) TP11 Z4 BZX84C15 TP22 1 2 3 To be soldered for AC voltage doubler configuration This drawing may not be reproduced by a third party unless permission is obtained in writing from ST MICROELECTRONICS +5V GND +15VDC D5 STTH112U STTH112U D9 C23 220N AC/DC input GMKDS 3/3-7,62 4 J3 MSTBA2,54/5-G-5,08 + 4 1 - 4 5 2 J5 8 7 6 5 1 2 C 1 A 2 B 3 GND 1 3 MOTOR BEMF_Daughter Board 3 2 1 2 1 1 1 2 TP15 Figure 9. 3 UM0379 Schematic diagrams Schematics sheet 2/2: power switch 19/21 Revision history 9 UM0379 Revision history Table 6. 20/21 Document revision history Date Revision Changes 7-Feb-2007 1 Initial release. 17-Dec-2007 2 Added list of changes to the MB459B board compared with the previous version in Section 8: Schematic diagrams. Update for release of STM32B-MCKIT motor control kit. UM0379 Please Read Carefully: Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to ST’s terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein. UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK. Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST. ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners. © 2007 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com 21/21