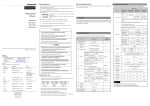

Download E1-Line configuration description (Type: DTVA)

Transcript