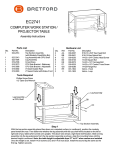

Download ERECTION - High Access Solutions

Transcript

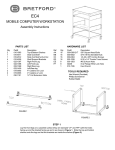

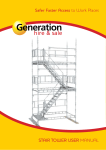

I GENERATION i BBANCHES Birmingham Glasgow TrinityStreet,OffTatBankRoad, 35 DuchessRoad,Ruthergien, Oldbury,WestMidlands.B694LA. Glasgow.G731AU. Tel:01215443355. Fax:01215443131. Tel:01416476969. Fax:01416475851. email:[email protected]:[email protected] Bristol MeritonStreet,St.PhillipsMarsh, Bristol,Avon.BS2OSlo Tei:01179724550. Fax:0117972 4502. email:[email protected] Leeds Unit2 LedgerPark HaighParkRoad, Stourlon,Leeds.LS101RT. Tel:0113277 8822.Fax:01132779977. email:[email protected] Cardiff MartinRoad,TremorfaIndustrialEstate, Cardiff.CF245SD. Tel:029 20463835. Fax:029 20463246. email:[email protected] London KierbeckBusinessComplex, NorthWoolwichRoad, Silvertown,London.E162BG. Tel:0207473 6056. Fax:0207473 2077. email:[email protected] Chelmsford Bannisters Yard,MayesLane, Newcastle Sandon,Chelmsford, Essex.CM27RP. ForwardHousePortobelloRoad Tel:01245227771. Fax:01245226111. PortobelloIndustrialEstate,' email:[email protected] Birtiey,Tyne& Wear.DH32SL. Tel:01914921190. Fax:01914111148. Edinburgh email:[email protected] 4 WestertonRoad,EastMainsInd.Est. Broxburn,WestLothian.EH55AU Tel:01506863864. Fax:01506863916. email:[email protected] Northampton DallingtonFieldsBusinessPark KingsfieldWay,OffGladstone Road, Dallington,Northampton. NN57aN. Tei:01604580444. Fax:01604580487. email:[email protected] Southampton ClaylandsRoad,BishopsWaltham, Hants.S0321BH. Tel:01489894411. Fax:01489894455. email:[email protected] ...... neration HAKIStairtower User's Guide Stockport Unit4 VauxhallIndustrialEstate, GregStreet,Reddish, Stockport.SK57BR. Tel:01614770131. Fax:01614777618. email:[email protected] Taplow(Thames Valley) PioneerWorks,MarshLane, Tapiow,Maidenhead, Berks.SL6ODF. Tel:01628673835.Fax01628634788. email:[email protected] SafetyCheckList 1. Is thescaffold/supporting structurecompletedandreadyfor theStairtower? 2. Is thegroundconditionadequateto takethe loadimposed? 3. Isthe correctequipmenton site? 4. Is theequipmentin goodworkingorder? 5. Isthe correctPersonalProtectionEquipment availableandin goodworkingorder? 6. Areallthe componentsintheircorrectpositionandall lockingcatchesengaged? 7. Isthe Stairtoweradequately bracedandanchored? 8. Haveanyitemsbeenremoved? HealthandSafelyat WorkAct,1974 HAKIequipmentis designedto meettherequirements of theaboveAct,Section6. It is alsothe customer'sresponsibilityto compiywiththe requirements of thisAct, particularlyto usetheequipmentin accordance withcurrentcodesof practiceandin ensuringthatcomponentsarein goodworkingcondilionpriorto eachuse. Weareabieto provideassistanceandadviceon mattersrelatingto safeandproperuseof HAKIequipment. .. GAneration ..;::; hire & sale FREEPHONE 0800 783 8376 TrinityStreet,OffTatBankRoad,Oldbury,WestMidlands.B694LA. Telephone. 01215432950. Fax.01215432951. E [email protected] Generation Generation/BP1.l0/04 . hire & sale [rnJ] HAKr BASICINFORMATION ANDMODULARMEASUREMENTS [rnJ] INTRODUCTION General Marking HAKIStair Tower is made All components with the exception of locks, from prefabricated components. The stair tower is built using standards, and ledger beams. Other stair tower components include stair flights, landings, handrail and guardrails. The stair tower can be built as a separate construction or integrated into other scaffolding or staging. All components are of galvanised HAKr bolt pins etc. come permanently marked with the HAKllogo and the year of manufacture (2 figures).(Forexample: lID.98) Guardrail frame Guardrail frame steel. Clip On Post Guardrail Top End Guard Frame Wall tie & A WARNING All INFORMATION CONTAINED IN THIS MANUAL APPLIES ONLY TO COMPONENTS Handrail post MANUFACTURED AND SUPPLIED BY HAKI. Handrail Standard ledger beam ANY COMPONENTS ORIGINATING FROM OTHER SOURCES WHICH ARE INCORPORATED INTO A STRUCTUREWill INVALIDATE THIS Stairflight Folding Guard Frame INFORMATION. IN SUCH CASE, HAKI HAS NO PRODUCT LIABILITY. BY MIXING COMPONENTS OF OTHER MANUFACTURE MAY INVALIDATE INSURANCE THIS landing Basejack POLICY COVER. ~OSI1] Published May 2003 subject to change Customers' responsibility to check for changes 2 3 m HAKr Name Article numbers and weights are for galvanized options unless otherwise stated. please refer to HAKIprice listfor the corresponding details for painted options. Name Art. No. Base Jack 1091001 Size Folding Weight (kg) Art. No. Locking Pin 0.5m 3.3 7017101 1.0m 1.5m 2.0m 3.0m 6.0 8.6 11.3 16.7 5141256 Q Weight (kg) 9.2 4.7 7017051 7017151 7017201 7017301 Size 1122191 Guard Frame Stair Flight Standard m HAKr LISTOF COMPONENTS LISTOF COMPONENTS 7101100 1.0m 35.3 7101150 1.5m 2.0m 42.1 7101200 I 33.6 0.3 Handrail Post - 4.9 7015100 I Ledger Beam 7021160 7021300 --oD 1.605m 3.0m 1.6m Ledger Beam has beenreplaced witha 1.6m SingleTube Beam. This change has no effect on the strength of the tower Landing Entron<e s~ - ,. 10.2 18.8 rI r 7022161 1.605m 6.3kg 7095000 29.1 7103160 15.1 I Stair Handrail It j I ......... Guardrail ~ 4 1211136 1222231 1.0m 1.5m 10.5 12.5 1222222 2.0m 13.8 8742160 8722216 8722300 1.605m 2.16m 3.0m 6.4 8.0 11.0 5 . [I] HAKrl GENERALNOTES LIST OF COMPONENTS Name Art. No. Size GuardrailFrame 7052160 7052300 1.605m 3.0m . Weight (kg) 10.9 15.4 J:fO 7122160 7121300 Diagonal Brace 1.605 (L=2.34m) 3.0m (L=3.49) 9.8 15.6 HAKIStairTower 7053000 7.3 ~ StairtowerHeight MaxPersons* 8 74 BaseJacks 10 91 The stair tower is mounted on Base Jacks which are adjustable in height. This means the standards can always be adjusted to ensure that the beams are horizontal. 12 108 14 125 16 127 18 125 20 122 22 119 24 116 Beams 26 114 The stair tower is built using 1.605m and 3.0m ledger beams, with 2.0m, 1.5m or 1.Ombetween the platforms depending on which stair flight is used. 28 III 30 108 32 106 34 103 36 100 38 97 40 95 42 92 44 89 46 87 48 84 50 81 Standards Anchorage 7015000 Clip On Post 6.6 The stair tower must be anchored to the structures at each platform levelon both sides (inner and outer standards) using scaffold tube and couplers - see Page 15. PermissibleLoadsOn Standards when calculating the permissible loads on standards, the followingvalues apply, provided that all other requirements are fulfilled. Stair tower with 2.0m stair flights 34kN per standard. Erection Platform 2091316 1.605xO.6m 15.0 Forheightsover 50m, consult SpecialSolutions HAKITechnicalDepartment For scaffolding constructions not covered by this User's Manual, please contact the HAKI Technical Department. 6 HAKr Number of personspermitted All HAKISystems have been designed to conform to current Britishand European Standards. The loading criteria contained in this manual have been calculated according to current BritishStandards. Standards of 3m and 2m in length are used wherever possible. Shorter standards may be used as top standards. Top End Guard Frame [I] * Basedon max. lOOkg per person 7 - [I] HAKrl ~ Ll.1 Note: Prior to starting ERECTION erection, determine position ERECTION of tower. Always for clockwise direction of ascent. BEFORE STARTING ERECTION, ALWAYS CHECK WHERE ACCESS POINTS . ALWAYS ENSURE THAT SIDE ACCESS POINTS ONLY OCCUR IN 2m 1[1]HAKr Check distance from structure. start with stair flight ARE REQUIRED. UFTS ! For base jacks as shown. Set out sole plates and base plates at position of standards, ledger beams and transom beams. Place base jacks onto sole plates, adjust to estimated final height. 1 5. ~ levell st liftfollowing clockwise direction. level by adjusting base jacks as necessary. 1. place standard on base jacks, ensure that pockets are running in direction as shown (Iowpocket, 1.605m direction, high pocket 3.0m position). 6. 2. Check base liftis square using a tape measure. Connect 3.0m ledger beam to higher level pockets. Connect 1.605m ledger beams to lower level pockets. 7. )l place 1 st landingA, on ledger beams as shown (fig 8).Place Erecting Platform,B,at opposite end of bay (foot lilt). Install2nd levelof ledger beams.(Check drawing for l.5m or 2.0m liftheights). Next landing,C, is located by working off Erecting Platform,B. The landing on this lift,and all further lifts,are initiallypositioned on ledger beams approximately O.5m from end of bay. Engage all locking catches as you proceed. ,t & ~ ~ 8. 8 9 ~ HAKrl ERECTION rr I ERECTION I ....1 .'\ I If I ~ outside face of the stair flight. 'i 12. 9. Fit entrance step to tower. I~ HAKr rIT\.;>uararall rrames and Guardrails to the ~.. ~ 1.1 ~ The stair tower must be anchored to the struc- tures at each platform level on both ends (inner and outer standards) using scaffold Uppermost erector clips to mid point of ledger beam. Both erectors then fix Stair Handrail tube and couplers. Postinto top and lower landings. Then, Stair Handrail is located into pockets of posts and locking catches engaged. Stair flight is positioned vertically and located into pockets of lower landing (11 A & 11B). Flight is then lowered onto landing above (11 C) and pushed along (11 D) until top of stair flight is fully located into pockets of upper landing (11 E). Note. At this stage check top and bottom of stair is fully engaged into both landing pockets. Stairflights should be erected for a clockwise ascent. 13. Fit Folding Guard Frame into handrail post and standard at entrance of stair. 11B. Re-position Erecting Platform onto next lift directly above lower landing. 15. 10 11 ..... [I] HAKrl ERECTION I ~ ERECTION 1[1]HAKr NB:Ties should be fitted to structure and tower ateach level before erecting next lift. Erector 1 proceeds up stair flightand fits temporary Clip-On Post to ledger beam close to erecting platform. Erector 1 then hooks to ledger, and, using clip-on-post for support, he climbs onto Erecting Platform. Note: Clip-On Post is only used to facilitate climbing to exposed landing 16. Erector 2 proceeds up stair flightonto landing, hooks onto ledger beam close to standard. Forfurther liftsrepeat procedures 8, 11-13, 15- 20 until reaching final exit levelor mid exit points. 17. Next standards are added to all four legs. Temporary Clip-On Post may now be removed to a safe place until it is required again - eg end 1.605m ledgerbeam. 21. Entrance/exit at top of tower. Erector 1 is safely standing on landing and hooked on to centre of 1.605m ledger beam, fits 3.0m guardrail frame with Erector 2 safely standing on erecting platform at opposite end of tower, hooked onto 1.605m ledger beam. Erector 1 then fitsTopGuard Frame into handrail post and landing as shown. 18. FitGuardrail Frames to face and end of tower as shown. Fitledger beams to next liftrequired (1.5m or 2.0m). Re-hook to upper ledger near standards. 19. 12 13 [I] HAKrl ERECTION = ERECTION 1[1] HAKr Shows construction of the HAKI Stair Tower with the 3.0m face parallel to the structure or scaffold (side exits). Forsideexit Erector 1 is safely standing on landing and fits clip on post to inside ledger beam. Erector 2 standing on erecting platform at opposite end oftower hooked onto 1.605m ledger beam. Bothoperators then fit2.16m guardrails or 2.16m guardrail frame into Clip On Postand standard ensuring lockingcatches are engaged. Means of access/ egress at side of tower is then complete. Using tube & couplers, the tower should be tied to the structure below each lift position (except first lift) through both inside & outside Forendexit Shows construction of the HAKI Stair Tower with the 1.605m face parallel to the structure or scaffold (end exits). standards. Erector 1 is safely standing on landing. Erector 2 standing on erecting platform at opposite end of tower clipped onto 1.605m ledger beam. Bothoperators then fit 3.0m guardrail frame at each side of tower. Remove 1.605m Guard from landing position. Means of access/egress at end of tower is then complete. Using tube & couplers, the tower should be tied to the structure below each lift position (except first lift) A. to inside standards, and B. using diagonal tubes to outside standards. Access For dismantling the Stair Tower, the reverse of the above squence should be followed. Points Itisonly possible to have a side access point (3.05m) in a 2.0m lift. Access to/from end of tower (1.655m) is not restricted, but 1.605m ledger Beam may have to be raised to create sufficientheadroom when access liftis less than 2.0m. --- 14 15