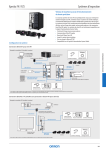

Download Vision System FH series - Digi-Key

Transcript