Download Каталог Affri

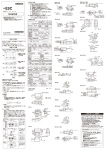

Transcript