Download View/Open - Oregon State University

Transcript

AN ABSTRACT OF THE THESIS OF

Brenda E. Thompson for the degree of Master of Science in Electrical and Computer

Engineering presented on January 17, 1995. Title: Three-Dimensional Finite Element

Design Procedure for the Brush less Doubly Fed Machine.

Redacted for Privacy

Abstract approved:

Dr. Alan K. Wallace

Brush less Doubly Fed Machines (BDFM) have potential advantages in variable

speed generation and adjustable speed drive applications. The most significant of these

advantages is a reduction in the power electronic converter rating, and therefore a

reduction in overall system cost. Presently, efforts are being directed at optimizing the

design of the BDFM and investigating areas of commercial feasibility. One possible aid

in the investigation of design alternatives is finite element analysis.

Finite element analysis is a numerical method for determining the field

distribution in a dimensional model. Finite element techniques have been successfully

used for some time in the design of induction, reluctance and permanent magnet

machines. However, the characteristics of the BDFM require adjustment of the finite

element design procedure used for conventional singly-fed induction machines. In this

thesis, a three-dimensional finite element design procedure for modeling the BDFM has

been developed. This design procedure avoids the difficulties previously associated

with finite element modeling of the BDFM.

.

The three-dimensional finite element design procedure developed in this thesis

was used to model the 6/2 pole 5 horsepower BDFM laboratory machine. From the

simulation results, the induced currents in the BDFM rotor bars were calculated.

In the course of investigating three-dimensional finite element analysis for the

BDFM, two different commercially available finite element analysis software packages

were examined and tested. The first was Maxwell 3D Field Simulator produced by

Ansoft Corporation, and the second was MSC/EMAS (Electromagnetic Analysis

System) and MSC/XL by MacNeal-Schwendler Corporation. These two software

packages are compared and their advantages and disadvantages/limitations are

discussed.

A tutorial for setting up and solving a three-dimensional BDFM model using

MSC/XL and MSC/EMAS is presented. This goal of this tutorial is to guide a new user

of MSC/XL and MSC/EMAS through the creation, setup, simulation, and analysis of a

BDFM model. This tutorial contains condensed information included in the MSC/XL

and MSC/EMAS program documentation provided by MacNeal-Schwendler. In

addition, modeling techniques particular to the BDFM, which are not included in the

program documentation, are described. This tutorial is applicable only to those

individuals interested in learning how to use MSC/XL and MSC/EMAS in order to

simulate a BDFM model.

Three-Dimensional Finite Element Design Procedure for the Brush less

Doubly Fed Machine

by

Brenda E. Thompson

A THESIS

submitted to

Oregon State University

in partial fulfillment of

the requirements for the

degree of

Master of Science

Completed January 17, 1995

Commencement June 1995

Master of Science thesis of Brenda E. Thompson presented on January 17, 1995

APPROVED:

Redacted for Privacy

Major Professor, representing Electrical and Computer Engineering

Redacted for Privacy

Chair of Department of Electric 1 and Computer Engineering

Redacted for Privacy

Dean of Graduate

I understand that my thesis will become part of the permanent collection of Oregon State

University libraries. My signature below authorizes release of my thesis to any reader

upon request.

Redacted for Privacy

Brenda E. Thompson, Auth r

ACKNOWLEDGMENTS

I would like to thank my major professor, Dr. Alan Wallace, for the amount of

time and effort he has put into guiding me towards the completion of my thesis, for first

suggesting that I get involved in working with finite element analysis of the BDFM, and

for his willingness to help when I had questions about the BDFM or my finite element

results. I would also like to thank Dr. Rene Spee and Dr. G. C. Alexander for their

helpful suggestions about my finite element work and other topics. Special thanks to

Dr. Alan Wallace, Dr. Molly Shor, Dr. G. C. Alexander, and Dr. David Butler, Graduate

Council Representative, for being on my defense committee.

I would like to thank all the student members of the BDFM research and design

group for their helpful suggestions about my work, during BDFM meetings and other

times: Shibashis Bhowmik, Michael Boger, Bhanu Gorti, Tim Lewis, Sreekumar

Natarajan, Arif Salim, Ernesto Weidenbrug, and Donsheng Zhou. I would like to thank

Arif Salim for introducing me to finite element analysis and teaching me how to use

Maxwell 2D Field Simulator by Ansoft Corporation.

I would like to thank James Neuner and Pat Lamers, members of the MacnealSchwendler customer support staff, for their willingness to answer questions about

Macneal-Schwendler's software in a timely manner. Their help was very valuable in

learning how to use this software.

I would like to thank Tom Lieuallan for his help in setting up the HP

workstation, installing the finite element software, and for his willingness to provide

help whenever I had a computer question or problem.

I would like to thank Ed Lake for helping me to proofread my thesis, and for his

help instructing me in the creation of the figures contained in this thesis with AutoCad.

Finally, I would like to thank my parents and close friends for their love, support

and encouragement during my years at Oregon State University.

Table of Contents

1.

Introduction

1

2.

Brush less Doubly Fed Machine

3

3.

4.

2.1

BDFM Characteristics

3

2.2

Basic Performance Equations

4

2.3

Applications of the BDFM

6

Finite Element Analysis Method

7

3.1

Definition and Concept

7

3.2

Finite Element Model

7

3.3

Solution of Maxwell's Equations

8

3.4

Data Recovery

Finite Element Design Procedure for the BDFM

4.1

4.2

4.3

12

13

Methods of Modeling Induction Motors

13

4.1.1 Solution Frequency

13

4.1.2 Periodic Boundary Conditions

14

FE Modeling of Doubly Fed Characteristics

15

4.2.1 Complications of the Nested Rotor Structure

4.2.2 Inclusion of Two Excitation Frequencies

4.2.3 Boundary Conditions More Difficult to Determine

15

15

15

Three-Dimensional Simulation of the BDFM

16

4.3.1 Modeling in the Rotor Reference Frame vs. the Stator Reference

4.4

Frame

4.3.2 Symmetry of the BDFM Model

17

18

Results of the BDFM Model Simulations

19

Device Geometry

4.4.2 A Coarse 360 Degree BDFM Model

4.4.2.1 Materials...

4.4.2.2 Excitations

4.4.2.3 Boundary Conditions

4.4.2.4 Solution Frequency for an AC Analysis

4.4.1

4.4.2.5 Results

4.4.2.5.1 Contour Plot of Magnetic Vector Potential

4.4.2.5.2 Arrow Plot of Magnetic Flux Density

4.4.2.5.3 Currents in the Rotor Bars

4.4.3 A Coarse 180 Degree BDFM Model

4.4.3.1 Boundary Conditions

4.4.3.2 Results

4.4.3.2.1 Contour Plot of Magnetic Vector Potential

4.4.3.2.2 Arrow Plot of Magnetic Flux Density

4.4.3.2.3 Currents in the Rotor Bars

4.4.4 A Detailed 180 Degree BDFM Model

4.4.4.1 Results

4.4.4.1.1 Currents in the Rotor Bars

4.4.4.1.2 Distribution of Conduction Current Density

Within the Rotor Bars

5.

Comparison of Two Three-Dimensional Finite Element Analysis Software

Packages

5.1

Introduction

5.2 Maxwell 3D Field Simulator by Ansoft Corporation

5.2.1

5.2.2

5.3

Advantages

5.2.1.1 Solid Modeling Procedure

5.2.1.2 Step-by-Step Design Procedure

5.2.1.3 Automated Meshing Technique

Disadvantages/Limitations

5.2.2.1 Only Two Analysis Modules Available

5.2.2.2 Solution Parameters have to be Re-entered each Time a

Modification is Made

5.2.2.3 Very Poor Program Diagnostics

5.2.2.3.1 Program Continues to Execute and Status is

not Available to the User

5.2.2.4 Poor Customer Support

5.2.2.5 No results due to Problem Encountered

MSC/XL and MSC/EMAS by MacNeal-Schwendler Corporation

20

22

23

24

24

26

27

27

27

30

32

34

34

35

36

36

39

40

40

43

49

49

49

49

49

51

52

53

53

54

54

55

55

56

56

5.3.1

5.3.2

6.

A.

Advantages

5.3.1.1 Many Modeling Modules Available for a Variety of

Problems

5.3.1.2 Well Documented Program Diagnostics

5.3.1.3 Setup Parameters are Saved and only have to be

Entered Once

Disadvantages/Limitations

5.3.2.1 Wireframe Modeler

5.3.2.2 No Step-by-Step Procedure Menu

56

56

57

57

58

58

59

Conclusions and Recommendations

60

BIBLIOGRAPHY

64

APPENDIX

66

Tutorial for Setting up and Solving a 3D BDFM Model using MSC/XL and

MSC/EMAS

67

A.1

Introduction

A.2 An Overview of MSC/XL

A.2.1

Screen Layout

A.2.2 Using the Mouse

A.2.3 Capabilities

A.2.4 Data Files

67

67

68

68

70

70

A.3 An Overview of MSC/EMAS

72

A.4 Modeling Tasks

74

A.4.1 Planning the MSC Session

A.4.1.1 Deciding on Units

A.4.1.2 Drawing a symmetry "Wedge"

A.4.1.3 Entering MSC/XL

A.4.2 Creating Geometry

A.4.2.1 "Undo" Command and "Delete Item" Option

A.4.2.2 Defining a New Coordinate System

A.4.2.3 Creating Points

A.4.2.3.1 Define Point

A.4.2.4 Creating Curves

A.4.2.4.1 Connect Points

A.4.2.4.2 Sweep Point

A.4.2.4.3 Reflect Curve

75

75

76

78

79

79

80

81

81

82

82

83

84

A.4.2.4.4 Rotate Curve

A.4.2.4.5 Define Curve

A.4.2.5 Creating Surfaces

A.4.3 Generating Finite Elements

A.4.3.1 Finite Element Terminology

A.4.3.1.1 Grid Points

A.4.3.1.2 Elements

A.4.3.2 Key Factors in Meshing

A.4.3.2.1 Element Choice

A.4.3.2.2 Element Connections

A.4.3.2.3 Mesh Density

A.4.3.2.4 Mesh Order

A.4.3.2.5 Element Distortion

A.4.3.3 Preparation for Meshing - Assigning PIDs

A.4.3.4 Meshing in MSC/XL

A.4.3.4.1 Parametric Meshing

A.4.3.4.2 Connect Grids

A.4.3.4.3 Reflecting and Rotating the Mesh

A.4.3.5 Mesh Checking Procedures

A.4.3.5.1 Duplicate Grid Points

A.4.3.5.2 Unconnected Grid Points

A.4.3.5.3 Duplicate Elements

A.4.3.5.4 Free Edges or Free Faces

A.4.3.5.5 Element Voids

A.4.3.6 Mesh Organization

A.4.3.6.1 Using Groups

A.4.3.6.2 Using Parts

A.4.3.7 Extruding the Two Dimensional Mesh to Make a

Three-Dimensional Mesh

A.4.4 Problem Setup

A.4.4.1 Material Properties

A.4.4.1.1 Permittivity

A.4.4.1.1.1 Isotropic Permittivity

A.4.4.1.1.2 Anisotropic (Symmetric)

Permittivity

A.4.4.1.1.3 Unsymmetric Permittivity

A.4.4.1.2 Conductivity

A.4.4.1.3 Permeability

A.4.4.1.4 Setting Material Properties in MSC/XL

A.4.4.1.5 Material Properties for the BDFM Model

A.4.4.2 Excitations

A.4.4.2.1 Available Excitations

A.4.4.2.2 Applying Excitations to the BDFM Model

A.4.4.3 Boundary Conditions

A.4.4.3.1 Fixed Boundary Conditions

84

86

87

87

88

88

89

89

90

91

92

92

93

94

96

97

98

99

101

102

103

103

103

105

106

106

107

108

111

111

112

112

113

113

113

114

115

117

118

119

119

122

123

A.4.4.3.2 Periodic Boundary Conditions

A.4.4.3.3 Applying Boundary Conditions to the

BDFM Model

A.4.4.3.3.1 Outer Boundaries

A.4.4.3.3.2 Periodic Boundaries for the 180

Degree Model

A.4.4.4 AC Analysis Preparation

A.4.4.4.1 Control Section

A.4.4.4.2 Unit Section

A.4.4.4.3 Degrees of Freedom

A.4.5 Solving the Problem

A.4.5.1 Invoking MSC/EMAS

A.4.5.2 System Requirements

A.4.5.3 Solution Time

A.4.6 Results and Validation

A.4.6.1 Accessing MSC/EMAS Results

A.4.6.2 Producing Contour Plots

A.4.6.3 Producing Arrow Plots

A.4.6.4 Results Plots on Cut Surfaces

A.4.6.5 XY Plotting along Cut Paths

A.4.6.6 Calculations

A.4.6.7 Generating Hardcopy Files

125

126

126

127

128

129

129

129

129

129

131

132

134

134

135

136

138

139

141

142

List of Figures

2.1 BDFM Stator Structure

3

2.2 BDFM Rotor Structure

4

2.3 Velocities of Interacting Fields

5

Stator Lamination

21

4.2 Rotor Lamination

20

4.3 Coarse Three-Dimensional 360 Degree BDFM Finite Element Model

22

4.4 Stator Excitations for the 360 Degree BDFM Model

25

4.5 Boundary Conditions for the 360 degree BDFM Model

26

4.6 Contour Plot of Magnetic Vector Potential along a Center Cross-Section

of the 360 Degree BDFM Model

28

4.7 Arrow Plot of Magnetic Flux Density along a Center Cross-Section of

the 360 Degree BDFM Model

29

4.8 Rotor Bar Labels for the 360 Degree BDFM Model

32

4.9 Coarse Three-Dimensional 180 degree BDFM Finite Element Model

33

4.10 Boundary Conditions for the Coarse 180 Degree BDFM Model

35

4.11 Contour Plot of Magnetic Vector Potential along a Center Cross-Section

of the Coarse 180 Degree BDFM Model

37

4.12 Arrow Plot of Magnetic Flux Density along a Center Cross-Section of

the Coarse 180 Degree BDFM Model

38

4.13 Rotor Bar Labels for the Coarse 180 Degree BDFM Model

39

4.14 Detailed Three-Dimensional 180 degree BDFM Finite Element Model

41

4.15 Rotor Bar Labels for the Detailed 180 Degree BDFM Model

41

4.16 Slot Span vs. Rotor Bar Current Magnitude

43

4.1

4.17 Path along which Conduction Current Density was Plotted from Bottom to Top

45

4.18 Conduction Current Density in Bar 6 (in reference to Figure 4.17)

46

4.19 Conduction Current Density in Bar 7 (in reference to Figure 4.17)

46

4.20 Path along which Conduction Current Density was Plotted from Right to Left

47

4.21 Conduction Current Density in Bar 6 (in reference to Figure 4.20)

48

4.22 Conduction Current Density in Bar 7 (in reference to Figure 4.20)

48

List of Tables

4.1 Material Properties used in the 360 Degree BDFM Model

24

4.2 Total Calculated Currents in the Rotor Bars for the 360 Degree BDFM

Model

31

4.3 Total Calculated Currents in the Rotor Bars for the Coarse 180 Degree

BDFM Model

4.4 Total Calculated Currents in the Rotor Bars for the Detailed 180 Degree

BDFM Model

36

42

List of Appendix Figures

A.1 MSC/XL Screen Layout

69

A.2 Data Flow in MSC/XL

71

A.3 Data Flow in MSC/EMAS

73

A.4 Radial Cross-Section of the BDFM Model

77

A.5 Finite Elements and Grid Points

89

A.6 Available Two and Three-Dimensional Elements

91

A.7 Distortion of Midedge Nodes, Aspect Ratios, and Taper Angles

94

A.8 Typical Mesh Errors

102

A.9 Fixed Boundary Conditions

123

A.10 Alternating Periodic Boundary Conditions

125

A.11 Disk Space Requirements for MSC/EMAS based on the cellular cube and

flat plate for MSC/NASTRAN solution 101 run [17]

133

List of Appendix Tables

A.1 MKS Units

76

A.2 Assignment of PIDs to Two Dimensional Elements

95

A.3 Assignment of PIDs to Three-Dimensional Elements

95

A.4 Supplied Materials in MSC/XL

116

A.5 Materials Used in the Setup of the BDFM Model

118

A.6 Six Pole Stator Winding Layout

119

A.7 Two Pole Stator Winding Layout

120

Three-Dimensional Finite Element Design Procedure for the Brush less

Doubly Fed Machine

1. Introduction

Due to recent improvements in power electronics, adjustable speed drives

(ASDs) are being installed in increasing numbers in industrial applications. However,

the majority of all industrial and commercial motors still operate at fixed speed.

Similarly, fixed speed generators provide the bulk of the world's power supply, although

many power sources could be more efficiently converted if variable speed generation

(VSG) were used.

The transition from fixed speed systems to ASD and VSG systems has been

delayed by the fact that the speed of AC machines is linked to their frequency. Although

frequency control by power electronics has made significant advances in recent years, it

still has two major obstacles preventing its more widespread application. First, the cost

of electronic power converters is many times higher than the cost of the machines they

control. Second, the electronic power converters pollute the power supply system with

harmonics of voltage and current. Possible solutions to the harmonic problem serve to

increase the cost of the system. Therefore, it is important to investigate possible

methods for minimizing the ratings, and hence costs, of power electronic converters.

Ongoing studies at Oregon State University have shown the potential for many

advantages by using a doubly-fed connection of the self-cascaded induction machine in

ASD and VSG applications [1-5]. The use of a self-cascaded, or brushless doubly-fed

machine (BDFM), in combination with a power electronic converter, can offer a number

of advantages over conventional induction machines in ASD and VSG systems. These

advantages include tolerance to power converter failure, controllable power factor, and

2

reduced harmonic pollution. Most importantly, depending on the requirements of the

application, a reduction in the power electronic converter rating, and therefore cost, can

be achieved.

Presently, efforts are being directed at optimizing the design of the BDFM and

investigating areas of commercial feasibility. One possible aid in the investigation of

design alternatives is finite element analysis. Finite element analysis is a numerical

method for determining the field distribution in a dimensional model. This thesis will

emphasize only the electromagnetic field distribution in a three-dimensional model

geometry. Finite element techniques have been successfully used for some time in the

design of induction, reluctance and permanent magnet machines. From a finite element

solution, important design quantities such as flux distribution, flux density, winding

inductance, eddy currents, hysteresis losses, force, torque and losses can be calculated.

Applying the finite element technique to the BDFM, however, has posed a number of

difficulties. This thesis will present a design method for modeling the BDFM using

finite element techniques.

3

2. Brushless Doubly Fed Machine

2.1

BDFM Characteristics

The stator winding connection of the BDFM is based on the work of L. J. Hunt

[6] and later developments by Creedy [7]. The BDFM stator, as shown in Figure 2.1,

consists of two sets of three phase stator windings of different pole numbers and

3phase

adj. frequency

Bidirectional

Converter

(25% rating)

3phase

60 hz

0

0

fP

p

Figure 2.1: BDFM Stator Structure

different frequencies. These two separate sets of windings are wound on the same stator

frame and share the same slots. One set of windings is the power winding, which is

connected directly to the power supply system and which supplies the bulk of the

machine power. The second set is the control winding, which supplies a fraction of the

machine power through a power electronic converter. The advantage of the BDFM

system over more conventional motors and generators is that most of the power flows

directly between the machine and the power system. Therefore, the rating of the

4

required converter should be a fraction of that required to process all of the machine

power, thus reducing cost and induced harmonics of the power electronics.

The rotor design of the BDFM is based on work by Creedy and Broadway [7,8].

As shown in Figure 2.2, the BDFM rotor is an unique, cage type rotor with nested loops.

Unlike the squirrel cage rotor of an induction motor, which has rings to short all the

rotor bars on both ends, the BDFM rotor has a ring to short all the rotor bars only on one

end while at the other end the bars are selectively shorted together to form distinct

loops. The rotor design is mechanically simple enough to be die-cast, while at the same

time having the capability of supporting two fields of different pole numbers and

different frequencies from the stator.

Isolated

Endring

n

1

Common

Endring

Figure 2.2: BDFM Rotor Structure

2.2

Basic Performance Equations

The number of loop groupings or rotor nests is determined by the sum of the

pole-pairs of the power and control windings:

5

Number of Nests = Pp + Pc

(Equation 2.1)

where Pp is the number of pole-pairs of the power winding, and Pc is the number of

pole-pairs of the control winding.

The BDFM has all the robust, maintenance-free features of a squirrel-cage

induction machine. In order to operate successfully, the BDFM must switch from

operation as two induction motors in the same magnetic circuit (the "double-induction"

mode) to a mode where the rotor field induced by one of the stator windings is locked

together with the stator field of the other stator winding, and vice versa (the

"synchronous mode").

fc

PP

Pc

f RC

rotor

fr

PP

positive

direction

Figure 2.3: Velocities of Interacting Fields

In the synchronous mode the field interaction and the mechanical speed of the

rotor, as shown in Figure 2.3, are related by [9]

Dp

P

and

= f.r + fRc

p

iP

(Equation 2.2)

6

f.=

f+

fRp

Pc

(Equation 2.3)

Pc

where f., and fe are the frequencies applied to the power and control windings,

respectively; fRp and fRC are the rotor frequencies induced by interaction with the fields

of the power and control windings; fr is the mechanical rotational frequency.

For synchronous operation to be attained, it is required that

Lc =fRP

(Equation 2.4)

with the result that

.fr =

f±L

PPP + Pc

(Equation 2.5)

The control frequency, fc, can either be positive (same sequence as fp), or

negative (opposite sequence to fp). The electrical frequency of rotor currents in

synchronous operation can be related to the system frequencies as [9]

fr,ri= fp Ppfr = Pcf, T- fc

2.3

(Equation 2.6)

Applications of the BDFM

The BDFM can be used in place of commercial and industrial squirrel-cage AC

induction machines. It is particularly suited for potential niche applications in ASD or

VSG systems including, but not limited to, pump drives, wind power generation, and

automotive alternators.

7

3. Finite Element Analysis Method

3.1

Definition and Concept

Finite Element Analysis (FEA) is a numerical method that is widely used to

solve many engineering problems. One application of FEA is to solve for the

electromagnetic fields in electrical devices. Electromagnetic fields represent the

foundation of all electrical engineering. Maxwell's equations, a system of four coupled

partial differential equations, serve as the basis for electromagnetic field calculations.

The solution of these equations, however, is a very difficult task.

Often engineers approximate field behavior through abstract concepts. Much

insight can be gained from analytic techniques and approximations. However, such

techniques are useful only in relatively simple devices, and at some point

approximations will fail. More often engineers require accurate solutions involving

complicated materials, geometries, and loading conditions. For this reason, engineers

are turning to numerical methods for answers to real life problems.

FEA is one numerical method of solving Maxwell's differential equations. There

are several steps that make up the finite element method.

3.2

Finite Element Model

The first step in FEA is to specify a finite element model. The model geometry

describes the size and shape of the device to be analyzed. The geometry is divided into

8

subregions called finite elements. Elements may be irregular so that the modeling of

complicated geometries is both easier and more accurate. Points where elements join

are referred to as grid points. Material properties, excitations, and boundary conditions

are applied to the finite element model. Material properties associated with elements

represent the permittivity, conductivity, and permeability properties of the various

materials in different regions of the model. Excitations such as currents are applied to

the model. Boundary conditions are used to simulate physical behavior outside the

model boundaries.

3.3

Solution of Maxwell's Equations

Maxwell's equations are the basis for electromagnetic field calculations. These

four partial differential equations relate the space and time variation of electric and

magnetic fields to material properties, and to excitations. They describe a broad range

of behavior, including electrostatics, magnetostatics, eddy currents, waveguides,

antennas, etc. Thus, Maxwell's equations form the basis for the analysis of virtually

every electromagnetic device, from computer microcircuitry, to large power generators

and transformers. Maxwell's equations [10] are traditionally written as:

v .n

P free

(Equation 3.1)

vh=o

(Equation 3.2)

vxt,ii

(Equation 3.3)

vxii=icond F ii

(Equation 3.4)

9

These four equations state the following:

Gauss's law: the sources of D are free charge

B has no sources

Faraday's law: electric fields are induced by time-varying magnetic fields

Ampere's law: the sources of T-1 are conduction current plus the

displacement current

The fields (electric field E and magnetic field B) are the primary unknown

quantities of interest in electromagnetic field analysis. However, there are three

disadvantages to solving directly for the unknown vectors E and /3 First, the six

.

unknown components of these two fields in three-dimensional space cannot be chosen

arbitrarily because they are related through Maxwell's equations. Thus, the number of

unknowns is larger than is actually needed. The second disadvantage is related to

discontinuities in material properties. There are two well-known boundary conditions

that must be met at such interfaces: (1) the normal component of D must be

continuous across the interface; (2) the tangent component of H must be continuous.

Any solution strategy that involves E and B must enforce these conditions at every

interface. This requirement puts an unnecessary burden on numerical computations.

The third disadvantage is that E and B may be infinite at sharp corners of certain

materials. These infinite solutions cause numerical difficulties in computers.

10

Therefore, electromagnetic potential functions are introduced to eliminate the

disadvantages of dealing with E and B directly. These potential functions are the

magnetic vector potential A , and a time-integrated electric scalar potential, If . In

terms of these potential functions, the electric and magnetic fields are given by [10]:

(Equation 3.5)

t= V

tif

A

(Equation 3.6)

Maxwell's equations are rewritten in terms of these potential functions. The

values of A and 'If at the model grid points are called degrees of freedom (DOFs).

There are four DOFs at each grid point: three components of the vector potential and

one component of the scalar potential.

The principle of virtual work is now used to formulate the overall energy stored

in the solution region according to the following energy relationships:

h

(Equation 3.7)

WE = 2 E :6

(Equation 3.8)

Wif =

17/

.

The objective is to solve for the unknown potentials A and I' by minimization of the

energy function [10]. The problem volume is divided into finite elements. The energy

associated with each element is computed in terms of the potential degrees of freedom;

the results are then summed over the elements to represent the energy of the entire

problem volume. When the energy function is set to zero, a single equation is obtained.

11

This equation is entirely equivalent to Maxwell's equations in their complete and

general form. This equation is [10]:

(Equation 3.9)

[6] 04+[a] fil}+[--1 1{u}={.-7}

where the vector {u} represents the four DOFs per grid point, the matrix [6] represents

permittivity, the matrix [a] represents conductivity, the matrix

[1

represents

permeability, and {J} is an excitation vector which represents the contributions of all

model excitations.

The associated initial condition is:

[E] f/1;1= Oil

(Equation 3.10)

These matrix equations, which are equivalent to Maxwell's equations in their

complete and general form, are solved using a formal series of matrix operations for the

unknown potentials:

(Equation 3.11)

The numerical methods used to solve Equations 3.7 and 3.8 are specified by

solution sequences [10]. Each sequence represents a particular mathematical technique.

Thus, a particular application may be analyzed using several techniques, such as

magnetostatic analysis, frequency response analysis, transient analysis, or eigenvalue

analysis.

12

3.4

Data Recovery

Once a solution for the potential DOFs at each grid point have been obtained,

the fields E and h are recovered within each element. Other quantities, such as

electromagnetic energies, induced conduction currents, power losses, etc., can also be

determined.

13

4. Finite Element Design Procedure for the BDFM

Methods of Modeling Induction Motors

4.1

Finite element analysis techniques have been used successfully for some time in

the design of induction, reluctance and permanent magnet machines. Neglecting end

effects, these machines can easily be investigated using two-dimensional finite element

analysis.

In three-phase ac squirrel-cage induction motors, the rotor current distribution is

one of the main unknown quantities of interest. One goal of finite element analysis for

induction machines is to calculate the induced or eddy current distribution in the rotor

conductors, as well as the total resulting magnetic field. This can be accomplished for

an induction motor by doing an ac analysis of a two-dimensional cross-section of the

machine.

4.1.1

Solution Frequency

In an ac induction machine analysis, the frequency selected as the solution

frequency is the slip frequency, or frequency seen by the machine rotor [11]. For

example, to model the machine at start up, the solution frequency would be 60 Hz. At

high speed, a low frequency as seen by the rotor is used. The slip frequency is

appropriate to use for an ac solution because currents are induced in the rotor conductors

at the frequency seen by the rotor.

14

4.1.2

Periodic Boundary Conditions

Finite element simulations of ac induction machines, as well as other types of

electric machines, have shown that machines have an identical magnetic field

distribution on a pole by pole basis [11]. The magnetic field patterns show that only one

pole pitch needs to be modeled in a machine with identical poles. Thus, the number of

elements and grid points in a finite element model can greatly be reduced if symmetry

can be used and only one pole of the machine modeled. This is advantageous because a

model with fewer elements and grid points will have a faster solution time and require

less resources such as disk space to solve.

In an induction machine having identical poles, each pole boundary has periodic

boundary conditions. For a two-dimensional model, the periodic boundary conditions

are expressed in polar (r ,0) coordinates as [12]:

A(r ,0 0 + p) = A(r ,0 0)

(Equation 4.1)

where A is vector potential, 00 is the angle of one radial boundary, and p the pole pitch

angle. This boundary condition is called an alternating periodic boundary condition. If

the geometry requires modeling two poles, then the vector potentials on the boundary are

set equal with no negative sign. This is referred to as a repeating periodic boundary

condition. Generally, an odd number of poles requires alternating and an even number

repeating boundary conditions.

15

4.2

FE Modeling of Doubly Fed Characteristics

Applying the techniques of induction machine analysis described above to the

BDFM is difficult due to the following considerations:

4.2.1

Complications of the Nested Rotor Structure

Because of the nested loop rotor structure, (the absence of a solid endring on one

side), the BDFM analysis problem is three-dimensional in nature. The nested loops

impose electrical constraints on the model that cannot be properly represented with a

two-dimensional analysis.

4.2.2

Inclusion of Two Excitation Frequencies

The presence of two stator windings carrying currents of differing frequencies

requires the consideration of two frequencies at any time. This poses a problem because

the ac solution method requires that a single solution frequency be specified.

4.2.3

Boundary Conditions More Difficult to Determine

The symmetry of the magnetic field distribution in the BDFM is not as simple to

determine as that of an induction machine, because of the presence of the two stator

windings of different pole numbers. Thus, determining the section of the BDFM that

should be modeled to properly represent the entire machine, and the selection of the

appropriate boundary conditions, requires some consideration.

16

This chapter discusses how these difficulties have been dealt with and a finite

element procedure for modeling the BDFM has been developed.

4.3

Three-Dimensional Simulation of the BDFM

Because the BDFM analysis problem is three-dimensional in nature, three-

dimensional finite element modeling of the BDFM has been investigated. A threedimensional analysis avoids the approximations involved in developing and/or

combining two-dimensional models, and allows accurate representation of the nested

rotor structure. For this three-dimensional analysis, a commercial software package

produced by MacNeal-Schwendler Corporation (MSC), called MSC/XL and

MSC/EMAS (Electromagnetic Analysis System) was used. The work was done on a

Hewlett Packard workstation, model 715/50, with 48 MB of RAM and approximately

2.5 GB of hard disk space.

Several three-dimensional BDFM models will be presented, along with the

materials, excitations, and boundary conditions used in the setup of the models. The

results of these BDFM model simulations will also be presented. Each of the BDFM

models presented is based on the prototype 5 hp laboratory machine, which has a 6 pole

power winding and a 2 pole control winding configuration. Analysis techniques used to

model BDFM will also be discussed.

17

4.3.1

Modeling in the Rotor Reference Frame vs. the Stator Reference Frame

In finite element simulation of ac induction machines, the solution frequency

used in an ac analysis is the frequency seen by the rotor, or the slip frequency. The

frequency seen by the rotor is not as simple to imagine for the BDFM, because of the

presence of two sets of stator windings operating at different frequencies.

A way of obtaining the frequency observed by the BDFM rotor for use as the

solution frequency for an ac analysis is to model the BDFM in the rotor reference frame.

The rotor reference frame frequency, or frequency of the rotor currents during

synchronous operation of the machine, is determined from Equations 2.5 and 2.6, which

are restated here:

f -±f

fr= Pp+ Pc

(Equation 4.2)

.1;4= fp Ppf, = Pcf,

(Equation 4.3)

Equation 4.3 determines the frequency seen by the BDFM rotor during

synchronous operation. Since during synchronous operation the fields induced in the

rotor by the power and the control windings are locked together at the same frequency,

only this one rotor frequency needs to be specified in the ac analysis. If it is desired to

determine the induced rotor currents during synchronous operation of the machine,

Equation 4.3 can be used to determine the solution frequency to be used in an ac

analysis. Thus, modeling the BDFM in the rotor reference frame eliminates the need for

two frequencies to be included in the simulation at once.

18

If it is desired to model the BDFM during startup, or during other conditions

when it is not operating in synchronous mode, the fields induced in the rotor would not

be locked together at one frequency. Therefore, it is not be possible to simulate the

BDFM under dynamic conditions with the ac analysis module, because the ac solution

method requires that a single solution frequency be specified. Possibilities exist to

overcome this difficulty by using the transient analysis module, which allows waveforms

of different types and/or frequencies to be included in the analysis simultaneously.

4.3.2

Symmetry of the BDFM Model

In induction machine analysis, it has been shown that only one pole pitch of the

machine needs to be modeled because of the symmetry of the magnetic field distribution

by pole pitch. The magnetic field symmetry of the BDFM model is not as simple to

determine because of the presence of two stator windings of different pole numbers.

The finite element model of the BDFM presented in this thesis is based on the 5

horsepower BDFM laboratory machine. The laboratory machine has a 6 pole power

winding and 2 pole control winding configuration.

Theoretically, the alternating periodic boundary conditions used to model

induction machines should be appropriate for a 180 degree model of a 6/2 pole BDFM.

This is because one pole of the two-pole winding and three poles of the six-pole winding

are present in a 180 degree model. Therefore, an odd number of poles is modeled for

both windings. Since alternating periodic boundary conditions are required for an odd

number of poles, theoretically alternating periodic boundary conditions should be the

19

appropriate boundary conditions for a 6/2 pole 180 degree BDFM model. Results of the

BDFM model simulations presented in this chapter verify this idea.

The MSC/EMAS Modeling Guide [13] suggests that the best way to determine

the correct boundary conditions is to make a coarse finite element model of the entire

device and observe the relationship obeyed by the vector potential A at grid points one

pole pitch, or other distance, apart. Then these constraints are applied to a fine finite

element model of that portion of the device.

4.4

Results of BDFM Model Simulations

Several three-dimensional BDFM models were constructed and analyzed using

MSC/EMAS. First, results from a coarse 360 degree model of the BDFM are presented.

Next, results from a 180 degree model, with a finite element mesh identical to the 360

degree model, and with alternating periodic boundary conditions applied along the

symmetry plane, are presented. Comparison of the full model and half model results

verifies that the alternating periodic boundary conditions are correct. Finally, results

from a more detailed 180 degree BDFM model are presented. For each analysis,

synchronous operation of the BDFM is assumed and the ac analysis module is used. It

should be noted that the ac analysis module is a linear analysis module that does not take

into account the B - H curve of magnetic materials.

20

4.4.1

Device Geometry

Each of the three-dimensional finite element BDFM models was based on the 5

horsepower laboratory machine. The dimensions of the laboratory machine stator

laminations are shown in Figure 4.1 (shown on the following page). The stator windings

consist of a 6 pole power winding and a 2 pole control winding. The stator contains 36

slots and the stator stack length is 100 mm.

The dimensions of the laboratory machine rotor laminations are shown in Figure

4.2. The rotor laminations were custom made to provide an air gap of 0.7 mm. The

rotor was designed with 40 slots. For the 6/2 pole BDFM, the required 4 nests have 5

loops each, and no common cage.

All measurements

are in millimeters (mm)

Figure 4.2: Rotor Lamination

10.16

6.86

22.82

1 08

3.1

Slot Detail

Stator Lamination (1/2 Size)

Figure 4.1: Stator Lamination

22

4.4.2 A Coarse 360 Degree BDFM Model

A coarse 360 degree three-dimensional finite element model of the BDFM was

constructed. The main goal in construction of this model was to determine if magnetic

field symmetry exists within the BDFM and to verify what portion of the device can be

modeled using appropriate boundary conditions to accurately represent the whole

machine.

The 360 degree model had a rather coarse finite element mesh consisting of

7776 hexahedron and pentahedron elements and 8325 grid points. The finite element

model is shown in Figure 4.3.

Figure 4.3: Coarse Three-Dimensional 360 Degree BDFM Finite Element Model

23

In constructing the 360 degree model of the BDFM, a simplifying assumption

was made about the laboratory machine rotor. The rotor was modeled with only 16 slots

(instead of the actual 40 slots) and only the first and third loops of each nest were

modeled, or two loops for each of the 4 nests (instead of the actual five loops for each of

the 4 nests). This simplification was made in order to reduce the complexity of the finite

element mesh, and hence reduce the amount of disk space required to generate a

solution.

The body of the machine was modeled with two layers of three-dimensional

elements, each 50 mm long, as shown in Figure 4.3. The nested loops of the rotor, as

well as the common endring, are modeled with one layer of three-dimensional elements

extending 6.76 mm beyond the machine body on opposite sides. Ideally, several more

layers of elements should be used to obtain a more accurate representation of the

machine. The configuration described was used because of disk space limitations.

4.4.2.1

Materials

Table 4.1 lists the material properties that were assigned to the objects that make

up the BDFM model.

Note that although the stator slot actually contain copper windings, they are

modeled as air since a current density excitation is used to specify the exact current

flowing in the windings. To model the stator windings as copper would cause the

program to induce additional eddy currents in the stator windings.

24

Material

Relative

Permeability

Relative

Permittivity

Electrical

Conductivity

(siemens/meter)

Shaft

Rotor

Rotor Bars

Air Gap

6 pole Stator Slot

2 pole Stator Slot

Stator

Nested Loops

End Ring

Air

Lam. Steel

Copper

Air

Air

Air

Lam. Steel

Copper

Copper

1

1

0

2000

1

0

1

1

5.8E+07

1

1

1

1

1

1

2000

1

1

1

1

1

0

0

0

0

5.8E+07

5.8E+07

Table 4.1: Material Properties used in the 360 Degree BDFM Model

4.4.2.2

Excitations

For the 360 degree BDFM model, an equivalent surface current density is used to

establish a current flow of 100 amp-turns peak in each of the 6 pole and 2 pole slots.

Figure 4.4 shows the 6 pole and 2 pole stator winding excitation locations and directions

and specified for use in the ac analysis.

In Figure 4.4, for the 6 pole winding, Phasea = 0° , Phase,, = 240° , and

Phase, = 120° . For the 2 pole winding, Phasea = 0° , Phaseb = 120°, and

Phase, = 240° .

4.4.2.3

Boundary Conditions

Figure 4.5 shows the applied boundary conditions for the 360 degree BDFM

model. A cylindrical coordinate system is used to define boundary directions. Along

25

6 pole Stator winding

2 pole Stator winding

Figure 4.4: Stator Excitations for the 360 Degree BDFM Model

the outer radius of the model, the tangential components of the magnetic vector potential

A are set to zero (43, As). The tangential components of A are also set to zero along

the motor ends (A 4) . Setting the tangential components of A to zero along the outer

boundaries of the machine constrains the magnetic fields to remain within the machine

outer boundaries.

s

,is

1

4

I-L00

I

1

*

°

60%

1

,

S

Insalt

11,,,\LILL

1\

L

.....

_10111111n1/0/// p

.**0

itsallfilW11111

P P -441;-1

e

-.0

ifo

4S''s4/vrtlp:

iv=-/I'Vrp

owl pm /Ulla

ainowur sio

"

*7r

.'111111.64

00,

111111111

/4,111,1,1,11itit%"

as

.1

1

27

reference frame frequency of 30 Hz, which was specified as the solution frequency in the

ac analysis. This corresponds to a machine speed of 600 rpm.

In the examination of the results that follow, the reader should note that the stator

solution is in the rotor reference frame.

4.4.2.5

Results

4.4.2.5.1 Contour Plot of Magnetic Vector Potential

A contour plot of magnetic vector potential, ;I, along a cross-section of the

BDFM located at the machine center is shown in Figure 4.6.

A line of constant magnitude of vector potential A is called a magnetic flux

line. Observing the pattern of the magnetic flux lines along a planar cross section of the

machine shows the symmetry present in the machine's magnetic field distribution.

Figure 4.6 shows that the BDFM exhibits 180 degree symmetry.

4.4.2.5.2 Arrow Plot of Magnetic Flux Density

An arrow plot of magnetic flux density, B, along a cross-section of the BDFM

located at the machine center is shown in Figure 4.7.

An arrow plot of magnetic flux density represents the direction and magnitude of

the magnetic flux density with colored arrows. The colors of the arrows indicate the

magnitude of the magnetic flux density, in tesla, at every location along the machine

cross-section. This allows the user to identify areas where the machine may be

IIIINIINMIMIMIMMEIIIIIIIINE

3.1e-07

1 0.00109

0_00109 0_00218

.0021.6

0.00321

0.00327

0.00437

0.00437 - 0.00546

0.00655

0.00546

,111

0 A011

\\

i

..wos,

Uu,,.)

0.00982

0.00982

0.01092

111,,

0000104/11/11

0

,

iiiii

/0

Niliiii

W63'

ii

2t

tk#10.1744Ei

oll

inalv\\

lLtii

jai

1: ResultsCalculator

FrequencyResponse Analysis

MagneticVectorPotential FullVector

GridResults FullVector

TypeOfData Magnitude

Subcase 1

Frequency 30

Figure 4.6: Contour Plot of Magnetic Vector Potential along a Center Cross-Section of the 360 Degree BDFM Model

INIMIENIMINIMI111

5.9e-05 - 0.03582

0.07158

1 0.03582

MMOMOMMUMM

0.32192

0.28616

0.35769

0.32192

11111111111111=11

0.17887 0.07158 - 0.10735 0.14311

0.21464

0.17887

0.10735

0.14311

,

\*

lit

I I

VotliIre

ii

1

0

,

I

IOW/

.%44/11motio,442 .:

*....,%.,..4.\%11:-1-43410111'1.111111731111f1.7....;,:

,. s

alls.-406-4:,.,:1:

1

1: ResultsCalculator

equencyResponse Analysis

MagneticVectorPotential FullVector

MagneticFlunDensity FullVector

TypeOfData Real

Subcase 1

Frequency 30

Figure 4.7: Arrow Plot of Magnetic Flux Density along a Center Cross-Section of the 360 Degree BDFM Model

30

saturating. The flux density values for this BDFM model (0.35925 tesla maximum)

show that the machine is not saturating, for the previously specified excitation level of

100 amp/turns peak per slot.

An arrow plot of magnetic flux density can also be used to observe the field

symmetry pattern of the machine. The arrow plot of Figure 4.7 also shows that the field

pattern exhibits 180 degree symmetry, giving credibility to this approach.

4.4.2.5.3 Currents in the Rotor Bars

The currents flowing in every rotor bar of the BDFM rotor were determined

using MSC/XL's solution calculator. The currents were calculated by specifying a plane

perpendicular to the rotor bar direction (the xy plane) and intersecting this plane with

one rotor bar at a time. The program then calculates the total current flowing in the rotor

bar in the positive z-direction from the conduction current density by the following

formula:

I = f(i, ds)

(Equation 4.4)

where J, is the conduction current density and ds is the integration surface.

The currents were calculated at several axial (z) positions along each rotor bar,

and identical results were obtained. The calculated total currents in each rotor bar are

presented in Table 4.2, and the rotor bar labels are identified in Figure 4.8.

Table 4.2 shows that the rotor bars currents are equal in magnitude and 180

degree out of phase for rotor bars connected by a loop. In other words, the rotor currents

31

Bar Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Real, Imaginary

Magnitude, Phase

(Amperes)

8.26766, 25.5532

-133.203, -33.6687

30.8736, -186.89

-7.13813, -87.3815

7.13833, 87.385

-30.8734, 186.89

-133.272, -33.6829

8.28426, 25.5654

-8.28503, -25.565

133.271,33.6827

-30.7961, 186.89

7.18307, 87.3974

-7.18318, -87.3998

30.796, 186.889

133.203, 33.668

-8.6676, -25.5533

(Amperes, Degrees)

26.8574, 72.0712

137.392, -165.815

189.423, -80.6197

87.6725, -94.6701

87.676, 85.33

189.423, 99.3803

137.463, -165.816

26.8741, 72.0455

26.874, -107.956

137.461, 14.1839

189.41, 99.3572

87.6921, 85.3015

87.6945, -94.6984

189.409, -80.6428

137.393, 14.1851

26.8572, -107.927

Table 4.2: Total Calculated Currents in the Rotor Bars for the 360 Degree BDFM

Model

are equal in magnitude but flowing in opposite directions for connected bars, as is

expected. Also, the magnitude of the rotor bar currents in the first loop are greater than

the currents in the third loop, as is expected by consideration of the laboratory machine.

Thus, the rotor bar currents indicate that the BDFM model has 180 degree symmetry.

32

4.4.3 A Coarse 180 Degree BDFM Model

A three-dimensional 180 degree model of the BDFM, with a finite element mesh

identical to the 360 degree BDFM model, was set up. The material properties,

excitations, and outer boundary conditions were identical to those used for the 360

degree model. An ac solution was generated at a rotor reference frame frequency of 30

Hz, as in the 360 degree model. Alternating periodic boundary conditions were used

Bar 4

Bar 5

4,A.

Bar 3

Bart

Bar 7

'`71-4,-eAd

-::::::

040

.

so

'ts

rit

Bar 16

ho*

s.

411"*Tt

.,4.

Bar 2

Bar 6

trist,--0144,;

ii 41.14.$7

4,1010

.1

A.:11145,00.

ov,

is4..

0

Bar 15

Bar 8

13tAtitut

..Nr.

.-...itamarik..+A.

Bar 14

Bar 13

_::-...

-

Bar 9

Bar 10

,.,....

Bar 12

Bar 11

Figure 4.8: Rotor Bars Labels for the 360 Degree BDFM Model

33

along the symmetry plane of the 180 degree model. The 180 degree finite element

model is shown in Figure 4.9.

This 180 degree model had a finite element mesh consisting of 3888 hexahedron

and pentahedron elements and 4280 grid points (basically half the number of elements

and grid points utilized in the coarse 360 degree model).

Figure 4.9: Coarse Three-Dimensional 180 degree BDFM Finite Element Model

The purpose of this coarse 180 degree model simulation was to verify that the

use of alternating periodic boundary conditions on a 180 degree BDFM model produces

results consistent with those obtained for a 360 degree model.

34

4.4.3.1

Boundary Conditions

Figure 4.10 shows the applied boundary conditions for the 180 degree BDFM

model. A cylindrical coordinate system is used to define the boundary directions. The

tangential components of the magnetic vector potential, )1 , are set to zero along the

outer radius of the model and along the motor ends, as in the 360 degree model.

Alternating periodic boundary conditions were applied along the two radial faces of the

symmetry plane, at 0 = 0 and 0 = 180 degrees. This boundary condition forces every

degree of freedom (three A components and 1' ) to be equal in magnitude but opposite

in direction as follows:

Ar(r,0 0 + p,z)= Ar(r ,0 0,z)

(Equation 4.5)

4 (r,00 + p, z) = -4 (r,00,z)

(Equation 4.6)

Az(r,0 0 + p,z)= AZ (r,0 0,z)

(Equation 4.7)

T(r,00 +p,z) = T(r,00,z)

(Equation 4.8)

where ;1 is vector potential, 00 is the angle of one radial boundary, and p the pole pitch

angle.

4.4.3.2

Results

Examination of the results obtained from the coarse 180 degree BDFM model are

in close agreement with the results obtained from the 360 degree model, verifying the

symmetry of the BDFM model and the use of alternating periodic boundary conditions.

35

(A.,Az =0)

(AA. =0)

:,..:)::,,41:,

\**ttalrie/

v `

kr

es.\..

2.$..

'

4,140-4140/11..

*,

*--.%

...":

\;,`,40,.....40,t

'11111a0tit*

..,:"Ant

Ir.44#

1r

--,,,*

----

.,-----.40

"4144411:i-TaiTa.-40°

takimili:wmp

I(r,180°,z)= -A(r,0°,z)

4-1(r,1 80° , z) = -W(r,0°,z)

0 = Cf

le

(AA, =0)

Figure 4.10: Boundary Conditions for the Coarse 180 Degree BDFM Model

4.4.3.2.1 Contour Plot of Magnetic Vector Potential

A contour plot of magnetic vector potential, A , along a cross-section of the

BDFM located at the machine center is shown in Figure 4.11.

This contour plot of magnetic vector potential is identical to Figure 4.6, the

contour plot of magnetic vector potential for the 360 degree model. This contour plot is

one verification that the alternating periodic boundary conditions are correct.

36

4.4.3.2.2 Arrow Plot of Magnetic Flux Density

An arrow plot of magnetic flux density, B, along a cross-section of the BDFM

located at the machine center is shown in Figure 4.12.

This arrow plot of magnetic flux density is almost exactly identical to Figure 4.7,

the arrow plot of magnetic flux density for the 360 degree model. This arrow plot is

another verification that the selected alternating periodic boundary conditions are

correct.

4.4.3.2.3 Currents in the Rotor Bars

The total current flowing in each rotor bar of the 180 degree model was

calculated using the same method used for the 360 degree model.

The currents were again calculated at several axial (z) positions along each rotor

bar, and identical results were obtained. The calculated total currents in each rotor bar

are presented in Table 4.3, and the rotor bar labels are identified in Figure 4.13.

Bar Number

1

2

3

4

5

6

7

8

Real, Imaginary

Magnitude, Phase

(Amperes)

8.29692, 25.0857

-132.462, -33.4865

30.8917, -186.883

-7.13535, -87.3859

7.13555, 87.3894

-30.8915, 186.883

-132.463, -33.4866

8.29609, 25.0859

Amperes, Degrees)

26.4222, 71.6987

136.629, -165.813

189.419, -80.6139

87.6767, -94.668

87.6802, 85.332

189.419, 99.386

136.63, -165.813

26.4221, 71.7006

Table 4.3: Total Calculated Currents in the Rotor Bars for the Coarse 180 Degree

BDFM Model

1111111111111111.1/

1

2.4e-07

0.00109

0.00109 - 0.00219

0.00219

0.00328

0.00328

0.00437

0.00437 - 0.00547

0.00656

0.00547

MMOMMMMOMM

0.00984

0.00875

0.80984

0.01093

RT 1: ResultsCalculator

FrequencyResponse Analysis

MagneticVectorPotential FullVector

GridResults FullVector

TypeOfData Magnitude

Subcase 1

Frequency 30

Figure 4.11: Contour Plot of Magnetic Vector Potential along a Center Cross-Section of the Coarse 180 Degree BDFM Model

-1.0e-15

1 0.03585

0.03585

0.07170

DX

1

4.07170 0.10755

0.10755

0.14340

OMMIIMMOMME

0.14340

0.17924

0.17924

0.21509

9

0.32264

0.35849

RT 1: ResultsCalculator

FrequencyResponse Analysis

MagneticVectorPotential FullVector

MagneticFluxDensity FullVector

TypeOfData Real

Subcase 1

Frequency 30

Figure 4.12: Arrow Plot of Magnetic Flux Density along a Center Cross-Section of the Coarse 180 Degree BDFM Model

39

Bar 4

Figure 4.13: Rotor Bars Labels for the Coarse 180 Degree BDFM Model

These total currents calculated for the 180 degree model agree within about 2 %

with the total currents calculated for the 360 degree model. The 2 % error may be due in

part to limitations within MSC/XL for applying the boundary conditions, that do not

allow the boundary conditions to be applied such that the 360 degree model is exactly

represented. Since the currents are in close agreement, the alternating periodic boundary

conditions are verified.

4.4.4 A Detailed 180 Degree BDFM Model

A finer and more detailed 180 degree model of the BDFM was constructed. The

goal of constructing this model was to obtain a more accurate representation of the 5

horsepower BDFM laboratory machine.

40

This detailed model included all 40 of the rotor bars present in the laboratory

machine, as well as all 5 of the loops per each of the 4 nests. A finer finite element mesh

was used, especially in the rotor conductors and the air gap, where field gradients change

most rapidly. The finite element mesh consisted of 8976 hexahedron and pentahedron

elements and 9510 grid points. The finite element model is shown in Figure 4.14.

The body of the machine was modeled with two layers of three-dimensional

elements, each 50 mm long, as shown in Figure 4.14. The nested loops of the rotor, as

well as the common endring, are modeled with one layer of three-dimensional elements

extending 6.76 mm beyond the machine body on opposite sides.

Identical excitations and boundary conditions, and similar material properties to

those used in the coarse 180 degree BDFM model were used in for the setup of this

detailed 180 degree model. An ac solution was generated, again using a rotor reference

frame frequency of 30 Hz.

4.4.4.1

Results

4.4.4.1.1 Currents in the Rotor Bars

The total current flowing in each rotor bar of the detailed 180 degree model was

calculated using the same method discussed previously.

The currents were again calculated at several axial (z) positions along each rotor

bar, and identical results were obtained. The calculated total currents in each rotor bar

are presented in Table 4.4, and the rotor bar labels are identified in Figure 4.15.

ar \

A940

IIIP°17

......,,01%

-

-

-

.

..

\.

.

,

...-0.=.1

.:

\

V

/O 00

'0*

-.ow=

17:0

...i

_......,

MVO

..---- ...---

A

.....:---

......

k.0-,---------00-_,....._,

/voamMI :7-41/

thnomiliza =

liOr

;'

Seitilj

\

4

41=4

lb

\\

41' 14 +

*_

N.

"*

1

\\

s

\Ile

A\t

4\

\

\

,

.

\

... N

I \i.

IL 1L,

# ii, 1

,

\ .k".

A

-..

Opror="--

aim Aloft

Amor left

saw 4ftv

.

%

ItsION'vz

.

.

...:

.

..

44%

UJj

W

"

4

4

ow. Avow

,

..:

is

-mutul

1011110111111111

s*****

\

42

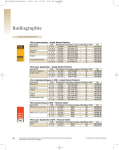

The rotor bar currents are equal in magnitude and 180 degrees out of phase for

rotor bars connected by a loop.

The magnitude of the rotor bar currents becomes greater as the slot span of the

loops becomes larger (moving from the inner to outer loops). Figure 4.16 is a graph of

slot span vs. rotor bar current magnitude, which shows that the current magnitude

increases from the inner to outer loops.

Bar Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Real, Imaginary

Magnitude, Phase

(Amperes)

0.0271658, -0.372618

3.10542, 0.175448

11.1839, 12.7192

-16.7531, 21.1527

115.5, -40.2878

30.2753, -140.761

-8.09887, -75.7353

-8.56011,-39.4474

1.19354, -28.9307

-4.10281,-3.87263

4.10331, 3.86986

-1.19341, 28.932

-1.19341, 39.4493

8.09896, 75.7372

-30.2749, 140.76

-115.502, -40.2885

-16.7533, 21.1523

11.1836, 12.7189

3.10525, 0.175529

0.0270078, -0.372556

(Amperes, Degrees)

0.373607, -85.8302

3.11038, 3.23362

16.9368, 48.675

26.9833, 128.379

122.325, -160.771

143.98, -77.8615

76.1671, -96.1038

40.3655, -102.243

28.9553, -87.6376

5.64184, -136.653

5.6403, 43.3229

28.9566, 92.362

40.3674, 77.7569

76.169, 83.8963

142.979, 102.138

122.326, -160.771

26.9832, 128.38

16.9364. 48.6752

3.1102, 3.23529

0.373534, -85.8537

Table 4.4: Total Calculated Currents in the Rotor Bars for the Detailed 180 Degree

BDFM Model

Information of this type, on slot span vs. rotor bar current magnitude for the

range of operating frequencies, should be used to design a more effective rotor for the

43

BDFM. A grading of bar size within the loops of each nest, with the outer loops having

the largest conductor size, should be investigated as a possible means of equalizing or

improving current distribution within the loops, or equalizing loss distribution to

minimize thermal problems.

4.4.4.1.2 Distribution of Conduction Current Density Within the Rotor

Bars

Distribution of conduction current density within each rotor bars was also

examined for the detailed 180 degree model. Plots of conduction current density across

each rotor bar from bottom to top and also from right to left were made in order to

observe how the current is distributed within the rotor bars.

Slot Span vs. Rotor Bar Current Magnitude

160

140

120

100

80

60

40

20

0

0

20

40

60

80

Slot Span (Degrees)

Figure 4.16: Slot Span vs. Rotor Bar Current Magnitude

100

44

Figure 4.17 shows the path along which the conduction current density was

plotted from bottom to top. Figure 4.18 is a plot of conduction current density in bar 6

along the path indicated in Figure 4.17. Figure 4.19 is a plot of conduction current

density in bar 7 along the path indicated in Figure 4.17.

These figures show that the conduction current density varies across the rotor

bars from bottom to top, but this variation is not great.

Figure 4.20 shows the path along which the conduction current density was

plotted from right to left. Figure 4.21 is a plot of conduction current density in bar 6

along the path indicated in Figure 4.20. Figure 4.22 is a plot of conduction current

density in bar 7 along the path indicated in Figure 4.20.

These figures show the conduction current density varies across the rotor bars

from right to left. This variation is greater than the variation observed from bottom to

top. This variation is due probably to the magnetic field distribution surrounding the

rotor bars, but is not of a sufficient magnitude to cause concern.

Figure 4.17: Path along which Conduction Current Density was Plotted from Bottom to Top

46

Conduction Current Density

E-06

4.22

4.21

E

4.2

<

4.19

p

4.18

ao

4.17

to

t

0

4.16

4.15

4.14

4.13

1

2

3

4

5

6

7

Distance across Rotor Bar 6 (mm)

Figure 4.18: Conduction Current Density in Bar 6 (in reference to Figure 4.17)

Conduction Current Density

E-06

2.24

E

cr

<

(-.1-)

2.23

2.22

0

t

2.21

V

2.2

0

0

2.19

2.18

0

1

2

3

4

5

6

7

Distance across Rotor Bar 7 (mm)

Figure 4.19: Conduction Current Density in Bar 7 (in reference to Figure 4.17)

Figure 4.20: Path along which Conduction Current Density was Plotted from Right to Left

48

Conduction Current Density

Distance across Rotor Bar 6 (mm)

Figure 4.21: Conduction Current Density in Bar 6 (in reference to Figure 4.20)

Conduction Current Density

0

1

2

3

4

5

6

7

Distance across Rotor Bar 7 (mm)

Figure 4.22: Conduction Current Density in Bar 7 (in reference to Figure 4.20)

49

5. Comparison of Two Three-Dimensional Finite Element Analysis Software

Packages

Introduction

5.1

In the course of investigating three-dimensional finite element analysis for the

BDFM, two different commercially available finite element analysis software packages

were examined and tested. The first was Maxwell 3D Field Simulator produced by

Ansoft Corporation [14], and the second was MSC/EMAS (Electromagnetic Analysis

System) [10] and MSC/XL [15] by MacNeal-Schwendler Corporation (MSC). This

chapter will compare these two software packages and discuss their advantages and

disadvantages/limitations.

5.2

Maxwell 3D Field Simulator by Ansoft Corporation

5.2.1

Advantages

The main advantages of Maxwell 3D Field Simulator by Ansoft Corporation are

its solid modeling procedure, step-by-step design process, and automated meshing

technique.

5.2.1.1

Solid Modeling Procedure

In a solid modeler, the finite element model is defined by the device structure or

geometry, which consists of a group of "solid" objects. Throughout the modeling

50

process, the solid objects that define the model are manipulated by referring to their

names. For example, as the device structure or geometry is being created, solid objects

such as cylinders, blocks, spheres, etc., are each assigned a name. Objects can then be

rotated, copied, displayed or removed from the display, and have material properties

assigned to them by referring to their names. This is a very convenient and easy way of

manipulating the device geometry.

The main advantage of a solid modeling procedure is that the finite element

model is defined by its geometry, a set of solid objects, and not by the finite element

mesh itself. This allows the mesh to be easily modified if necessary, without having to

redefine that entire model. The mesh can be refined throughout the model, or only in a

particular object by specifying the object name.

The solid modeling procedure is one major advantage that Maxwell 3D Field

Simulator has over MSC/XL. MSC/XL uses a wireframe modeling procedure, in which

the finite element model is defined by the actual finite elements and grid points. A

wireframe modeler is more difficult to use than a solid modeler. A wireframe model is

manipulated by referring to collections of finite elements that make up the geometry.

Therefore, the user must keep track of which element identification numbers belong to

what part of the geometry. If the model is large, this can be quite a task. Also, in a

wireframe modeler, once the finite element model is completed, it is not possible to

change or refine the mesh without creating the whole model over again, which requires a

substantial investment of time.

51

With Maxwell 3D Field Simulator's solid modeling procedure, analysis results

can be calculated and displayed for a particular object by selecting its name. The solid

modeling procedure makes creation, viewing, refinement of the mesh, and results

analysis easy for the user.

5.2.1.2

Step-by-Step Design Procedure

Maxwell 3D Field Simulator uses a step-by-step design procedure, which makes

the program easy for users unfamiliar with finite element analysis to learn and use.

When the program is started, the Maxwell 3D Field Simulator main menu appears,

listing the general procedure steps for the user to follow. These general procedure steps

are [14]:

Select Solver Type

Draw Geometric Model

Setup Materials

Setup Boundary Conditions

Setup Executive Parameters

Setup Solution Parameters

Solve

View Fields

The program displays a check mark next to each step after it has been successfully

completed. In general, the steps must be chosen in the sequence listed above. For

example, the "Setup Materials" step is operable only after a geometric model has been

52

created using the "Draw Geometric Model" step. This step-by-step procedure is helpful

for new users because it makes sure that each design step is completed, and in the

appropriate order.

5.2.1.3

Automated Meshing Technique

The Maxwell 3D Field Simulator uses an automated meshing technique. The

program automatically generates an initial finite element mesh when "Setup Materials"

is chosen from the main menu. If desired, the user has the option of refining the mesh in

selected areas once the initial mesh in complete, by choosing the object to be refined.

The program then automatically adds a specified number of additional elements to the

selected object.

The automated meshing procedure used by Maxwell 3D Field Simulator has the

advantage of being faster and much easier to use than a manual meshing technique, such

as the one used by MSC/XL. Manual meshing is slow and requires a lot of attention

from the user, as it is prone to user errors. An automatic meshing procedure is very

helpful for users unfamiliar with finite element analysis, who may not know how to

design an effective finite element mesh.

The automated meshing procedure used by Maxwell 3D Field Simulator does not

give the user control over the exact size, shape, and position of each individual element,

as the manual meshing technique used by MSC/XL does. However, this type of user

control is probably not necessary. Automated meshing is faster, much easier for the

53

user, and reduces the chance of user error. An automated meshing technique is

definitely a benefit for new users.

5.2.2

Disadvantages/Limitations

5.2.2.1

Only Two Analysis Modules Available

At the time of this evaluation, Maxwell 3D Field Simulator included only two

analysis modules (or solution methods) that were available as full releases. These were

the Electrostat module and the Magnetostat module. The Electrostat module is used to

compute static electric fields due to voltage distributions and charges. It has no use for

the BDFM analysis problem. The Magnetostat module is used to compute static

magnetic fields, due to DC currents, static external magnetic fields, and permanent

magnets. It has some use for the BDFM problem if the rotor bar currents are already

known from lab data and the magnetic field distribution and magnitude needs to be

calculated. It cannot be used to calculate induced currents in the rotor conductors, one of

the main quantities of interest in the BDFM analysis problem.

The Maxwell 3D Field Simulator analysis module that was used predominately

was the Eddy Current module. This module can be used to calculate time-varying

magnetic fields due to AC currents and oscillating external magnetic fields. It should be

used for the BDFM problem to calculate currents induced in the rotor bars by the AC

three-phase stator windings. However, at the time of evaluation, the Eddy Current

54

Module was still a "beta test version", which can explain the many glitches and

problems that were encountered in working with it.

5.2.2.2

Solution Parameters have to be Re-entered each Time a

Modification is Made

In the setup procedure used by Maxwell 3D Field Simulator, all of the material

property and excitation setup parameters for the entire model have to be re-entered each

time any modification is made. Likewise, each time a modification is made to the model

boundary conditions, all of the boundary conditions must be re-entered. In finite

element modeling, it is often informative to observe the effect of changing one model

property at a time. For example, the material property of one object in the model may be

changed, the magnitude of the excitations may be varied, or a particular boundary

condition may be changed. Having to re-enter all of the material properties and

excitations or re-enter every boundary condition each time a small modification is made

is not very convenient.